Floating Fish Feed Making Machine

Floating fish feed making machine, also called floating feed extruder machine, floating fish feed machine. Based on the characteristics of floating fish, floating fish feed pellet making machine refers to floating fish feed machines.

With the continuous development and progress of feed production technology and equipment, in the production process of aquatic feed, floating fish twin screw extruder machines are more and more widely used, and extruded aquatic feed has been gradually applied and developed in production.

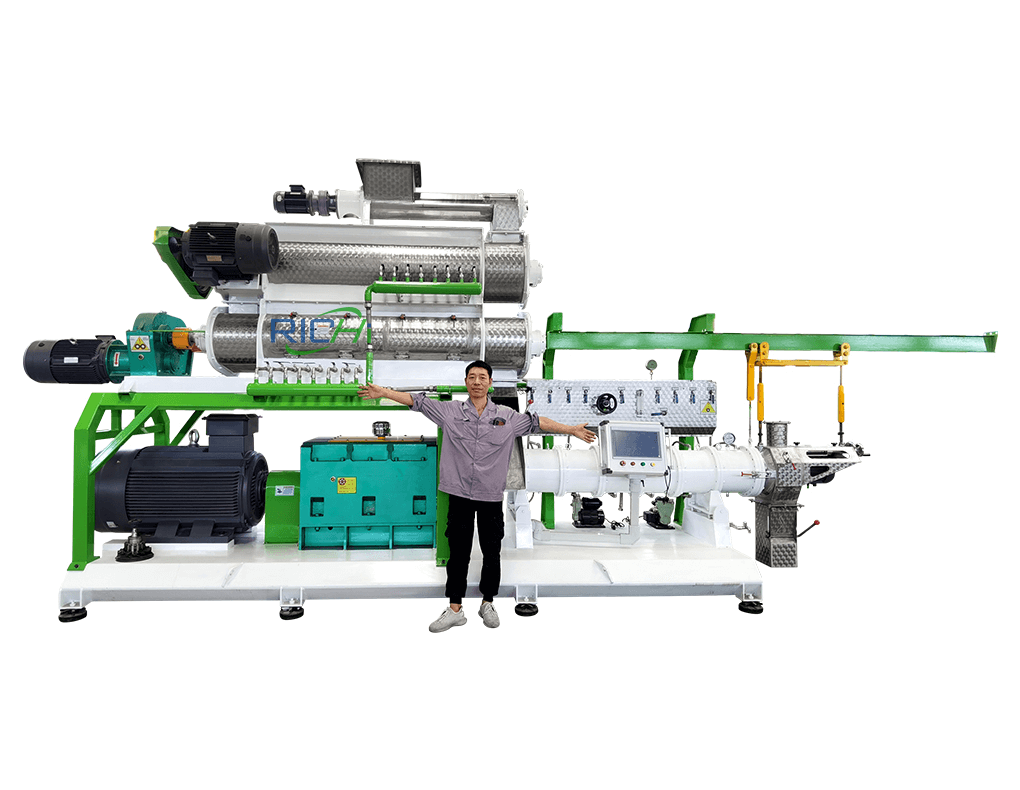

Richi Machinery pursues to provide customers with more abundant and systematic integrated floating fish feed production line solutions. The company’s R&D team has invested a lot of money to develop a new floating fish feed machine that can meet the diverse needs of customers with high quality and high output.

Floating Fish Feed Pellet Machine Types

Floating fish feed making machine is a combination of screw and machine boring.

When the material is conveyed to the extrusion cavity by extrusion, the material is subjected to mixing, stirring, friction and shearing forces to form a hydrothermal conditioning environment and play a role in sterilization, promote the comprehensive effects of starch gelatinization, crude fiber degradation, etc.

Due to the pressure difference between the extrusion cavity and the outside world, the material extrusion template hole will expand rapidly to achieve the purpose of puffing. It meets the needs of floating fish feed mills for production capacity and production of different varieties and specifications.

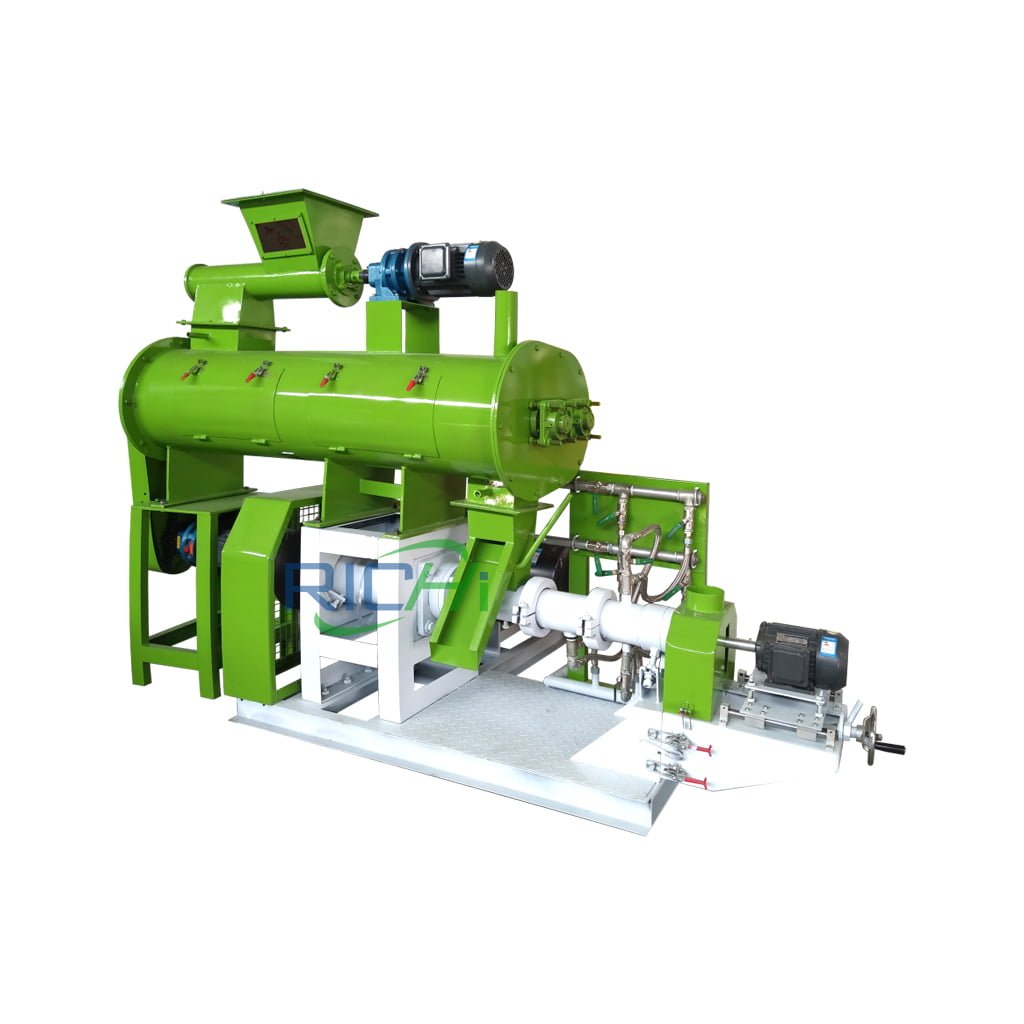

Single Screw Floating Fish Feed Pellet Machine

At present, the mainstream floating fish feed equipment is mainly twin-screw floating fish pellet machine and single-screw floating fish pellet machine.

