How Much is The 1-40T/H Animal Feed Manufacturing Plant?

1-40T/H animal feed manufacturing plant cost is between 10000-850000USD.

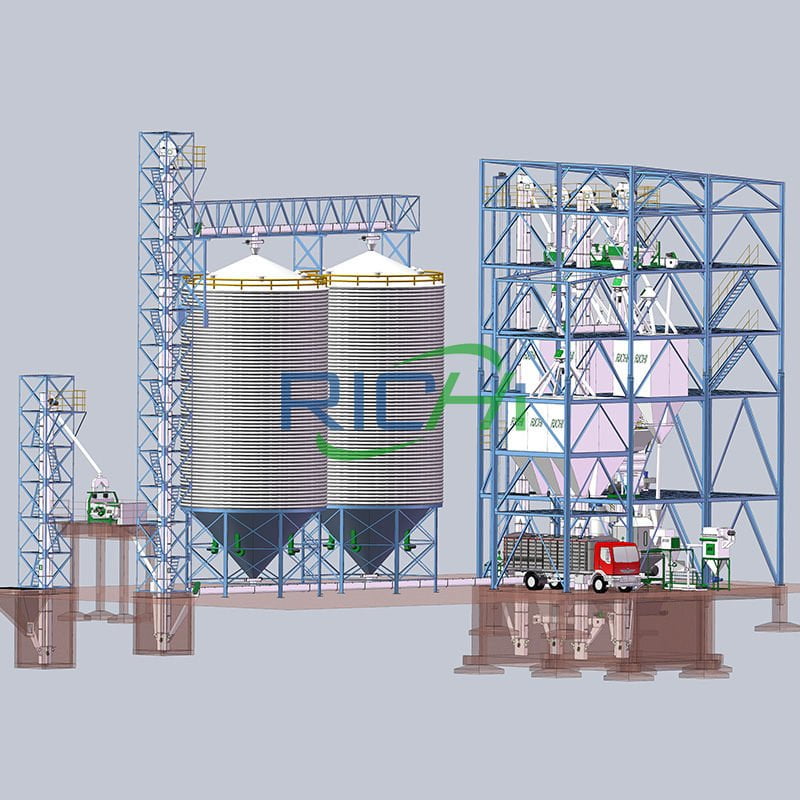

The animal feed plant designed by Richi Machinery is mainly used for the production of pellet feed, powder feed and premix for poultry (chicken, duck, goose), livestock (cattle, sheep, pig, rabbit, camel).

The animal feed plant cost given above mainly refers to the price of a complete set of feed mill equipment, these main equipment include feed grinders, mixers, feed pellet machines, feed extruders, sprayers, feed dryers, coolers, screening machines, packing scales wait. In addition to equipment prices, building a production line requires some other investment. Read on, and RICHI will share it with you.

Types of animal feed manufacturing plant

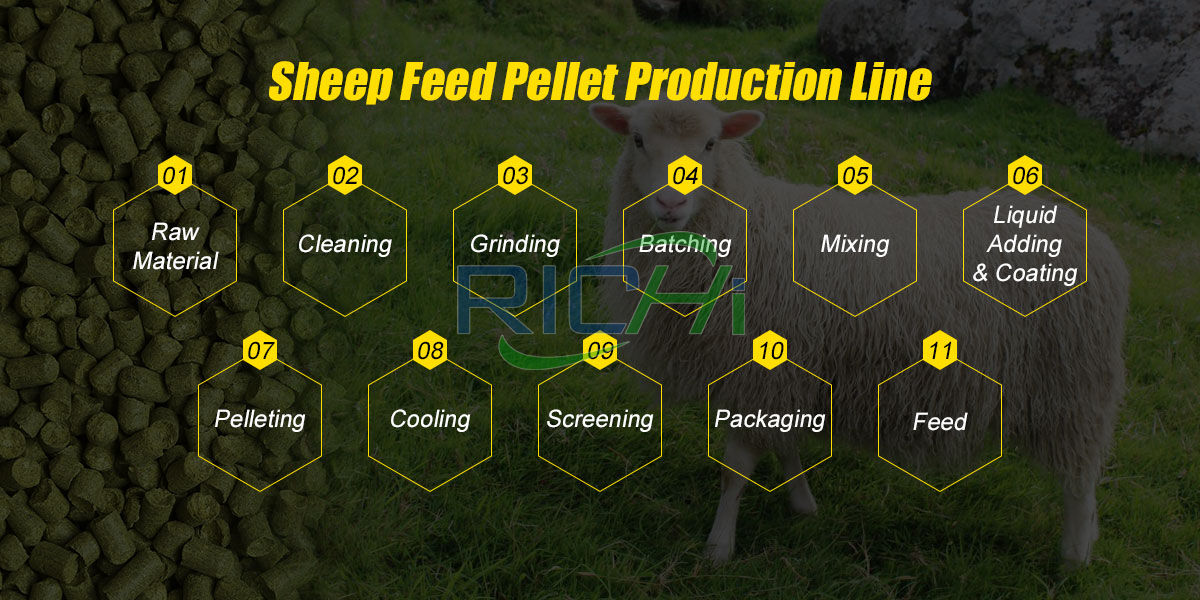

Our customized lines are suitable for processing one or more types of feed.

