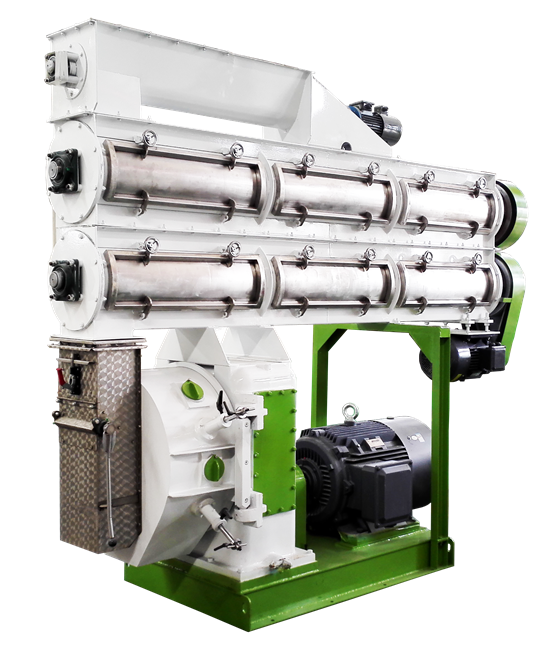

Feed Granulator Machine

SZLH558 feed granulator machine is used in the pelleting section of feed mills to process animal feed pellets of various sizes and formulas.

SZLH558 feed granulator systems operate at different temperatures, preserving nutrients and enzymes, and ensuring consistent quality. Feed pellets can be produced in a wide range of sizes — from chicken, pig and cattle to sheep, rabbits, fish, shrimp and horse.

- Model: SZLH558

- capacity: 15-25T/H

- power: 180/200KW

- Price: FOB 48,000-55,000 USD

Features of SZLH558 feed granulator machine

We understand that the feed you produce contributes to the well-being of animals and, by extension, to the sustenance of the world. Our feed granulator machines are built to handle the toughest challenges, ensuring that your animal feed mill operates at peak performance, delivering top-quality feed while minimizing costs.

- The main transmission housing is a casting with large load-bearing capacity, good stability and long service life;

- The main transmission system adopts gear transmission with high efficiency, and its output is 15% higher than that of the belt type; it adopts high-precision aviation-grade gear grinding technology to ensure smooth gear transmission and low noise;

- RICHI feed granulator machine system upgrade, production efficiency increased by 10~15% again;

- The conditioning time can be increased to 35 seconds, which greatly improves the maturity of feed;

- The current RICHI feed granulator housing is made of diesel engine cylinder material, and the service life is more than doubled;

- The surface paint adopts spraying technology, and the corrosion resistance is greatly improved, which is truly durable;

- The overall technical improvement makes the daily maintenance cost of RICHI granulator much lower than that of belt type;

- RICHI SZLH558 feed granulator is easy to operate, and one operator can operate multiple granulators at the same time. It is easier to achieve automatic control;

- 558 and above feed pellet granulators are equipped with external thin oil lubrication device (with cooling, filtering and oil break alarm function), forced lubrication of main shaft, gear shaft and hollow shaft rear bearing, reduce the temperature of the whole housing, and increase the service life of oil seal and O-ring;

- Double-layer and three-layer conditioner feed granulator machines can be customized to produce high-quality livestock and poultry aquatic feed.

Advantages of SZLH558 feed granulator machine

01 Longer lifetime of the die and rollers

The benefit is the increased life expectancy of the die and rollers up to 30%. By linking the operation of the dosing screw to the roller distance, the rollers will retract when the feed granulator machine is not producing.

02 Easy die-cleaning mode

The feed granulator system is equipped with a die-cleaning mode, enabling the operator to clean the die after a batch. This will also provide a quick start-up of the pellet granulator after a standstill because the product doesn’t get the opportunity to “cake” to the die.

03 Easy-to-clean coating

All critical components are treated with an easy-to-clean coating.

