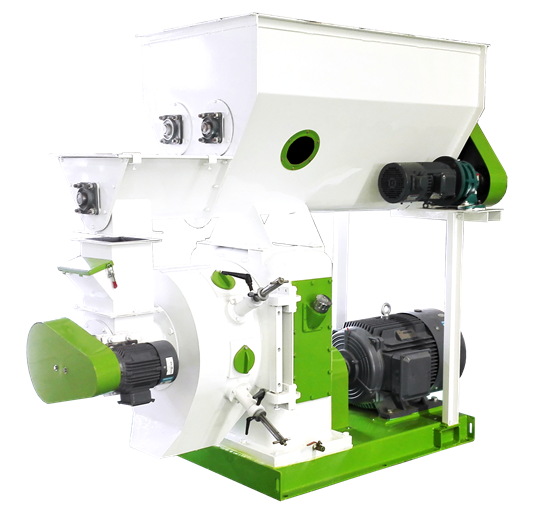

Poultry Manure Pellet Machine

The poultry manure pellet machine uses poultry manure, various livestock manure and agricultural waste as the main raw materials, and is used to process organic fertilizer granules rich in organic matter and nutrients.

Granulators are often used in the processing and manufacturing of poultry manure pellets such as chicken manure pellets, hen manure pellets, duck manure pellets, goose manure pellets and other organic fertilizers. Its efficient and high-quality granulation effect enables it to perform well in various production scenarios requiring organic fertilizer granulation.

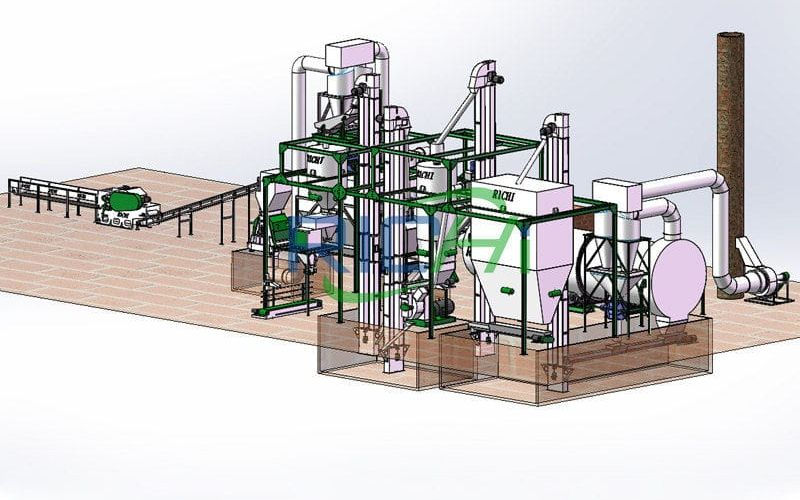

The poultry manure fertilizer pellet machine is the core equipment for processing poultry manure. In addition to stand-alone machines, we also provide full-process services such as design, manufacturing, delivery, installation, and training of complete poulry manure pellet production line equipment.

- Capacity:1-12T/H

- Price: 10,000-100,000 USD

- Application: Organic fertilizer factory, compound fertilizer factory, chemical fertilizer factory, poultry farm, sugar factory, sewage treatment plant, waste disposal site, food processing plant, slaughterhouse, etc.

Why use poultry manure as raw material for organic fertilizer?

Poultry manure mainly includes chicken manure, pigeon manure, quail manure, etc. This type of manure usually contains high nitrogen content, moderate moisture, and contains more calcium and other medium and trace elements.

It is suitable to be combined with raw materials with higher carbon content such as crop straw, mushroom residue, peat, sawdust, etc. Usually when it is taken out from the farm, part of it may have been decomposed.

Due to the high nitrogen content and high pH value, it will release ammonia and cause ammonia loss, and it is also easy to produce odor. A low pH value conditioner may be needed to reduce the pH.

Poultry manure is easy to decompose and has a high decomposition temperature. It is a thermal fertilizer. It uses poultry manure as raw material. It is fermented and decomposed quickly and can be made into fertilizer with higher nutrients. It is a very good organic fertilizer raw material.

