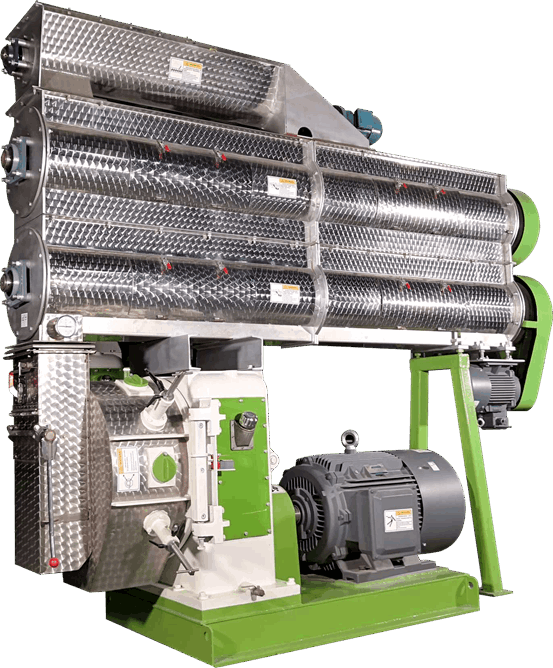

Commercial Feed Pellet Mill

SZLH768 commercial feed pellet mill has been developed for high-capacity animal feed pelletizing. Its direct drive system eliminates the need for a transmission system, lowering energy consumption by up to 10%, whilst delivering operational and maintenance benefits.

- Model: SZLH768

- capacity: 25-40T/H

- power: 250/280KW

- Price: FOB 70,000-80,000 USD

This commercial feed pellet machine is usually used in large poultry feed production lines, cattle feed production line, livestock feed production lines, chicken feed mill plant, fish feed production lines, shrimp feed mills, broiler feed mills, pig feed mills, sheep feed mills, etc.

At RICHI Machinery, we design complete turnkey commercial feed pellet mill systems for all of your pellet processing needs. Because we design, engineer, and build each system ourselves, we can have you up and running in under 24 hours once delivered, on site. We also offer a complete animal feed pellet production line of ancillary equipment including feed grinder, feed mixers, conveyors, pellet coolers, pellet crumbler, silos, and more.