04 Motor-operated roller adjustment

The motor-operated roller adjustment enables the operator to easily choose the desired roller distance to the die, even when the feed granulator machine is in full operation. This system offers precise and recipe controlled roller gap settings enabling you to optimize the pellet quality.

05 Active roller slip control

This system detects roller slip and activates the system to automatically resolve the slip if desired, reducing the downtime of the feed granulating machine caused by roller slip to nil.

It also offers you the opportunity to experiment with the roller distance and steam addition for the recipes to boost feed quality and production efficiency. You can rely on this system while exploring the settings for the most optimum production.

Structure and working principle of feed granulator machine

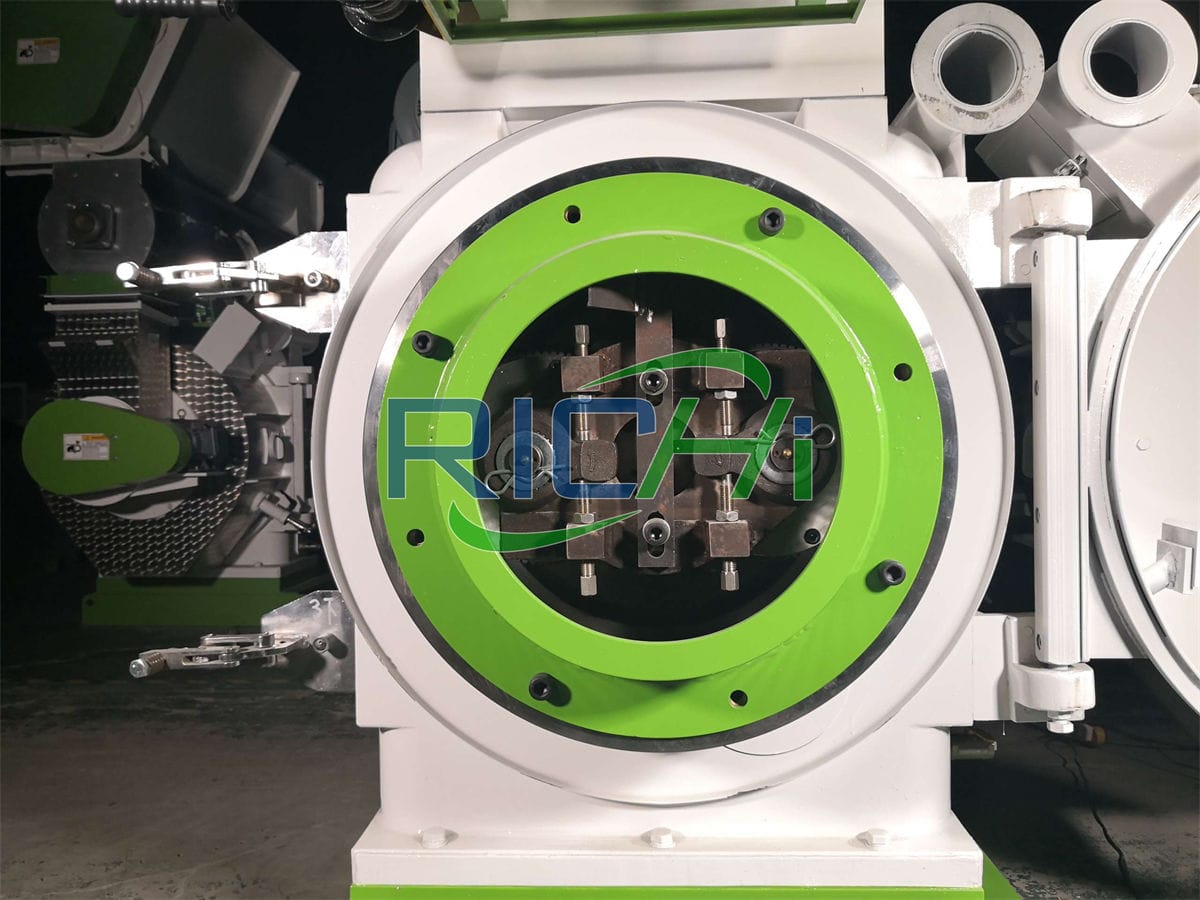

The ring die feed granulation machine is usually composed of a feeder, an extrusion chamber, a ring die, an extrusion roller, a cutting knife, a lubrication system, etc. The entire equipment has a compact structure, a small footprint, and is easy to install and operate.

1. Ring die:

It is one of the most important components of the ring die feed granulator machine and is also a key feed processing technology. There are two common materials for the ring die: one is high-strength alloy steel and the other is stainless steel. There are many tiny holes inside the ring die. After multiple processes such as extrusion, thermal expansion and cooling, the feed raw materials are finally formed into pellets of specified size and shape.