Technical characteristics of poultry manure pellet machine

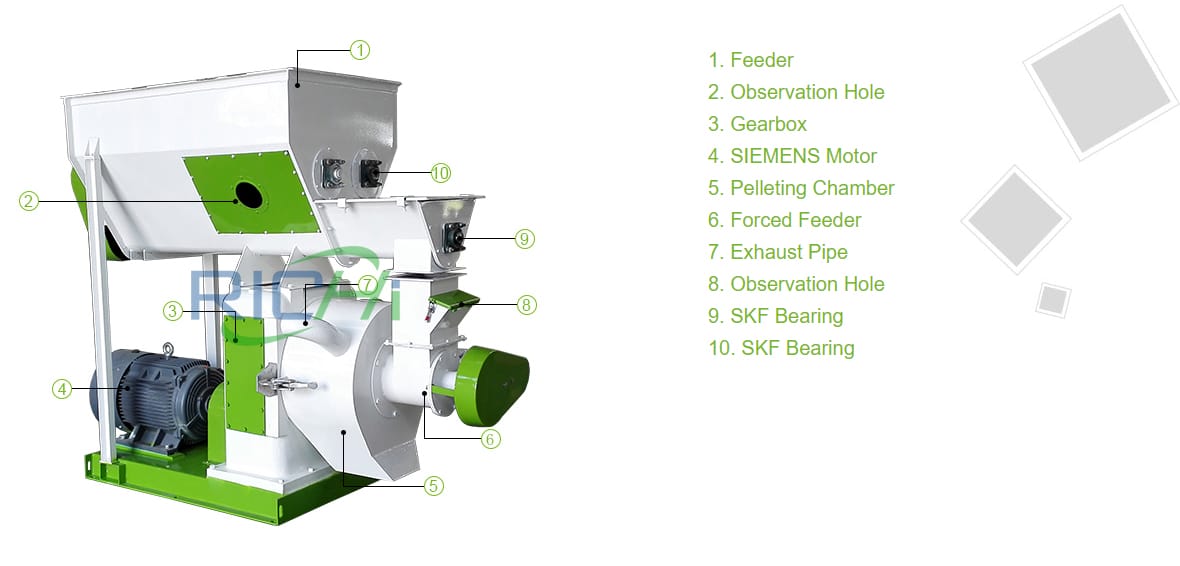

- This model poultry manure pellet machine uses a strong gear box transmission system, has ideal transmission efficiency, rotation steady, output high, noise low, no oil leak pollution, maintenance cost low;

- The feeder is driven by an inverter motor or an electromagnetic motor, which can adjust the feeding amount easily and ensure the feeding is even.

- The optimized adjusting shaft speed and blade arrangement form, so that the material can be fully stirred and enough heat preservation time, the shell adopts the jacket type, and the heat preservation effect is better.

- The gear and gear shaft adopt high quality steel, optimized transmission gear design and advanced processing and heat treatment technology, make the gear life longer, the transmission efficiency is higher.

- According to the characteristics of the material, the rotational speed of the ring die is optimized, and the production of poultry manure pellet machine improved greatly, and the particle quality is better.

- The improved feed scraper enables the material to be evenly distributed to two pressing areas, which is more uniform and runs more smoothly.

- Can be equipped with pneumatic self-service grease lubrication system, more convenience and better lubrication effect.

If you want to find a reliable poultry manure pellet machine supplier, MiKim is your best choice. RICHI poultry litter equipment has passed CE, ISO and other certifications. 30 years of machine manufacturing experience ensures product quality and safety.

How does the poultry manure pellet machine work?

Ring die poultry chicken manure pellet machine is a common granulation equipment, mainly used to process raw materials into granules. Its product structure mainly consists of feed hopper, compression chamber, granulation chamber, lubrication system, discharge port and other parts.

The working principle is: first add the raw materials into the hopper, and in the compression chamber the raw materials are compressed into a solid state under the action of pressure, and then enter the granulation chamber for granulation.

Finally, they are lubricated by the lubrication system to form granular products, which are discharged from the discharge port.

