0.3-1 T/H Small Wood Pellet Plant solution

Small wood pellet plant is a wood pellet production system of less than 1 ton per hour, which usually covers slicing, cleaning, crushing, drying, granulating, cooling, screening, packaging and other processes. The entire small wood pellets plant adopts modular equipment, which can be customized according to the actual needs of customers.

Cost: 30,000-150,000 USD

Small Wood Pellet Plant Solution

Why Start Small Wood Pellet Plant? The use of wood fuel and other biomass agricultural waste in order to produce renewable energy is one of the most important challenges in order to achieve sustainability in the world we live in.

With its care about sustainability, Richi Machinery has been building and testing for years, under the most harsh operative conditions, a whole range of hi-tech wood pellet machinery and small wood pellets plants for the processing of wood and agricultural waste.

01 Features of Small Wood Pellet Plant

- The whole small capacity wood pellet production plant is equipped with an integrated control cabinet, more easy and convenient to control the working conditions.

- Various materials can be mixed together to make biomass pellets such as agricultural / harvest residues like Wood, Sawdust, Shaving, Bamboo, Empty Fruit Bunches (EFB), Oil Palm Fronds (OPF), Rice husk, Straws, Bagasse.

- Heavy duty design wood pellet maker machine.

- Lowest operating costs.

- Highest efficiency and operation safety.

02 Small Wood Pellet Plant Cost

30,000-150,000 USD

Equipment needed to start Small wood pellet plant

Wood Hammer Mill

Capacity:

3-25T/H

Main Power:

