bIOMASS PELLET PLANT

Our existence is to better serve the construction of global biomass fuel pellet plant projects and biomass feed pellet plant projects. Richi Machinery is committed to quality improvement and continues to meet customers’ processing needs for different biomass pellets as the source of lean manufacturing.

Biomass pellet plant and equipment is a high value-added product independently developed by Richi Machinery.

It has a number of patents and can process various agricultural and forestry waste pellets for fuel or feed , can also produce special raw material pellets, such as waste tire pellets, tofu cat litter pellets, bentonite cat litter pellets, coal pellets, paper pellets, air purifying pellets, etc.

biomass pellet production line

With more than 200 reference biomass pellet plants worldwide, RICHI is a leader in biomass pellet manufacturing technology. Our business is based on meeting the requirements of forestry groups, energy companies, wood industries, and industrial as well as financial investors in biofuel pellet plants.

biomass pellet plant with different scale

biomass pellet manufacturing plant

1-2T/H biomass pellet manufacturing plant is a combination of biomass crushing, conveying, drying, pelleting, cooling, screening and bagging parts.

Not all of them are necessary

biomass pellet making plant

The biomass pellet making plant offered by Richi Machinery can not only make wood pellets with different diameter, but also can produce pellets from different kinds of biomass waste raw material.

biomass pellet line

Wood waste, straw, husk and other agriculture residues are suitable for biomass pellet line. We can offer customized plan for your biomass pellet business according to your specific requirements.

biomass pelletizing plant

Almost all kinds of biomass, such as wood, straw, stalk, peanut shell, rice husk, bamboo shaving, grass, alfalfa, etc. are suitable for our biomass pelletizing plant. Any questions, we are happy to offer supports!

pellet machine line

A complete biomass pellet machine line is composed of biomass chipper machine, biomass hammer Mill, biomass dryer, biomass pellet mill, pellet cooler, screener, biomass pellet packaging machine, etc.

pellet mill line

We supply complete biomass pellet plant design from A to Z. Our pellet mill line can make all available biomass materials into pellets.

pellet mill plant

Pelletization solutions with pellet mill plant at Richi Machinery. Explore 15-20t/h biomass pellet plant options for industrial production.

pellet line for sale

No matter what kind of biomass pellets you want to produce, RICHI can provide you suitable complete pellet mill plant solutions.

turnkey pellet plant

Our large biomass turnkey pellet plant technology is applicable to various agricultural and forestry wastes, and some urban waste.

biomass pellet plant for different application

how to make biomass pellets?

Whether you wish to build or expand a biomass pellet plant, RICHI can design, manufacture, supply, and optimize the machinery for producing high-quality biomass pellets. Our biomass pellet solutions are always backed by technical consulting, engineering, installation, and aftermarket service by our global service centers.

biomass pellet mill

In the biomass pellet production industry, Richi Machinery uses biomass pellet machines, straw pellet machines, grass pellet machines, palm husk pellet machines, rice husk pellet machines, bamboo pellet machines and other agricultural and forestry waste pellets machine as the core granulation equipment for biomass pellet plants.

On this basis, we have developed more than 10 series and more than 60 models to form high, medium and low matching, which can meet customers’ production capacity and pellet production needs of different raw materials.