Specifications of poultry manure pellet machine

| Model | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH768 | MZLH858 |

| Output (t/h) | 1-2 | 3-4 | 5-6 | 7-8 | 9-10 | 10-12 |

| Main motor power (kw) | 22 | 37 | 90 | 132 | 250 | 280 |

| Main motor series | 8P | |||||

| Ring die diameter (mm) | 320 | 350 | 420 | 520 | 762 | 858 |

| Finished pellet diameter (mm) | 2-12 | |||||

| Device Configuration | Ring die material: 42CrMo Stainless steel feeder: with anti-caking function Door of pelleting room: 6mm /SUS304 Forced feeding: Worm gear reducer Gear box: HT250 Gear: 42CrMo Gear shaft: 42CrMo Spindle: 42CrMo Empty shaft: 42CrMo Bearings: The gear shaft and main shaft bearings are SKF, and the pressure roller bearings are domestic high-quality bearings Oil seal: Germany/Taiwan Overload mechanical protection: safety pin Serpentine spring coupling drive Lubrication system: Configurable automatic oil injection system | |||||

poultry manure pellet machine price

The price of poultry manure pellets machine is generally 10,000-100,000 USD. The price of poultry manure organic fertilizer pellet making machine is affected by the following factors:

- Equipment specifications and models: Poultry compost pellet making machines of different specifications and models have different processing capabilities and functions, and their prices will also vary.

- Brand and manufacturer: Poultry manure pellet machines from well-known brands and high-quality manufacturers are usually more expensive because their product quality and after-sales service are more reliable.

- Market supply and demand: The relationship between supply and demand is an important factor in determining product prices. If the demand in the market is high and supply is relatively scarce, the price of the poultry manure granulator may rise accordingly.

- Materials and processes: The manufacturing materials and processes of the granulator have a direct impact on its performance and life. High-quality materials and workmanship tend to drive the price up.

- Transportation and installation costs: Poultry manure pellet machines usually need to be transported and installed on the construction site, and these costs will affect the price.

- Economic environment and exchange rate fluctuations: The macroeconomic environment and exchange rate fluctuations may lead to changes in raw material prices and production costs, thereby affecting the price of the poultry manure organic fertilizer pellet mill.

In short, the price of the poultry manure pellet machine is affected by multiple factors, and buyers should choose according to their own needs and budget. The price of poultry manure pellet mills varies depending on factors such as model, brand, configuration, etc.

Featured poultry manure pellet machine projects

poultry manure pellet machine In Vietnam

- Country: Vietnam

- Production: 2500 t/a

- Ingredients: poultry manure, industrial waste

- project price: 80,000 USD

poultry manure pellet machine In Mexico

- Country: Mexico

- Production: 10,000 T/A

- Ingredients: poultry manure, livestock manure

- project price: US$110,000

poultry manure pellet machine In United States

- Country: United States

- Production: 50,000 T/A

- Ingredients: poultry manure, pig litter

- project price: US$430,000

poultry manure pellet machine In australia

- Country: australia

- Production: 35,000 T/A

- Ingredients: poultry manure, food waste

- project price: 410,000USD

poultry manure pellet machine In Thailand

- Country: Thailand

- Production: 55,000 T/A

- Ingredients: poultry manure, cattle manure

- project cost: 570,000 USD

poultry manure pellet machine In indonesia

- Country: indonesia

- Production: 10,000 T/A

- Ingredients: poultry manure, straw

- project cost: 190,000 USD

poultry manure pellet machine In canada

- Country: canada

- Production: 6,000 T/A

- Ingredients: poultry manure, livestock manure

- projecte cost: $160,000

poultry manure pellet machine In germany

- Country: germany

- Production: 30,000 T/A

- Ingredients: poultry manure, cow manure

- project cost: $385,000 USD

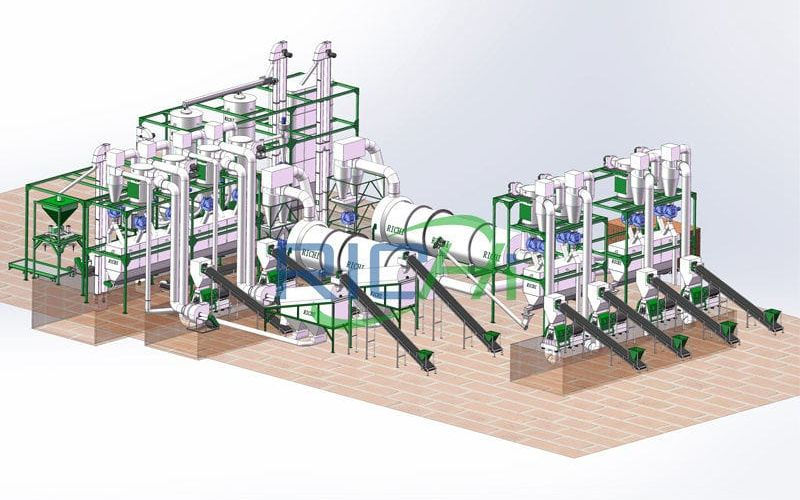

How to process granulated poultry manure? Complete poultry manure composting process flow

