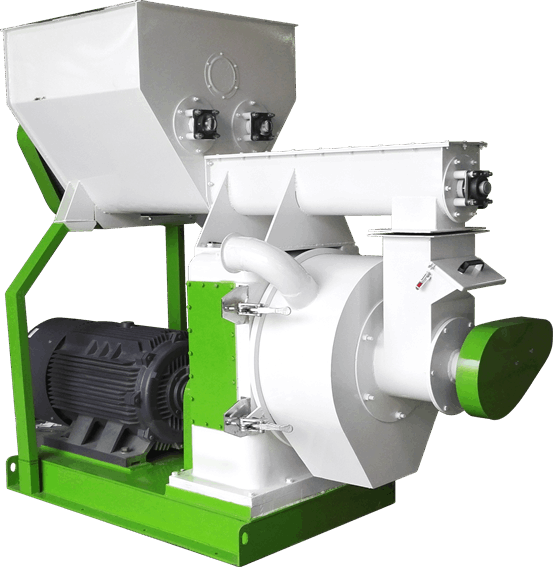

Biomass Pellet Machine For Sale

Biomass pellet machine is a pellet fuel forming machine that uses straw, rice husk, efb, coconut shell, coffee shell, bagasse, bamboo, sawdust, wood chips, leaves and other agricultural and forestry waste as raw materials.

- Model: MZLH858

- Capacity: 4-40T/H

- Power: 280KW

- Price: FOB 60,000-100,000 USD

Biomass pellets are made after crushing, drying, compression and other processes. These pellets can be used in fireplaces, boilers, gasifiers, and biomass power plants, industrial factories, etc.

Richi Machinery focus on biomass pellet machine for sale, our MZLH858 biomass pellet machine is the spear tip of our biomass pelleting presses models. It was designed to work extremely difficult products, but it is able to get an incredible output and can handle electric motors with a power rating of up to 280 kW.

The raw materials suitable for biomass pellet machine are very wide, including:

- Sawdust, shavings, bark, sanding powder, waste wood, branches and twigs produced in wood processing and artificial board production;

- Various types of straw produced after crop harvest;

- Other types of combustible biomass as raw materials, without adding any adhesive, through equipment processing, can produce biomass pellet fuel.

Technical features of MZLH858 biomass pellet machine for sale

- RICHI has patented biomass pellet machine for sale, it adopts innovative feeding mechanism, uniform and reliable feeding, specially designed for forage, peanut vines, straw, crude fiber materials;

- The main transmission box is a casting, with large load-bearing capacity, good stability and long service life;

- Adopting gear transmission system, the transmission ratio is ideal, the driving torque is large, and the transmission is stable; there are ring dies of various diameters and thicknesses, and users can choose according to different needs to obtain better technical and economic benefits;

- The transmission part of the whole biomass pellet machine uses high-quality bearings from Sweden and Japan to ensure effective, stable and reliable transmission;

- The alloy steel ring die manufactured by internationally advanced biomass pelletizing equipment and technology has a long service life, smooth discharge and high quality;

- The ring die is made of internationally advanced steel, fully automatic gun drilling, vacuum heat treatment furnace quenching treatment, working surface hardness HRC62-65, and life is more than 500 hours;

- The internationally advanced level of compensation type serpentine spring coupling has excellent performance such as novel structure, compactness, stability, low noise and low failure.

- The main field control cabinet is easy to operate, and the optional biomass pelletizing machine automatic control system is interlocked with the central control room.

Richi Machinery has nearly 30 years of experience in the production of biomass pelletizing machine, and has been engaged in the renewable biomass pellet machine for sale, and at the same time provides a complete set of biomass pellet plant design.

Advantages of MZLH858 biomass pellet machine for sale

- The continuous extrusion molding technology is adopted to produce pellets with high density and strength;

- Made of stainless steel, it has the characteristics of wear resistance and high temperature resistance;

- The whole biomass pellets machine has a reasonable and compact structure and beautiful appearance;

- The biomass pelletizer machine runs smoothly and reliably, and is easy and safe to operate;

- High output: the output per pellet maker for biomass is about 5-40 tons per hour (depending on the raw materials);

- Good environmental performance: it can be used directly without adding any adhesive;

- Low investment cost and fast effect: 1-3 months to recover the cost, 1 year to recover the entire investment, 2-3 years to obtain net income, and above can recover the investment cost and make a profit;

- Strong adaptability: It is suitable for various wood fibers and waste paper to be processed into biomass fuels and domestic waste treatment;

- Good quality: All bio pellet machine has passed ISO, CE and other international certifications. The pellet machine for biomass fuel produced has passed strict testing procedures and can only be sold after passing the inspection;

- Good after-sales service: one-year warranty – installation guidance – training – accessories – regular return visits – full-cycle free technical guidance.

