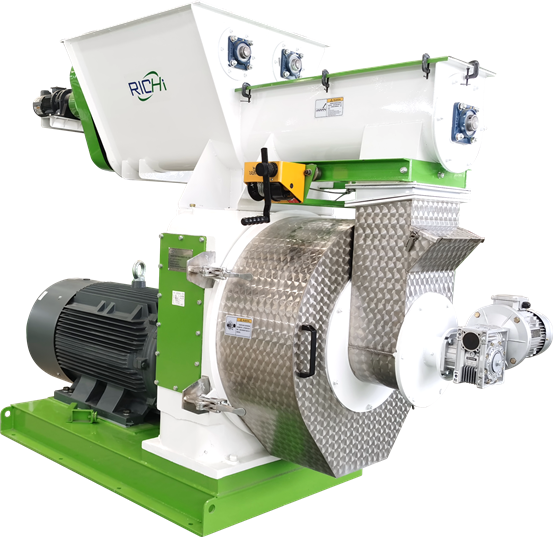

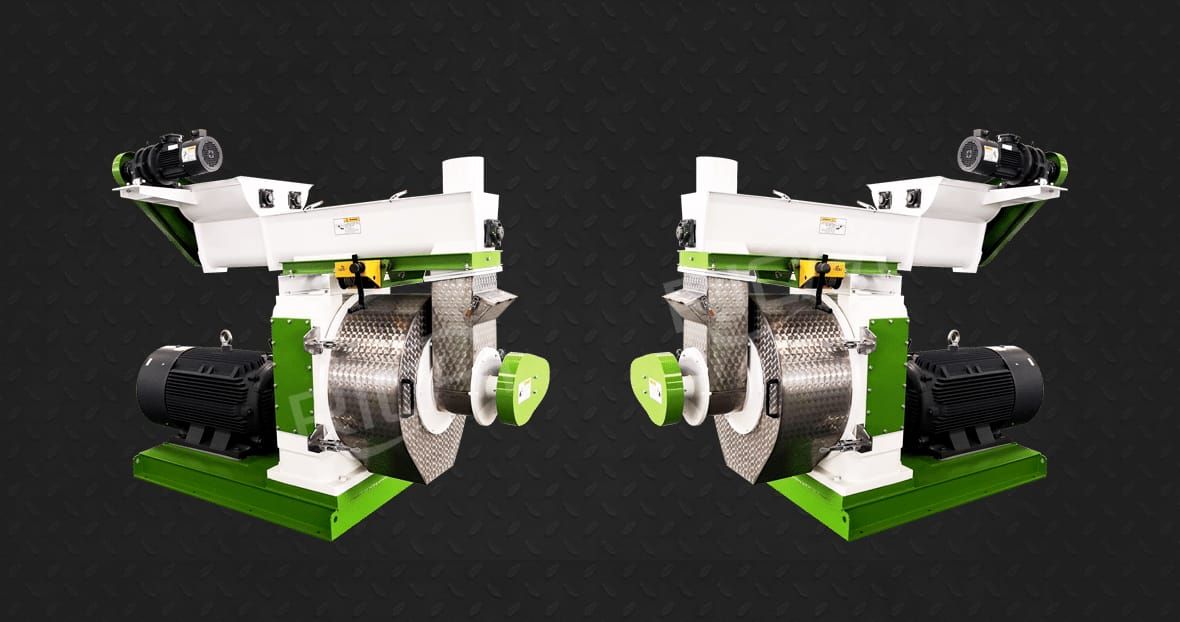

Goat And Sheep Manure Pellet Machine

The goat and sheep manure pellet machine is a device that processes various sheep manure waste into granular organic fertilizer through a granulation process.

- Capacity:1-12T/H

- Price: 10,000-100,000 USD

- Application: Organic fertilizer factory, compound fertilizer factory, chemical fertilizer factory, sheep farm, breeding farm, sugar factory, sewage treatment plant, waste disposal site, food processing plant, slaughterhouse, etc.

what’s goat and sheep manure pellet machine?

The sheep manure organic fertilizer granulator is an equipment that processes organic matter-rich raw materials such as sheep manure and plant straw into pure natural green organic fertilizer through granulation technology. The sheep manure organic fertilizer granulator is mainly suitable for the harmless processing of sheep manure to achieve resource recycling.