Let’s take a look at how to make poultry manure into dried poultry manure pellets, the followings are complete organic fertilizer production line processes:

- Fermentation and decomposition: Add auxiliary materials such as straw, branches, and mushroom residues to the poultry manure in a ratio of 7:3 to adjust the carbon-nitrogen ratio and moisture. Then sprinkle aerobic fermentation bacteria and let it ferment for about 25-45 days. During the fermentation process, the pile should be turned according to the temperature change of the pile. It is recommended to use a pile turner when turning to save labor costs and improve fermentation efficiency.

- Material crushing: After 25-45 days of fermentation and decomposition, the poultry manure turns gray-brown and has no odor. Large agglomerates, bones, pebbles, etc. in the material can be crushed using a vertical high-humidity material crusher.

- Add nutrients: In order to make the organic fertilizer richer in nutrients, you can add appropriate amounts of trace elements, humic acid and other nutrients. Dynamic batching machine can accurately control the batching amount.

- Stir evenly: After adding the ingredients, the ingredients and organic fertilizer need to be fully stirred. If the output is relatively small or you want to save investment costs, you can stir manually. If the quantity is relatively large, it is recommended to use a blender.

- Granulation: Use a poultry manure pellet machine to granulate the mixed materials. You can choose the appropriate model of granulation equipment according to the actual situation.

- Drying: The formation of granulated poultry manure requires the addition of moisture, so after granulation is completed, the granules need to be dried to prevent sticking.

- Cooling: In order to facilitate storage, the dried poultry manure pellets needs to be cooled. If the output per hour is less than 1 ton or there is a large enough drying space, the organic fertilizer can be allowed to cool by itself, otherwise a cooler will be used for cooling.

- Screening of finished products: In order to make the poultry manure pellets uniform in size and sell at a higher price, it is necessary to screen the poultry manure pellets in size. Organic fertilizers that do not meet the size must be returned to the crushing stage for re-granulation.

- Packaging: Qualified finished poultry manure pellets are quantitatively weighed and packaged through an automatic packaging machine.

The above are the common standard steps for making poultry manure into poultry manure pellet organic fertilizer. If you have special process requirements, contact us and the RICHI Machinery‘sengineering team will provide you with customized process designs to meet all poultry manure pellet processing needs.

equipment for Whole set poultry manure pellet plant

poultry manure Turner

Turning height:

0.5-2.0 m

Motor:

32-300 KW

poultry manure Grinder

Capacity:

3-25T/H

Main Power:

30-160KW

poultry manure Mixer

Capacity:

250-2000 kg/P

Main Power:

4-30 KW

poultry manure Dryer

Capacity:

Customized

Rotate Speed:

3-8 R/Min

poultry manure pellet machine

Capacity:

1-12T/H

Main Power:

37-280KW

How to choose poultry manure pellet machine?

1. Clarifying your own needs is the basic prerequisite for purchasing a poultry manure pellet machine. Different poultry manure pellet production projects require different organic fertilizer equipment. Therefore, before purchasing a poultry manure pellet granulator, you need to conduct a comprehensive understanding and analysis of your own organic fertilizer production project and clarify your needs.

2. The choice of brand is also very important. Choosing a well-known brand can ensure the quality and performance of the product and get better after-sales service. Well-known brands mean that their product performance and quality are well guaranteed.

Therefore, when purchasing an poultry dung compost granulating machine, you should choose a well-known brand to avoid later maintenance and service problems caused by improper brand selection.

3. Comprehensive consideration of cost performance is a factor that needs to be paid attention to when purchasing an organic poultry manure making machine. Although high-priced poultry manure pellet machine usually have better performance and quality, it does not necessarily mean that they are the most suitable choice.

It is the wisest choice to choose the product that suits you based on your actual needs and economic situation. Therefore, when purchasing an organic manure making machine, don’t just focus on the price, but consider the cost-effectiveness comprehensively.