Features of SZLH768 commercial feed pellet mill

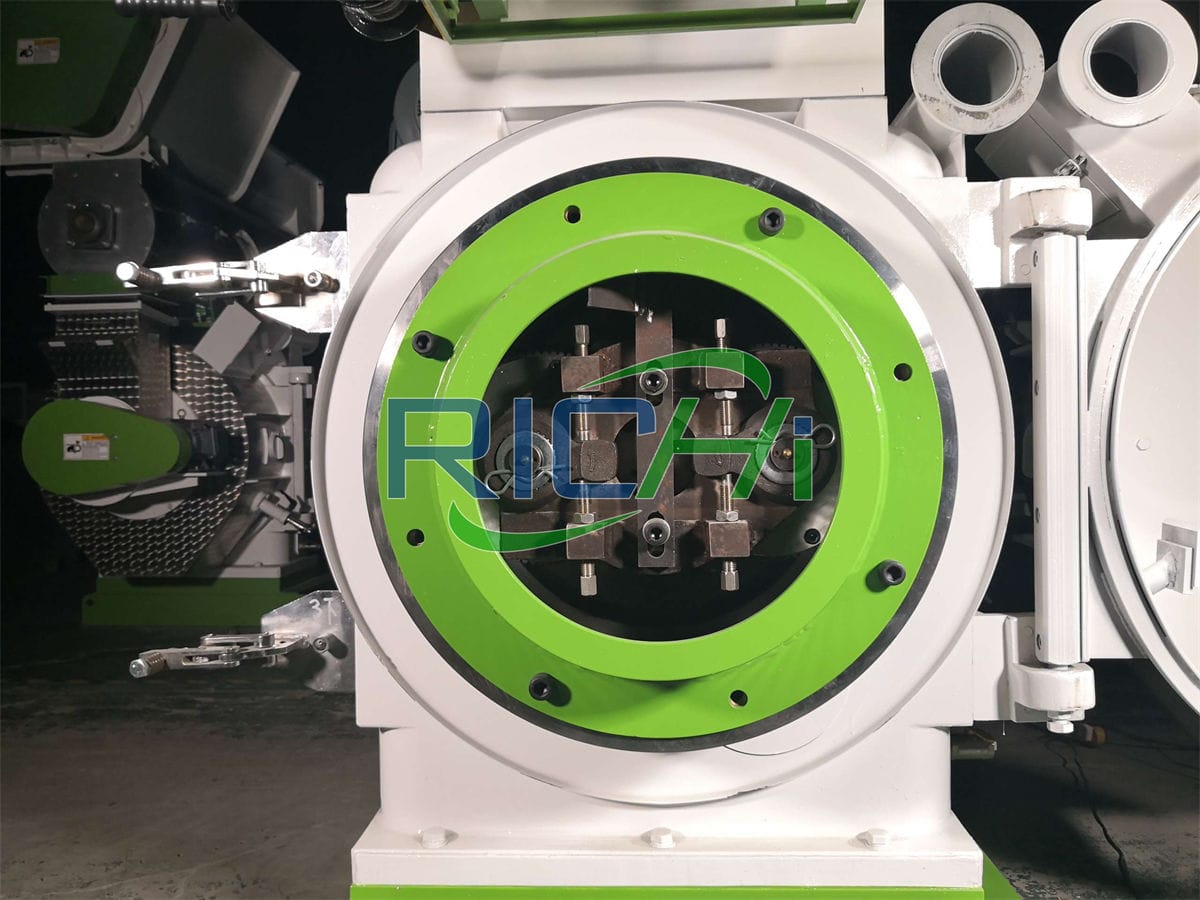

- The main drive adopts high-precision gear drive, and the ring die adopts quick-release clamp type, which increases the output by about 20% compared with the belt drive type;

- The transmission part of the whole commercial feed pellet mill machine (including the motor) uses high-quality bearings from Switzerland and Japan to ensure effective, stable and low noise transmission;

- The all-stainless steel enlarged reinforced feed conditioner adopts frequency conversion speed control to ensure high quality of pellet feed;

- The feeder adopts an “O-type” cylinder, which not only improves the uniformity of feeding, but also effectively prevents steam from rising.

- The alloy steel ring die is made of the internationally advanced German gun drill and American vacuum furnace heat treatment manufacturing process, with long service life, smooth pellets and high quality;

- The internationally advanced level of compensation type snake-shaped spring coupling has a novel structure, compactness, stability, low noise and low fault performance;

- High-performance permanent magnetic magnet device;

- Adopting internationally advanced piping system and pressure regulating valve;

- Advanced supporting products, such as countercurrent cooler, rotary grading screen and advanced fine-toothed pelletizer, can achieve good feed pellets;

- Double-layer and three-layer conditioner pelletizers can be customized to produce high-quality livestock and poultry aquatic feed.

Advantages of SZLH768 commercial feed pellet mill

01 Suitable for a wide range of recipes

The SZLH768 commercial pellet mill can process even the most difficult feed recipes with a high fat or high fiber content.

02 High productivity

The SZLH768 feed pellet mill is a highly efficient mill, capable of producing up to 40 tons of 3-4 mm pellet poultry feed per hour.

03 Low energy consumption

The SZLH768 commercial feed pellet machine has a direct gear drive, where the motor is directly connected to the main shaft without a transmission system. This can reduce your energy consumption by up to 10%.