Sheep manure organic fertilizer is organic matter that is not completely digested by sheep. It is a new type of organic fertilizer that does not contain any chemical components after special treatment. It is widely used in the geological improvement of sandy land, alkaline land, and barren land, and can quickly improve the ground moisture. , increasing soil permeability, which has a good effect on increasing crop yields.

RICHI has ring die type goat and sheep manure pellet machine for your reference. Whether the large-scale fertilizer production or small-scale production, we can meet your needs. Especially, our goat and sheep manure pelletizers are also applicable for you to make chicken manure, poultry litter and cattle dung fertilizer pellets.

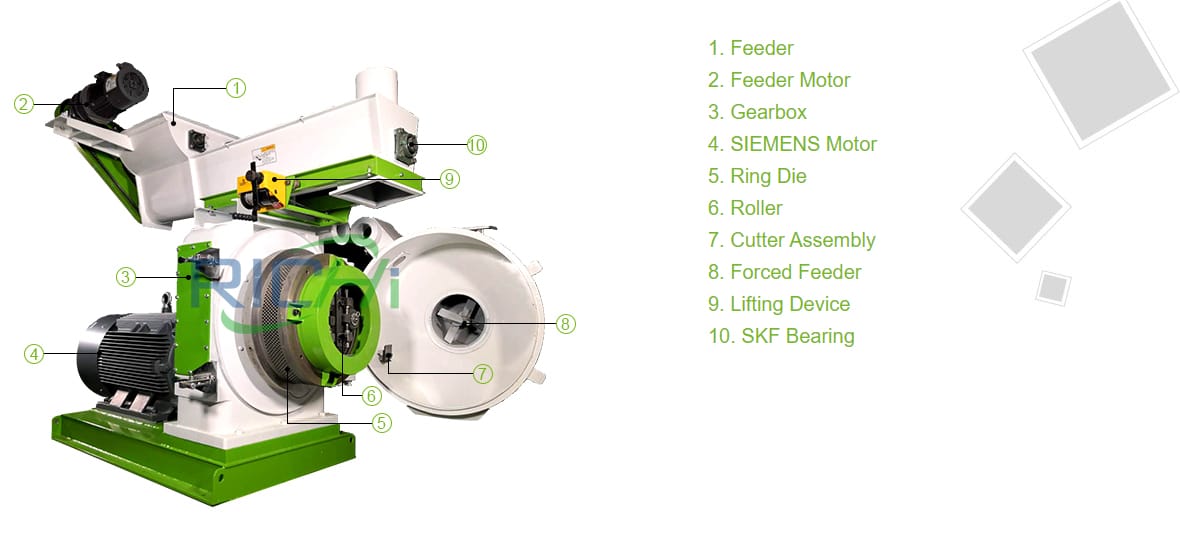

Technical characteristics of goat and sheep manure pellet machine

- The drive part of the machine including motoroptimize the high quality SKF bearings made in Switzerland, which ensure high efficient and steady driving with low noise.

- The ring die in our sheep manure granule machine is made of high-quality stainless steel, which makes it highly durable. It can withstand the pressure and friction generated during the pelletizing process.

- Using rotating rollers and fixed ring dies, this design enables efficient, uniform granulation, resulting in high-quality granules of consistent size and density.

- This model has φ2-φ12mm many kinds of aperture and thickness link model; the user can willfully select according to different need to obtain the best technology and economic efficiency;

- Adopt international advanced pipeline system and inlet pressure regulator.

- The international advanced compensation type flexible coupling is of novel and compact structure, safety, low noise and less trouble.

- Fixed stainless steel pelletizing knife equipment, adjustment is more intuitive; Quick-discharge anchor ear link model, can match coordinated type pressure roller regulating mechanism and link mold hoisting equipment;

- This model sheep manure pellet machine uses a strong gear box transmission system, has ideal transmission efficiency, rotation steady, output high, noise low, no oil leak pollution, maintenance cost low.

RICHI Machinery prepare the teaching videos in terms of installation, operation, parts replacements, repair and maintenance parts. and 7/24 email and phone call service is available.

How does the goat and sheep manure pellet machine work?

When working, the organic fertilizer raw materials are fed into the granulation chamber from the feeder. After the rotation of the pressure wheel, the material is continuously and evenly distributed on the surface of the inner cavity of the mold (the contact surface between the pressure roller and the mold).

The powder is crushed by the pressure roller. The material passes through the hole in the mold.