4. When purchasing an organic fertilizer granulator, you also need to pay attention to inspection. Inspecting the goods in person with the organic fertilizer granulator dealer can avoid purchasing “fake and shoddy” products and protect the rights and interests of customers.

The specific contents of the inspection include:

- Check whether the purchased fertilizer granulation equipment has product certificate, instruction manual, “Three Guarantees” and relevant technical documents;

- Check whether the product cooperation certificate contains the product factory number, inspector badge number, factory date, etc.

- At the same time, check whether the tools, accessories, and spare parts that come with the purchased organic fertilizer granulator are consistent with the packing list.

- Finally, a test run is required, including product performance and appearance quality of the organic fertilizer granulator.

5. You need to carefully check the quality of the poultry manure pellet machine.

- First, check the appearance. Fake and inferior organic fertilizer granulator machine products usually have low smoothness and may have obvious defects such as cracks, sand holes, slag inclusions, and burrs. These problems can easily lead to oil leakage, water leakage, air leakage and other failures.

- In addition, some parts, if stored improperly, are prone to deformation, and their geometric dimensions cannot meet the requirements for use, making them unable to be used normally. Therefore, we should carefully observe whether there are problems such as cracks and distortion to ensure that we choose high-quality products.

- It is necessary to pay attention to check whether there are problems such as rust, looseness and jamming in the organic fertilizer poultry manure pellet machine. Qualified product assembly components should rotate flexibly and the gap size should comply with standard specifications. Counterfeit products may be inflexible or excessively loose.

- In addition, due to poor storage or long storage time, some spare parts may suffer from corrosion, oxidation, discoloration, deformation, aging, etc. If we find that the above situation occurs, we should carefully consider purchasing an poultry fertilizer pellet machine.

6. We remind everyone to pay attention to after-sales service when purchasing a poultry manure pellet machine. It is very important to choose a brand that provides good after-sales service.

Ask for an official purchase invoice, that is, one supervised by the tax department, to ensure that the purchased poultry manure pellets processing machine is legal and valid. The brand’s after-sales service team can promptly solve problems encountered during use and ensure the normal operation of the poultry manure pellet fertilizer machine.

Therefore, before purchasing, we should understand the brand’s after-sales service policy and choose a reputable dealer.

7. We also need to remind everyone that some poultry manure pellet machines can enjoy government subsidies. When purchasing, if you meet the requirements, you can apply for subsidy policies from the local agricultural department. This will not only reduce purchase costs, but also promote the development of agricultural modernization.

Once again, it is emphasized that when purchasing a poultry manure pellet machine, you need to comprehensively consider factors such as your own needs, brand, cost performance, product performance, and after-sales service.

Only in this way can we choose products that suit us, improve production efficiency, and achieve the goal of sustainable agricultural development.

How to choose a poultry manure pellet machine manufacturer?

When choosing a poultry manure pellet machine manufacturer, you need to consider the following four criteria: source factory, reputable brand, reasonable price, and quality assurance, making your poultry manure pellet business investment more worry-free, more secure, and more profitable.

When choosing a poultry manure pelletizer machine manufacturer, you must not only consider the type, specifications, appearance, and functions of the poultry manure pelleting machine, but also consider the background, strength, reputation, and service of the manufacturer.

The following are four main criteria for selecting poultry manure pellet machine manufacturers. You can filter and compare different manufacturers according to these criteria to find the most suitable partner for you.

01 Source factory

Source factories have the following advantages:

- Price advantage: The source factory has no intermediate links and can directly give you the lowest ex-factory price, saving you a lot of costs.

- Quality advantage: The source factory has a complete production process and quality inspection system to ensure the quality and safety of the organic fertilizer granulator, giving you no worries.

- Innovation advantages: The source factory has a professional R&D team and designers who can customize poultry manure pellet machines and poultry manure pellet plants according to market demand and customer needs.

02 Word-of-mouth brand

Word-of-mouth brands refer to manufacturers that have a certain degree of popularity and influence in the poultry manure pellet equipment industry. Word-of-mouth brands have the following advantages:

- Reputation advantage: Word-of-mouth brands have good business reputation and social responsibility, and will not engage in bad behaviors such as fraud, breach of contract, cutting corners, etc., making your cooperation more secure and smoother.