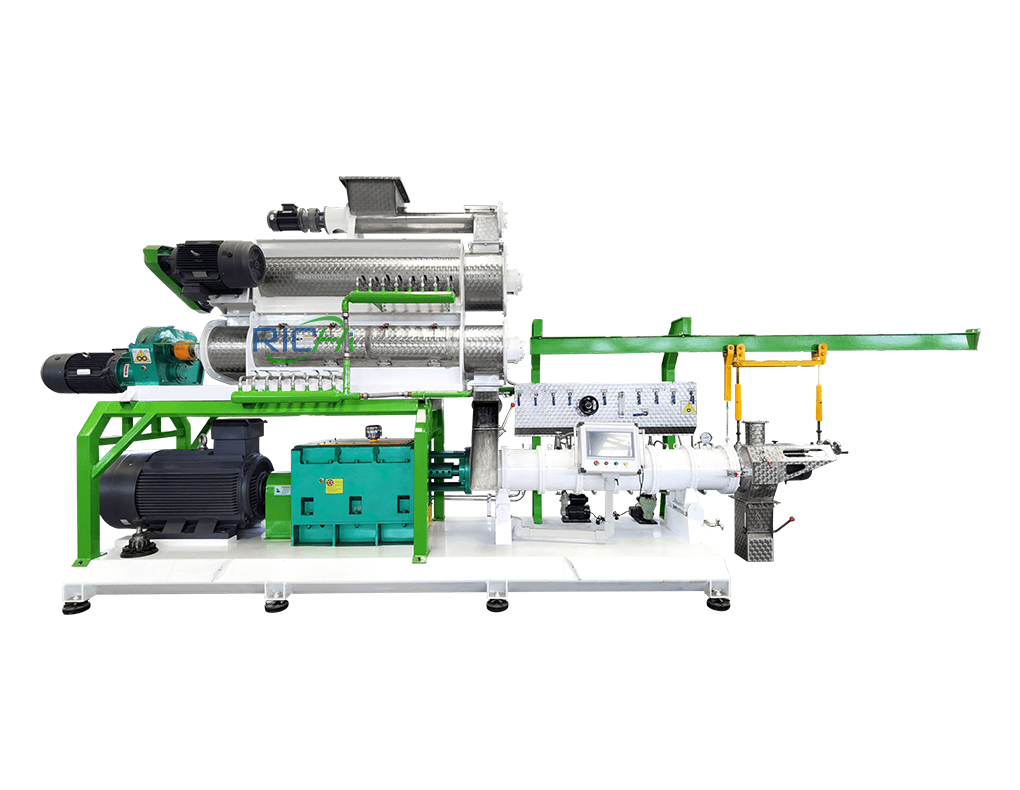

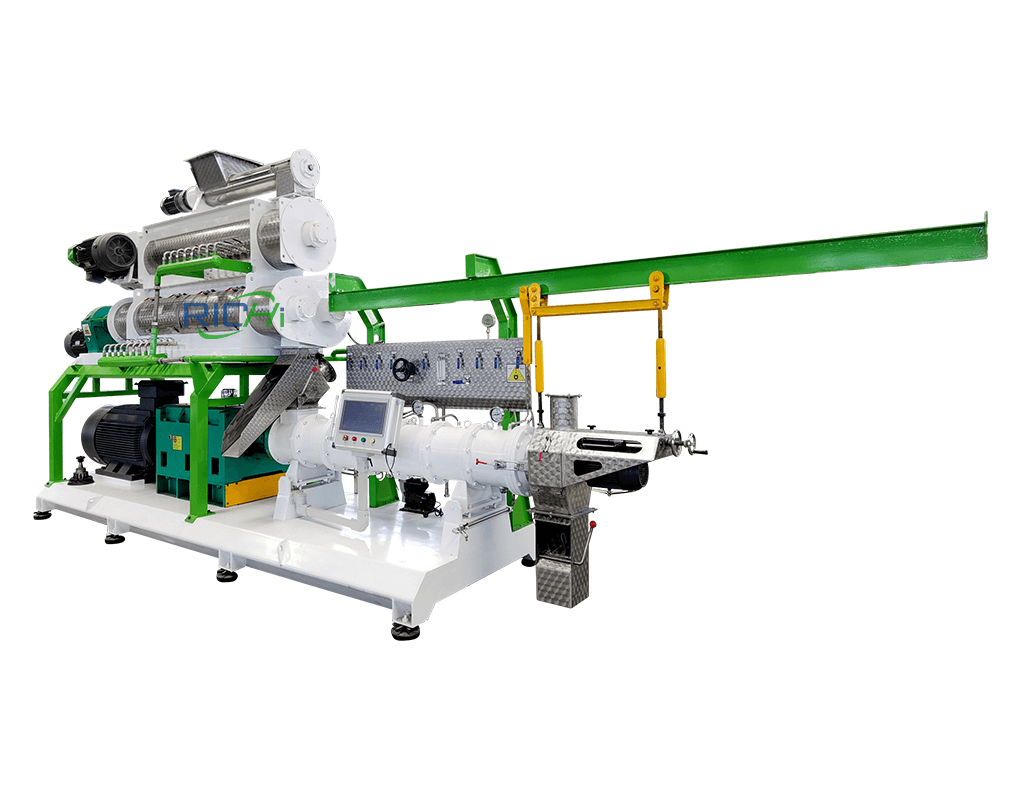

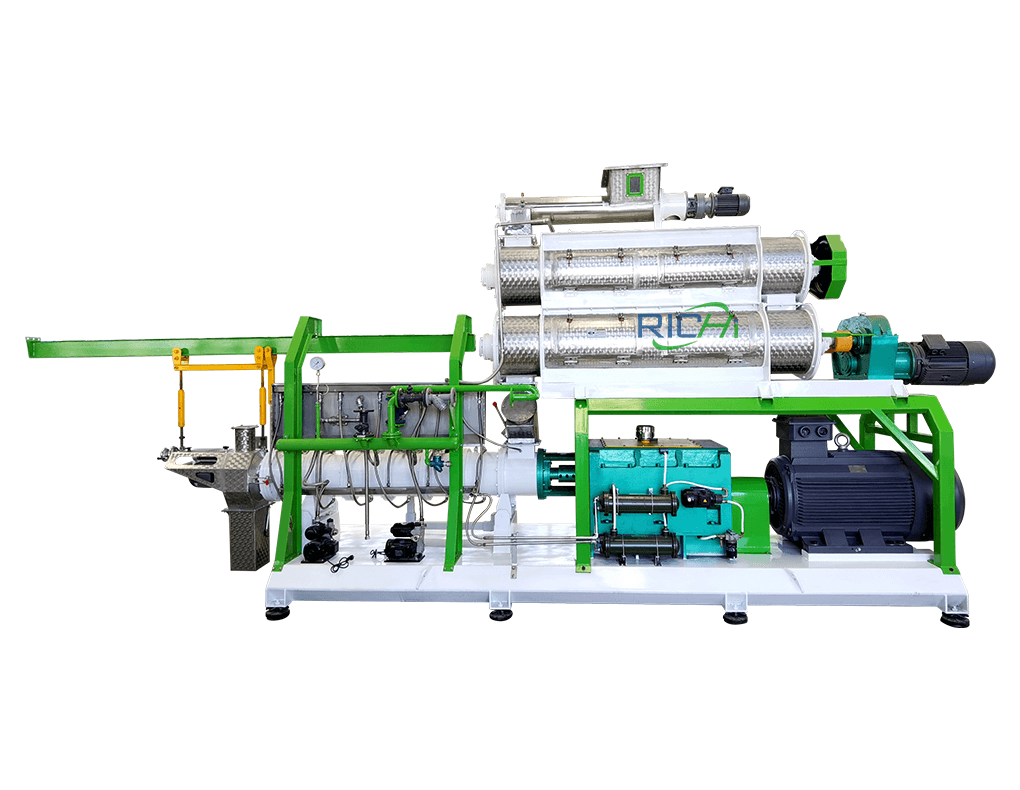

Twin Screw fish Feed Making Machine

Compared with single-screw floating fish pellet machines, twin-screw floating fish feed pellet mills can be used in a wider range. Due to the assistance of the two screws, the direction of the material during the extrusion process is ideally controlled to avoid reverse gap flow, the material is balanced in force, the residence time in the machine is consistent, and the product is uniform.

Even if the moisture content of the raw material is more than 40% and the oil content is more than 17%, the product with high molding rate can still be obtained. The twin-screw floating feed machine does not need to set up resistance grooves on the inner wall of the machine bore, and there is little material residue in the machine, which is easy to clean up for changing varieties and before shutdown.

To produce high-grade aquatic products or feed raw materials are rich, such as containing high protein, high fat, the moisture range of the raw material is wide, and the diameter of the aquatic product changes greatly, it is more suitable to choose a twin-screw floating fish feed making machine.

In addition, when the product type changes greatly, such as the production of floating, sinking and slow sinking feed, the choice of twin-screw floating fish feed extruder machine is more adjustable, and the parameter settings are also easier to change.

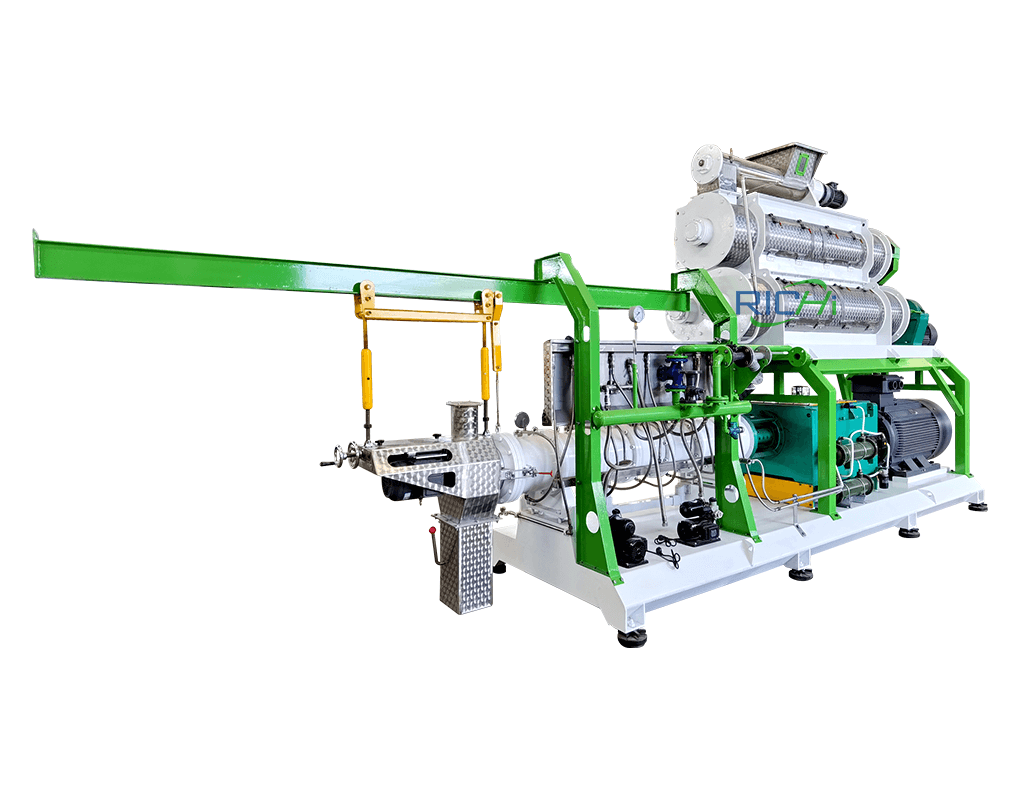

01 Advantages Of Twin Screw Floating Fish Feed Making Machine

- The unique screw combination of precision machining makes the oil content in the formula up to 22%, which improves the floating fish’s absorption rate of oil and is environmentally friendly;

- Advanced hole layout technology and die hole structure, consistent product pellet size and smooth surface;

- It can be adapted to the precise processing of various formulas such as low starch, high protein and high oil. Two density control systems can be configured according to different needs of customers to meet the needs of customers to process floating and sinking feed at the same time;