- fully automatic cattle feed plant

- poultry feed plant for sale

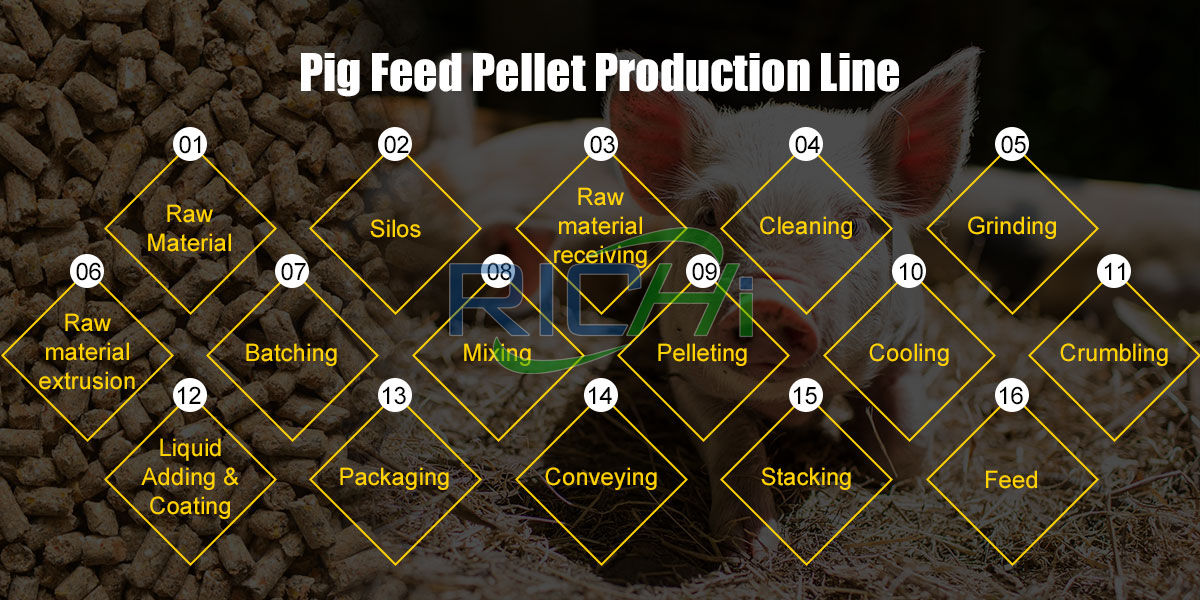

- Pig feed mill

- premix feed mill

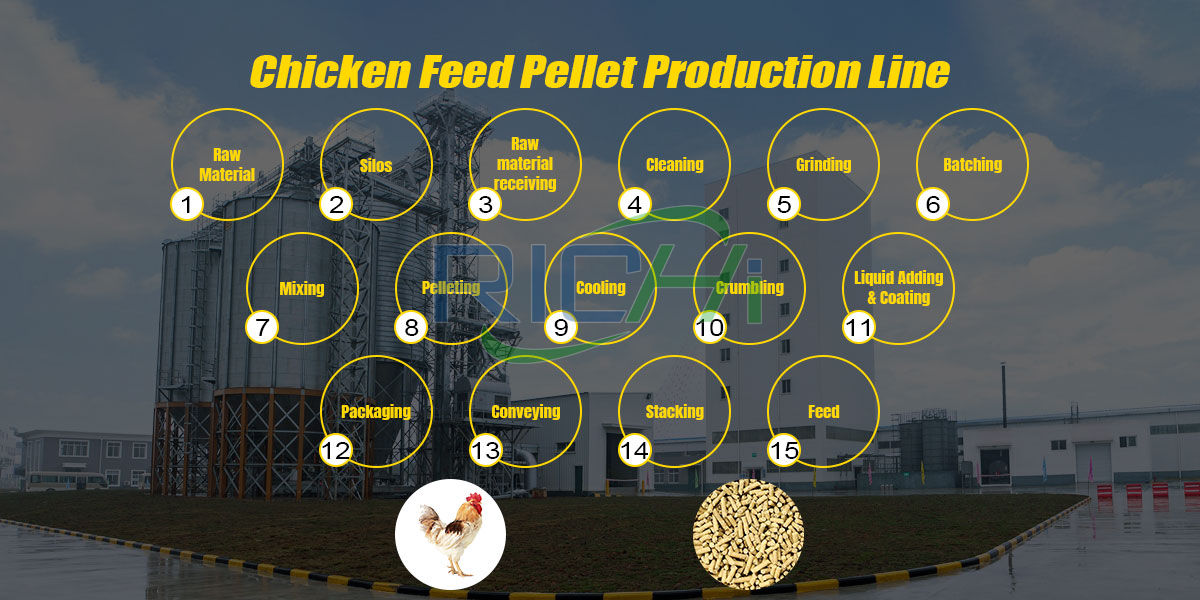

- chicken feed manufacturing plant

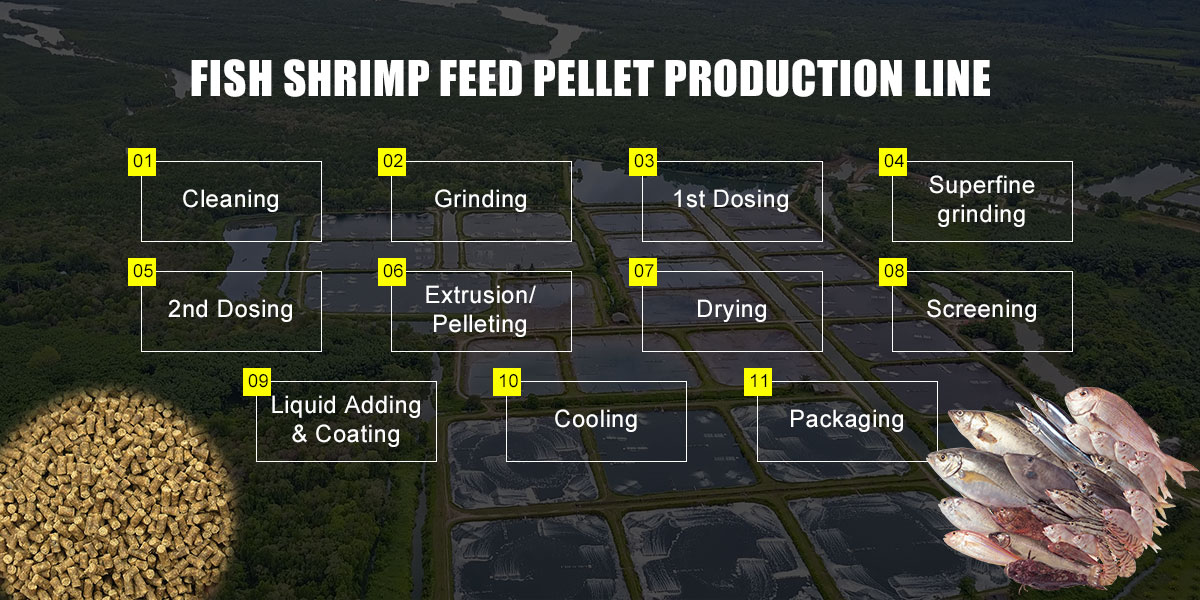

- fish feed manufacturing plant

- Rabbit feed manufacturing plant

- Horse feed manufacturing plant

- Mash feed manufacturing plant

- …

Composition of animal feed manufacturing plant cost

01 Plant construction and electricity costs

The construction of a feed processing plant needs to meet the basic requirements of feed processing equipment for raw material workshops, processing workshops, finished product workshops, and power load verification to see if they can work normally.

The power investment of the animal feed manufacturing plant is determined according to the local consumption level.

02 Raw material cost

Raw material reserves should not be incomplete. It needs to be based on the production capacity of the equipment to ensure daily processing without excessive storage. Raw material investment should be based on local consumption levels.

03 animal feed manufacturing plant equipment price

As mentioned at the beginning, the 1-40 t/h animal feed manufacturing plant cost is 10,000-850,000 USD.

According to customer budget, formula, production scale, and customer needs, we can customize simplified animal feed plants, low-profile feed production lines, standard animal feed mill plant, high-profile feed production lines, fully automatic feed plants, semi-automatic feed production lines, PLC feed production lines, manual feed production lines, etc.

These feed production plants usually require equipment such as pulverizers, feed mixers, feed granulators, coolers, screeners, bucket elevators, screw conveyors, packing scales, and silos.