Richi Machinery specializes in biomass pellet machine for sale. If you have a demand for biomass pellet maker equipment, you are welcome to consult online or WhatsApp, and Richi Machinery will customize a biomass pellet machine plant configuration that is more suitable for your specific situation according to your output, raw materials, and finished pellet size.

Working principle of MZLH858 biomass pellet machine

The crushed biomass material enters the die cover through the forced feeding mechanism, and is evenly fed into the two pressing areas in the ring die, i.e. the wedge-shaped space formed by the two pressing rollers and the ring die, through the centrifugal force generated by the feeding device and the rotation of the ring die and the action of the feeding scraper.

Under the strong squeezing action of the ring die and the pressing roller, the material is gradually compacted, squeezed into the die hole of the ring die and formed in the die hole.

Since the extrusion of the material between the ring die and the pressing roller is continuous, the formed material is continuously discharged from the die hole in a columnar shape, and then cut into biomass pellets of the required length by the cutter.

Technical specifications of MZLH858 biomass pellet machine

| Type | MZLH858 |

| Output(t/h) | 5~40 |

| Main motor power(kw) | 280 |

| Main motor series | 6/8P |

| Forced Feeder (KW) | 3 |

| Conditioner Power(kw)(Optional) | 15 |

| Ring die diameter (mm) | 858 |

| Finished pellet diameter (mm) | 2-12mm |

Configuration of MZLH858 biomass pellet machine for sale

- Ring die material: 42CrMo

- Stainless steel feeder: with anti-caking function

- Door of pelleting room: 6mm /SUS304

- Forced feeding: Worm gear reducer

- Gear box: HT250

- Gear: 42CrMo

- Gear shaft: 42CrMo

- Spindle: 42CrMo

- Empty shaft: 42CrMo

- Bearings: The gear shaft and main shaft bearings are SKF, and the pressure roller bearings are domestic high-quality bearings

- Oil seal: Germany/Taiwan

- Overload mechanical protection: safety pin

- Serpentine spring coupling drive

- Lubrication system: Configurable automatic oil injection system

We can customize the biomass pellet machine for sale the world according to the actual needs of customers, including voltage, electrical components, product color matching, and can also customize biomass pellet machine plant process, biomass pellet machine parts and different compression ratio according to different biomass raw materials, etc.

biomass pellet machine for sale worldwide

We have exported biomass pellet machine for sale Asia, North America, Europe, Oceania, South America, South Africa.

biomass pellet machine for sale Vietnam

- pellet machine selection: MZLH858

- Production: 15000 t/a

- Ingredients: wet corn Straw waste

- biomass pellet project cost: 180,000 USD

biomass pellet machine for sale India

- pellet machine selection: MZLH858

- Production: 20,000 T/A

- Ingredients: bamboo, rice husk

- biomass pellet project cost: US$370,000

biomass pellet machine for sale United States

- pellet machine selection: MZLH858

- Production: 50,000 T/A

- Ingredients: Miscanthus, Hay, flax straw

- biomass pellet project cost: US$650,000

biomass pellet machine for sale brazil

- pellet machine selection: MZLH858

- Production: 35,000 T/A

- Ingredients: palm waste, straw, husk, wood waste

- biomass pellet project cost: 710,000 USD

biomass pellet machine for sale indonesia

- pellet machine selection: MZLH858

- Production: 40,000 T/A

- Ingredients: palm waste, Sawdust

- biomass pellet project cost: 290,000 USD

biomass pellet machine for sale poland

- pellet machine selection: MZLH858

- Production: 55,000 T/A

- Ingredients: Peanut shells, straw, rice husks

- biomass pellet project cost: 770,000 USD

biomass pellet machine for sale canada

- pellet machine selection: MZLH858

- Production: 10,000 T/A

- Ingredients: Straw, hay, Sawdust, blocks, planks

- biomass pellet project cost: $260,000

biomass pellet machine for sale argentina

- pellet machine selection: MZLH858

- Production: 80,000 T/A

- Ingredients: cotton stalk, sawdust

- biomass pellet project cost: $985,000 USD

How to process biomass pellets?

The production process of biomass pellet machine plant is the process of making biomass materials such as crop straw, cotton stalks, and sawdust into pelletized fuel through a series of processing.

