Chicken Manure Pellet Machine

Chicken manure pellet machine is mainly used to process granular chicken manure organic fertilizer. We offer a wide range of organic fertilizer chicken manure processing equipment for personal and commercial uses, including different scale chicken manure fertilizer pellet making lines.

- Capacity:1-12T/H

- Price: 10,000-100,000 USD

- Application: Organic fertilizer factory, compound fertilizer factory, chemical fertilizer factory, chicken farm, breeding farm, sugar factory, sewage treatment plant, waste treatment plant, food processing plant, slaughterhouse, etc.

what’s chicken manure pellet machine?

The chicken manure pellet machine is a technological product developed by RICHI Machinery based on years of experience in the design and production of chicken organic fertilizer machine.

The chicken litter pellets processing machine is used to granulate fermented chicken manure and various organic fertilizers. It breaks through the conventional organic granulation process and is developed to keep continuous chicken manure fertilizer granulation, achieving a super-efficient fertilizer granulation process in organic fertilizer production. lines with different production scale.

RICHI Machinery is dedicated to the quality manufacturing of chicken manure pellets machines, providing not only complete sets of organic manure making machines but also complementary services. Offer you a complete chicken manure fertilizer production solution.

What is chicken manure organic fertilizer?

Chicken manure made by chicken manure pellet machine is a relatively high-quality organic fertilizer, containing approximately 1.63%, 1.54%, and 0.85% pure nitrogen, phosphorus, and potassium.

Chicken manure must be fully decomposed before application. Parasites and eggs in chicken manure, as well as some infectious bacteria, can be inactivated through the decomposition (retting) process.

Because chicken manure generates high temperatures during the decomposition process, it is easy to cause nitrogen loss.

Therefore, add an appropriate amount of water and 5% superphosphate before decomposition, and the fertilizer effect will be better. The decomposition method can be to put the chicken manure into the manure tank for soaking, or to make a surface sealing pile for retting.

Chicken manure becomes a high-quality base fertilizer for planting crops after it is fully decomposed, or it is often used as a base fertilizer for planting fruit trees in winter and used throughout the year.

Technical characteristics of chicken manure pellet machine

- The spindle system adopts a double support structure, the spindle will not shake, and can provide greater ring die extrusion force;

- The ring die roller adjustment device adopts an external structure, which can adjust the mold roller gap without stopping the chicken manure pelletizer machine;

- The pressure roller is cooled by circulating water. The bearing has low operating temperature and long service life, which can reduce grease consumption;

- The main shaft and pressure roller bearings are equipped with temperature measurement devices to monitor the working status of the bearings;

- Key parts such as main shaft, transmission wheel, and gears are all made of high-strength forged alloy steel, and the gears are processed by high-precision gear grinding machines;

- The transmission system uses brand bearings to ensure the reliability and service life of the chicken manure pellets machine;

- The ring die and pressure roller are made of high-strength forgings, drilled by automatic gun drilling and vacuum quenching heat treatment. The working life of the ring die is >500 hours.

Working principle of chicken manure pellet machine

The working principle of the chicken manure organic fertilizer granulator machine mainly relies on the pressure and friction between the template and the mold to gradually shape the raw materials and finally cut them into granular products.

The specific process is as follows:

- Feeding: The raw materials are fed through the feeder, and then sent into the hopper of the compost granulating machine after pretreatment such as crushing and mixing.

- Extrusion: The raw materials are subjected to the force between the high-speed rotating template and the stationary mold in the hopper, and gradually form granular materials.

- Cutting: After extrusion, the granular material is pushed to the inside of the mold to form a ring shape. The cutting edge on the inside of the mold cuts the particles to produce granular products with the same length.

- Discharging: The granular products are sent into the discharging port to produce the products of the manure pellet mill.