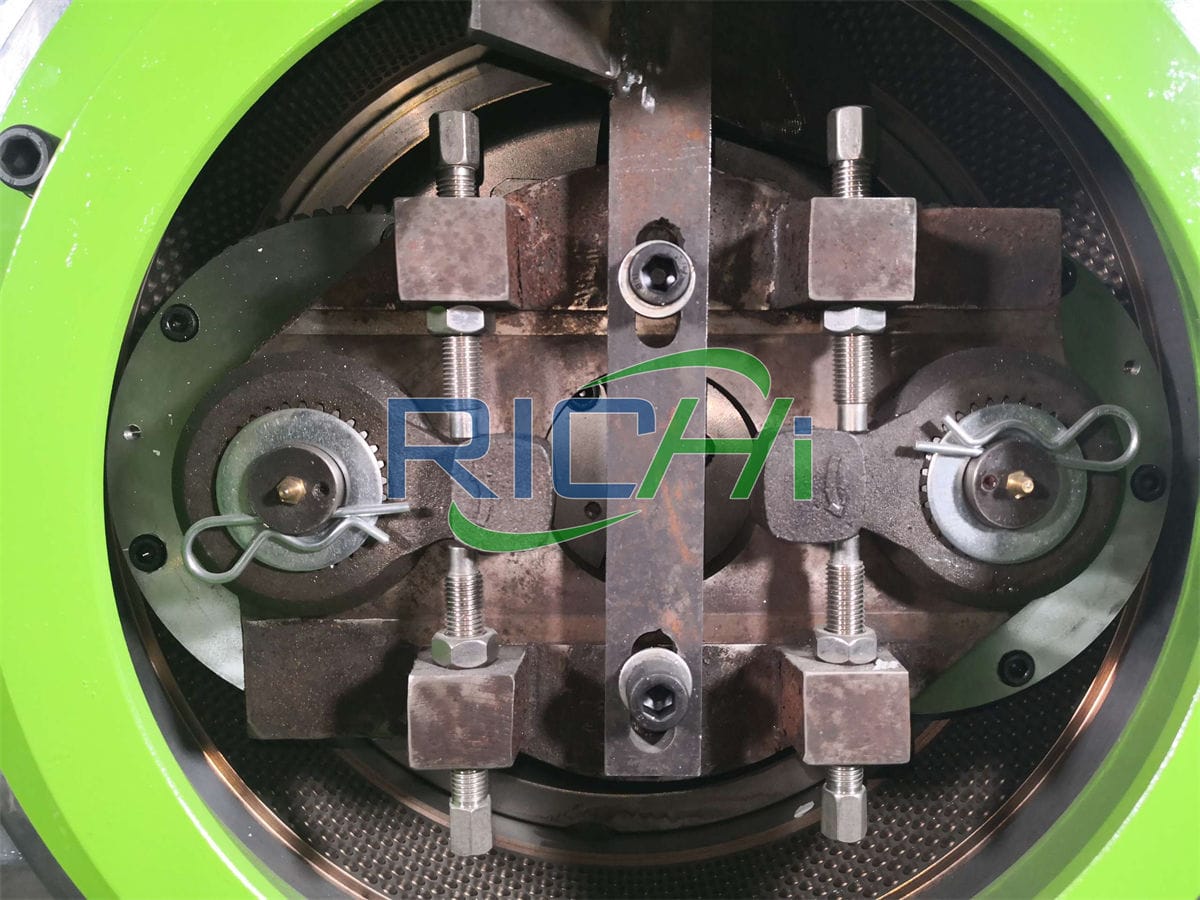

2. Press roller:

The press roller is the main source of motion for the feed raw materials in the ring die. The diameter and length of the press roller are different and can be customized according to different processing needs. There are two arrangements of the extrusion roller: parallel and toothed. In production, the movement speed of the extrusion roller should be adjusted according to factors such as the type, moisture content and viscosity of the raw materials to ensure the quality and output of the animal pellets.

3. Feeder:

During the production process, the feeder sends the animal feed raw materials into the extrusion chamber for the next step of processing. The feeder usually has a feed trough with an adjustable length to meet the production needs of raw materials of different lengths.

4. Cutter:

The cutter is usually installed under the ring die to cut the extruded long strip pellets into pellets of specified length. The cutter can be adjusted according to the length and shape of different pellets.

Specifications of SZLH558 feed granulator machine

| model | SZLH558 |

| Output (t/h) | 15~25 |

| Main motor power (kw) | 180/200 |

