Ring Die Feed Pellet Machine

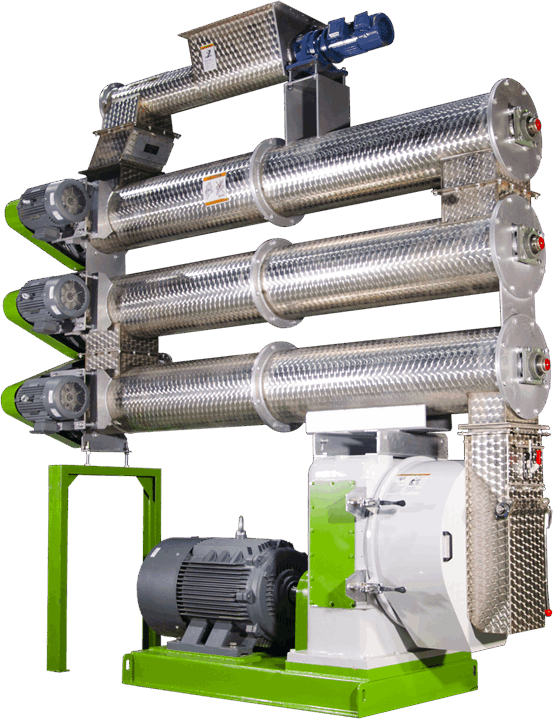

SZLH858 ring die feed pellet machine is a model specially used for large animal feed mills. It is also the largest pelleting equipment designed by RICHI after years of research and development.

For a reasonable cost, RICHI ring die feed pellet mill can design a custom nutrition pelleting system scaled to large size feed mill plant operation. Our pellet mills for animal feeds and supplements give you complete control over inputs and better resulting outputs.

- Model: SZLH858

- capacity: 28-45 T/H

- power: 315/355 KW

- Price: FOB 80,000-100,000 USD

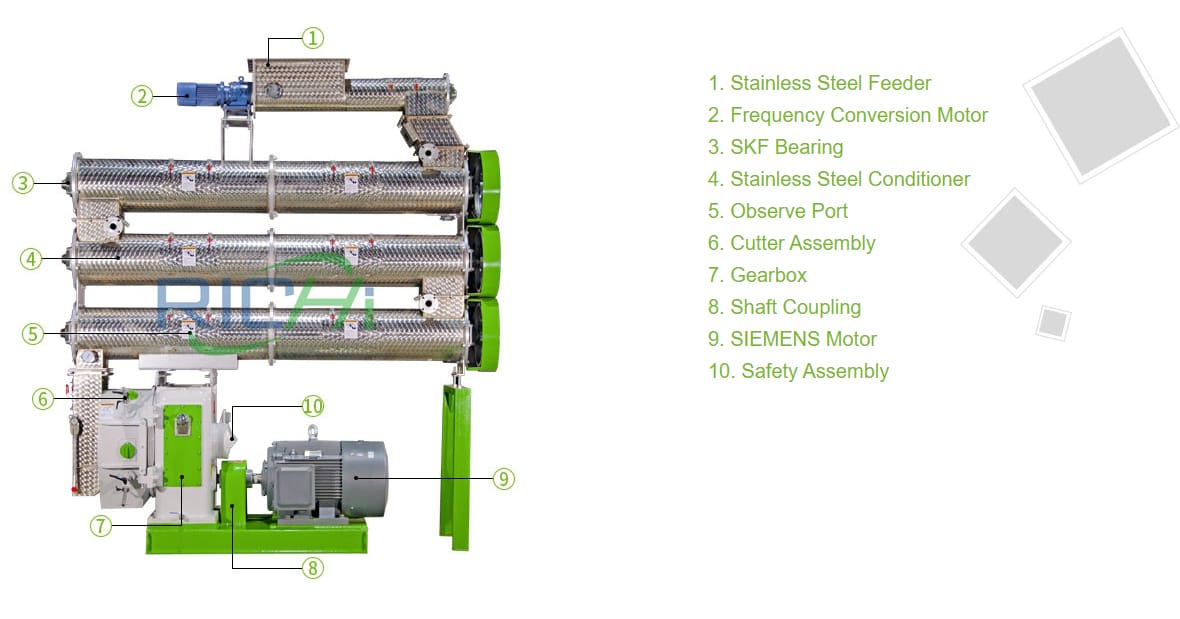

Features of SZLH858 ring die feed pellet machine

- CPM model, internationally advanced, direct drive system, 20% higher efficiency, variable frequency feeding to ensure uniform feeding of materials, all stainless steel, lengthened and thickened, large door strengthening conditioner, 2.6 times higher volume, long maturation time, 3-5% higher feed conversion rate, advanced steam injection device to effectively prevent steam back-spray.