30-160KW

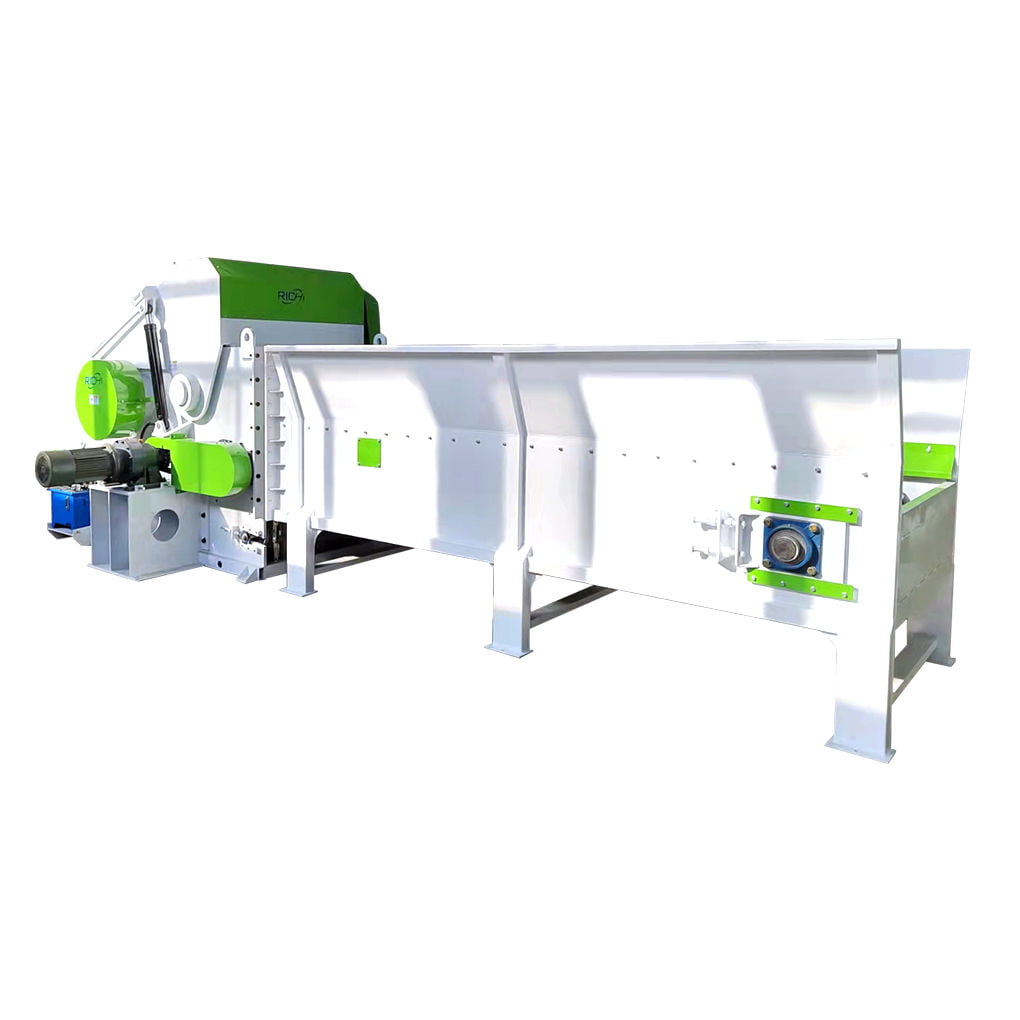

Pallet Shredder

Capacity:

3-12T/H

Main Power:

50-110KW

wood pellet screen Machine

Capacity::

3-20T/H

Main Power:

1.5-5.5KW

wood pellet Production plant projects

10T/H

Wood pellet mill plant in united states

2T/H

wood pellet plant for sale poland

2-2.5T/H

wood pelletizing plant in romania

5T/H

wood pellet production line in austria

Small Wood Pellet Plant Business Plan

There are huge business potentials to start wood pelletizing plant. Not only can one outsource to individuals or small communities, but also big corporations and industries. The selection of the right wood pellet manufacturing equipment and technology for a wood pellet plant is critical when establish your own biomass fure wood pellet manufacturing business.

Next, I will list two wood pellet line projects we have done for you, hoping to help you.

【Featured Case 1】: 300KG/H small wood pellet plant project

The customer is a company specializing in the production of fuel, and the land used by the company is leased land. The entire plant covers an area of 1200m².

The total investment of this small scale wood pellet production project is $70,000, the enterprise covers an area of 1200m², and the total construction area is 1100m². The project content mainly includes production workshops, office rooms, etc. The project components are shown in the following list:

- Production Workshop: The construction area is 700m², mainly for crushing, drying, granulating and packaging production processes, 1F (built, steel frame structure);

- Warehouse: The construction area is 300m², mainly for raw materials and finished product storage, 1F (built, steel frame structure).

- Office room: The construction area is 100m² (mainly office and rest area), 1F (built, brick-concrete structure).

Product plan and scale

| Product name | Capacity |

|---|---|

| Biomass wood pellets | 800t/a, 300kg/h |

Main equipment needed in the 300KG/H small wood pellet plant

| Device Name | Number of Devices |

|---|---|

| Wood crusher | 2 |

| Sieve shaker | 1 |

| Drying oven | 1 |

| Wood pellet mill | 1 |

| Packing machine | 1 |

| Conveyor belt | 1 |

Consumption of main raw and auxiliary materials

| Name | Annual Consumption | Remarks |

|---|---|---|

| Sawdust | 912 tons | Outsourcing |

| Packaging bag | 1600 | Outsourcing |

| Electricity | 200,000 kW·h/year | Local Power Supply Bureau |

| Water | 1350m³/a | Local water supply network |

| Oven biomass fuel | 200 tons | Self-produced |

Public works

- Water supply: The water used in the 300kg/h small wood pellet plant project will be used for township water supply, which can meet the production and living needs of employees. (Related product: wood pellet machine for sale)

- Power supply: The project is powered by townships, which can meet the production and living needs of the project.

- Drainage: Rain and sewage diversion is implemented, and rainwater enters the rainwater ditch around the factory area and is discharged; no production wastewater is generated and discharged during the operation of the project, and the main wastewater comes from the domestic sewage of employees.