In this process, the material is subjected to high pressure and high temperature, resulting in physical changes or appropriate chemical changes, causing the powdery material to form an ever-lengthening cylindrical solid body.

The sheep pellets fertilizers are then cut off by a cutting knife and discharged from the discharge port. This is the process of suppressing the sheep pellets fertilizer.

Specifications of goat and sheep manure pellet machine

| Model | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH768 | MZLH858 |

| Output (t/h) | 1-2 | 3-4 | 5-6 | 7-8 | 9-10 | 10-12 |

| Main motor power (kw) | 22 | 37 | 90 | 132 | 250 | 280 |

| Main motor series | 8P | |||||

| Ring die diameter (mm) | 320 | 350 | 420 | 520 | 762 | 858 |

| Finished pellet diameter (mm) | 2-12 | |||||

| goat and sheep manure pellet machine Configuration | Ring die material: 42CrMo Stainless steel feeder: with anti-caking function Door of pelleting room: 6mm /SUS304 Forced feeding: Worm gear reducer Gear box: HT250 Gear: 42CrMo Gear shaft: 42CrMo Spindle: 42CrMo Empty shaft: 42CrMo Bearings: The gear shaft and main shaft bearings are SKF, and the pressure roller bearings are domestic high-quality bearings Oil seal: Germany/Taiwan Overload mechanical protection: safety pin Serpentine spring coupling drive Lubrication system: Configurable automatic oil injection system | |||||

goat and sheep manure pellet machine price

The price of sheep manure granule machine is generally 10,000-100,000 USD. The goat and sheep manure pellet machine cost is determined by the following factors:

- Equipment quality: The price is closely related to its quality. High-quality equipment is usually made with higher-quality raw materials and more advanced production processes, and therefore costs more.

- Specifications and models: Goat and sheep manure pellet machines of different specifications and models have different processing capabilities and application ranges, so the prices will also be different. Generally speaking, larger models of equipment are more expensive.

- Manufacturer: Goat and sheep manure pellet machines produced by different manufacturers also differ in quality, price, etc. Some well-known brand manufacturers pay more attention to details and quality during the production process, so the prices are relatively high.

- Market demand: Market demand is also an important factor affecting the price. If the market demand is high, the equipment price may rise; if the market demand is low, the equipment price may fall.

To sum up, the price of goat and sheep manure organic fertilizer pellet making machine is determined by multiple factors. When purchasing equipment, you need to consider comprehensively based on your own needs and budget, and choose equipment with high cost performance.