04 animal feed manufacturing plant certificate fee

- EIA procedures

- Feed Production License

- business license

- Tax registration certificate

- health permit

- employee health certificate

- Other documents required by local authorities

Depending on the size of the specific animal feed manufacturing plant, the procedures required at different stages are gradually increasing, and the costs are different in different countries and regions. But this cost is not high.

(Due to the differences in civil construction costs and labor costs in each country and region, the animal feed manufacturing plant cost given by RICHI refers to the price of a complete set of feed making equipment.)

different animal feed manufacturing plant cost with Different Capacity

For different production capacity, the price of animal feed manufacturing plant is of course different, which should not be reflected in the animal feed mill equipment configuration.

Compared with the animal feed plant with small output, the feed plant with large output needs to be equipped with stand-alone equipment with larger output and more quantity. The following RICHI will show you the animal feed manufacturing plant price list.

small scale feed mill

- Hourly capacity:1-2 t/h

- animal feed manufacturing plant cost: 10000-50000 USD

animal feed production plant

- Hourly capacity:3-4 t/h

- animal feed manufacturing plant cost: 50000-120000 USD

animal feed pellet plant

- Hourly capacity:5-7 t/h

- animal feed manufacturing plant cost: 70000-250000 USD

animal feed processing plant

- Hourly capacity:8-10 t/h

- animal feed plant cost: 150000-300000 USD

feed preparation plant

- Hourly capacity:12-20 t/h

- animal feed plant cost: 250000-580000 USD

feed pellet production line

- Hourly capacity:25-40 t/h

- animal feed plant cost: 450000-850000 USD

Do you want more details of cattle feed manufacturing plant cost, poultry feed manufacturing plant cost, fish feed mill plant cost? If you also want to build 1-40t/h animal feed manufacturing plant, please feel free to consult Richi Machinery!

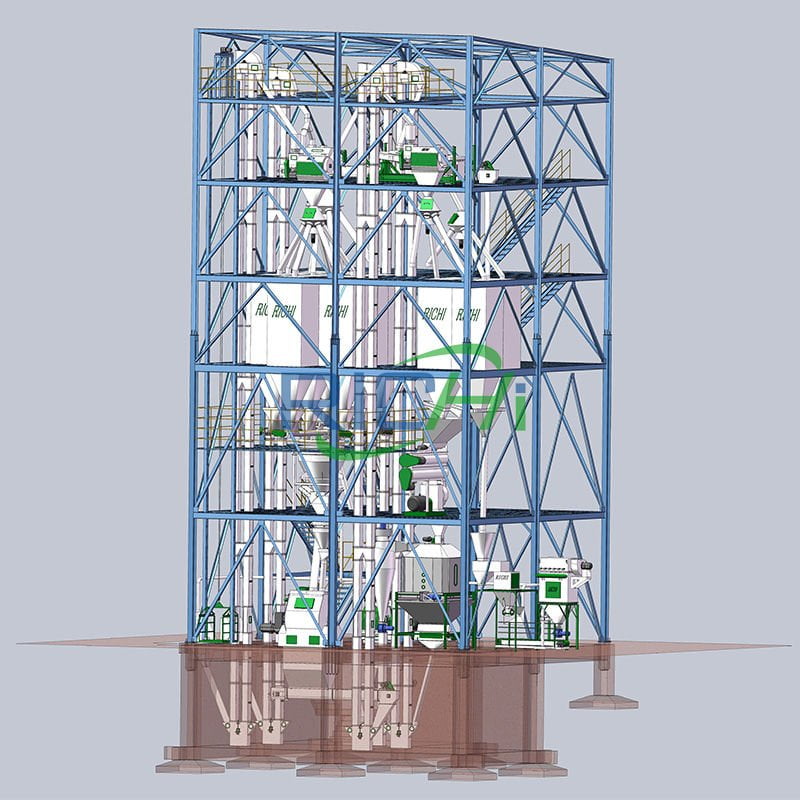

different design, different animal feed manufacturing plant cost

Some customers want to process chicken feed, and some customers want to process cattle feed; some customers’ formulas are all grains, and some customers’ formulas contain 100% grass powder; some customers have very small plant space, and engineers constantly adjust the plan and plant layout to make full use of the plant space; some customer plant height limit, our engineers must adjust the transportation plan in the process, and constantly optimize the entire feed system. design. . .

For different types of feed processing, for different animal feed manufacturing plant conditions, and for different feed ingredients and feed formulations, we provide customized feed process design for global customers.