- Stainless steel door cover, strong anti-corrosion ability, long service life, the box body is processed by machining center, high precision, large oil storage, low noise.

- Advanced and reliable overload protection device, clamp-type rapid ring die disassembly, main bearings and standard parts are imported, and the movable pneumatic oil pump is convenient and timely.

- The main shaft is processed by German deep hole gun drilling, which is in place at one time and refueling is smooth.

- The transmission parts of the whole ring die feed pellet machine (including the motor) are selected from Switzerland and Japan High-quality bearings, internationally advanced power transmission couplings, internationally advanced steam regulating valve system, machining center processing box, German deep hole drilling processing spindle oil hole, gears are processed by precision grinding, low noise, and the output is about 20% higher than that of belt transmission.

- It adopts quick-release clamp type high-end ring die, internal design, manufacturing quality has reached the international leading level, and the model is leading in the industry.

- Customizable double-layer and three-layer conditioner ring die feed pellet machines to produce high-quality livestock and poultry aquatic feed.

At RICHI Machinery, our dedication to serving the animal feed industry isn’t just about producing machinery; it’s about providing the tools that enable you to meet the ever-evolving demands of your customers.

RICHI Machinery offers industry-leading animal feed production line solutions, from the ring die feed pellet machine to the top-tier hammermill, tailored to meet your needs.