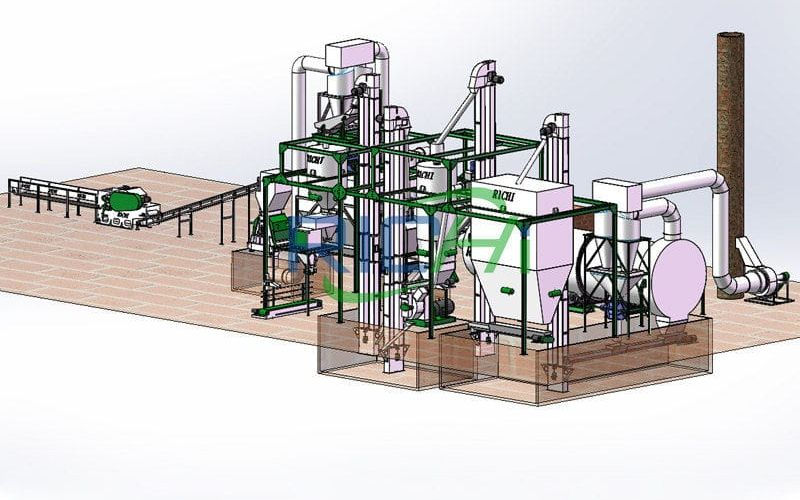

Featured goat and sheep manure pellet machine project

goat and sheep manure pellet machine In Thailand

- Country: Thailand

- Production: 55,000 T/A

- Ingredients: sheep manure, chicken manure

- project cost: 570,000 USD

goat and sheep manure pellet machine In indonesia

- Country: indonesia

- Production: 10,000 T/A

- Ingredients: sheep manure, straw

- project cost: 190,000 USD

goat and sheep manure pellet machine In canada

- Country: canada

- Production: 6,000 T/A

- Ingredients: sheep manure, hen manure

- project cost: $160,000

goat and sheep manure pellet machine In Pakistan

- Country: Pakistan

- Production: 30,000 T/A

- Ingredients: sheep manure, cow manure

- project cost: $385,000 USD

goat and sheep manure pellet machine In Vietnam

- Country: Vietnam

- Production: 2500 t/a

- Ingredients: sheep manure, industrial waste

- project price: 80,000 USD

goat and sheep manure pellet machine In Mexico

- Country: Mexico

- Production: 10,000 T/A

- Ingredients: sheep manure, poultry manure

- project price: US$110,000

goat and sheep manure pellet machine In United States

- Country: United States

- Production: 50,000 T/A

- Ingredients: sheep manure, poultry litter

- project price: US$430,000

goat and sheep manure pellet machine In Lithuania

- Country: Lithuania

- Production: 35,000 T/A

- Ingredients: sheep manure, food waste

- project price: 410,000USD

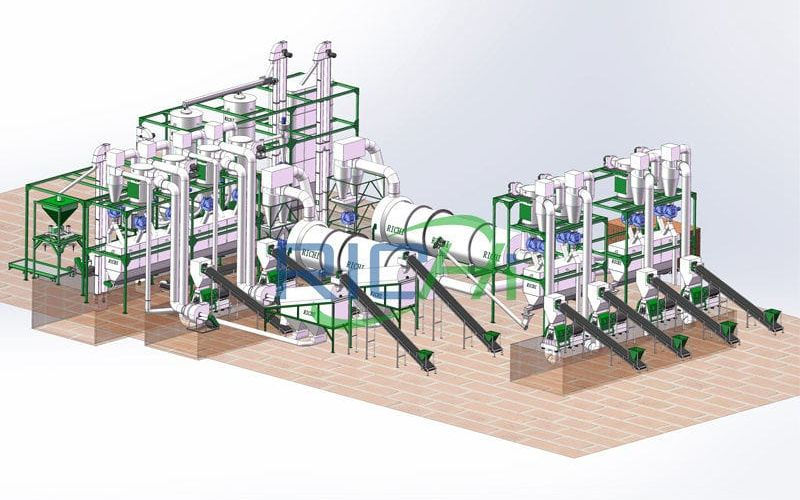

How to process goat and sheep manure pellets? Complete sheep pellets fertilizer process flow

Sheep manure organic fertilizer production line process flow:

- The raw materials of sheep manure and plant straw are mixed and then fermented. It is recommended to use a ground turner for ground piles, or a trough-type turner for placing materials in the fermentation tank. During fermentation, the raw materials need to be turned from time to time.

- The fermentation time varies depending on the temperature in different places. Generally, the fermentation time is 7-15 days. After complete fermentation and decomposition, use a forklift to collect the pile directly.

- Use a forklift to transport the fermented sheep manure raw materials to the silo, where the raw materials are sent to the organic fertilizer crusher via a belt conveyor for crushing.

- The crushed raw materials are sent to the organic fertilizer mixer through a belt conveyor for uniform mixing and mixing, and then sent to the sheep manure pellet making machine.

- After the raw materials are made into pellets through the goat and sheep manure pellet machine, they are directly sent to the sheep manure dryer. The sheep manure pellets are dried to facilitate transportation and storage.

- In order to prevent the sheep manure pellets from clumping, the dried particles need to be sent to the sheep manure pellet cooler for cooling to increase their pellet strength.

- The cooled pellets are sent to the sheep manure pellets creening machine for screening, the unqualified particles are sent to the sheep manure pellet machine for re-granulation, and the qualified sheep manure pellets enter the next process.

- The qualified sheep manure pellets after screening are packed into bags using an automatic packaging machine or manually, and placed in a dry and ventilated place, which completes the entire production process.

The above is the process flow of the sheep manure organic fertilizer production line. The sheep manure organic fertilizer production line can be divided into: sheep manure powder production line and sheep manure pellet production line. Since the actual output and production process of each customer are different, the required fertilizer processing equipment is also different.

goat and sheep manure making machine list

The following are the main equipment used for sheep manure organic fertilizer processing. RICHI Machinery has been focusing on the production of various livestock and poultry manure organic fertilizer production lines and related supporting equipment for many years. If you need to know the specific production plans and detailed prices, you are welcome to call or visit us at any time.

goat and sheep manure Turner

Turning height:

0.5-2.0 m

Motor:

32-300 KW

goat and sheep manure Grinder

Capacity:

3-25T/H

Main Power:

30-160KW

goat and sheep manure Mixer

Capacity:

250-2000 kg/P

Main Power:

4-30 KW

goat and sheep manure Dryer

Capacity:

Customized

Rotate Speed:

3-8 R/Min

goat and sheep manure pelletizer

Capacity:

1-12T/H

Main Power:

37-280KW

How to choose goat and sheep manure pellet machine?