| Main motor series | 4P |

| Feeder power (kw) | 2.2 |

| Conditioner power (kw) | 11 |

| Ring die diameter (mm) | 558 |

| Finished pellet diameter (mm) | 2~12 |

configuration of SZLH558 feed granulator machine

- Ring die material: stainless steel

- Door cover of granulation room: 6mm /SUS304

- Feed chute: 3mm /SUS304

- Gear box: HT250

- Gear: 42CrMo

- Gear shaft: 20CrMnTi

- Bearing: Import

- Oil seal: Germany/Taiwan

- Overload mechanical protection: safety pin

- Serpentine spring coupling drive

- Using Siemens Motor

Operation requirements of feed granulator machine

| Animal feed types | Requirements Before Entering Granulator(mm) | Pellet Diameter(mm) | Pellet Length(mm) | Ring Die Compression Ratio | Conditoning Temperature(℃) | Conditoning Time(s) | Equipped Conditioner |

| Poultry chicken | 2.0-3.0 | 2-4 | 4-8 | 1:10—-1:13 | 150 | 60-120 | one layer/two-layer |

| Cattle | 3-5mm | 6-12 | 12-18 | 1:6:1:9 | 150 | 30-60 | one layer/two-layer |

| pig | 2-3 | 2-4 | 3-8 | 1:3.5—-1:5 | 150 | 60-120 | One layer/two layer |

| fish | 1.0-2.0 | 2-6 | 4-12 | 1:16—-1:18 | 150 | 90-180 | Two layer/three layer |

| shrimp | 95%≥80 mesh | 1.2-2.0 | 1.8-4 | 1:20—-1:25 | 150 | 120-180 | three layer |