The domestic sewage of this project passes through grease traps and septic tanks. The pond treatment facility will irrigate the surrounding woodland after reaching the dry farming standard.

Labor quota and work system

- Employees: There are 8 project employees who are nearby residents.

- Working system: The annual working hours are about 300 days, with one shift per day and 8 hours per shift.

300KG/H small wood pellet plant process design

01 Crushing and screening:

The biomass wood pellet fuel production of the project mainly uses sawdust, sawdust, etc. as raw materials, and the raw materials are purchased from outsiders.

The purchased raw materials are crushed and screened, and the unqualified screened materials are returned to crushing; (Maybe you are interested in solution: 2.5T/H wood pellet plant)

02 Drying:

The raw material contains a certain amount of moisture, and the raw material that meets the size requirements after crushing is dried in a drying furnace. The drying furnace uses biomass particles as fuel and is indirectly heated.

This process is carried out in a closed manner. (The project has a drying furnace for burning biomass briquettes, which is self-built under the guidance of RICHI.

The annual working time is 300 days, 8 hours a day, and the biomass briquette fuel burned by the drying furnace is 83.33kg/h per hour. The fuel adopts the biomass briquette fuel produced by the customer, and the annual consumption of biomass pellet fuel is 200t.)

03 Granulation:

The dried raw materials are dropped vertically on the surface of the wood pellet granulator frame plate from the feed port, and the material is continuously and evenly distributed on the surface of the inner cavity of the mold (the contact surface between the pressure roller and the mold) through the rotation of the frame plate.

The powdery material passes through the holes of the mold (evenly distributed on the inner surface of the mold) under the rolling. In this process, the material is subjected to high pressure and high temperature, which makes the powder particles form a continuously elongated cylindrical solid body.

The cylindrical solid body continues to elongate until it is cut by the cutter around the uniform mold, forming pellets of a certain size, scattered on the The pellets around the mold are concentrated to the discharge port by the pulling teeth, and the pellets fall automatically under the action of gravity. At this point, the pressing process of the pellets is completed.

04 Packaging:

Check and weigh the pellets fuel, and pack it into the warehouse or sell it out if it passes the test.

Environmental Engineering

(1) Exhaust gas treatment:

Crushing, screening, granulating dust: The 300kg/h small wood pellet processing plant project sets up a dust collection hood to collect dust in the crushing, screening, and granulating processes, and leads it to the bag filter through pipelines. After treatment, it is discharged from the 1#15m high exhaust pipe, and the gas The collection efficiency of the hood is 95%, the air volume is 2000m³/h, and the dust removal efficiency of the bag filter is 99%.

Exhaust gas from the drying furnace: After cooling, the flue gas from the drying furnace of the project is dedusted by a bag filter (efficiency 95%), and then discharged from a 20-meter-high chimney at high altitude.

(2) Wastewater treatment

The domestic sewage of this project will be used to irrigate the surrounding woodland after being treated by the grease trap and septic tank sewage treatment facilities, and will not be discharged outside.

(3) Noise reduction

Plant sound insulation, foundation shock absorption, distance attenuation, air absorption and other measures.

(4) Solid waste treatment

The project sets up a general solid waste temporary storage room with an area of 6 square meters and a volume of 12 cubic meters in the southeast corner of the production workshop. Set up trash cans and separate disposal of solid waste.

Case 2: 750KG/H small wood pellet plant project

The project is a 750kg/h biomass pellet construction project. The customer leases the existing vacant factory building for construction. The project covers an area of about 2000m², of which the construction area is about 1600m². After completion, the annual production of material shaped particles is 1500 tons.

- Project investment: The total investment is $120,000;

- Production system and number of employees: The project has a fixed number of 5 employees, all of whom do not have board and lodging in the project; work 8 hours a day, 250 days a year;

- Planning layout: The construction content of this project mainly includes production area, office area and warehouse.