Are you still worried about how to choose goat and sheep manure pellet equipment? We teach you how to choose!

As the animal husbandry industry develops more and more rapidly, the whereabouts of livestock and poultry manure has become a common concern for many farms and farms. The emergence of goat and sheep manure pellet machine can be said to solve this big problem. So, what should we pay attention to when choosing fertilizer equipment? These are all issues we must consider! Let’s take a look today!

- Determine the output of the goat and sheep manure fertilizer production line.

For example, the annual output of tens of thousands of tons, or the number of tons per hour, can determine the specifications of goat and sheep manure production equipment. - Determine the shape of the pellets.

It is a matter of choice what kind of compost pellet making machine: be it powder, column, flat ball or standard garden. The most professional and commonly used organic fertilizer granulation equipment is the ring die pellet machine. The choice of goat and sheep manure pellet machine should be determined based on the preferences of the local fertilizer sales market. The particle shapes are different, the organic fertilizer production processes are different, and the prices of organic fertilizer equipment are different. - Determine the configuration level of goat and sheep manure pellet machine.

The level of equipment configuration determines the price of the equipment, the amount of labor, and the ability of the equipment to operate stably. High configuration generally requires adding some links, such as automatic batching device, automatic packaging device, automatic quantitative feeding device, cyclone dust removal, centralized dust removal, etc. - Determine the type of fertilizer produced.

It is compound fertilizer equipment or organic fertilizer equipment. When the output is the same, organic fertilizer pellet mill equipment generally has a high water content, the bacteria are not resistant to high temperatures, and the model is generally larger than that of compound fertilizer.

Generally speaking, there are four types of organic fertilizers, such as pure organic fertilizers, organic-inorganic compound fertilizers, bio-organic fertilizers and compound microbial fertilizers. Different types of goat and sheep manure pellet machine are also different. - Fermentation turning machine:

General fermentation forms include: rod pile fermentation, shallow tank fermentation, deep tank fermentation, tower fermentation, and drum fermentation. The fermentation methods and equipment for organic fertilizer fermentation are different. Generally, it is more suitable to choose a shallow groove dumper.

The advantages of the shallow tank dumper: it conforms to the principle of aerobic fermentation, is not easy to form anaerobic, has sufficient and thorough fermentation, and has a fast fermentation speed.

After reading our above introduction, do you know better how to choose when choosing goat and sheep manure pellet machine and whole set equipment?

To put it simply, let’s first look at what raw materials are? And how much raw production do you want? The size of the venue and the budget all determine what equipment you choose! I hope the above content can be helpful to you who are paying attention to organic fertilizer goat and sheep manure machine!

How to choose goat and sheep manure pellet machine manufacturer?

Choosing a suitable goat and sheep manure pellet machine manufacturer is crucial to achieving a stable, reliable and continuously operating organic fertilizer granulation process. Choosing the right manufacturer is a critical decision. Here are some guidelines to help you make your choice:

- Define requirements: First clarify your granulation requirements, including the type of materials to be processed, output requirements, pellet size, etc. Make sure you know your specific requirements so you can better evaluate whether the manufacturer can meet your needs.

- Market research: Conduct market research and find reliable goat and sheep manure pellet machine manufacturers. You can collect information about various manufacturers through Internet searches, industry exhibitions, and by referring to other users’ reviews and word-of-mouth.

- Experience and knowledge: Consider the manufacturer’s experience and expertise. Learn about their experience and technical strength in the field of manure pellet mills, including their R&D capabilities, technological innovation, product quality, etc.

- References and word-of-mouth: Understand other customers’ reviews and feedback. You can get more information through online reviews, customer recommendations, or industry forums. This will help you understand the manufacturer’s reputation and customer satisfaction.

- Technical support and after-sales service: Ensure that the manufacturer provides comprehensive technical support and after-sales service. This includes support in installation, commissioning, training and maintenance to ensure proper operation and troubleshooting of equipment.