main equipment used in biomass pellet plant

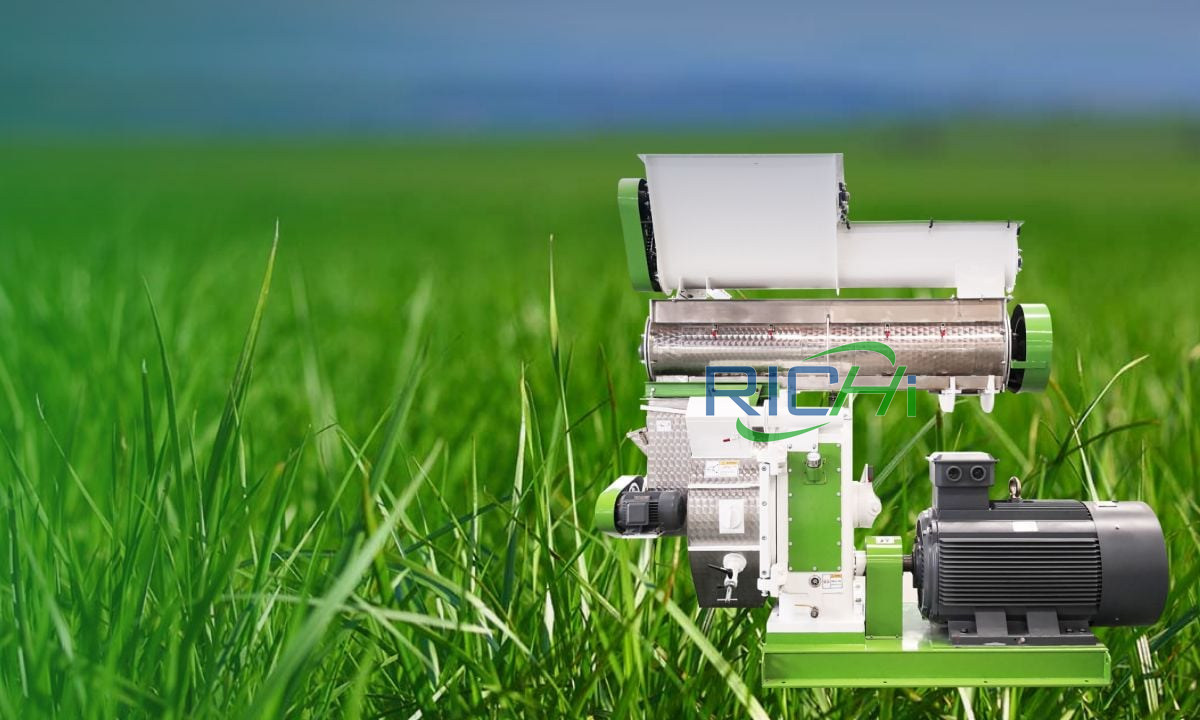

small biomass pellet machine

Our small biomass pellet machine stands for sustainability and efficiency. It is one of the most important machines in the biomass pellet plants. They are simple and solid machines, with high reliability and very low maintenance costs.

- Capacity: 0.3-4.0 T/H

- Power: 37KW

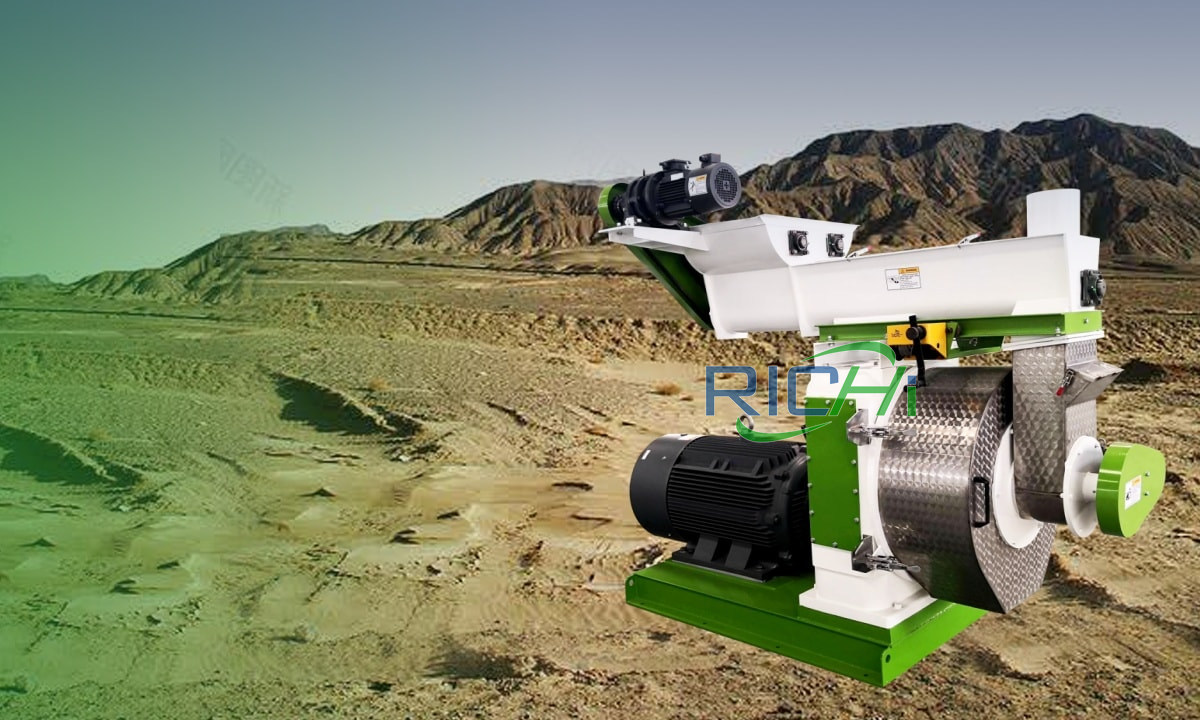

biomass pellet press

Biomass pellet press is mainly used in large scale commercial production with the features of long working life, high output and low consumption. The work of pressing the mash into a pellet is done through the die in the main mill.

- Capacity: 0.5-6.0 T/H

- Power: 55KW

biomass granulator

RICHI offers a comprehensive range of biomass granulator machine in a variety of sizes and application, mainly used for making biofuel pellets and animal feed pellets from agricultural and forestry waste.

- Capacity: 1.0-10 T/H

- Power: 90KW

biomass fuel pellet machine

Biofuel pellet machine is a patented product developed by Richi Machinery on the basis of absorption ring die granulation technology and concept.

- Capacity: 2.0-15 T/H

- Power: 132KW

biomass pellet making machine

Biomass pelletizer equipment breaks through the bottleneck of wood pellet production capacity and has achieved remarkable results in biomass pellet processing.

- Capacity: 2.5-30 T/H

- Power: 250KW

biomass pellet machine

Biomass pellet machine stands for sturdy and durable technology that will cope with your continuous operation needs of biomass pellet plant.