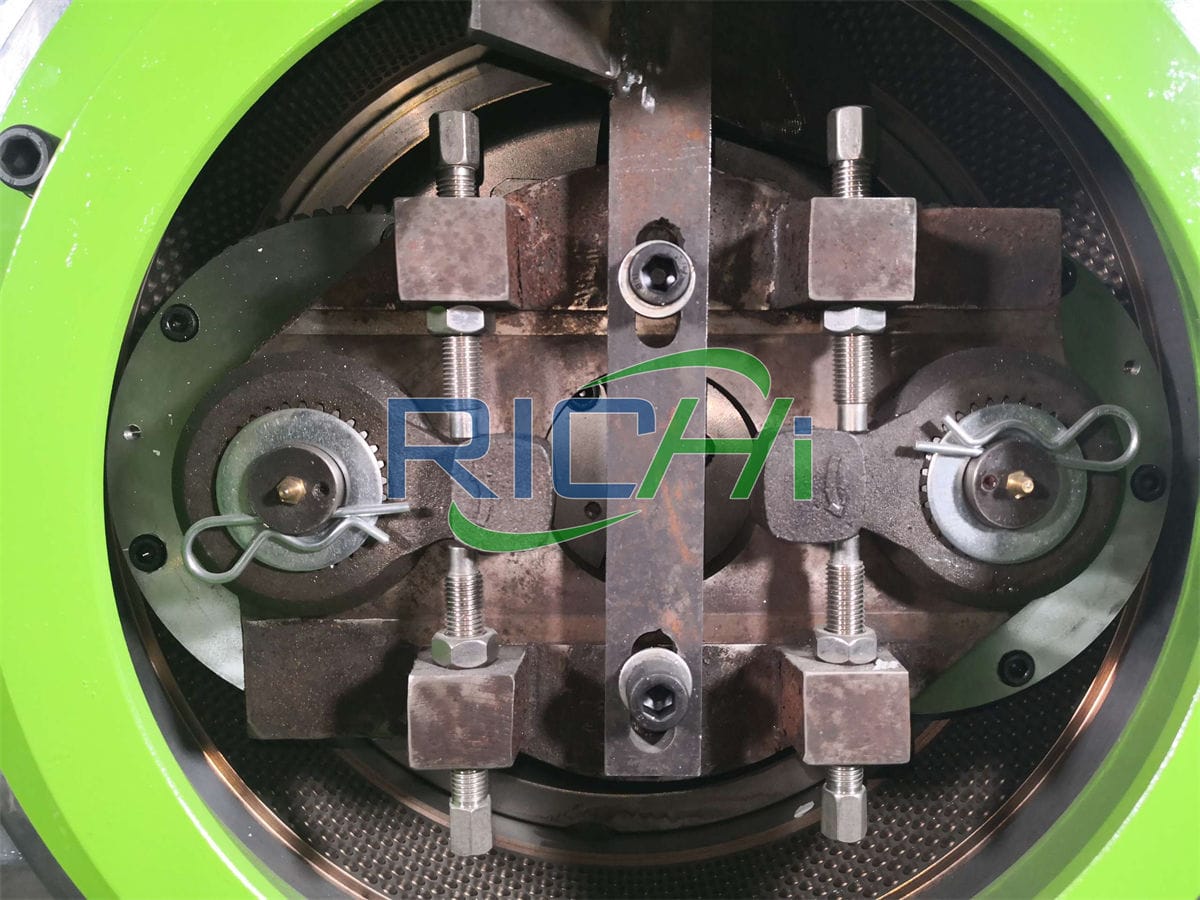

Working principle of SZLH768 commercial feed pellet mill

The modulated crushed material is fed from the chute through the die cover, and with the help of gravity, the centrifugal force generated by the rotation of the ring die, and the action of the feeding scraper, it is evenly fed into the two pressing areas in the ring die, that is, the wedge-shaped space formed by the two pressing rollers and the ring die.

Under the strong extrusion of the ring die and the pressing roller, the material is gradually compacted, squeezed into the die hole of the ring die and formed in the die hole.

Since the extrusion of the material between the die and the roller is continuous, the formed material is continuously discharged from the die hole in a columnar shape and then cut into pellets of the required length by the cutter.