Specifications of chicken manure pellet machine

| Model | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH768 | MZLH858 |

| Output (t/h) | 1-2 | 3-4 | 5-6 | 7-8 | 9-10 | 10-12 |

| Main motor power (kw) | 22 | 37 | 90 | 132 | 250 | 280 |

| Main motor series | 8P | |||||

| Ring die diameter (mm) | 320 | 350 | 420 | 520 | 762 | 858 |

| Finished pellet diameter (mm) | 2-12 | |||||

| Device Configuration | Ring die material: 42CrMo Stainless steel feeder: with anti-caking function Door of pelleting room: 6mm /SUS304 Forced feeding: Worm gear reducer Gear box: HT250 Gear: 42CrMo Gear shaft: 42CrMo Spindle: 42CrMo Empty shaft: 42CrMo Bearings: The gear shaft and main shaft bearings are SKF, and the pressure roller bearings are domestic high-quality bearings Oil seal: Germany/Taiwan Overload mechanical protection: safety pin Serpentine spring coupling drive Lubrication system: Configurable automatic oil injection system | |||||

chicken manure pellet machine price

The price of chicken manure pellets machine is generally 10,000-100,000 USD

As we all know, the price of chicken manure organic fertilizer pellet mills has fluctuated in recent years. There are many factors that affect the price of chicken litter pellets processing machines.

Among them, the price of steel, the price of raw materials, and the price of organic fertilizers will all affect the organic fertilizer industry, and in turn affect the quote for chicken manure pelleting equipment. At present, the price factors of pelleting machine for chicken manure are mainly affected by factors such as production cost, product quality, market supply and demand, etc.

Here will analyze the factors that affect the price of chicken manure compost granulating machines:

1. Cost of production

Factors that affect the price of chicken poultry manure pellet machines, the first thing that should be considered is the production cost. The level of production costs has a key and direct impact on the price of chicken manure pellets machines. The production cost is the input of raw materials.

Most of the parts of the entire equipment are cast from stainless steel and alloy steel, so the fluctuations in steel on the market determine the price of the chicken manure compost granulating machine.

2. Product quality

The quality of chicken manure pellet machines is related to the operating costs of consumers. Good product quality can create considerable economic efficiency for consumers, and will also establish the economic efficiency of hard brands for manufacturers. Good quality chicken manure fertilizer pellet making machine is naturally more expensive, so the product quality determines the price.

Product quality is the foundation of an enterprise. RICHI has always regarded product quality as the foundation of the company, always putting the interests of users first, and conscientiously doing every aspect of the work. The product quality has been well received by users.

3. Market demand

The supply relationship of the market will also affect the price of chicken manure pellet machine. When the chicken dung organic fertilizer pellet machine provided on the market is greater than the actual demand, the price will fall. On the contrary, the price will rise, and the market demand will also affect the organic fertilizer. Key factors in granulator price.

In recent years, the demand for high-quality organic fertilizers in planting, agriculture, flowers and other industries has increased sharply, which has also promoted the increase in the demand for high-quality chicken dung organic fertilizer pellet machines among organic fertilizer processors. Therefore, some manufacturers have raised the price of chicken manure pellet machines in pursuit of profits.

The above three situations are important factors that cause the price of chicken manure pellet machine to fluctuate. The price of chicken manure fertilizer pellet machine is difficult to control. Therefore, when purchasing an organic fertilizer granulator, you must choose the right time and find a good one.