- Capacity: 4.0-40 T/H

- Power: 280KW

featured biomass pellet mill for biomass pellet plant

agri pellet machinery

RICHI offers a broad spectrum of biomass pellet plant equipment. Agriculture waste pellet mills provide a sustainable energy option by utilizing organic materials such as agricultural leftovers, palm waste, bagasse, bamboo, wood chips, sawdust, and other biomass sources. We have the experience and know-how to cover your biomass pelleting needs.

equipment for straw type biomass pellet plant

straw pellet machine

According to the different straw pellet production characteristics, raw material properties, external conditions and customer needs, the combined assembled straw pelletizer machine technology is tailored to meet the objective requirements of straw pellet plant project implementation.

equipment for grass type biomass pellet plant

grass pellet machine

RICHI grass pelletizer machine absorbs modern grass pellet technology and focuses on the processing of various types of grass pellets (alfalfa/lucerne/hay/hops/elephant grass/napier grass/giant king grass, etc.), and the pellet size is adjustable and controllable.

equipment for husk type biomass pellet plant

husk pellet machine

RICHI husk pellet machine can process single raw material pellets, such as rice husk pellets, peanut shell, sunflower husk, coconut husk, walnut shells, poppy shells, coffee shells, etc.; it can also process mixed biomass raw material pellets, such as husk and sawdust pellets, husk and straw pellets, etc.

equipment for special type biomass pellet plant

special pellet machine

This kind of biomass pellet mills are mainly used in commercial pellet plant with the features of long working life, high output and low consumption. The biomass pellet plant solutions we have developed cover various cat litter pellets, bentonite granules, paper pellets, waste tire pellets, PET plastic pellets, rat poison pellets, and rubber pellets.

supporting equipment for biomass pellet plant

RICHI has the ability to manufacture and supply each and every key bioprocessing machine in the pellet production line. We offer single machines for production of biomass pellets, solid biofuel, and waste pellets. Each model is specially developed for the global market, which also means that all countries regulations and standards are adhered to.

biomass Hammer Mill

mixing machine

Biomass Dryer

Chipper Machine

biomass pellet plant projects

Richi Machinery enjoys a high reputation in more than 140 countries and regions around the world, and has won the trust of many brands and companies around the world with its high-quality biomass pellet equipment and project services!

biomass pellet plant in the world

Customer Visit

biomass pellet plant videos

how to build biomass pellet plant?

The demand for biomass pellet production is increasing every year and setting up biomass pellet production line is popular project around the world since biomass pellets are considered an eco-friendly fuel that does not harm the environment like the traditional fuels do. And, the raw material to make pellets such as sawdust, rice husks, etc. are very easy to have or can be brought at very cheap price.

The construction of a biomass pellet plant can be complex and one with lots of challenges. Acquiring the right machinery, manpower and even materials aren’t enough to guarantee the success of the plant. If you are looking forward to learning some of the very essentials to starting an effective and successful biomass pellet plant, check here.

1

Find stable biomass material supply

2

Locate your factory near the raw materials and with convenient traffic

3

Choosing a professional consultant, design your factory layout, and put safety measures right

4

Purchase wood pellet production equipment according to your demand, and recruit staffs

5

Develop customers and agents at home and abroadt

About RICHI MACHINERY

Founded in 1995, Richi Machinery is mainly engaged in the R&D and manufacturing of pellet plant equipment required for industry projects such as animal & aqua & pet feed, biomass agricultural and forestry waste utilization, organic fertilizer, pet litter and urban waste.

All products have passed ISO international quality system certification, EU CE certification and Customs Union CU-TR certification.

At present, the marketing network of Richi Machinery has spread to more than 140 countries and regions in Asia, Africa, Europe, America and Oceania, and has established overseas offices in many countries.

Consultation and Tailor-made design

Equipment manufacturing and testing

Equipment packaging & delivery

Equipment installation & Training

1

What materials can I make pellets from?

We have experiance with “pelletizing” a wide range of materials, applicable to all agricultural and forestry waste

2

Are You biomass pellet plant Manufacturer?

We are biomass pellet machine and complete biomass pellet plant equipment manufacturer, not a middleman. All equipment are factory prices.

3

Does the material need to be prepared before entering the biomass pellet mill?

Yes, The material should be a suitable size and moisture. Therefore, in addition to the granulator, it is also necessary to configure biomass crushers, biomass chippers, biomass materials dryers and other biomass pellet plant equipment.

4

What size does the bio material need to be for biomass pellet plant?

The size of material corresponds with the pellet size desired, usually to make ¼” (6 mm) pellets we need ¼” (6 mm) material. This is often accomplished by processing the materials through a hammer mill.

5

What moisture works best for biomass pellet plant to making pellets?

We recommend an approximate moisture content of 15%. If your material is too dry you can add moisture. If it is too wet you can dry it or mix it with another lower moisture material (like cardboard).

6

Can You Provide Turnkey Service?

We offer a complete turnkey biomass pellet plant service including project consultation, site survey, sample analysis to plan design, manufacturing, delivery, installation and commissioning, and maintenance guidance to ensure that all links are in place with customers in a timely manner solve customer needs.