WOOD PELLET MILL

We provide you with industry-leading wood pellet mill machine products and 0.3-90t/h complete wood pellet production line solutions.

Wood pellet mill is special pelletizer system for wood pellets production, which is built to the highest possible standards and designed to make your job easier, safer, and more efficient—and deliver you the best possible pellet, suitable for wood pellet plants, sawdust mills, furniture factories, power plants and other fields.

RICHI is one step ahead in the sector by designing a special machine for wood waste pelleting with its R&D studies on the wood pellet mill, which is the main machine of the wood pellet production process.

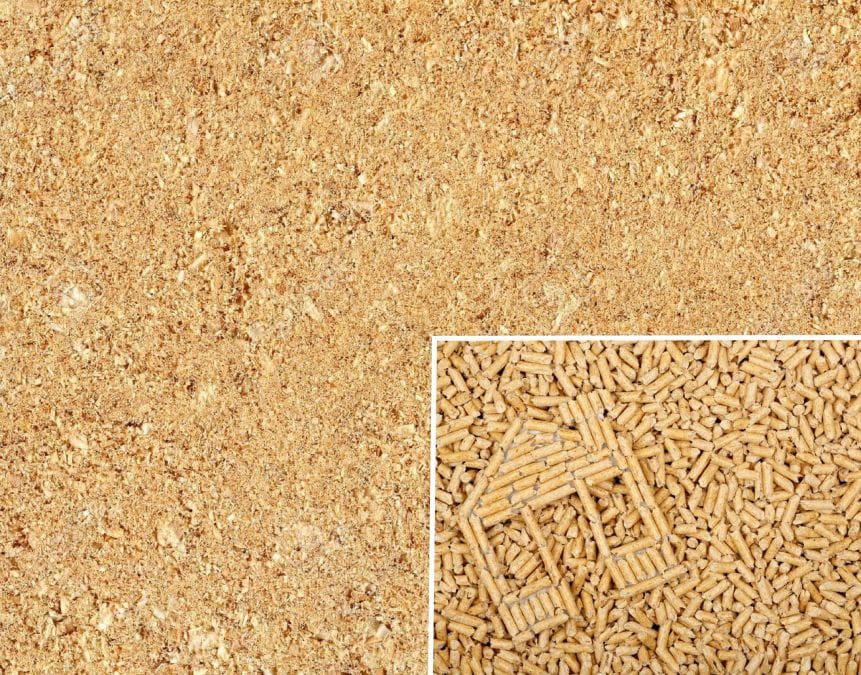

wood pellet mill machine

Whether it’s pounds of pellets per hour or tons of pellets per hour, you can depend on RICHI wood pellet mills to meet your toughest requirements. Your pellet maker will come loaded with features like our gear drive train. As a wood pellet mill manufacturer for more than 25 years, we professionally provide users with various series of ring die wood waste pelletizing machine for selection.

wood pellet mill with different models

Wood Pellet Machine For Sale

Efficiency, durability and safety are the attributes that best describe wood pellet machines. It has a wide range of applications, equipped with the latest technology and with maximum efficiency.

- Capacity: 0.3-0.4T/H

- Power: 37kw

Wood Pellet extruder Machine

Wood pellet extruder machines combine extremely efficient work processing with a particularly high level of operability and huge power. The use of high-quality branded components also ensures maximum reliability.

- Capacity: 0.5-0.7T/H

- Power: 55kw

Wood Pellet Maker For Sale

Wood pellet makers are stable, safe and environmentally friendly. These machines process wood pellets efficiently and flexibly, offering the ideal combination of cost-effectiveness, ruggedness and environmentally friendly operation.

- Capacity: 1.0-1.2T/H

- Power: 90kw

Wood Pellet press For Sale

With a wood pellet press, you can process high-quality wood pellets that comply with ENplus standards efficiently, safely and reliably. You can choose to use a single wood pellet mill or a complete wood pellet system.

- Capacity: 2.0-2.5T/H

- Power: 132kw

Wood Pelletizer For Sale

Wood pelletizer is the perfect solution for wood pellet processing. WThanks to state-of-the-art technology and proven RICHI quality, you can handle challenging pelletizing tasks in the wood pellet industry reliably and precisely.

- Capacity: 2.5-4.0T/H

- Power: 250kw

Wood Pelletizer Machine

Wood pelletizer machine is a multifunctional pellet equipment that can be deployed where there are large amounts of biomass wood materials. It is a real powerhouse that impresses for its high efficiency and cost-effectiveness.

- Capacity: 3.0-4.5T/H

- Power: 280kw

wood pellet mill for different application

waste wood pellet machine

With strong reliability and ease of operation, your RICHI wood pellet machine is suitable for all wood waste and different applications, and is backed by the best service and support teams in the wood pellet making industries. You won’t find a better pellet machine anywhere.

wood pellet production line

During the research and development process of RICHI wood pellet mill equipment, in addition to the stand-alone machine, we also focused on the configuration of the overall solution for the complete wood pellet mill plant. In order to give full play to greater production line efficiency and closely integrate with market demand, RICHI provides customized pellet production line services. We provide you with one-stop solutions of different sizes for different application scenarios, material size and moisture.