Structure of SZLH858 ring die feed pellet machine

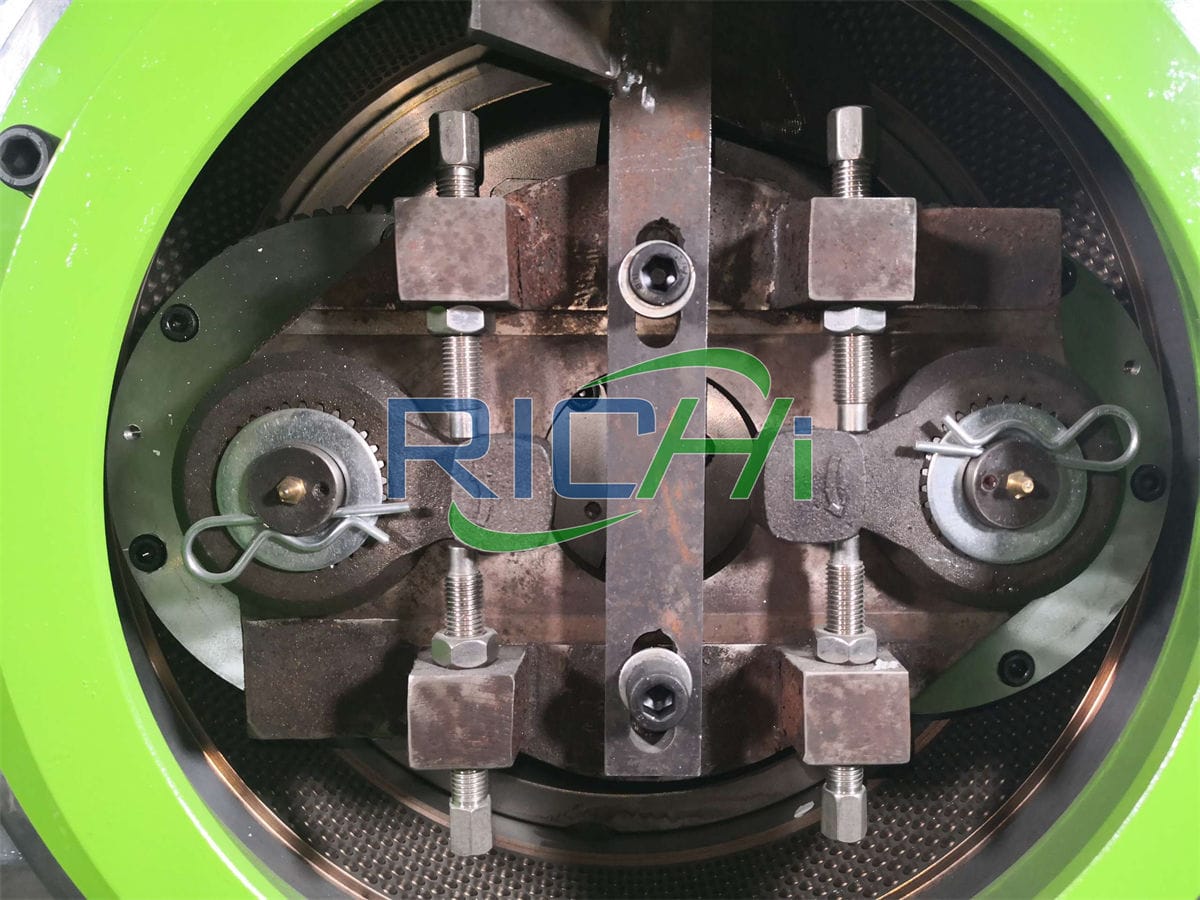

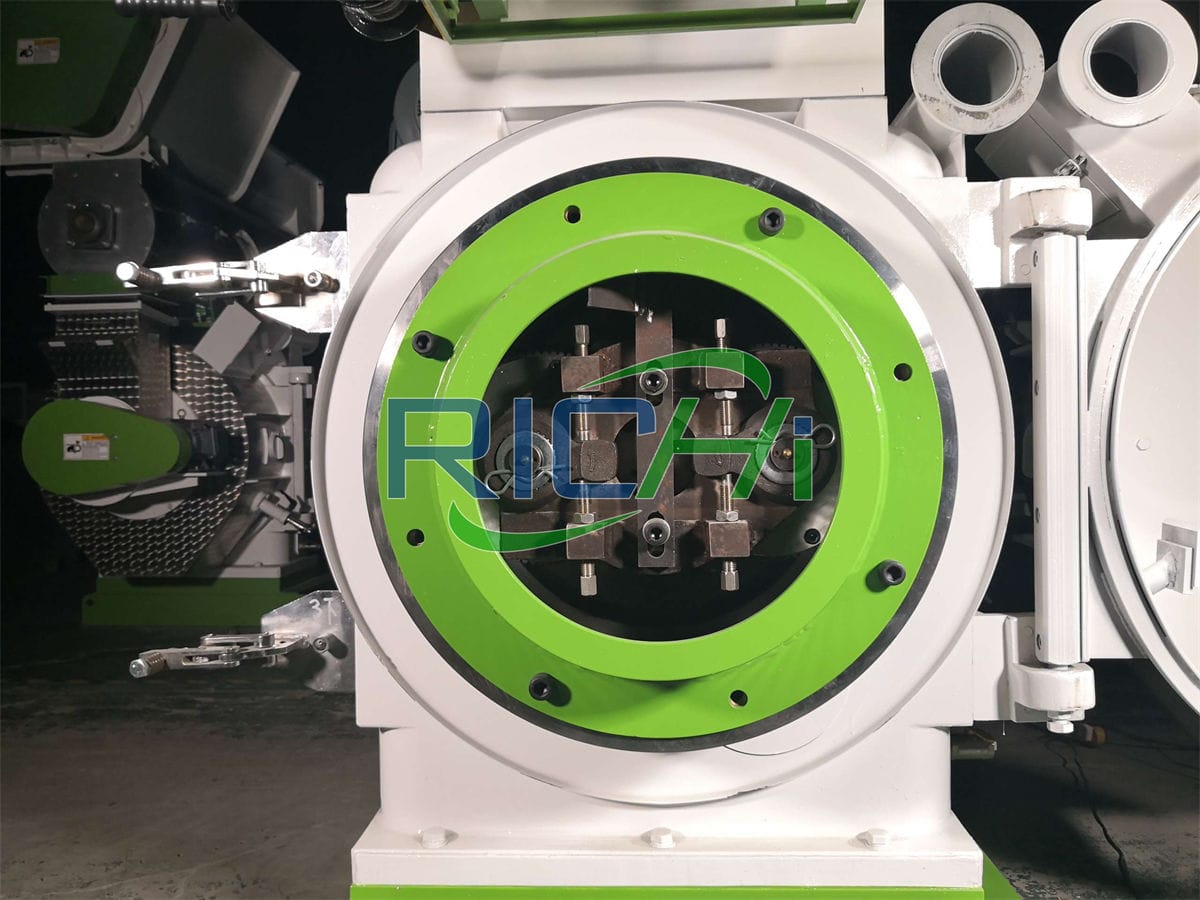

The SZLH858 ring die feed pelletizer is mainly composed of ring die and supporting parts, pressure roller and supporting parts, and transmission mechanism. Among them:

- The ring die and supporting parts are mainly composed of the ring die, the ring die mounting plate, the granulator door cover, the granulator housing, etc.;

- The pressure roller and supporting parts are mainly composed of the pressure roller, the pressure roller shaft, the mounting sleeve, the locking nut, etc.;

- The transmission mechanism is composed of the motor, the reducer, the bearing, the granulator main shaft, etc.

Working principle of SZLH858 ring die feed pellet machine

The inverter drives the motor, and transmits power to the ring die feed pellet machine main shaft through the transmission wheel and the transmission belt.

When the ring die type feed pellet machine has excessive torque on the main shaft due to blockage or other reasons, the main shaft will slip with friction with the transmission belt, thereby avoiding damage to the motor due to excessive torque.

- The main shaft of the ring die feed pellet machine is fixedly connected to the ring die mounting plate, and the ring die and the ring die sealing ring are fixedly connected to the ring die mounting plate through special nuts;

- The main shaft of the ring die pellet machine drives the ring die mounting plate, the ring die, and the ring die seal to rotate together;

- The loose feed raw materials after conditioning enter the gap between the ring die and the pressure roller, and under the extrusion of the ring die and the pressure roller, they are extruded through the ring die hole and cut into pellet feed of a certain length by the cutter located on the outer edge of the ring die.

The scraper is installed on the door cover of the pellet mill for animal feed. When the material enters the ring die feed pellet machine, the scraper plays the role of pushing the material and evenly distributing the material.

Specifications of SZLH858 ring die feed pellet machine

| model | SLZH858 |

| Output (t/h) | 28~45 |

| Main motor power (kw) | 315/355 |

| Main motor series | 4P |

| Feeder power (kw) | 2.2 |

| Conditioner power (kw) | 15 |

| Ring die diameter (mm) | 858 |

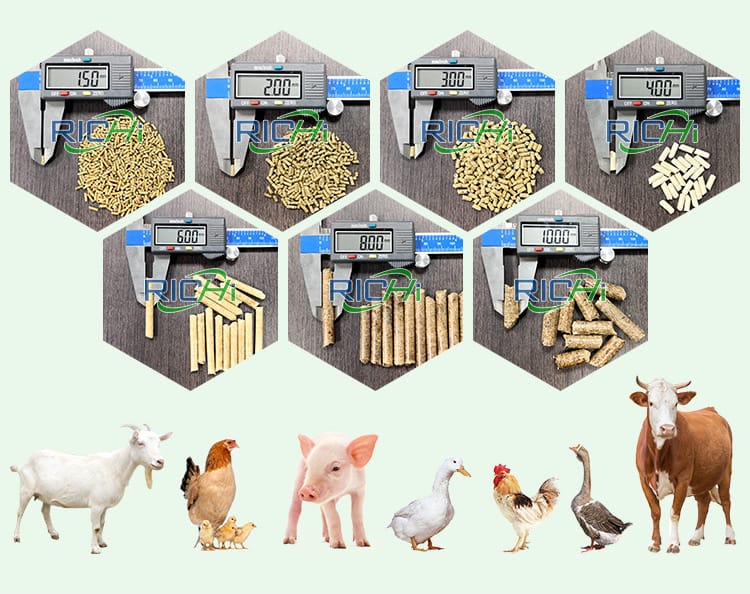

| Finished pellet diameter (mm) | 2~12 |

Configuration of SZLH858 ring die feed pellet machine

- Ring die material: stainless steel

- Door cover of granulation room: 6mm /SUS304

- Feed chute: 3mm /SUS304

- Gear box: HT250

- Gear: 42CrMo

- Gear shaft: 20CrMnTi

- Spindle: 42CrMo

- Empty shaft: 42CrMo

- Bearing: Import

- Oil seal: Germany/Taiwan

- Overload mechanical protection: safety pin

- Serpentine spring coupling drive

- Using Siemens Motor

Operation requirements of SZLH858 ring die feed pellet machine

| Animal feed types | Requirements Before Entering Granulator(mm) | Pellet Diameter(mm) | Pellet Length(mm) | Ring Die Compression Ratio | Conditoning Temperature(℃) | Conditoning Time(s) | Equipped Conditioner |