- Strong material adaptability, innovative die head, 3 times wear resistance of screw and bushing, imported gear box, integral forging bushing, flexible density control matching, efficient automatic control system;

- Adopt international first-class imported brand gear box, and equipped with torque limiter, reliable use and low maintenance cost;

- One-piece molding, greatly reducing the risk of cracks, long product life;

- Upgrade on the basis of test data of die material and process, die hole structure, hole layout process, etc. to ensure consistent product pellet size and beautiful appearance;

- The bushing wear detection technology can be used to detect the wear of each section of the bushing without disassembling the machine to ensure the production capacity of the floating fish pellet machine and the quality of the floating pellet fish food product.

- Extruded feed machinery is a high-end product in the industry. Compared with traditional floating pellet machine, its products (expanded feed) are more environmentally friendly, safe, do not pollute water quality, and are easier to absorb by fish and shrimp, improve digestibility, and reduce breeding costs.

02 Parameters Of Twin Screw Fish Feed Making Machine

SPHS 1-2 T/H Fish Feed Making Machine

The output of this model floating fish feed extruder machine is 1-2t/h, innovative patented kneading structure specially designed for pet food, advanced equipment and stable operation.

SPHS 120*2 Fish Pellet Making Machine

The output of this type of floating fish feed extruder machine is 3-4t/h, precise screw processing clearance is as low as 0.5 mm, which can accurately meet the requirements of high standards of formula.

SPHS 150*2 Fish Feed Making Machine

The output of this type of floating fish feed making machine is 4-5t/h, the unique wire thread insert cooling structure can greatly reduce the cooling time and improve the operation efficiency of the equipment.

SPHS 6-7 T/H Floating Fish Feed Machine

The output of this model floating fish feed production machine is 6-7t/h, use PLC Touch Screen Technology to realize man-machine dialogue and switch between manual and automatic operation.