- Stacking of raw materials: The amount of raw materials used in this project is relatively large, and the required storage capacity in the general factory area is about 300t. The raw materials of the project are stacked in the raw material warehouse, not in the open air, and the material stacking in the raw material warehouse is covered with dust-proof cloth and other windproof measures.

Main Raw and Auxiliary Materials

The 750kg/h small wood pellet plant project not only used sawdust as raw material, but also purchased a large amount of straw waste in order to reduce the cost of raw materials.

| Name of raw and auxiliary materials | Annual usage | Source |

|---|---|---|

| Wood sawdust | 1000 tons | Outsourcing (sawmill) |

| Straw | 510 tons | Outsourcing (farm) |

Raw material requirements: no gravel, iron filings, sediment, plastic and other impurities.

Main equipment needed in 750KG/H small wood pellet plant

The main production equipment of this 750kg/h small wood pellet plant project is shown in the table below:

| No. | Device Name | QTY |

|---|---|---|

| 1 | Wood pellet machine | 2 |

| 2 | Wood pellet hamer mill | 1 |

| 3 | Slicer | 1 |

| 4 | Packing machine | 1 |

750KG/H small wood pellet plant process flow

- Crushing: The purchased raw materials are loaded by the loader to the conveyor line, transported to the crusher by the belt for crushing, and the crushed material is sent to the warehouse for storage by the conveyor belt. Due to the high moisture content of raw materials, the amount of dust generated is small, about 0.04% of the raw materials. The amount of raw materials used in this project is 1510t/a, and the amount of dust generated is about 0.604t/a. The annual production time is 250 days, one shift per day, If the working time is 8 hours, the dust generation rate is 0.3kg/h.

- Pelleting and forming: The wood pelletizer is the key equipment of the wood pellet production line. The crushed raw materials pass through the wood pelletizer machine in a closed environment to form finished biomass fuel pellets with a diameter of 8mm and a length of 20~40mm.

- Packaging: The pressed and formed products are packaged after passing the inspection and transported to the finished product warehouse, and the unqualified products are returned to the crushing production line for reprocessing.

Construction Content

- Production area:Processing raw materials, covering an area of 900 m²;

- Warehouse:Raw material and product warehouse, covering an area of 550 m²;

- Office area:Office space, covering an area of 150 m²;

- Water supply:From the local water supply network;

- Power supply:Supplied by the municipal grid;

- Heating:Project production does not require heating, and the office area is cooled and heated by air conditioners;

- Exhaust gas:The dust generated in the production process is processed through the bag filter that comes with the equipment, and at the same time, it is prevented by strengthening the mechanical ventilation of the workshop;

- Wastewater:No water is needed in the production process, and no production wastewater is discharged; domestic sewage is used for irrigation of surrounding forests after being treated in a three-stage septic tank;

- Noise:Noise reduction measures such as sound insulation, vibration reduction, and noise reduction;

- Solid waste:Household waste is handed over to the environmental sanitation department for unified removal and disposal; cloth bags collect dust and defective products and return them to production.

Public works

01 Water supply:

No water is needed during the production process of this 750kg/h small wood pellet plant project, and no production wastewater is generated. The number of employees in this project is 5, and none of them have board and lodging in the project; the working system is 250 days a year, 8 hours a day.

02 Drainage:

There is no production wastewater in this project; the domestic water consumption of employees is 0.2m3/d, and the domestic sewage production is calculated as 90% of the domestic water consumption, so the domestic sewage production is 0.18m³/d, 45m³/a. Domestic sewage is treated by three-stage septic tank. After reaching the farmland irrigation water quality standard, it will be used to irrigate the surrounding woodland.

03 Power supply:

The electricity used in this project is supplied by the municipal power grid.

04 Heating:

This project does not require heating and cooling, and the office area uses air conditioning for heating and cooling.