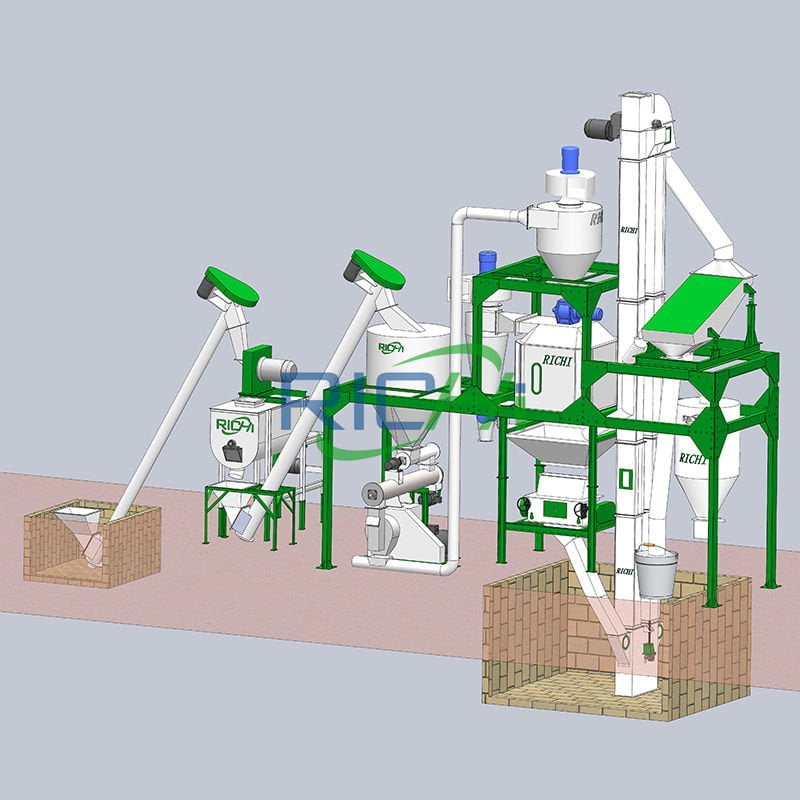

Below RICHI takes 10 tons animal feed manufacturing plant as an example to show you what is called “same capacity, different design”.

10T/H feed plant design plan 1

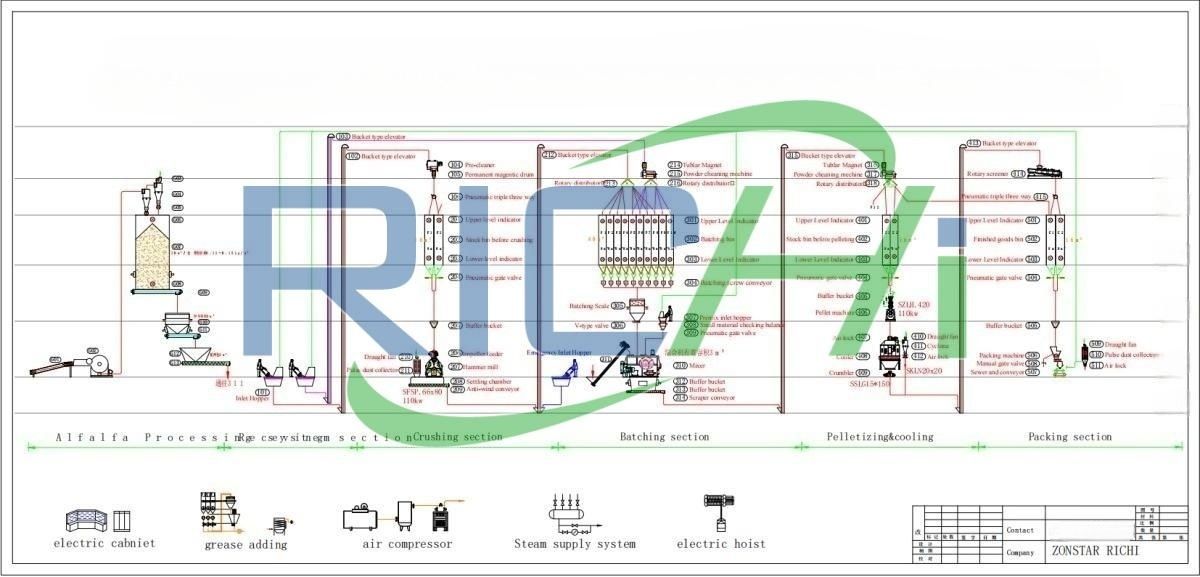

This is a very complex livestock and poultry animal feed manufacturing , which can also be called 10T/H Pellet feed & 15T/H mash feed composite production line. The 10t/h pellet system of this solution is used to process 6t/h (30%)straw alfalfa pellet feed & 4t/h (70%) straw 4t/h pellet feed.