- Influence advantages: Word-of-mouth brands have extensive market awareness and customer reputation, which can provide more publicity and promotion for your poultry manure pellet fertilizer processing plant.

- Service advantages: The word-of-mouth brand has a complete pre-sales, sales and after-sales service system, which can provide you with professional consulting, planning, installation, training, repairs, maintenance and other one-stop services to make the operation of your poultry manure pellet factory easier, more efficient.

03 Reasonable price

Reasonable price means that the price of the poultry manure pellet machine matches its performance, quality and service. Reasonable price has the following advantages:

- Cost advantage: Reasonably priced poultry manure pellet equipment can make your investment costs lower, the payback cycle shorter, and the profit margin larger, making your poultry manure pellet fertilizer plant investment more valuable.

- Cost-effectiveness advantage: Reasonable-priced organic fertilizer equipment can make your poultry manure pellet machine’s performance, quality, and service better, and produce higher-quality organic fertilizer products, making your organic fertilizer plant investment more meaningful.

- Market advantages: Reasonably priced poultry manure pellet machines can make your organic fertilizer factory more competitive and advantageous in the same industry, attracting more organic fertilizer users.

04 Quality Assurance

Quality assurance means that the poultry manure pellet machine has relevant quality certification and insurance, rather than some organic fertilizer machines that are unqualified or have hidden dangers. Quality assurance has the following advantages:

- Safety advantages: Quality-assured poultry manure pellet machines can make your organic fertilizer production process safer, avoid accidents, protect the safety of employees and equipment, and make your organic fertilizer factory investment more worry-free.

- Legal advantages: Quality-assured poultry manure pellet machines can make your organic fertilizer factory more compliant with relevant national and local regulations and standards, avoid being investigated or fined for violations, and make your organic fertilizer factory investment more compliant.

- Brand advantage: Quality-assured poultry manure pellet machines can make your organic fertilizer factory more brandable, establish a good social image and reputation, win the trust and respect of organic fertilizer users and partners, and make your organic fertilizer factory invest more prestigious.

Prospects for processing poultry organic fertilizer

Poultry manure organic fertilizers made by poultry manure pellet machine have the characteristics of many types, wide sources, and long fertilizer effects.

Most of the nutrients they contain are in an organic state, which is difficult for crops to use directly. Through the action of microorganisms, a variety of nutrients are slowly released, and nutrients are continuously supplied to crops.

The application of poultry manure organic fertilizers can improve soil structure, coordinate water, fertilizer, air and heat in the soil, and improve soil fertility and land productivity. Because of these superior properties, organic fertilizers are also known as “resources for sustainable agricultural development.”

The development of new fertilizers has become the mainstream of the current development of the fertilizer industry around the world.

01 Many countries in the world, especially developed countries, have formulated and implemented poultry manure organic fertilizer resource management policies.

With further development of the industry and product popularization, the global organic fertilizer market is expected to reach US$206.3 billion in 2026. It is not difficult to see that the current regional characteristics of the development and consumption of the global organic fertilizer industry are particularly significant, mainly concentrated in regions with relatively developed economies and developed planting industries such as Europe, the United States, and Asia.

Among them, the highest proportion of organic fertilizer use in Western Europe is about 31.8%, North America is about 29.9%, the Asia-Pacific region is about 21.7%, and other regions are about 16.6%.

02 In recent years, many countries have paid more and more attention to the protection of cultivated land.

On the one hand, they have introduced policies to delineate red lines to protect the quantity of cultivated land, and on the other hand, they have actively improved the quality of cultivated land. These measures are of great significance to promoting green and high-quality development of agriculture.

In the future, the inevitable market demand will promote the development of global organic agriculture, the entire organic fertilizer market will also be further developed, and the growth trend of the organic fertilizer market will continue in the long term.

03 The concept of rational utilization of resources and the enhancement of awareness of environmental protection have made people rethink new agronomic development methods.

The rational use of organic fertilizers not only changes agricultural planting behavior, but also makes consumers more confident and secure about organic food. As relevant departments have provided favorable policy support, diversified infrastructure and financial support to organic fertilizer manufacturers, the organic fertilizer industry has ushered in a period of rapid development.

In the future, with the synergy of multiple parties, the organic fertilizer industry will achieve greater development with the ultimate goal of saving resources and maintaining a good ecological environment. (Find RICHI on YouTube)