Featured chicken manure pellet machine projects

chicken manure pellet machine for sale Vietnam

- Country: Vietnam

- Production: 2500 t/a

- Ingredients: chicken manure, industrial waste

- project price: 80,000 USD

chicken manure pellet machine for sale Mexico

- Country: Mexico

- Production: 10,000 T/A

- Ingredients: chicken manure, livestock manure

- project price: US$110,000

chicken manure pellet machine for sale United States

- Country: United States

- Production: 50,000 T/A

- Ingredients: chicken manure, cow litter

- project price: US$430,000

chicken manure pellet machine for sale russia

- Country: russia

- Production: 35,000 T/A

- Ingredients: chicken manure, food waste

- project price: 410,000USD

chicken manure pellet machine for sale Thailand

- Country: Thailand

- Production: 55,000 T/A

- Ingredients: hen manure, sheep manure

- project cost: 570,000 USD

chicken manure pellet machine for sale indonesia

- Country: indonesia

- Production: 10,000 T/A

- Ingredients: chicken manure, crop straw

- project cost: 190,000 USD

chicken manure pellet machine for sale canada

- Country: South Africa

- Production: 6,000 T/A

- Ingredients: chicken manure, livestock manure

- project cost: $160,000

chicken manure pellet machine for sale Pakistan

- Country: Pakistan

- Production: 30,000 T/A

- Ingredients: chicken manure, Bagasse

- project cost: $385,000 USD

How to process chicken pellets manure? Complete chicken poo pellets process flow

The chicken manure fertilizer pellet line pelletizes animal manure (chicken manure, cow dung, pig manure, etc.) into nutrient-rich chicken litter pellets. It can meet most investors’ chicken fertilizer pellets production demands.

The design features of the chicken manure organic fertilizer production process include:

- Highly efficient composite strains and their propagation technology;

- Advanced raw material blending technology and biological fermentation system

- The best special fertilizer formula technology (can flexibly design the best combination of product formulas based on local soil and crop characteristics);

- Reasonable secondary pollution control technology (exhaust gas and odor);

- Design and manufacturing technology of complete sets of fertilizer making process equipment.

The whole process includes crushing, fermenting, mixing, granulating, packaging, screening, drying, cooling, and granule polishing.

1. Collection of chicken manure

Chicken manure collection is mainly carried out in the chicken house. Generally, the chicken manure is collected to a designated location when the chicken house is cleaned every day. The collected chicken manure should be kept fresh and avoid being exposed to the air for a long time to ensure the quality of the chicken manure.

2. Fermentation of chicken manure

Chicken manure fermentation is an important step in the preparation of organic fertilizer. Its principle is to use the action of microorganisms to decompose and convert organic matter in chicken manure into organic fertilizer. The fermentation method usually uses aerobic composting.

The chicken manure is piled to a certain height, and the pile turning equipment or manual turning is used to fully contact the chicken manure with the air for aerobic decomposition. Fermentation time generally takes 2-3 weeks, and the specific time depends on the composition of chicken manure and environmental conditions.

3. Chicken manure pellet processing

The main purpose of chicken manure processing is to make fermented chicken manure into standard organic fertilizer. The processing flow includes crushing, granulating, drying, screening and other operations of fermented chicken manure.

The processing method can be selected according to market demand and processing conditions, and the processing cost varies depending on the processing method and scale.

4. Chicken manure packaging

Packaging is an important part of the sales and transportation of chicken manure, and the time and location of packaging should be determined according to sales and transportation needs. Packaging materials generally use woven bags or paper bags, which should be tightly sealed to prevent air leakage and contamination.

Packaged chicken manure should be clearly labeled, including product name, production date, packaging weight and other information.

5. Chicken manure sales

Chicken manure sales channels include fertilizer markets, agricultural cooperatives, farmers, etc. Prices vary depending on quality and market supply and demand, and should generally be comparable to similar local products.

In terms of market demand, with the development of green agriculture, the demand for organic fertilizers is gradually increasing. Therefore, the rational development, utilization and promotion of chicken manure organic fertilizers will have broad market prospects.

In short, through reasonable collection, fermentation, processing, packaging, sales, transportation and use, chicken manure can be effectively converted into organic fertilizer, realizing waste resource utilization and sustainable agricultural development.

At the same time, we will strengthen safety management in relevant links to ensure environmental protection and safety during production and use.