SPHS 8-10 T/H Floating Fish Feed Extruder

The output of this model floating fish feed machine is 8-10t/h, the whole service life of the imported gearbox is greater than 50000 hours, automatic intelligent control system ensures high management efficiency.

SPHS 185*2 Floating Fish Feed Machine

The output of this type of floating fish feed making machine is 10-12t/h, precise and unique double-screw structure increases oil content up to 22%, can increase the absorption rates of oil for aqua animals.

| Model | SPHS 120*2 | SPHS 120*2 (6.6*1.6*4M 6T) | SPHS 150*2 | SPHS 150*2 (8*2*4.3M 8T ) | SPHS 185*2 | SPHS 185*2 |

|---|---|---|---|---|---|---|

| Main Power (KW) | 75 | 90 | 160 | 200 | 315 | 355 |

| Dia. of Screw (mm) | 120 | 120 | 150 | 150 | 185 | 185 |

| Capacity (T/H) | 1-2 | 3-4 | 4-5 | 6-7 | 8-10 | 10-12 |

| Matching flat bottom arch breaking warehouse (model-power) | PGC900/700-1.5 | PGC900/750-1.5 | PGS900/800-1.5+0.3 | PGS900/800-1.5+0.3 | PGS900/800-2.2/0.3 | PGS900/800-2.2/0.3 |

| Matching feeder (model-power) | WLQ219×1200-1.5kw | WLQ219×1200-1.5kw | WLQ219-1300-1.5kw | WLQ219-1300-1.5kw | WLQ219-1300-2.2kw | WLQ219-1300-2.2kw |

| Matching single shaft conditioner (model-power) | DC420-244-7.5 | DC500/244-11 | DC500/244-11 | DC600/300-15 | DC600/300-15 | |

| Matching differential conditioner (model-power) | DDC400/300/244-11kw | DDC400/300/244-11kw | DDC500/300/244-11kw | DDC500/300/244-11kw | DDC500/300/300-15kw | DDC500/300/300-15kw |

Single Screw Floating Fish Feed Machine

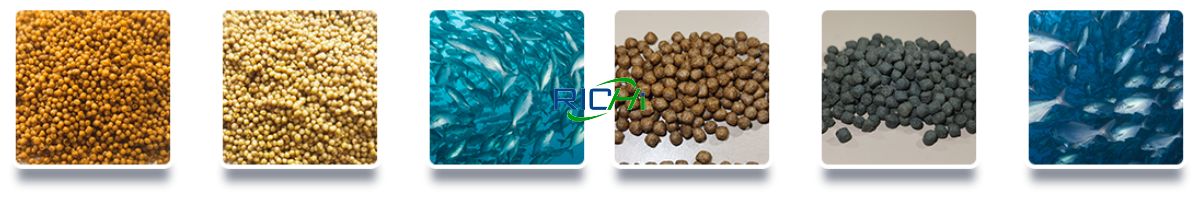

The single-screw floating fish feed making machine can be used to produce various types of aquatic feeds, which can produce both high-grade and low-grade feeds. It can be used as both a floating extruded feed and a sinking extruded feed. Feed pellets range from 1 mm to 14 mm.

Richi Machinery has made innovative achievements in reducing energy consumption and saving costs, providing more advanced floating fish equipment for the production of environmentally friendly aquaculture and safe feed, and its technology has reached the leading level of similar products.

Extrusion has become a common technology in the feed industry, we can use not only pelleting but also other processes. Single-screw floating fish pellet machines provide the appropriate operating range and operate more economically than twin-screw floating fish feed pellet mills.

01 Advantages Of Single Screw Floating Fish Feed Making Machine

- The floating fish food machine has the characteristics of high output, good performance, low energy consumption, low noise and beautiful appearance;

- The floating fish feed machine runs smoothly, works reliably, and has a high degree of maturation of the extruded material;

- The differential diameter conditioner is used, and the conditioning is sufficient and the effect is good;

- The feeder adopts frequency conversion motor to control the speed, and the speed can be adjusted freely;

- Equipped with a full set of oil, water and steam adding systems, and Siemens PLC is used to realize automatic control of the entire extrusion process;

- The product has high technical content and high production efficiency. The design and manufacture of this floating fish feed making machine model belongs to the cutting-edge floating fish feed products and technologies;

- Confirmed from the feedback information, whether it is the equipment that has just been installed and debugged, or the equipment that has been put into production for a long time, it can meet the performance requirements of the floating fish feed production process, and the use effect is stable and good.

02 Parameters Of Single Screw Floating Feed Making Machine

DGP40-C Floating Fish Feed Machine

The output of DGP40-C floating feed machine is 30-40kg/h, electric control with high degree automatization, ensure the fish feed extruder operate stably and long continuous operating time.

DGP60-C Floating Fish Feed Extruder

The output of DGP60-C floating fish feed production machine is 120-150kg/h, the extruded feed with high determination of starch gelatinization and good stability in water.

DGP90-B Fish Feed Extruder Machine

The output of DGP90-B floating fish feed machine is 300-350kg/h, the extruder meet the market’s sinkable and float aquatic feed, pet feed and other special aquatic feed production.

DSP120-B Floating Fish Pellet Extruder

The output of DSP120-B floating fish feed machine is 700-800kg/h, meet the market demand,let customers get the best benefits. Compared with domestic same type fish feed extruder, higher output, more beautiful appearance.

DSP135-B Floating Fish Feed Machine

The output of DSP135-B floating fish feed extruder machine is 1000-1200kg/h, main pipeline accessories use Spike products, no steam leakage and accurate control. Main drive with SKF high quality bearings,long operating life.

DSP200-B Floating Fish Pellet Machine

The output of DSP200-B floating fish feed extruder is 3-4t/h, the screw thread insert with lamination structure, add cold water or steam into lamination, providing cooling or keep warm action, achieving the best extruded effect.

| DGP Single Screw Fish Feed Extruder Model | Capacity(TPH) | Main Motor Power(kw) | Feeder Motor Power(kw) | Screw diameter(mm) | Cutter power(kw) |

|---|---|---|---|---|---|

| DGP40-Cs | 0.03-0.04 | 3.0*2 | 0.4 | Φ40 | 0.4 |

| DGP40-C | 0.03-0.04 | 5.5 | 0.4 | Φ40 | 0.4 |

| DGP50-C | 0.06-0.08 | 11 | 0.4 | Φ50 | 0.4 |

| DGP60-C | 0.12-0.15 | 15 | 0.4 | φ60 | 0.4 |

| DGP70-B | 0.18-0.2 | 18.5 | 0.4 | φ70 | 0.4 |

| DGP80-B | 0.2-0.25 | 22 | 0.4 | φ80 | 0.6 |

| DGP90-B | 0.30-0.35 | 37 | 0.6 | φ90 | 0.8 |

| DGP120-B | 0.5-0.6 | 55 | 1.1 | φ120 | 2.2 |

| DGP135-B | 0.7-0.8 | 75 | 1.1 | φ133 | 2.2 |

| DGP160-B | 1-1.2 | 90 | 1.5 | φ155 | 3 |

| DGP200-B | 1.8-2.0 | 132 | 1.5 | φ195 | 3.0-4.0 |

| DSP Single Screw Fish Feed Extruder Model | Capacity(TPH) | Main Motor Power(kw) | Feeder power(kw) | Screw diameter(mm) | Cutter power(kw) |