- Customization capabilities: If you have special granulation needs or specific process requirements, it will be more advantageous to choose a manufacturer that can provide customized goat and sheep manure pellet plant solutions. They are able to design and manufacture compost granulating machine to specific specifications and requirements according to your needs.

- Price and cost-effectiveness: Consider the price and cost-effectiveness of the fertilizer granulation equipment. Choose a manufacturer that offers a good balance of quality, service, and price to ensure you get the best return on investment.

01 Why choose RICHI Machinery as your sheep manure granule machine manufacturer?

There are the following reasons for choosing RICHI as a sheep manure granule machine manufacturer:

- Manufacturer reputation and experience: An fertilizer granulator manufacturer with good reputation and rich experience has been in the pelleting machine industry for many years and has established a good reputation in the market.

- Diversified product lines: Provide diversified goat and sheep manure equipment to meet the needs of different industries and applications. Products include crushers, mixers, dryers, granulators, coolers, screening machines, balers, etc. It can adapt to the process requirements of different organic fertilizers.

- High-quality products: Committed to providing high-quality goat and sheep manure granulator machine products to ensure product stability, durability and superior performance. Their equipment performs better in terms of service life, granulation efficiency and granulation accuracy.

- Competitive price: By optimizing the production process and cost control, the product price is controlled within a reasonable range to provide customers with cost-effective solutions. At the same time, they also offer flexible customization options to meet customers’ specific needs.

- Timely supply and after-sales service: Able to provide timely supply and provide comprehensive after-sales service. They have a complete supply chain management and warehousing system to ensure timely delivery of products. In addition, they also provide services such as technical support, equipment installation, commissioning and training to ensure that customers can use the equipment smoothly and receive satisfactory service.

02 Misunderstandings when purchasing goat and sheep manure pelletizer manufacturers

When choosing a goat and sheep manure pellet machine manufacturer, the following are some common misunderstandings that should be avoided:

- Focus only on price: Although price is an important consideration, it is unwise to limit the decision to choose a manufacturer solely to price. Low-priced goat and sheep manures may have quality problems, and subsequent technical support and after-sales service may be imperfect. Instead, consider price alongside factors such as quality, service, and performance.

- Ignore the manufacturer’s experience and reputation: The manufacturer’s experience and reputation are important factors in selection. Ignoring these factors may lead to choosing an unprofessional and unreliable manufacturer. Carefully research the manufacturer’s background, history, and customer feedback to understand their industry experience and business reliability.

- Not understanding your own needs: Before choosing a goat and sheep manure pellet machine manufacturer, make sure you clearly understand your own granulation needs. Without clear needs, it is difficult to find suitable manufacturers and equipment. Define specific requirements such as output, particle size, compression ratio, material characteristics, etc., so that you can better communicate and compare with manufacturers.

- Ignore technical support and after-sales service: Technical support and after-sales service are important components of long-term cooperation. If you neglect to understand the manufacturer’s technical support capabilities, response time, and after-sales service quality, you may encounter problems during equipment installation, maintenance, and troubleshooting. Ensure that manufacturers can provide timely and professional technical support and after-sales service.

- No on-site inspection and testing: To understand the actual performance and adaptability of the organic fertilizer granulator machine, it is best to conduct on-site inspection and testing. This can help you personally observe equipment operation, understand the process flow, and have in-depth communication with the manufacturer’s engineers. This allows for a better assessment of the quality, performance and adaptability of the organic manure making machines.

- Do not compare multiple manufacturers: It is unwise to communicate and compare only with a single manufacturer. By comparing with multiple manufacturers, you can better understand the products, services and prices of different manufacturers on the market and make a more informed choice.

By considering the above factors, you can better evaluate and select a suitable goat and sheep manure pellet machine manufacturer to meet your needs and obtain reliable equipment and services. Before making a decision, it is recommended to compare and contrast with multiple manufacturers to ensure you make an informed choice.

Why process sheep manure organic fertilizer?

After being fermented through a special process, sheep manure can become an organic fertilizer that is beneficial to the growth of crops.

It is used in the cultivation of various crops, plants, flowers, etc., promoting the reform of agricultural planting, and playing an important role in the growth of crops, etc.

There are many users who are curious about the unique features of this mysterious fertilizer. Next, we will go into the world of sheep manure organic fertilizer to learn more.

1. Wide range of use

A practical sheep manure organic fertilizer made by goat and sheep manure pellet machine is like we often say that the bricks of the motherland should be moved wherever they are needed. Fertilizer made from sheep manure is not picky about the scope of use.