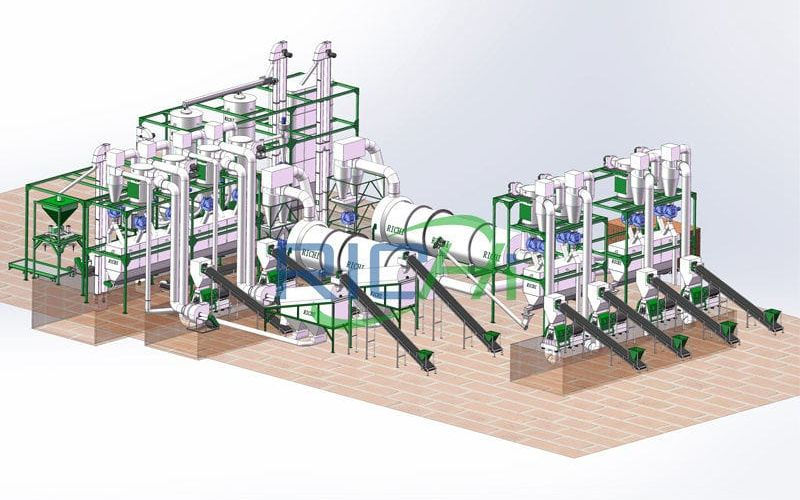

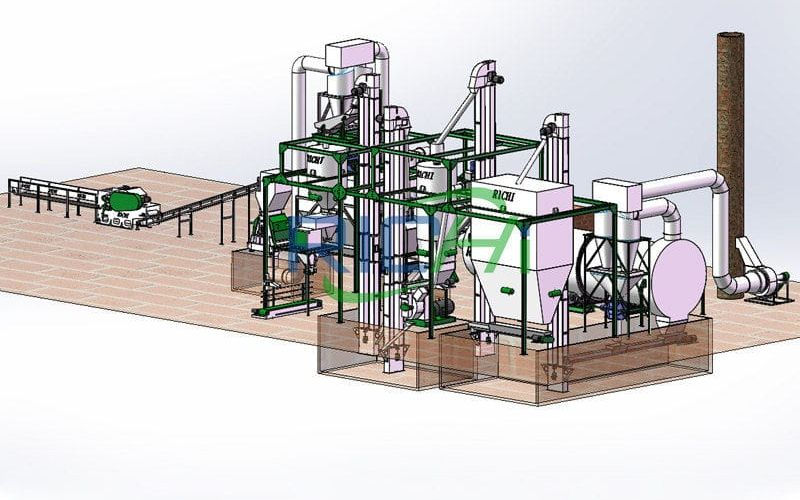

Whole set chicken manure processing equipment list

The production process of chicken manure organic fertilizer is closely related to the equipment configuration of the organic fertilizer production line.

Generally, the complete set of equipment of the chicken manure fertilizer pellet making line mainly consists of a fermentation system, a drying system, a deodorization and dust removal system, a crushing system, a batching system, a mixing system, a granulation system, and a screening system. and finished product packaging system.

chicken manure Turner

Turning height:

0.5-2.0 m

Motor:

32-300 KW

chicken manure Grinder

Capacity:

3-25T/H

Main Power:

30-160KW

chicken manure Mixer

Capacity:

250-2000 kg/P

Main Power:

4-30 KW

chicken manure Dryer machine

Capacity:

Customized

Rotate Speed:

3-8 R/Min

chicken manure pellet machine

Capacity:

1-12T/H

Main Power:

37-280KW

The chicken manure processing equipment requirements for each link of the organic fertilizer production process are described in detail below:

- The fermentation system consists of a feed conveyor, a biological deodorizer, a mixing mixer, a proprietary lifting and throwing machine, and an electrical automatic control system;

- The main equipment of the drying system includes belt conveyors, drum dryers, coolers, induced draft fans, hot blast furnaces, etc.; the deodorization and dust removal system consists of a settling chamber, a dust removal chamber, etc. Zhengzhou Changwei Heavy Industry provides free drawings and free guidance to users build a fort;