| DSP60-B | 0.18-0.2 | 15 | 0.4 | Φ60 | 0.4 |

| DSP70-B | 0.25-0.30 | 18.5 | 0.6 | Φ70 | 0.6 |

| DSP80-B | 0.35-0.40 | 22 | 1.1 | Φ80 | 0.8 |

| DSP90-B | 0.50-0.60 | 37 | 1.1 | Φ90 | 1.1 |

| DSP120-B | 0.70-0.80 | 55 | 1.1 | Φ120 | 1.5 |

| DSP135-B | 1.0-1.2 | 75 | 1.5 | Φ135 | 2.2 |

| DSP160-B | 1.8-2.0 | 90 | 2.2 | Φ155 | 2.2-3.0 |

| DSP200-B | 3.0-4.0 | 132 | 2.2 | Φ195 | 3.0-4.0 |

| DSP200-B | 3.0-4.0 | 132 | 2.2 | Φ195 | 3.0-4.0 |

(Note: Richi Machinery’s products are always updated and improved. Therefore, if there is any difference between the pictures, feature descriptions and performance parameters of the actual model, please refer to the actual product.)

Richi Machinery maintains the tradition of continuous innovation. Every time a new product is put into the market, it will form a huge shock wave, and then gradually occupy the market, steadily realize the upgrading of new and old products, and maintain technological leadership and continuous product competitiveness. Click the button below to inquire about high level floating fish feed making machine details.

Floating Fish Feed Machine Price

The floating feed machine price is generally 3000-300000USD. Regarding the floating fish feed machine price, it involves specific equipment configuration. The prices of different types of floating fish feed making machine are very different. We need to determine the machine selection and quotation according to specific production requirements.

If you want to know the specific price , you can submit the required floating feed making machine output, the type of floating fish feed to be processed, the particle size and other information to the online customer service.

“Made in China” continues to challenge and break the inherent stereotypes, gradually becoming a respected label, more and more recognized and loved by global users, demonstrating the rise of the power of Chinese products. It is believed that in the arena of the global market, including Richi Machinery, it is growing into a high-quality “Light of Made in China”, allowing more customers to feel the confident attitude of Made in China. Click the button below to inquire about high level floating fish feed making machine details.

RICHI PELLET MACHINE

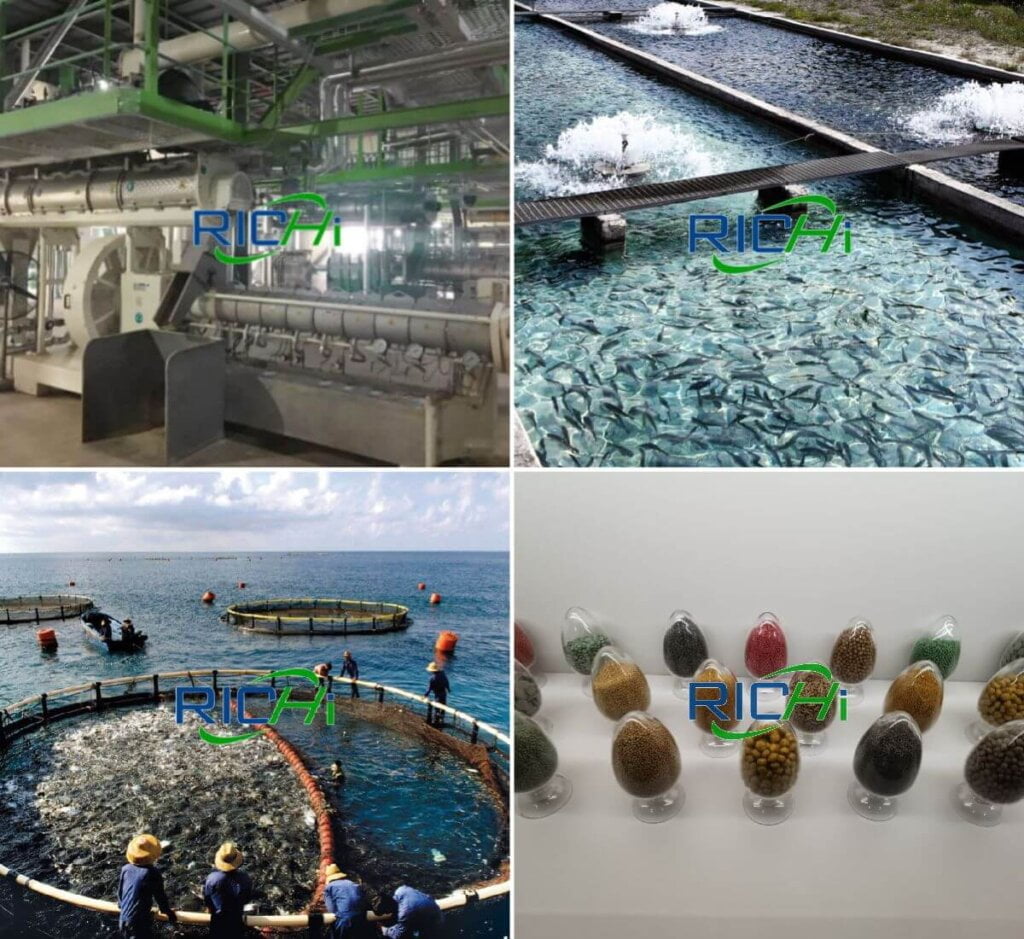

Floating Fish Feed Making Machine Projects

Adhering to the corporate core values of “creating value and sharing value”, Richi Machinery has determined the strategy of “extending to the product industry chain”, “taking customers as friends” and “building a service system”, focusing on fish feed making machine research and development, focusing on customer value creation , focusing on a higher-level business model to achieve a win-win situation with customers. (Related case: Fish Food Production Line In Iran)

Floating Feed Making Machine In 20 T/H Floating Fish Feed Plant

Floating Fish Making Machine In 10 t/H Floating Fish Feed Mill

Floating Pellet Making Machine In 5 t/H Floating Fish Feed Mill

100-150KG floating fish feed machine for sale Ukraine

5-6T/H floating feed machine For Sale Russia

1.5TPH fish floating feed machine For Sale Uzbekistan

In recent years, Richi Machinery has continuously optimized the technical system, production system, supply chain system, and service system, serving more than 130 countries and regions around the world, and has established in-depth and friendly cooperative relations with more customers, and they are more trustworthy.

Operational data shows that in recent years, Richi Machinery has faced an increasing number of customers, the quality of new customers is getting higher and higher, and the proportion of old customers’ transactions has increased year by year.

Video Of Floating Fish Feed Making Machine Site

Continuous breakthroughs in high-end core technologies, in-depth and solid global layout, and steady improvement in development quality and efficiency, Richi Machinery has shown vigorous vigor and vitality.

Behind every highlight moment is RICHI’s perseverance in belief, and behind every leadership is Richi Machinery’s pursuit of excellence in equipment manufacturing. The perfect operation of each equipment is the best answer to Richi Machinery’s efforts and accumulation.