Animal feed manufacturing plant cost: 380,000-420,000 USD

The feed production process design:: Alfalfa/Straw Processing system——Materials receiving& pre-cleaning system——Crushing system——Batching& mixing system——Pelletizing& cooling& screening system——Packing& dust collecting system. This production line also includes Oil adding system, MCC Control Center; Mimic Control Panel, Batching System (Computer controlled).

Main equipment configuration: Belt conveyor*TDSJ120*600, Straw/Alfalfa/plant crusher*9FQ56-120, U-Type screw conveyor*TLSU32, Drum type precleaner*SCY63, Hammer mill*SFSP66*80, Rotary distributor*TFPX6, Batching scale *PLC1.5A, 2-Layer Conditioner Cattle Poultry Feed Pellet Making Machine*SZLH420, Cooling Machine*SKLN20x20, Rotary screener*SFJH125*2C, Automatic Packing machine*DCS-50, etc.

This animal feed manufacturing plant can be used to process the following types of feed:

| Kinds of feed | Size of feed | Capacity |

| Chicks in 0-10 days | 1.0-1.5mm | 5-6T/H |

| Chicken in 10-30 days | 2.5-3.0mm | 8-10T/H |

| Chicken in 30-45 days | 3.5-4.0mm | 10-12T/H |

| Layer, Also can feed chicks | Powder feeds | 15-16T/H |

| Cattle/Goat(Without grass in recipe) | 6.0-12.0mm | 10-12T/H |

| Cattle/Goat(30% grass in recipe) | 6.0-12.0mm | 6-7T/H |

| Cattle/Goat(50% grass in recipe) | 6.0-12.0mm | 4-5T/H |

| Cattle/Goat(70% grass in recipe ) | 6.0-12.0mm | 3-3.5T/H |

| Cattle/Goat(100% grass in recipe ) | 6.0-12.0mm | 2-2.5T/H |

| Sinking fish feed | 1.5-12.0mm | 5-6T/H |

| Shrimp/lobster feed | 1.5-12.0mm | 4-6T/H |

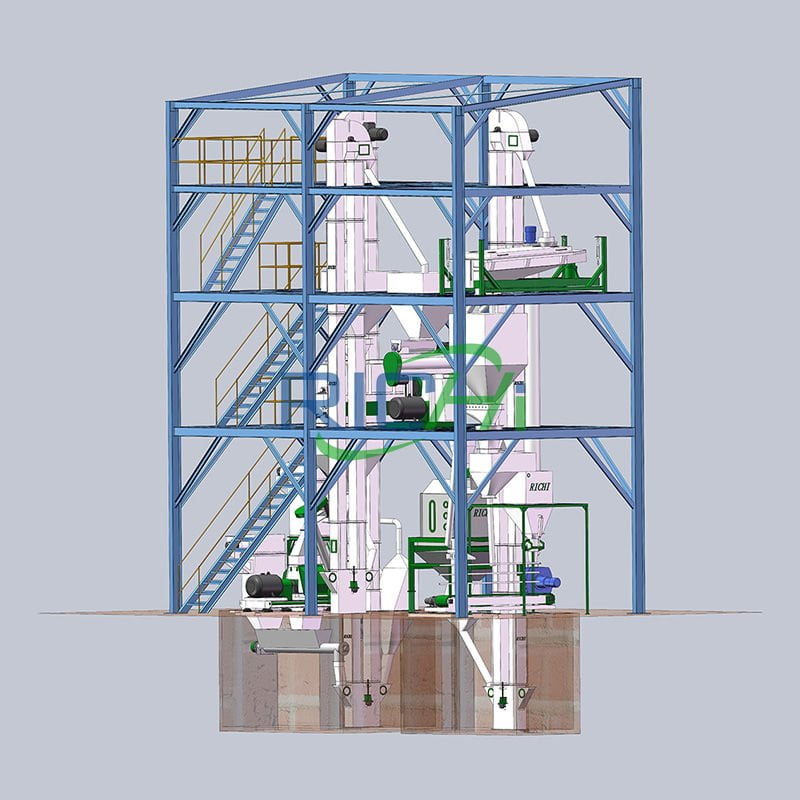

10T/H Feed Plant Design Plan 2

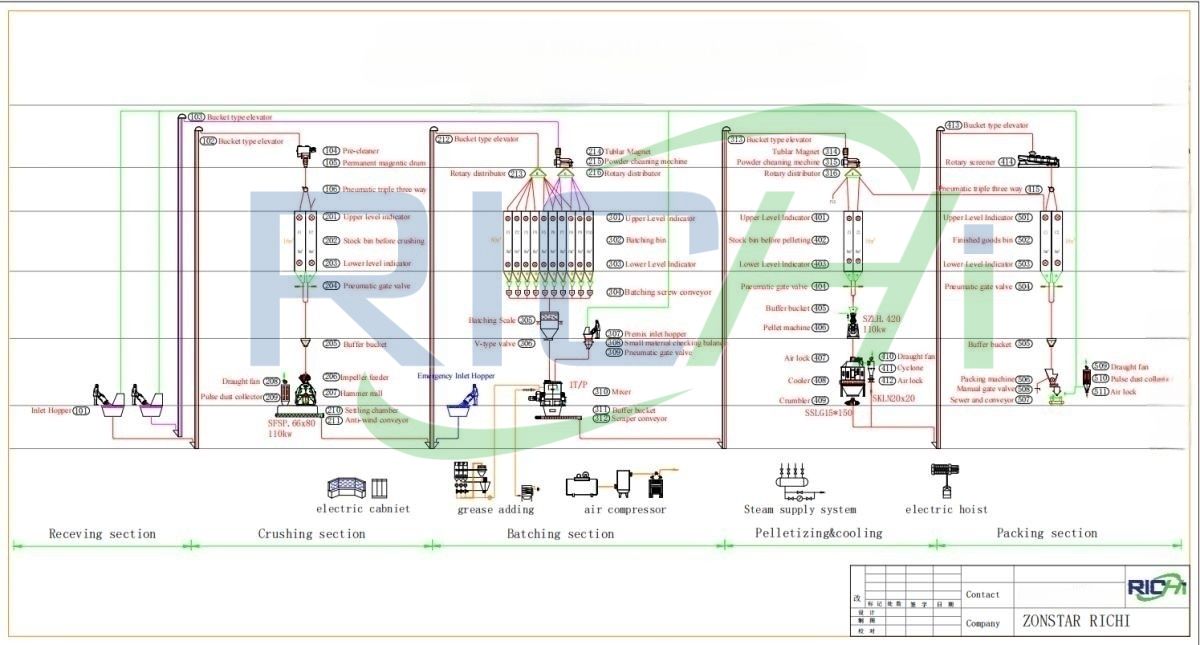