| … | |||||||

feed granulator machine projects

feed granulator for sale Argentina

- granulator machine selection: sZLH558

- Feed Size: 2-10mm pellets

- project cost: 370,000 USD

feed granulator for sale Afghanistan

- granulator machine selection: sZLH558

- Feed Size: 1.5-6mm pellets

- project cost: 790,000 USD

feed granulator for sale in Mexico

- granulator machine selection: sZLH558

- Feed Size: 2-3mm pellets

- project cost: 559,700 USD

feed granulator for sale Indonesia

- granulator machine selection: sZLH558

- Feed Size: 2-10mm pellets

- project cost: 550,000 USD

feed granulator machine for sale Algeria

- granulator machine selection: sZLH558

- Feed Size: 2-6mm pellets

- project cost: 320,000 USD

feed granulator equipment in Uzbekistan

- granulator machine selection: sZLH558

- Feed Size: 2-5mm pellets

- project cost: 420,000 USD

feed granulator equipment for sale United States

- granulator machine selection: sZLH558

- Feed Size: 3-6mm pellets

- project cost: 750,000 USD

feed granulator machine for sale Malaysia

- granulator machine selection: sZLH558

- Feed Size: 2-4mm pellets

- project cost: 650,000 USD

Application of feed granulator machine

SZLH558 feed granulator machine is mainly used for animal feed production lines with an output of 15 tons or more.

The feed pellet production line is designed for manufacturing feed pellets for various animals including chicken, cattle, pig, fish, rabbit, sheep, horse, fish, shrimp, duck, goose, quail, pigeon, etc.

This complex and sophisticated system encompasses several steps and technologies.

From the selection of raw materials to the processing of the final product, each link in the feed processing flow carries important functions and responsibilities.

RICHI, one of the top feed granulator machine and whole set animal feed mill equipment manufacturers, has helped many investors successfully implement many animal feed mill plant projects in many countries around the world.

Regardless of the size of the production, we offer complete feed mill plants and can customize a solution to fit your needs.

We provide full technical support and service to ensure the efficient and stable operation of your complete feed mill plant.

If you want to get a feed production line solution of more than 15 tons, click the button to get a detailed solution design, feed mill equipment configuration list and poultry livestock cattle fish feed production line quotation.

Video of feed granulator machine

FAQs of feed granulator machine

How much does SZLH558 feed granulator machine cost?

The price of a SZLH558 feed granulator machine is generally between FOB 48,000-55,000 USD.

In the production process of feed mills, feed granulator machines are increasingly used and have become one of the indispensable equipment in many industries. However, when companies purchase animal feed pellet mills, price is an important consideration. Below RICHI will discuss the relevant issues of companies purchasing feed granulators from two aspects: price factors and market analysis.

1. Specifications and sizes of feed pellet granulator machines

The specifications and sizes of feed pellet mills are one of the key factors affecting animal feed pellet machine prices. Feed granulators of different specifications and sizes require different materials, processes, and time costs in the production process. Generally, larger feed pellet mills require more materials and longer production cycles, so the price is relatively high.

2. Technical requirements and functions

The technical requirements and functions of feed granulator machines are also important factors affecting their prices. For example, some special industries may require feed granulator machines with special functions such as high-precision temperature control, explosion-proof, and anti-corrosion.

These special functions require higher technical levels and more complex production processes, which will increase the customized purchase price.

3. Material selection

The material selection of animal feed granulator machine is also one of the factors affecting its price. Different materials have different performance and prices, such as stainless steel, alloy steel, etc. Enterprises need to choose suitable materials according to their own needs and budget.

4. Production process and quality

Advanced production technology and strict quality control can ensure the stable performance and reliability of feed granulator machines, but will also increase production costs. Therefore, production technology and quality are also one of the factors affecting the price of feed pellet mills.

RICHI Machinery recommends that enterprises need to consider price factors and market analysis when purchasing feed granulator machines.

By understanding the key factors affecting the price of feed granulator machines, enterprises can better choose suitable equipment and formulate reasonable procurement strategies based on market demand and trends.

At the same time, enterprises also need to pay attention to market competition and the development trends of emerging markets in order to maintain competitive advantages in the market.

How to choose feed granulator machine?

1. Equipment type

The type of feed granulator machine is the first step in choosing equipment. Common equipment types include SZLH250, SZLH320, SZLH350, SZLH420, SZLH508, SZLH678, SZLH768, SZLH858, etc. Each equipment has its specific purpose and applicable scenario. When choosing equipment, you need to decide which type of equipment to purchase based on your own needs and budget.