Specifications of SZLH768 commercial feed pellet mill

| model | SZLH768 |

| Output (t/h) | 25~40 |

| Main motor power (kw) | 250/280 |

| Main motor series | 4P |

| Feeder power (kw) | 2.2 |

| Conditioner power (kw) | 11 |

| Ring die diameter (mm) | 762 |

| Finished pellet diameter (mm) | 2~12 |

configuration of SZLH768 commercial feed pellet mill

- Ring die material: stainless steel

- Door cover of granulation room: 6mm /SUS304

- Feed chute: 3mm /SUS304

- Gear box: HT250

- Gear: 42CrMo

- Gear shaft: 20CrMnTi

- Spindle: 42CrMo

- Empty shaft: 42CrMo

- Bearing: Import

- Oil seal: Germany/Taiwan

- Overload mechanical protection: safety pin

- Serpentine spring coupling drive

- Using Siemens Motor

operation requirements of SZLH768 commercial feed pellet mill

| Animal feed types | Requirements Before Entering Granulator(mm) | Pellet Diameter(mm) | Pellet Length(mm) | Ring Die Compression Ratio | Conditoning Temperature(℃) | Conditoning Time(s) | Equipped Conditioner |

| Poultry chicken | 2.0-3.0 | 2-4 | 4-8 | 1:10—-1:13 | 150 | 60-120 | one layer/two-layer |

| Cattle | 3-5mm | 6-12 | 12-18 | 1:6:1:9 | 150 | 30-60 | one layer/two-layer |

| pig | 2-3 | 2-4 | 3-8 | 1:3.5—-1:5 | 150 | 60-120 | One layer/two layer |

| fish | 1.0-2.0 | 2-6 | 4-12 | 1:16—-1:18 | 150 | 90-180 | Two layer/three layer |

| shrimp | 95%≥80 mesh | 1.2-2.0 | 1.8-4 | 1:20—-1:25 | 150 | 120-180 | three layer |

| … | |||||||

commercial feed pellet mill projects

commercial feed pellet mill for sale Russia

- commercial pellet machine selection: SZLH768

- Feed Size:1-5mm pellets

- Poultry Feed Plant cost: 650,000 USD

commercial feed pellets mill for sale Mexico

- commercial pellet machine selection: SZLH768

- Feed Size: 2-4mm pellets

- Poultry Feed Plant cost: 750,000 USD

commercial feed pellet machine for sale India

- commercial pellet machine selection: SZLH768

- Feed Size: 4-8mm pellets

- Poultry Feed Plant cost: 820,000 USD

commercial feed pellet mill for sale Indonesia

- commercial pellet machine selection: SZLH768

- Feed Size: 3-6mm pellets

- Poultry Feed Plant cost: 540,000 USD

commercial feed pellet press for sale Algeria

- commercial pellet mill selection: SZLH768

- Feed Size: 2-8mm pellets

- Poultry Feed Plant cost:520,000 USD

commercial feed pellet granulator for sale Vietnam

- commercial pellet machine selection: SZLH768

- Feed Size: 3-6mm pellets

- Poultry Feed Plant cost: 800,000 USD

commercial feed pellet machine for sale Saudi Arabia

- commercial pellet mill selection: SZLH768

- Feed Size: 2-5mm pellets

- Poultry Feed Plant cost: 700,000 USD

commercial feed pellets mill for sale Pakistan

- commercial pellet machine selection: SZLH768

- Feed Size: 2-4mm pellets

- Poultry Feed Plant cost: 730,000 USD

Application of SZLH768 commercial feed pellet mill

SZLH768 commercial feed pellet mill machine is mainly used for feed production lines above 25 tons.

The components of a complete animal feed pellet line can be turnkey made, since RICHI Machinery is professional in making animal feed processing plans, we can give you the most suitable feed pellet production Business Plan.

All the machines used in the pellet plant are strictly developed and manufactured to guarantee premium quality. You can choose it for making many kinds of animal feeds, such as cattle, dairy cow, goat, sheep, horse, pig, chicken, broiler, duck, rabbit, fish, goose, etc.

We have experienced engineers for overseas installation and comissioning. We will also train your workers on how to operate the animal feed mill equipment.