- The crushing system includes material crushers, belt conveyors, etc.;

- The batching system includes equipment such as electronic batching system, feeder, and vibrating screen, and can be configured with multiple raw materials at one time;

- The mixing system consists of optional horizontal mixer, vibrating screen, belt conveyor, etc.;

- The granulation system requires the use of compost pellet making machine. Optional granulator equipment include: ring-die chicken manure pellet machine, rounding machine, etc.;

- The screening system is mainly completed by a rotary classification screen or a vibrating screen. A primary screening machine and a secondary screening machine can be set up to achieve a higher yield and better pellets;

- The finished product packaging system generally includes electronic quantitative packaging scales, silos, automatic bag sewing machines, etc. In this way, fully automatic and intermittent production of the chicken manure production line can be realized.

The construction scale of chicken manure organic fertilizer production line equipment configuration is generally 10,000-200,000 tons per year. Local resources, market capacity, and market coverage must be comprehensively considered.

The investment scale and product plan design need to be formulated based on the following conditions: raw material resource characteristics, local soil conditions, local planting structure and main crop varieties, factory site conditions, degree of automation of production, etc.

How to choose chicken manure pellet machine?

1. Principles of chicken manure pellet machine selection

- ① Engineering applicability – the selected chicken manure pellets machine is suitable for the needs of your project.

- ② Technological advancement – on the premise of meeting needs, its performance indicators are required to maintain advanced levels, improve product quality and extend its technical life.

- ③ Economic rationality – low energy consumption and maintenance costs during use.

- ④ Equipment reliability and maintainability – Reliability is a prerequisite for maintaining and improving equipment productivity. Reliability lies to a large extent in equipment design and manufacturing. Therefore, the design and manufacturing quality should be considered when selecting chicken manure processing equipment. Similarly, the maintainability of the equipment must be good. When selecting equipment, the maintainability of the equipment can be measured from the following aspects:

- The technical drawings and information of the chicken manure pellet machine are complete, which makes it easy for maintenance personnel to understand the structure of the equipment and is easy to disassemble and inspect.

- The structural design is reasonable. The overall layout of the equipment structure should be reasonable. Each component and structure should be easy to access for inspection and maintenance. The structure of the equipment should be simple. The fewer parts that need to be repaired, the better, and it should be easier to disassemble. And can quickly replace wearing parts.

- Principles of standardization and combination, the chicken manure pelleting equipment uses standard parts and components as much as possible, can be easily disassembled into several independent parts, devices and components, and can be assembled into a complete machine without special means. Advanced structure.

- ⑤ Equipment safety and operability – Safety is the performance of chicken manure pellet machine to ensure production safety, that is, the equipment should have the necessary safety protection design and devices to avoid human and machine accidents and economic losses, the operation should be simple and easy to understand.

- ⑥ Environmental protection and energy saving of equipment – When selecting chicken manure pellet machine, its noise, vibration frequency and harmful emissions must be controlled within the scope of national and regional standards. The purchased equipment must be Comply with various standards and requirements stipulated in the national “Energy Conservation Law”.

2. Equipment reliability

The selection and configuration of the organic fertilizer pellet making machine for chicken manure pellet production line are completely in accordance with the requirements of the bidding documents and construction drawings.

How to choose a chicken manure pellet machine manufacturer?

Choosing the right chicken manure pellets machine manufacturer is key to ensuring you get quality equipment and good after-sales service. The following are key factors to consider when choosing a chicken manure pelletizer manufacturer:

- Reputation and word-of-mouth: Look for manufacturers or brands with good reputation and good reputation. You can learn about the reputation of manufacturers through organic fertilizer communities, forums, evaluation websites, or recommendations from other pelleted chicken manure fertilizer processors.