It is not restricted by region, species, soil, etc., and there is no rule that it can only be used for planting flowers or plants. As long as there is a need for nutrient fertilizer for planting, users can rest assured and bold use.

2. High nutritional content

Quality-guaranteed sheep manure organic fertilizer contains a large amount of nutrients needed by plants, including various nitrogen, potassium, etc.

These organic substances are crucial for the growth of plants. It can not only promote the metabolism of plants and accelerate their growth, but also provide sufficient nutrients for the growth of plants, allowing them to thrive. This will help shorten the cultivation cycle of crops and even increase yields.

3. Natural antibiotics

Normally, people eat mutton in winter to build up their immunity. Sheep themselves are healthy and less likely to get sick, and their feces are rich in nutrients and are called natural antibiotics.

After the sheep manure organic fertilizer acts on the planted crops, it can enhance the flood and drought resistance of the planted products. In general, one of the special features of sheep manure fertilizer is that it can improve the ability of planted species to withstand natural disasters.

Animal dung is an inconspicuous thing, but after processing with human wisdom and long-term fertilization experiments, it can also be used in the agricultural market. Nowadays, sheep manure organic fertilizer has become a hot topic in the fertilizer market.

It has the characteristics of wide range of use, high business composition and the ability to become a natural antibiotic for planting crops. It is undeniable that organic fertilizer made from sheep manure is an ideal choice for users to grow various crops.

Market prospects of goat and sheep manure organic fertilizers production

Goat and sheep manure pellet organic fertilizer is a fertilizer made from natural organic matter as the main raw material and is an important part of agricultural production. It is favored by more and more consumers for its advantages such as environmental protection, health, and improving the quality of agricultural products. The market prospect of organic fertilizer is very broad.

01 First of all, goat and sheep manure organic fertilizer meets environmental protection requirements.

As the global population continues to grow and industrialization accelerates, chemical fertilizers used in traditional agricultural production seriously pollute soil and water sources, causing significant harm to the environment.

Organic fertilizers are made of natural organic substances and do not contain harmful chemicals. They can effectively prevent soil and water contamination and comply with society’s environmental requirements. As people’s awareness of environmental protection increases, the demand for organic fertilizer market will also continue to increase.

02 Secondly, organic fertilizers made by goat and sheep manure pellet machine can significantly improve the quality of agricultural products.

Although chemical fertilizers used in traditional agricultural production can quickly increase yields, the agricultural products have poor taste, low nutritional content, and cause potential harm to human health.

Organic fertilizers can not only improve the quality of agricultural products and make them taste more delicious, but are also rich in organic substances and trace elements, which can improve the nutritional value of agricultural products and meet people’s demand for high-quality, healthy agricultural products. Therefore, the organic fertilizer market has a broad Expansion capacity.

03 Thirdly, goat and sheep manure organic fertilizer can improve soil quality and improve the ecological environment of farmland.

Organic fertilizers are rich in organic matter and microorganisms. The application of organic fertilizers can improve the soil structure, increase soil fertility, improve the soil’s ability to retain water and fertilizer, and increase the soil’s resistance to diseases and insect pests.

This is of great significance for improving the ecological environment of cultivated land and enhancing the sustainable utilization capacity of land. As people pay more attention to the sustainable development of agriculture, the market demand for organic fertilizers will continue to grow.

04 Finally, the market prospects of goat and sheep manure organic fertilizers are also strongly supported by government policies.

As society pays attention to environmental protection and food safety, the government has increased its support for environmentally friendly agriculture and organic agriculture. Through financial support, tax exemptions and other measures, it encourages farmers to use organic fertilizers and promotes the development of organic agriculture.

The government’s support measures will further promote the growth of the organic fertilizer market and provide a good policy environment for the development of organic fertilizer.

To sum up, goat and sheep manure organic fertilizer, which is made by goat and sheep manure pellet machine, as an environmentally friendly, healthy and high-quality fertilizer, has broad market prospects.

With the improvement of environmental awareness and health awareness, people’s demand for organic agricultural products is increasing, which will drive the market demand for organic fertilizers.

In addition, organic fertilizer has multiple advantages such as improving soil quality, improving the quality of agricultural products, and improving the ecological environment of farmland, and has received strong support from the government.

Therefore, the market prospect of organic fertilizer is very broad and has huge development potential. (Find RICHI on YouTube)