According to the specific requirements of customers, we can tailor-made biomass pellet machine for sale and supporting overall design. Through the optimized combination of various types of equipment, different biomass pellets machine plant process requirements can be met.

The following is a detailed introduction to the production process of biomass pellets.

- First, the raw materials are preliminarily processed.

The raw materials mainly include biomass materials such as straw, cotton stalks, and wood chips. First, the raw materials are crushed. Wood crushers, straw crushers, and other equipment can be used to crush the raw materials into particles of appropriate size. Then, the crushed raw materials are placed in the material feeder. - Secondly, the material is pre-treated.

Under the action of the material feeder, the raw materials are transported to the hopper. Then, the raw materials are transported to the drum through the screw feeder, and an appropriate amount of water is added for mixing. The purpose of this step is to increase the humidity of the raw materials so that they are easier to form particles during the pressing process. - Then, the pressing is performed.

The molding of biomass pellets is mainly completed by biomass pellet machine. Under the action of the biomass pellet maker press, the raw materials are pressed into pellets of a certain shape and size after a series of filtering and pressurizing operations. In this process, the lignin and cellulose in the raw materials will polymerize at a certain temperature and pressure to form particles with a compact structure. - Then, the cooling process is performed.

Biomass pellets must be dried to reduce their moisture content. Through cooling equipment, the moisture in the pellets is evaporated to a certain degree of dryness. This helps to improve the combustion efficiency and storage stability of the biomass pellets. - Finally, packaging and storage.

During the production process, biomass pellets need to be packaged and stored for transportation and sales. Plastic bags, woven bags and other packaging forms are usually used, and the pellets are stored in a dry and ventilated warehouse to avoid moisture and oxygen affecting the quality of the pellets.

Richi Machinery not only focuses on the biomass pellet machine for sale, but also have more than 25 years of experience in biomass pellet plant design.

The production process of biomass pellet machine plant mainly includes raw material processing, material pretreatment, pressing, drying, packaging and storage.

The completion of these steps requires corresponding mechanical equipment, and it is necessary to control appropriate parameters such as temperature, humidity and pressure to ensure that the produced biomass pellets are of high quality and high combustion efficiency.

At the same time, it is also necessary to pay attention to environmental protection requirements and reduce the impact on the environment.

Equipment for whole biomass pellet machine plant

In addition to the biomass pellet machine, the biomass pellet production line also requires a series of equipment to complete the entire process from raw material processing to final product packaging.

Richi Machinery not only provides a single biomass pellet machine for sale, but also a complete set of biomass pellet plant equipment.

These biomass pellet making equipment mainly include:

Bale breaker

Capacity:

1-20T/h

Main Power:

30-90KW

biomass Hammer Mill

Capacity:

3-25T/H

Main Power:

30-160 KW

biomass Crusher Machine

Capacity:

0.3-3T/H

Main Power:

22-93KW

biomass Mixing Machine

Capacity:

250-2000KG

Main Power:

4-55KW

biomass Dryer

Capacity:

Customized

Rotate Speed:

3-8 R/Min

- Crusher: used to crush and grind the raw materials to achieve a size suitable for subsequent process steps. There are many types of crushers, such as hammer crusher, two-stage rotor crusher, etc., and the appropriate model can be selected according to different requirements and material properties.

- Dryer: used to remove moisture from biomass raw materials, and commonly used are drum dryers. The heat source can be a hot air furnace, which can burn coal, wood chips, or electricity. Although the cost is high, it is flexible and diverse.

- Biomass pellet machine: It processes the processed materials into regular shapes and is the core equipment in the biomass pellet line. There are many types of biomass granulators, and the most common one is the ring die biomass pelletizing machine.

- Cooler: Cool down the biomass pellets that have just been processed to prevent cracking and other problems in the biomass pellets.

- Screening machine: used to screen impurities in the raw materials and screen the pellets later to ensure the uniform quality and specifications of the pellets. Common screening equipment includes drum screens, vibrating screens, etc.

- Packaging machine: Packing the classified biomass pellets is the last link in the biomass pellet production line.

Some people will look for small biomass pellet machine for sale online, and some people will look for large biomass pellet machine for sale. depending on the scale and needs of the biomass pellet machine line, other auxiliary equipment may be required, such as conveyors, dust removal equipment, etc.

These biomass pellet equipment together constitute a complete biomass pellet production line, ensuring smooth production from raw materials to final products.

Video of biomass pellet machine for sale

FAQs of biomass pellet machine for sale

What is the the price of MZLH858 biomass pellet machine for sale?