- Product quality: Understand the manufacturer’s product quality and manufacturing standards. View the product’s detailed description, materials, production processes, durability and more.

- Technical support and after-sales service: Ensure that the manufacturer provides good technical support and after-sales service. Being able to promptly resolve equipment issues and provide professional advice is critical to the chicken litter pellets manufacturing process.

- Customization options and flexibility: Some chicken manure pellet machine manufacturers may be able to provide customized equipment to meet your special needs. Flexibility and customizability are features favored by some chicken manure pellet processors.

- Price and budget: Consider whether the price of the device matches your budget. The price differences between different manufacturers may be large, so choose the appropriate chicken manure fertilizer pellet machine based on your budget.

- Experience and history: Understand the manufacturer’s experience and history. Manufacturers that have been engaged in chicken manure pellet equipment manufacturing for a long time and have rich experience are usually more reliable.

- Customer reviews and feedback: Check the chicken manure pellet machine manufacturer’s customer reviews and feedback. Understanding other customers’ experiences can help you better evaluate the manufacturer’s service and product quality.

- Sustainability and environmental awareness: Consider whether the manufacturer’s equipment meets environmental standards and sustainability requirements. This is an important consideration for some chicken manure pellet processors.

When choosing a chicken manure pellet machine manufacturer, comprehensively consider the above factors and conduct full investigation and research.

Try to choose a manufacturer that can provide high-quality fertilizer granulation equipment and quality services to ensure the smooth progress of the organic fertilizer processing process and obtain high-quality organic fertilizer chicken manure recycling pellet machine.

Characteristics of chicken manure organic fertilizer

Based on advanced processing technology and the material characteristics of chicken manure, chicken manure organic fertilizer made by chicken manure pellet machine has the following characteristics:

- Rich in organic matter: Chicken manure organic fertilizer is rich in organic matter, which can improve soil fertility and promote plant growth.

- Rich in nutrients: Chicken manure organic fertilizer contains a large amount of nitrogen, phosphorus, potassium and other nutrients. These elements are required for plant growth and can provide sufficient nutrients for plants.

- Improve soil: Chicken manure organic fertilizer can improve soil structure, increase soil porosity, enhance soil permeability and water retention, and maintain soil moisture.

- Safety and environmental protection: Chicken manure organic fertilizer does not contain harmful chemicals and will not cause pollution to the soil and environment. It is a safe and environmentally friendly fertilizer.

Market prospects of chicken manure organic fertilizer business

The chicken manure organic fertilizer business is an investment and entrepreneurial project with good market prospects and can earn considerable profits.

01 Market prospects of chicken manure organic fertilizer processing

In recent years, with the increasing awareness of environmental protection and the rise of organic agriculture, the market demand for organic fertilizers has gradually increased. As a high-quality organic fertilizer, chicken manure organic fertilizer is becoming more and more popular in the market due to its low production cost, good fertilizer efficiency, environmental protection and other advantages.

At the same time, chicken manure organic fertilizer made by chicken manure pellet machine is also widely used in fruit and vegetable planting, flower maintenance and other fields. In the cultivation of some high-end fruit and vegetable products, the use of organic fertilizers has become a trend, and chicken manure organic fertilizer has become a popular choice due to its high nutrient content and easy absorption.

02 Profits from chicken manure organic fertilizer business

The production cost of chicken manure organic fertilizer is low. The raw materials in the production process are mainly wastes such as chicken manure and straw. These raw materials can effectively reduce production costs. At the same time, due to the increasing market demand for organic fertilizers, market prices are relatively stable and profit margins are relatively high.

Take the production and sales of chicken manure organic fertilizer as an example. Under normal circumstances, the cost of producing 1 ton of chicken manure organic fertilizer is around tens to 100 US dollars, while the selling price on the market is generally between 200-800 US dollars, and market demand It has been in a strong state and can be said to be a very good entrepreneurial and investment project. (Find RICHI on YouTube)