Complete wood pellet mill plant solution

small wood pellet plant

The wood pellet expert around you creates an integrated complete set of 0.3-1t/h small wood pellet plant solutions.

wood pellet line

Independently developed 1-2t/h complete wood pellet line equipment to fully meet the current and future needs of customers.

wood pellet plant design

Based on customer needs and actual working conditions, we provide a more reliable wood pellet plant with professional technology.

complete wood pellet plant

RICHI is committed to global complete wood pellet plant solutions, including chippers, crushers, dryers, granulators, coolers, screeners, etc.

wood pellet processing equipment

Wood pellet plant includes a series of equipment such as crushing and pelleting, forming a complete closed industrial chain of pellet equipment.

wood pellet processing plant

RICHI’s wood pellet processing plant solution truly realizes a complete set of sustainable products in the field of pellet processing.

wood pellet production plant

6-7T/H wood pellet production plant covers sawdust, wood chip, log pellet line, etc., targeting the global wood pellet market.

wood pellet making equipment

Wood pellet mill plant solves customers’ personalized problems in environmental, site, process, etc., and fully meets customized needs.

wood pellet manufacturing equipment

RICHI carefully develops complete wood pellets equipment to form a complete set of 8-10t/h solutions with high efficiency and safety.

wood pellet factory

The 12-15T/H wood pellet factory solution can solve the inefficiency hazards and cost challenges caused by traditional processing methods.

wood pellet manufacturing plant

Wood pellet manufacturing plant meets the wood pellet production needs of different fields such as biomass fuel pellet factories, lumber factories, sawdust factories, and furniture factories, etc.

wood pellet making line

The commercial wood pellet mill can meet the wood pellet processing needs of various scales, various raw materials, and various plant spaces. The equipment has high efficiency, safety and stability.

turnkey wood pellet mill

RICHI is committed to creating complete sets of wood pellet line solutions for customers, with projects covering major markets such as Indonesia, the United States, Canada, and Germany.

large wood pellet mill

In response to global energy demand, RICHI provides complete large wood pellet mill solutions, and can flexibly configure a series of equipment according to customers’ actual conditions.

How to make wood pellets from different wood waste?

how to make wood pellets?

How do you make wood pellets? What are your raw materials? Sawdust, shavings, chips, logs or pallets? Cost leadership, value is king, condense value recognition, and provide customers with customized wood pellet mill plant solutions for different wood raw materials!

turning sawdust into pellets

turning wood logs into pellets

turning wood chips into pellets

turning branches into pellets

turning wood pallet into pellets

turning leaves into pellets

supporting equipment for wood pellet mill plant

As an indispensable part of the wood pellet production line, Richi Machinery has also made great efforts in auxiliary equipment such as slicing, crushing, drying, screening and packaging. It has successively developed wood chipper machines, wood sawdust making machines, drying barrels, and template crushers and screening machines, wood pellet bagging machines and other equipment.

wood pellet mill projects

Richi Machinery enjoys a high reputation in more than 140 countries and regions around the world, and has won the trust of many brands and companies around the world with its high-quality products and services!

Countries

Customer Visit

wood pellet mill videos

set up your wood pellet mill plant

Your funds and budget are the first things to consider in your wood pellet mill plant construction. Your budget tends to tell the scale of the wood pellet plant regarding large size or small scale. In case you do not have sufficient funds, then consider lowering your capacity. Consequently, you can get even lower some relatively unimportant equipment. However, in cutting cost, it is never advisable to substitute the necessary equipment with low price and low-quality ones. You might end up regretting the move.

Your workshop is another thing that you need to consider in wood pellet mill line construction. In fact, the funds available to you will tend to determine your workshop size in that the higher the resources, the bigger the workshop you can build. Again, consider having your wood pellet plan design near your raw material to ensure that you cut the cost of raw material transportation. Consequently, if you have a workshop, determine its height, width, and length. Consider then designing your wood pellets depending on your workshop size to ensure it is enough to lace the equipment.

Please provide us with wood pellet mill plant project information as much as possible:

1

For a complete wood pellet mill plant project: the raw material availability, the required production capacity, the process technology, your budgetary and financing status, the estimated starting time, etc.

2

For single wood pellet mill machine: the model, the capacity, your budget information, other requirements, etc.

3

For spare parts: size and dimensions, material and weight, and your drawings with details, you can send the drawing to [email protected].

About RICHI MACHINERY

Founded in 1995, Richi Machinery is mainly engaged in the R&D and manufacturing of pellet plant equipment required for industry projects such as animal & aqua & pet feed, biomass agricultural and forestry waste utilization, organic fertilizer, pet litter and urban waste.

All products have passed ISO international quality system certification, EU CE certification and Customs Union CU-TR certification.

At present, the marketing network of Richi Machinery has spread to more than 140 countries and regions in Asia, Africa, Europe, America and Oceania, and has established overseas offices in many countries.

Consultation and Tailor-made design

Equipment manufacturing and testing

Equipment packaging & delivery

Equipment installation & Training

1

Do You Provide A Layout Diagram Of The Entire wood pellet mill Factory?

We will provide a series of drawings such as the entire wood pellet mill plant layout, equipment layout, and steel frame drawings. We can provide everything mainly needed to install the pellet plant.

2

Are You A wood pellet mill Manufacturer?

Yes, we are wood pellet machine and complete wood pellet production line equipment manufacturer, not a middleman. All equipment prices are ex-factory prices.

3

Can You Test The wood pellet mill Machine Before Shipping?

All RICHI wood pellet equipment supports trial service. This is for customers and even more for the RICHI brand.

4

Can You Provide Installation Services?

We provide installation and commissioning services for all wood pellet plant equipment, and will be responsible for all after-sales technical support services!

5

Can You Provide Turnkey Service ?

We offer a complete turnkey wood pellet mill plant service including project consultation, site survey, sample analysis to plan design, manufacturing, delivery, installation and commissioning, and maintenance guidance to ensure that all links are in place with customers in a timely manner solve customer needs.