This is 10t/h animal feed manufacturing plant including computer ingredients, with a very high degree of automation. This animal feed plant is designed for the customer’s formula and is not suitable for grass-containing feed processing. And this feed manufacturing plant only produces pellet feed. After comparing the two schemes, it can be seen that the design of the grass-containing animal feed pellet manufacturing plant is more complicated and requires more equipment.

Animal feed manufacturing plant cost: 250,000-320,000 USD

Process design: Materials receiving& pre-cleaning system——Crushing system——Batching& mixing system——Pelletizing & cooling& screening system——Packing& dust collecting system. In addition, this production line also includes Oil adding system, MCC Control Center ; Mimic Control Panel, Batching System (Computer controlled), Cables & Cable Bridge Tube.

Main equipment configuration: Drum type precleaner*SCY63, Hammer mill*SFSP66*80, Rotary distributor*TFPX8, Powder precleaner*SCQZ60 *50*100, Batching scale*PLC1.0A, Single-shaft mixer*SLHJ2A, Permanent magnetic sleeve*TCXT20, 1-Layer Conditioner Cattle Chicken Feed Pellet Machine*SZLH420, Cooling Machine*SKLN20x20, Crumbler*SSLG15*150, Rotary Screener*SF JH125* 2C, Automatic Packing Machine*DCS-50, etc.

This 10t/h animal feed manufacturing plant can be used to process the following types of feed:

| Kinds of feed | Size of feed | Capacity |

| Chicks in 0-10 days | 1.0-1.5mm | 5-6T/H |

| Chicken in 10-30 days | 2.5-3.0mm | 8-10T/H |

| Chicken in 30-45 days | 3.5-4.0mm | 10-12T/H |

| Layers, Also can feed chicks | Powder feeds | 12-15T/H |

| Cattle/Goat (Without grass in recipe) | 6.0-8.0mm | 10-12T/H |

| Cattle/Goat(With grass in recipe) | 6.0-8.0mm | X |

| Sinking fish feed (Add a conditioner) | 1.5-3.0mm | 5-6T/H |

With only 10 tons per hour animal feed manufacturing plant, we can design hundreds of solutions for customers. And what we can provide is 1-160 tons of feed plant design and production equipment processing. If you are interested in building an feed plant, please contact us for an animal feed manufacturing plant cost!