2. Equipment performance

The performance of the feed granulator machine has a vital impact on its use effect. When choosing equipment, you need to consider its power, conditioner size, ring die diameter, compression ratio, maturation time and other performance indicators. According to your own use needs and budget, choose equipment that can meet your needs.

3. Brand

Brand is an important factor to consider when choosing a feed granulator machine. The reputation and credibility of the brand will affect the quality and after-sales service of the equipment.

Generally speaking, the performance of feed granulator machines of well-known brands is relatively stable, and the after-sales service is relatively reliable. At the same time, when choosing a brand, you also need to consider the matching of the corresponding price and your own budget.

4. Maintenance

In the process of using feed granulator machines, maintenance is inevitable. Therefore, when choosing a feed granulator machine, you also need to consider the maintenance of the equipment.

You need to pay attention to the warranty period and warranty scope of the equipment, as well as the convenience and cost of the maintenance service. Choosing equipment that is more convenient to maintain can reduce the cost and trouble of maintenance and repair in daily use.

In summary, when choosing a feed granulator machine, you need to decide what type of equipment to purchase based on your needs and budget, and comprehensively consider factors such as the performance, brand, and maintenance of the equipment to choose the equipment that suits you.

How to choose a feed granulator machine manufacturer?

With the widespread application of feed granulator machines, the demand for feed pellet mills has increased. How to choose a feed granulator machine manufacturer has become a difficult problem for users who need feed granulation machine.

First, you should decide based on the budget; second, you should choose based on the quality of the feed granulator machine. No matter what kind of feed granulating machine the animal feed manufacturing plant needs, it generally will not choose a manufacturer that is too bad.

If the products brought by a manufacturer that is too bad are not of good quality, it will cause trouble to its own production and will not be suitable for long-term use, resulting in greater waste.

So how to choose an animal feed granulator machine manufacturer?

1. Is there a physical factory and production workshop?

Speaking of factories and workshops, many people will find it ridiculous. How can feed granulator machine manufacturers produce without physical factories and production workshops? How can they be called manufacturers?

In fact, most of the companies on the market are just companies, only offices, no physical factories, let alone production capacity. After receiving orders, these companies basically go to manufacturers with production capacity to entrust production, or find small manufacturers to produce and process on their behalf. In this way, many rights and interests of customers are not guaranteed.

2. Technology and quality.

When choosing a feed granulator machine manufacturer, it mainly depends on product quality and technical strength. Details determine product quality, product quality determines product quality, and product quality determines product use time. Only when the technical quality meets the standards can the product use time be long. Therefore, it is necessary to choose a feed pelletizing machine manufacturer with technology.

3. Product price and specifications

The feed granulator machines produced by manufacturers are generally one-to-one customized products. The parameters of the feed pellet granulator machines required are very detailed. Water quality testing should be carried out according to customer needs. If the water quality index parameters provided by some users are not prepared, the products produced may not be used. This is because they do not have production capacity and production technology.

A good feed granulator machine manufacturer will have a laboratory to design and select the type of feed pellets that customers want to process, and provide users with more and more reliable solutions, so that customers can buy more suitable products with good processing effects at a more affordable price.

4. After-sales guarantee capabilities of feed granulator machine suppliers.

Regular feed granulator machine manufacturers will be equipped with relevant after-sales technicians and professional technical service teams. Some manufacturers’ sales staff may solve the problems encountered by customers smoothly, but companies without production capacity may not be able to solve some problems.

If they encounter larger faults, they may need to be solved by the processing manufacturer, which will delay the work and there is no guarantee for after-sales.

The above four points are what you need to pay attention to when choosing a feed granulator machine manufacturer. Good products will have good services. When choosing a feed granulator manufacturer, do not blindly choose companies that have no strength, which can avoid a lot of trouble. (Find RICHI on youtube)