How To Choose Floating Fish Feed Machine?

01 Single Screw Vs Twin Screw Floating Fish Feed Extruder

What is the difference between a single screw floating fish food machine and a twin screw floating fish feed machine? Which is more suitable to choose? Take a look at the comparison below, it may be helpful to you:

In addition, the single-screw floating feed machine adopts belt drive, and the twin-screw floating fish feed making machine adopts gear box drive. Both of them are very different in terms of manufacturing and transmission efficiency, so they will directly affect the performance of the fish floating feed machine.

Twin-screw floating feed making machine has obvious advantages in quality control and processing flexibility, and can process viscous, oily, high-moisture raw materials, so it is widely used in feed processing, especially in aquatic feed processing.

Extrusion processing is a high-temperature, high-pressure, instantaneous, and aging process. The extrusion machine integrates the functions of material transmission, crushing, mixing, shearing, stretching, extrusion, molding, and disinfection.

There are thousands of feed and food varieties that can be developed and produced by the fish feed floating pellet making machine, and the general production process cannot be compared at all.

Today, more and more customers and the market recognize the gradual upgrade of products, and they are willing to accept new products with high standards and more advanced.

To this end, Richi Machinery’s project managers and R&D engineers continue to go to customer sites, communicate with workers and customers, understand the actual operating conditions of equipment, collect operating parameters, so that each new product has strong data analysis and technical support, and finally achieve High stability target for device performance. It is believed that the newly released RICHI floating fish feed equipment will quickly grow into a new business card in the “super family” of Richi Machinery.

In addition, all of Richi Machinery’s technical products have part or all of the independent intellectual property rights, and the products with all the independent intellectual property rights account for more than 70% of the total product value, and independent research and development has become one of the core competitiveness.

02 Hard Pellet Machine Vs Floating Fish Feed Making Machine

In recent years, with the rapid development of aquafeed, the market awareness has gradually increased, and the demand has also increased year by year. This kind of equipment is required for both the equipment renovation of the old floating fish feed mill factory and the aquatic process equipment of the new floating fish feed production line.

Why use a floating feed extruder machine instead of a traditional fish hard feed pellet machine for processing floating fish feed? At present, extruded feed machinery has become the direction of aquatic feed production equipment, and will definitely replace the existing hard pellet feed machine.

At present, in many countries and regions in Europe, a new model of floating fish feed processing and breeding with extruded pellet feed as the mainstream has been formed. In recent years, with the development of the aquaculture industry in the direction of large-scale, intensive and specialization, its requirements for floating fish feed are getting higher and higher.

The floating fish compound feed produced by traditional ring die fish feed pellet machine exists. Poor stability in water, fast sedimentation, easy to cause feed loss and water pollution and other drawbacks, has become more and more unsuitable for the development of modern aquaculture.

The extruded aquafeed made by floating fish feed making machine can better solve these problems and is an ideal form of feed suitable for the development of modern aquaculture.

However, because the processing technology of aquatic floating fish feed is more complicated than that of hard pellets, in the actual production process, the same feed formula can be used in the aqua hard pellet fish feed production plant, but the product cannot be processed in the extrusion fish feed production line, or the same feed formula is not as good as the extruded floating feed.

The reason is that the temperature is as high as 120-150℃ in the process of puffing and granulation, and the whole floating fish feed mill process is high temperature, high pressure and high humidity, and the functions of most heat-sensitive vitamins, enzyme preparations and microbial preparations are destroyed.

Comparison Of Extruded Pellet Feed And Hard Pellet Feed

According to the feeding situation of floating fish in water, this feed is required to have high water stability and digestion and absorption rate, and it is difficult for traditional pelletizing process to meet the above requirements.

According to different processing techniques, fish feed is divided into hard pellet feed and extruded pellet feed. Although the ingredients of these two pellet feeds are the same, and the cost of extruded pellet feed is higher than that of hard pellet feed, the extruded pellet feed is still have better economic benefits can be produced with floating fish feed pellet machine.

In addition, based on the characteristics of sinking fish and shrimp, traditional fish feed pellet machines can be used. At least two layers of conditioners are required for sinking fish, and three layers of conditioners are required for processing shrimp feed.

What kind of fish feed making machine do you need? Floating fish feed machine or sinking fish feed equipment? Click the button below for professional guidance.

Start A Floating Fish Feed Mill Plant

Fish feed extruder machine usually does not work independently, but forms a complete set of floating fish feed mill together with fish food grinder, micro pulverizer, feed mixer machine, fish feed dryer machine, pellet cooler machine, vibrating screen, automatic bagging machine, etc., to achieve accurate processing of different floating fish feed and improve the pertinence of products. increase its market value.

The floating fish feed production line process is: Cleaning – Grinding – 1st Mixing – Ultra-Fine Grinding – 2nd Batching (Micro proportioning, fat adding) – 2nd Mixing – Extrusion & Pelletizing – Drying & Cooling – Crumbling – 1st Screening – Liquid Adding & Coating – Cooling – 2nd Screening – Packaging – Stacking.

01

After the raw materials are initially cleaned, coarsely pulverized and mixed once, the mixture is pulverized into fine particles by an ultra-fine pulverizer;

02

Then clean up the impurities in the mixture or classify the mixture according to particle size;

03

After adding the small material, the mixture is subjected to heat and moisture treatment to make starch gelatinized, protein denatured, and material softened, so that the subsequent extruder can improve the quality and efficiency of granulation, and improve the palatability and stability of the feed. Improve the digestion and absorption rate of feed (conditioning process);

04

The mixture is formed into a bulky and porous feed through continuous mixing, conditioning, heating and pressurization, aging, extrusion die hole and sudden pressure reduction (expansion process);

05

After drying, the moisture content of the semi-finished product reaches the specified requirements, and then enters the oil-spraying bin, sprayed with grease by the spraying machine, and then sent to the cooler for cooling;

06

Finished products that meet the feed pellet size requirements are screened for post-packaging.

Note:

The crushing particle size of the raw materials should be below 0.5mm, which is not only conducive to puffing and granulation, but also improves the utilization rate of nutrients in the raw materials; adding water and mixing is a key step, and the moisture content of the raw materials should be controlled between 23% and 30%.

If the moisture is too low, it is difficult to puff, it is easy to block, and the moisture is too high, the puffing may be insufficient and affect the molding; the floating fish feed pelleting generally adopts a wet extrusion floating fish feed extruder, and the raw materials are extruded and pushed by the screw in the floating feed extruder machine.

High temperature and high pressure, the temperature and pressure drop sharply at the moment of passing through the die hole, so that the moisture in the raw material evaporates rapidly, the volume expands, and the specific gravity becomes lighter.

As an overall solution provider for floating fish feed plants, Richi Machinery can not only provide a wide range of product models, but also focus on more needs of customers, from experimental research, process design, equipment supply, organization and construction, customer assurance, accessories supply to Customer training to create greater value for customers with expertise covering the entire process chain of floating fish feed processing.

Why Choose Richi Machinery?