different animal feed manufacturing plant cost in Different project

6-10T/H poultry animal feed plant in Algeria

- animal feed manufacturing plant cost:80,000-400,000 USD

- Date: Sep 31th, 2015

10-15T/H chicken animal feed plant in Uzbekistan

- animal feed manufacturing plant cost: 150,000-400,000 USD

- Date: July 1th, 2019

5T/H animal feed plant for poultry chicken In Peru

- animal feed manufacturing plant cost: 220,000-250,000 USD

- Date: February 2021

3-5T/H broiler feed plant In Malaysia

- animal feed manufacturing plant cost: 60,000-65,000 USD

- Date: October 29, 2021

1-2T/H poultry livestock feed plant in Nigeria

- poultry feed manufacturing plant cost: 25,000-29,000 USD

- Date: June 30, 2020

16T/H stock poultry Feed Plant

- animal feed manufacturing plant cost: 500,000 USD

- Date: December 2020

5-7 t/h poultry cattle feed plant in Russia

- animal feed manufacturing plant cost: 97160 USD

- date: 2022.06.09

10T/H Livestock cattle Pellet Plant in Uzbekistan

- animal feed plant cost: 460,000 USD

- Project date: 2018.09.13

5 T/H animal feed plant for premix In El Salvador

- animal feed plant cost: 480,000 USD

- date: 2022. 09.13

10 t/h poultry animal feed plant for premix in Thailand

- animal feed plant project cost: 120,000 USD

- date: 2021. 07. 22

30-40T/H animal Feed Plant for poultry in China

- animal feed manufacturing plant cost: 960,000USD

- Date: June 2019

35-40T/H animal Feed Plant in China

- animal feed manufacturing plant cost: 1,250,000 USD

- Date: December 2018

5 t/h cow goat feed plant in Argentina

- animal feed plant project cost: 184500USD

- Project date: 2021.10.11

5-10 t/h fish poultry animal feed plant in New Zealand

- animal feed manufacturing plant cost: 131820 USD

- Project date: 2022.10.14

15 t/h animal feed manufacturing plant in Uganda

- animal feed manufacturing plant cost: 159070 USD

- Project date: 2022.06.30

20T/H Ruminant animal feed plant in USA

- animal feed manufacturing plant cost: 550000USD

- Project date: 2019.05.10

How to build an animal feed manufacturing plant?

01 Determine the production scale of the animal feed manufacturing plant

- Based on the feed pelleting system: Example: 10 tons/hour pellet mill, means the output of animal feed manufacturing plant is 10 ton/hour

- Design: Generally speaking, according to:annual output=8H*300 days (The situation of each project is different. Some projects have to run 20 hours a day, while others only process 5 hours a day. .)

02 Determine the feed processing technology and select related feed making equipment

- The variety, quality, and output requirements of the produced (finished) products;

- Formula for feed processing;

- Production technology and equipment, then the animal feed manufacturing plant cost can be determined;

- The performance and quality of the feed equipment;

- Cleaning and maintenance of feed equipment;

- Production cost and usage cost;

- Standardization, serialization and generalization of parts;

- The construction space of the animal feed plant project;

- Environmental protection, fire protection and other national rigid requirements.

03 Selection of control mode

- Capacity

- Complex or simple feed production process

- How many product varieties

04 Selection of animal feed manufacturing plant structure

- Full concrete structure

- Semi-steel structure

- All steel structure

- Slip mode structure

05 Planning the general layout of the animal feed manufacturing plant area

Considerations

- Logistics distance

- Safety regulations

- Avoid mutual interference

- Factory focus

- Visual effects

The overall layout of the animal feed manufacturing plant varies according to the feed production nature, scale and technological process. usually:

- Buildings should account for 30-35% of the total area of the animal feed manufacturing plant

- Factory roads account for 13% of the total area

- The green area is not less than 10-15% of the whole animal feed plant area

What we can do for you?

The Ability to Produce High Quality, High-Performance Feeds Efficient and Effectively, Comes from the use of Speialized Process Technology is best when it comes from a company with an in-deflection of each step in the process.

Richi manufactures and support all the machine in the animal feed manufacturing plant and partners with each of our customers to design a solution that best matches their specific processing needs. When designing a customer specific plant solution, we always take account of :

Better and more efficient production

Minimizing operation cost

Maximizing energy efficiency

Environmental protection considerations

We work closely with you to keep you one step ahead. Our animal feed plant solutions come in a modular design so you can customize them to match your production process. We also offer services, maintenance, repairs, automation, technology support. These are all designed to deliver high quality products and cost-effective processes. Our animal feed manufacturing plants and equipment also meet the most stringent sanitation standards.

RICHI Machinery adheres to the work style of seeking truth and being pragmatic, serving customers at home and abroad with excellent products and reasonable animal feed manufacturing plant cost, and creating value for customers. If you are interested in our equipment, solution and projects, please do not hesitate to contact us!(Find RICHI on Facebook)