If you want to get a 25-40t/h animal feed production line solution, click the button below to get a detailed solution design, feed mill equipment configuration list and production line quotation.

Video of commercial feed pellet mill

FAQs of commercial feed pellet mil

How much does a SZLH768 commercial feed pellet mil cost?

The price of a SZLH768 commercial feed pellet mill is generally between FOB 70,000-80,000 USD.

The price of a commercial feed pellet mill varies depending on factors such as brand, model, and configuration. Generally speaking, the price of domestic equipment is relatively low, while the price of imported equipment is higher. The following are the main factors affecting the animal feed pellet machine price:

- Equipment materials and manufacturing processes: The material and manufacturing process requirements of the animal feed pellet mill are relatively high, such as the need to withstand high-pressure water flow and high-precision cutting requirements, so the equipment cost is relatively high.

- Technical level: The pelleting technology of the ring die feed pellet machine is relatively complex, and equipment research and development and production require a lot of funds and technical support, so the technical level is also an important factor affecting the price of the commercial feed pellet equipment.

- Equipment configuration: The configuration of the commercial pellet mill is also a factor affecting the price, such as the quality and configuration of core components such as the ring die, roller, bearing, motor, conditioner, and forced feeder.

- Market supply and demand relationship: The supply and demand relationship is also a factor affecting the price of the commercial feed pellet mill. If the market demand is greater than the supply, the equipment price may rise; conversely, if there is an oversupply, the price may fall.

How to choose a commercial feed pellet mill

1. Understand your needs

Before purchasing a commercial feed pellet making machine, you must first clarify your specific production needs, such as the types of products, production volume, process flow, etc. Only by understanding your needs can you choose equipment in a targeted manner.

2. Consider the quality of the equipment

The quality of the commercial feed pellet mill machine is directly related to production efficiency and product quality. Therefore, when purchasing equipment, you should pay special attention to the quality of the equipment and choose equipment produced by heavyweight brands and manufacturers.

It is best to choose equipment produced by manufacturers with a good reputation and ISO9001 quality certification.

3. Comprehensively consider the function and price of the equipment

In addition to considering the quality of the commercial feed pellet making machine, you should also fully consider the function and price of the equipment. Generally speaking, good equipment should have multiple functions and be reasonably priced. If the price is too low, it may hide some quality risks and is not recommended for purchase.

4. Understand after-sales service guarantee

After-sales service guarantee is also an important thing. Good after-sales service can make you more assured during the operation process. Therefore, when purchasing a commercial feed pelletizer mill, you should consider good after-sales service so that you can get timely technical support and service when you encounter problems in daily use.

5. Read more reviews

If you have no experience in the relevant field, you can learn about the reputation and experience sharing in the field through tools such as question-and-answer communities, blogs, and forums in the relevant field.

Reading more reviews and word of mouth can better understand the advantages and disadvantages of the equipment and its scope of application.

The above are the things you need to pay attention to when purchasing a good feed pellet machine. In short, choosing a good commercial feed pellet mill equipment requires comprehensive consideration of multiple aspects.

Don’t just focus on price, but ignore the importance of quality, function and after-sales service. At the same time, you must purchase from regular manufacturers and sales channels. (Find RICHI on youtube)

How to choose a commercial feed pellet mill manufacturer?

1. Standardized operating procedures

The operating procedures are the basis for ensuring product quality. When choosing a commercial feed pellet mill you must have a certain understanding of the operating procedures of the animal feed mill plant.

2. Implementation of conventional processing standards

As for processing standards, any enterprise engaged in commercial feed pelleting machine processing should pay attention to this. Processing standards are the guarantee of accuracy after the product is made. Only when they meet the standards can qualified products be manufactured.

3. Quality of workpiece delivery

The quality of workpiece delivery is the most intuitive way to reflect the strength of the commercial pellet mill manufacturer. To consider the quality of workpiece delivery, you can get to know the companies that have cooperated with the machining plant before. Ask them whether the surface quality and size of the workpieces they received are the same as the drawings.