In recent years, Richi Machinery has a professional manufacturing workshop responsible for the machining, casting, assembly of equipment, and the standardized production of accessories. It has nearly 100 sets of advanced large-scale vertical lathes, planers and other equipment, and has a complete set of modern metal cutting equipment, equipped with advanced Solidworks three-dimensional mechanical design system, simulation test system, and world-class production lines and modern testing bases.

All products are strictly design, production, assembly and testing are carried out in accordance with the international quality certification system standards, and have successfully passed ISO9001:2000, CE (European Union) and GOST (Russia) certification.

The continuous improvement of hard power provides a stronger guarantee for Richi Machinery to achieve higher goals, while the blessing of soft power makes Richi Machinery more firm in its core corporate values of “value co-creation and value sharing” with customers.

Richi Machinery has been focusing on the field of aquatic feed and floating fish feed for more than 30 years. With a deep understanding of floating fish feed machine and floating fish feed production line process, and long-term accumulation of equipment technology solutions, we can provide you with professional processing technology, solutions and a complete set of floating fish feed making machine.

Richi Machinery has continuously developed aqua feed mill equipment that leads the market demand in recent years, and the new technologies applied to these floating fish feed pellet machine have contributed to a substantial increase in the service life.

Supplementary Information Of Floating Fish Feed Production

How To Produce High Quality Floating Fish Pellet?

The advantages of floating fish feed are very suitable for modern aquaculture and have good market potential. Therefore, the majority of feed manufacturers should develop extruded floating feed varieties as much as possible.

High-end varieties should also be developed for the widely-raised four domestic fish, tilapia and other medium and low-grade varieties. At the same time, formula quality and production technology should be improved to expand production regulations, reduce floating pellet fish food production costs, and improve feed quality.

Main links affecting the production quality of floating fish pellet:

01 The Focus Of Product Processing Quality Control

The focus of extruded feed before extrusion is:

- whether the nutritional indicators meet the standard;

- whether the screening and removal of impurities is in place;

- whether the crushing particle size and mixing uniformity meet the standard;

- whether the cross-contamination prevention and control situation;

- whether the conditioning and maturation meets the standard, etc.

The focus is on the changes of nutritional indicators, pellet uniformity, specific gravity/floating rate, softening/water resistance time, pellet viscoelasticity after softening, powder content and appearance color.

02 Analysis Of Links Affecting Processing Quality

01

Recipe Of Raw Materials

The physical and chemical properties of raw materials, material pretreatment and formulation components will affect the processing quality of extruded materials. Specifically, the puffing quality coefficient of the raw material affects the puffing effect and puffing cost of the feed.

Whether the material is impurity-removed, whether the particle size meets the standard, and whether the pre-conditioning treatment is carried out will affect the puffing effect; and the starch, oil and crude fiber content of the feed formula are all in a certain extent, it determines the final effect of feed extrusion.

02

Floating Fish Feed Equipment

Host structure (uniaxial or biaxial, D:L value, distribution of spiral configuration), process equipment configuration (crushing, screening, drying and spraying) and extrusion die hole parameters (single hole structure and die hole area) will affect the quality of the extruded material.

03

Squeeze Operation

The amount of water and steam added will affect the pellet size and appearance and color of the product; considering the production capacity demand and actual output of the floating fish feed production line, attention should be paid to the control of filling degree and material residence time when adjusting the screw speed; and the control of extruding temperature and extruding pressure is directly determined. The starch gelatinization degree and puffing degree were measured.

04

Other Aspects

The wear and aging of the floating fish pellet machine and whether the operator is a novice will affect the quality of the extruded product to a certain extent.

This requires us to conduct operation training for novices before taking up the job and formulate a standardized operation manual for reference, and at the same time regularly track the wear of the screw, bushing and mold to decide later maintenance and replacement.

Want to produce high quality floating fish feed pellet? Feel free to contact Richi Machinry.

Characteristics Of Floating Fish Feed

The production of fish feed by extrusion floating fish pellet machine is an important research achievement in feed processing. The current floating fish feed making machine can produce floating, slow sinking and sinking feeds according to the needs of aquaculture production. Among them, the extruded floating fish feed has been well popularized and applied due to its special functions and functions that cannot be compared with sinking feeds.

The extruded floating fish feed is convenient for feeding and management

Because the extruded floating fish feed can float on the water surface for a long time, the feeder can observe the feeding situation of the fish well after feeding, and it is convenient to adjust the feeding amount according to the feeding situation of the fish; Changes and how fish come to the surface to feed to learn about their growth and health. Breeders can calculate the amount of bait to be fed according to the species, specifications, quantity, water temperature and feeding rate of the fish to be farmed, and feed them quickly, which not only saves a lot of time, but also improves labor productivity.

Extruded floating fish feed is beneficial to improve feed utilization rate

Due to the high temperature and high pressure processing conditions of extrusion and puffing, the starch in the feed is ripened, and the fat is more conducive to digestion and absorption, and the fiber structure and cell wall are destroyed and softened, and the gossypol in cottonseed meal and the antitrypsin in soybean are destroyed. and other harmful substances, thereby improving the palatability and digestion and absorption rate of the feed.

In addition, due to the physical and chemical changes in the extruding process, the extruded feed generally produces less than 1% of the powder, which directly improves the effective utilization of the feed. Under normal circumstances, the use of extruded floating feed for fish farming can save 5% to 10% of feed compared with powder or other pellet feeds.

The use of extruded floating fish feed can reduce the pollution of water quality

The extruded floating fish feed will not dissolve in the water for a long time, and the high-quality floating fish feed can float for more than 12 hours, and it is easy to observe and control when feeding, so as to reduce or avoid the impact of powder and remaining bait on the water body. pollution, which is extremely beneficial to environmental protection and the growth of fish.

Extruded floating fish feed has a wide range of application prospects. From the perspective of farming methods, extruded floating fish feed has a wide range of applicability, and floating fish feed can be used in pond fish farming, paddy field fish farming, running water fish farming, cage fish farming, industrial fish farming, and intensive farming on large water surfaces.

From the perspective of cultured species, whether it is freshwater fish or marine fish, except for a few benthic fish that are extremely difficult to domesticate to feed on the water surface, they can eat floating fish feed well. For species such as frogs and sea bass with special physiological functions, it is more convenient to use floating feed for breeding, and its superiority can be shown.

According to different species and different growth and development stages, we can produce extruded floating fish feeds that are suitable for their nutritional needs, which can well meet the needs of conventional aquaculture and special aquaculture for their feeds.

What kind of floating fish feed do you want to process? Tilapia feed? Catfish feed? carp feed? Herring feed? Eel feed? Salmon feed? Ornamental fish feed? Shrimp feed? Feel free to contact Richi Machinery for technical support.

Raw Material Selection For Floating Fish Feed

From the perspective of formula technology, floating fish feed can adjust the density and shape of feed, and can adapt to the world’s rich aquaculture species. At the same time, the puffing process improves the digestion and absorption rate of some raw materials, making the formula selection space and width wider. The complex processing technology of fish feed also puts forward higher requirements for raw materials. The following points should be paid attention to:

01

Pulverized Particle Size

The crushing particle size is very important for the extrusion process of floating fish feed. Coarse material crushing particles will reduce the expansion coefficient of the product and easily block the mold; it will affect the effect of pre-conditioning and extrusion mixing; it will cause great wear and tear on the floating fish feed making machine and high mechanical energy consumption; it will also make the appearance of the product pellets rough. Therefore, it is necessary to determine the most economical particle size according to the product grade and extrusion requirements.