The MZLH858 biomass pellet machine cost is generally between FOB 60,000-100,000 USD.

There are many factors that affect the biomass pelletizer quotes. Here are some common factors:

- Raw material cost: Biomass pellet machine manufacturing usually requires the use of various metals, plastics and other raw materials. The price fluctuations of these raw materials will directly affect the biomass pellet machine cost.

- Labor cost: Biomass pellet machine manufacturing requires workers to perform assembly, testing and maintenance. Changes in labor costs will also affect the price of the machine.

- Technical level: The application of high-tech technology will improve the performance and efficiency of biomass pellet machine, but it will also increase R&D and production costs, thereby affecting the biomass pellet machine price.

- Equipment and facilities: Equipment manufacturing requires the use of various equipment and facilities, including production lines, instruments and equipment, etc. The purchase and maintenance costs will also affect the price of biomass pellet machine.

- Market competition: The market competition is fierce, and the competition between different brands and suppliers will affect the price level of biomass pellet machines.

- Sales regions and channels: Market demand and sales channels in different regions will also affect the pricing strategy of biomass pellet machines.

- Supply and demand relationship: The balance between supply and demand will directly affect the biomass pellet machine price. If demand is higher than supply, the price may rise; if there is an oversupply, the price may fall.

- Policies and regulations: Government policies and regulations have a certain impact on the machinery manufacturing and sales industry, such as tariff policies, environmental protection requirements, etc. These factors will also affect the price of biomass pellet machines.

These factors interact with each other and have a comprehensive impact on the price of biomass fuel pellet machines. The importance of the above factors may vary under different machine types and market environments.

Are you looking for biomass pellet machine for sale? Contact Richi Machinery for details.

How to choose a biomass pellet machine?

- Raw material type: The physical properties of the raw materials are the key indicators that determine the pellet process and pellet machine configuration.

- Raw material moisture content: Too high a moisture content will make pelleting difficult, affecting pelleting efficiency and pellet quality.

- Pellet requirements: The final pellet product determines the required biomass pellet machine model and pelleting process.

- Construction site: site area, equipment placement, etc. also affect the selection of biomass pellet machine.

- Output requirements: Output determines the specifications of biomass pellet machine, which in turn affects input and output.

In summary, scientific selection of biomass pellet machine requires comprehensive consideration of factors such as material properties, pellet requirements, construction site and output requirements. Only by choosing the right equipment can we ensure efficient, safe and environmentally friendly production.

Richi Machinery specialize in biomass pellet machine for sale, our biomass pellet machine is carefully designed for customers according to the actual requirements. Feel free to contact us for details.

How to choose a biomass pellet machine manufacturer?

1. Evaluate product quality

To select an excellent biomass pellet machine manufacturer, you first need to evaluate their product quality. To understand whether the product quality is up to standard, you can examine it from the following aspects:

- Quality management system: Understand whether the manufacturer has a strict quality management system, such as detection, testing and traceability systems.

- Production process: Understand whether the manufacturer’s production process meets industry standards and whether the product has a certificate of conformity. For key components such as ring dies, rollers, bearings, motors, etc., whether high-quality materials are used.

- Product performance: Understand whether the manufacturer’s product performance indicators meet industry standards, such as motor efficiency, noise and life.

2. Evaluate production capacity

In addition to product quality, when choosing an excellent biomass pellet machine manufacturer, you also need to evaluate their production capacity. A good manufacturer should have stable production capacity and flexible supply chain management to meet the personalized needs of customers.

- Production scale: Understand the manufacturer’s production capacity, including the number of equipment produced each year, supporting production lines and storage capacity.

- Supply chain management: Understand whether the manufacturer’s supply chain management is excellent and whether it can cope with emergencies such as material shortages and process changes.

3. Evaluate service level

When choosing an excellent biomass pellet machine manufacturer, its service level is also very important, including service response speed and after-sales service.

- Service response speed: Understand whether the manufacturer’s sales team, technical support and after-sales service team are professional and whether they can respond to customer needs quickly and accurately.

- After-sales service: Understand whether the manufacturer’s after-sales service, including repair, maintenance, upgrades, etc., has professional service personnel and a complete service system.

Through the above evaluation, you can choose an excellent biomass pellet making machine manufacturer with high product quality, strong production capacity, excellent service level, and can provide customers with cost-effective products and services.

Richi Machinery, a professional biomass pellet machine manufacturer, has been focusing on biomass pellet machine for sale for 25+ years.

If you want to buy biomass pellet machine or biomass pellet production line, please feel free to consult Richi Machinery!