| Poultry chicken | 2.0-3.0 | 2-4 | 4-8 | 1:10—-1:13 | 150 | 60-120 | one layer/two-layer |

| Cattle | 3-5mm | 6-12 | 12-18 | 1:6:1:9 | 150 | 30-60 | one layer/two-layer |

| pig | 2-3 | 2-4 | 3-8 | 1:3.5—-1:5 | 150 | 60-120 | One layer/two layer |

| fish | 1.0-2.0 | 2-6 | 4-12 | 1:16—-1:18 | 150 | 90-180 | Two layer/three layer |

| shrimp | 95%≥80 mesh | 1.2-2.0 | 1.8-4 | 1:20—-1:25 | 150 | 120-180 | three layer |

| … | |||||||

ring die feed pellet machine projects

ring die feed pellet machine in Russia

- ring die pellet machine selection: SZLH858

- Feed Size:1-5mm pellets

- project cost: 650,600 USD

ring die pellet press in Thailand

- ring die pellet machine selection: SZLH858

- Feed Size: 2-4mm pellets

- project cost: 850,300USD

ring die feed granulator machine in Indonesia

- ring die pellet machine selection: SZLH858

- Feed Size: 2-6mm pellets

- project cost: 920,000 USD

ring die feed pelletizing machine in Vietnam

- ring die pellet machine selection: SZLH858

- Feed Size: 3-8mm pellets

- project cost: 540,900USD

ring die feed pelleting machine in India

- ring die pellet machine selection: SZLH858

- Feed Size: 2-8mm pellets

- project cost: 1,484,500 USD

ring die Food pellet machine in Kyrgyzstan

- ring die pellet machine selection: SZLH858

- Feed Size: 1.5-6mm pellets

- project cost: 1,131,800 USD

ring die feed pellet mill in Uzbekistan

- ring die pellet machine selection: SZLH858

- Feed Size: 2-3mm pellets

- project cost: 1,159,000 USD

ring die feed pelletizer machine in Iran

- ring die pellet machine selection: SZLH858

- Feed Size: 2-10mm pellets

- project cost: 1,050,000 USD

Application of SZLH858 ring die feed pellet machine

SZLH858 ring die feed pellet mill is mainly used for feed production lines above 28 tons, used for pelleting animal feed for optimal nutrional feed and high feed conversion.

An animal feed mill plant consists of several steps, where a ring die feed pelleting machine is the main machine. At RICHI we provide complete pelleting solutions with high quality feed mill pellet machines and equipment such as crumblers, sifters, and coolers. A pelleting line in connection with the SZLH858 ring die feed pellet machine provides many advantages.

Tell us your raw material, requirements of capacity and budget for the animal feed processing plant. Then RICHI can design a suitable and specific solution for you.

To ensure the success of your business, we will provide detailed solutions including material storage, pretreatment, crushing … pelleting, cooling, packaging and waste disposal.

We supply turnkey solutions of feed production, from project design, process engineering to procurement local manufacturing, installation and debugging, after sales service, and financing (price & cost control).

We study every details of the pelleting solution, so that to ensure you get the best feed mill equipment, best service and best plan.

If you want to obtain a solution for a feed pellet production line of more than 28 tons, click the button below to obtain a detailed solution design, equipment configuration list and production line quotation.

Video of ring die feed pellet machine

FAQs of ring die feed pellet machine

How much does a SZLH858 ring die feed pellet machine cost?

The price of a SZLH858 pellet mill is generally between FOB 80,000-100,000 USD.

The price of a SZLH858 feed pellet mill is not static. It is affected by many factors, such as configuration, manufacturer, competitiveness, etc. Different influencing factors will result in a very different market quotation for the equipment.

- Configuration factors:

Since the specific conditions of each manufacturer are different, the SZLH858 ring die feed pellet machines they configure are also different.

Generally speaking, the larger the model and capacity of the equipment configured by the user, the higher the market price of the equipment will be, and the smaller the model and capacity of the equipment configured, the lower the market price will be. - Equipment manufacturer factors:

Different ring die feed pellet mill machine manufacturers have different strengths, scales, production experience, and production materials.