02

Starch Content

Reasonable and slightly high starch content will increase the expansion coefficient and increase the floating water rate; make the extrusion operation width larger, and it is easy to stabilize the product quality; Improve pellet appearance quality. Better starch raw materials are high-gluten flour, corn flour and potato starch.

03

Crude Fat Content

For a single-shaft floating fish feed making machine, if the crude fat content of the raw material before extrusion exceeds 8%, the material will be poorly homogeneous during extrusion, the quality will be unstable, the viscosity of the product will be reduced, and the water resistance will be reduced; The force is reduced, and the floatation rate of the product is reduced.

Therefore, when the total fat content of the extruded floating feed exceeds 8% before extrusion, the excess oil should be added by spraying outside to reduce the impact on extrusion processing. It has been confirmed by production practice that high-fat raw materials are beneficial to improve the oil level. The minimum uniform external fuel injection is related to the particle size and surface smoothness. The smaller the particle, the easier it is to be uniform.

04

Crude Protein

The source and content of crude protein of raw materials have a great influence on the extrusion effect. Generally speaking, animal protein has a large difference in puffing performance, while vegetable protein has better puffing performance as a whole. Within a certain range, the crude protein content is increased, the friction coefficient is small, the equipment wear is reduced, the product is well organized, and the viscoelasticity is increased.

05

Raw Materials For Fur And Shell

The larger the proportion of raw materials such as cottonseed meal, coconut seed meal, rapeseed meal, etc. in the formula, the more difficult the material is to be crushed, and the crushing efficiency decreases linearly. The irregular shape of fur and shell raw materials is also difficult to fine screen, which easily leads to mold blockage and increased production failure rate. For products with many shell raw materials, the bubbles generated during processing are easy to burst, and the appearance of the product particles is poor.

06

Use Of Hydrophilic Raw Materials

Aquatic adhesives such as polymethyl urea, sodium polyacrylate, etc., monosaccharides or polysaccharides such as sucrose, fructose, pectin or agar, etc., generally decrease the gel-forming ability after extrusion, and the bonding effect is not obvious. The hydrophilic properties of water-based raw materials significantly reduce the extrusion shear force during the extrusion process, resulting in a smaller puffing degree of the finished feed.

Want to know if your raw materials are suitable for processing floating fish feed? Feel free to contact Richi Machinery for technical support.

The Formula Principle Of Floating Fish Feed

The characteristic of floating fish feed is that it is extruded and has a certain porosity so that the specific gravity of the feed is smaller than that of water and kept floating on the water.

However, different feed materials have different puffing degrees. For some raw materials, such as fish meal, the puffing coefficient is very low. If a large amount of fish meal is used in the formula, it may not puff up. Some raw materials have higher expansion coefficients, such as cornstarch. Therefore, the expansion coefficient of the overall formula should be considered in the formula design, so that the product can meet the expansion requirements.

In addition, the oil content in the floating fish feed production line puffing process also affects the puffing coefficient, and the oil is easily oxidized at high temperature, especially the fish oil in the special aquatic feed. Therefore, for floating feeds with high oil requirements, some oil can only be added by spraying after pelleting, but not all of them can be added during mixing. Generally, it is ideal to control the oil content below 8% during mixing.

We are committed to providing customers with a good service experience. Richi Machinery can customize floating fish machine configuration solutions for customers according to their needs. In addition, as long as you leave your email and requirements, our sales staff will get in touch with you as soon as possible to provide you with consulting services for various products.

Want to know more about floating fish feed formula? Feel free to contact Richi Machinery for technical support.

Storage Of Extruded Floating Pellet Fish Food

Due to the bulking effect, the extruded floating feed made by floating fish feed pellet making machine contains high porosity from the surface to the inside, so the diffusion rate of oxygen into the feed is many times faster than that of ordinary extruded pellets.

Therefore, extruded floating fish feed is more likely to deteriorate due to oxidation and moisture absorption than ordinary extruded feed. And the preservation conditions of extruded floating fish feed are more severe than ordinary extruded feed.

01

Backing Plate

The pad can separate the floor from the feed, which not only prevents the moisture from the wet floor from directly diffusing into the feed, but also facilitates the ventilation and keeping the feed dry.

02

Ventilation

The extruded feed is generally sprayed with oil, and this part of the oil is easily exposed to oxygen due to the many pores of the extruded floating fish feed. Therefore, the higher the temperature, the more easily the oil is oxidized and rancid. Secondly, the extruded feed is much more hygroscopic than the ordinary extruded feed, and any moisture in the warehouse space is easily absorbed by the feed. Therefore, it is very important to keep the warehouse dry with good ventilation conditions.

03

Shelf Life

Although the shelf life provided by the manufacturer is generally longer. However, in view of the characteristics of extruded feed that is easy to absorb moisture and easy to oxidize, it is best not to store it in the warehouse for too long, and it is generally best to use it up within 1 week. In addition, if it is stored in the warehouse for a long time, although it is still within the shelf life, it is best to check it carefully before using it. If you find a peculiar smell, it is best not to use it.

Use Of Extruded Floating Fish Feed

The extruded feed floats on the water surface, the feeding situation of the fish is clear at a glance, and it is easy to manage, which is the favorable side of the extruded feed. But the extruded feed is easy to absorb water, fluffy, and has a strong sense of satiety. Therefore, feeding slowly and for a longer period of time is more beneficial than fast feeding.

Secondly, after the extruded feed is sprinkled into the pond, it will quickly absorb the pond water. If the water quality of the pond is not good, the ammonia nitrogen and nitrite are too high, and the bacteria and algae are not good. feed, will greatly affect health, and even life-threatening.

In particular, algae in pond water produce some fat-soluble substances after aging, and these substances are often highly enriched on the oil film on the water surface. If extruded floating fish feed made by floating fish feed making machine is placed on the water surface with such oily film, a large amount of toxins may be absorbed in the feed.

Some fishes that are sensitive to toxins, such as eels, will refuse to eat (spit), while some fishes that are not sensitive to toxins or predatory fish are easily poisoned. There have been cases where channel catfish ingested extruded feeds that absorbed cyanobacterial neurotoxins in ponds. Cases of mass deaths after a few minutes of feeding.

Therefore, the use of extruded floating fish feed made by floating fish feed making machine requires higher water quality. If extruded feed is used in a pond with poor water quality, it is best to soak it with high-quality photosynthetic bacteria or EM bacteria solution first, and let it absorb water before feeding to avoid aquatic animals poisoning.

In Richi Machinery, “customer service” is not simple. Technical expertise and service are only basic requirements. Thinking about problems from the perspective of customers, creating value, and pleasing your heart are the pursuit. Either fighting alone or forming a “group”, we overcome all kinds of difficulties, act as a bridge between the company and customers, and meet the needs of customers. There are many types of floating fish feed making machine. When choosing, be sure to consult experts in floating fish feed, or learn about the situation from those manufacturers who sell floating fish feed machine.