What is the prospect of processing biomass pellets with biomass pellet machines?

The biomass pellet market has been hot since ten years ago, and the driving force behind it comes from many factors.

With the gradual relaxation of energy-saving and environmental protection policies, the number of people who switch to biomass pellet machines has increased significantly, and the market scale has continued to expand.

This phenomenon heralds a bright future and makes us full of confidence in the prospects of the biomass pellet market.

The widespread use of biomass pellet machines not only complies with the new environmental protection and energy-saving policies of various countries, but also wins the favor of the market with its unique advantages. This equipment has a wide range of raw materials and is not picky.

The waste of various crops can be used as its production raw materials. This flexibility makes the raw material cost of biomass pellet machines very cost-effective, and also opens up new ways for the resource utilization of waste.

As a renewable energy source, biomass pellets are gradually replacing some non-renewable energy sources and have made positive contributions to environmental protection.

With the promotion of applications, the user group of the biomass pellet market is also expanding, attracting more and more new users to join. This trend indicates the continued growth of the biomass pellet market size and lays a solid foundation for the future development of the industry.

In summary, based on the promotion of energy-saving and environmental protection policies, the widespread use of biomass pellet machines and their non-picky characteristics for raw materials, we have reason to believe that the biomass pellet market will continue to expand in the future and usher in a broader market prospect.

If I want to open a biomass pellet machine plant, what issues should I pay attention to?

As a new type of clean energy, biomass pellets have a wide range of raw materials, including crop waste, wood processing residues, etc., and the production cost is relatively low. The emerging industry of biomass pellet processing, with its clean and environmentally friendly characteristics, caters to the current social demand for sustainable development, and market demand continues to grow.

The rise of the biomass pellet processing industry not only provides entrepreneurs with a low-threshold, high-return business opportunity, but also contributes to the sustainable development of society. When investing in biomass pellet machine line, biomass pellet processors should fully understand the relevant laws and regulations to ensure compliance with regulations.

It is worth noting that although the biomass pellet processing industry has broad market prospects and rich returns, it also has certain risks. For example, the stability of raw material supply and fluctuations in market demand may have an impact on the operation of the enterprise. Therefore, while entrepreneurs seize opportunities, they should also fully assess risks and develop reasonable business strategies.

In summary, as an emerging and highly profitable industry, the biomass pellet processing industry has huge development potential.

However, its healthy development requires legal regulation and guidance, as well as support and supervision from government departments. Biomass pellet processors should fully understand relevant laws and regulations and market risks to ensure compliance and success.

From customized non-standard models to multi-combination standard models, Richi Machinery not only focus on biomass pellet machine for sale, but always in accordance with market trends and customer needs, constantly seeking changes and improving, timely innovation, and adjusting according to biomass pellet manufacturers’ actual processes.

How to improve the production efficiency of biomass pellet machines and increase benefits?

Biomass pellet machines have become a very popular environmental protection equipment in recent years, but for novice operators, there will always be problems due to improper operation. If these problems are not handled well, it will directly affect the output of the equipment. So how to improve the production efficiency of biomass pellet machines and increase benefits?

RICHI has accumulated rich experience in the production and sales of pellet machines for many years and summarized some tips. I hope it can help you.

- Choose biomass pellet machine that suits your production capacity. For example, if the actual output is 3-4 tons, if you choose a machine that produces 5-6 tons per hour, wouldn’t it be a waste?

- The feeding process should be uniform, so as to ensure smooth operation of the machine and uniform pelletizing without blocking.

- Control the gap between the mold and the pressing wheel. After the material is matured at high temperature, it is pressed and formed by the pressing wheel. In this way, the particles are dense, strong and beautiful.

- Choose a suitable mold aperture according to your actual needs. If the aperture is too small, it will cause low output and no material, and will seriously affect the production efficiency of the biomass pellet machine.

- Regularly lubricate and clean. Long-term friction between the mold and the pressing wheel will damage the mold. Regular oiling and cleaning can not only ensure the cleanliness of the mold, but also reduce the friction between the two, reduce costs, and improve production efficiency.

In summary, in addition to choosing the right equipment, we should also pay attention to some small details in the normal production process to improve the production efficiency of the biomass pellet machine.

Richi Machinery focuses on biomass pellet plant and biomass pellet machine for sale, as a professional biomass pellet maker machine supplier, in fact, Richi Machinery does not only regard biomass pelletizing plant as a “turnkey project”, we hope it is a key to entering the new model of whole biomass pellets plant project management, and jointly maintain the stable and healthy development of the market. (FInd RICHI on youtube)