Therefore, the cost of their production equipment is also different, which affects the quotation of the equipment. If the manufacturing cost of the equipment is high, the price will be high; if the pelleting cost is low, the price will be relatively low. - Competitiveness factor:

The current economic downturn has led to great competition in all industries, and the same is true for feed pellet mill manufacturers. The greater the competition, the lower the price of the equipment produced will be, and if the competition is not great, the price of the SZLH858 ring die feed pelletizer machine will be relatively high. - Material used:

The material also has a certain impact on the price of the feed pellet mill. The quality of the material directly affects the performance of the feed pellet mill and the quality of the feed pellets.

If the equipment material is good, the SZLH858 ring die pellet machine produced will have high quality, good performance, and long service life, and of course the price will be high. Therefore, the different materials used in the feed pellet mill will also have a certain impact on its price. - Market demand:

When the market has high requirements for feed pellet mills, but there are few such equipment on the market, the price of the feed pellet mill will be relatively high. On the contrary, if the market demand is not great, but there are more equipment circulating in the market, the price of the SZLH858 ring die feed pellet machine will be lower.

How to choose a ring die feed pellet machine?

1. Product specifications

When purchasing a ring die feed pellets machine, the first thing you need to consider is the products you produce, such as product specifications, size, weight, material, etc. Different equipment has different performance and functions for products of different specifications, so you need to choose the right equipment according to your product needs.

2. Production efficiency

In addition to product specifications, production efficiency is also a key factor to consider when purchasing a feed pellet mill. Production efficiency is related to the speed and accuracy of the machine, so when purchasing factory equipment, you need to consider whether its production efficiency can meet your own needs.

3. Energy consumption and maintenance

The energy consumption and maintenance of the equipment are also key factors to consider when purchasing a ring die feeds pellet machine. For equipment that is used for a long time, energy consumption costs are also an issue that cannot be ignored.

Therefore, it is necessary to understand the energy consumption and electricity expenses of the equipment, and consider which type of ring die feed pelletizing machine to purchase based on the situation of your own feed mill factory.

At the same time, it is also necessary to consider the maintenance cost of the feed mill equipment, and it is necessary to understand the warranty and after-sales service of the equipment when purchasing.

4. Safety

When purchasing a ring die feed pellet machine, the safety of the equipment is also a key point to consider. Whether the safety of the staff can be ensured during production and whether there are safety measures such as overload protection are one of the key factors to consider.

Therefore, before purchasing the equipment, you need to understand the safety performance and safety measures of the equipment.

5. Cost

Finally, cost is also one of the key factors when purchasing a feed pelletizer. In addition to the purchase price of the equipment, you also need to consider the subsequent maintenance costs, consumables costs, etc., to determine whether it is suitable for your production situation.

At the same time, you also need to understand important parameters such as the service life of the equipment to better evaluate its cost performance.

In summary, there are many factors to consider when purchasing a ring die feed pellet machine. Sometimes price is not the only determining factor, but you should choose the animal feed mill equipment that suits you according to your own production needs.

How to choose a ring die feed pellet machine manufacturer?

The following aspects need to be considered when choosing a suitable ring die feed pelletizer manufacturer:

- The reputation and reputation of the manufacturer: Understand the manufacturer’s history, scale, production capacity and market reputation. You can learn about it through online searches, consulting industry insiders or visiting the manufacturer.

- Equipment quality and performance: The quality and performance of the ring die feed pellet machine are important factors in choosing a manufacturer. You can evaluate the quality and performance of the equipment by checking the technical parameters of the equipment and understanding the production process and materials of the equipment.

- After-sales service: Choosing a manufacturer with good after-sales service can ensure the maintenance and upkeep of the equipment during use. You can learn about the manufacturer’s after-sales service policy, service network, and repair response time.

- Price: Price is also an important factor in choosing a ring die feed pellet making machine manufacturer. You need to compare the prices of different manufacturers and make a decision by comprehensively considering factors such as the quality, performance, and after-sales service of the equipment.

- On-site inspection: It is best to visit the manufacturer to understand the manufacturer’s production environment, the actual operation of the equipment, and the manufacturer’s technical strength.

Comprehensive consideration of the above factors can help you choose a suitable ring die feed pellet machine manufacturer. At the same time, you also need to make a decision based on your actual needs and budget. (Find RICHI on youtube)