Compost Granulating Machine

MZLH520 compost granulating machine is mainly used in granular organic fertilizer processing systems with an output of 7-8 tons per hour.

- Capacity:7-8T/H

- Price: 40,000-50,000 USD

- Application: Organic fertilizer factory, compound fertilizer factory, chemical fertilizer factory, breeding farm, sugar factory, sewage treatment plant, waste disposal site, food processing plant, slaughterhouse, farm, plantation+, etc.

what’s MZLH520 compost granulating machine?

The MZLH520 compost granulating machine uses ring-die granulation and microbial fermentation technology to make livestock and poultry manure, urban garbage, etc. into highly efficient organic fertilizer, which can be used in grain fields, fruits, vegetables and flowers.

It is suitable for new factories or original plants. There are technological transformations of compound fertilizer plants.

Organic fertilizer refers to applying organic matter such as animal and plant residues, human and animal manure, crop straw, etc. into the soil.

Through processes such as microbial decomposition and release of mineral elements, it provides crops with nutrients and materials needed for growth. Organic fertilizers are of great significance to agricultural production.

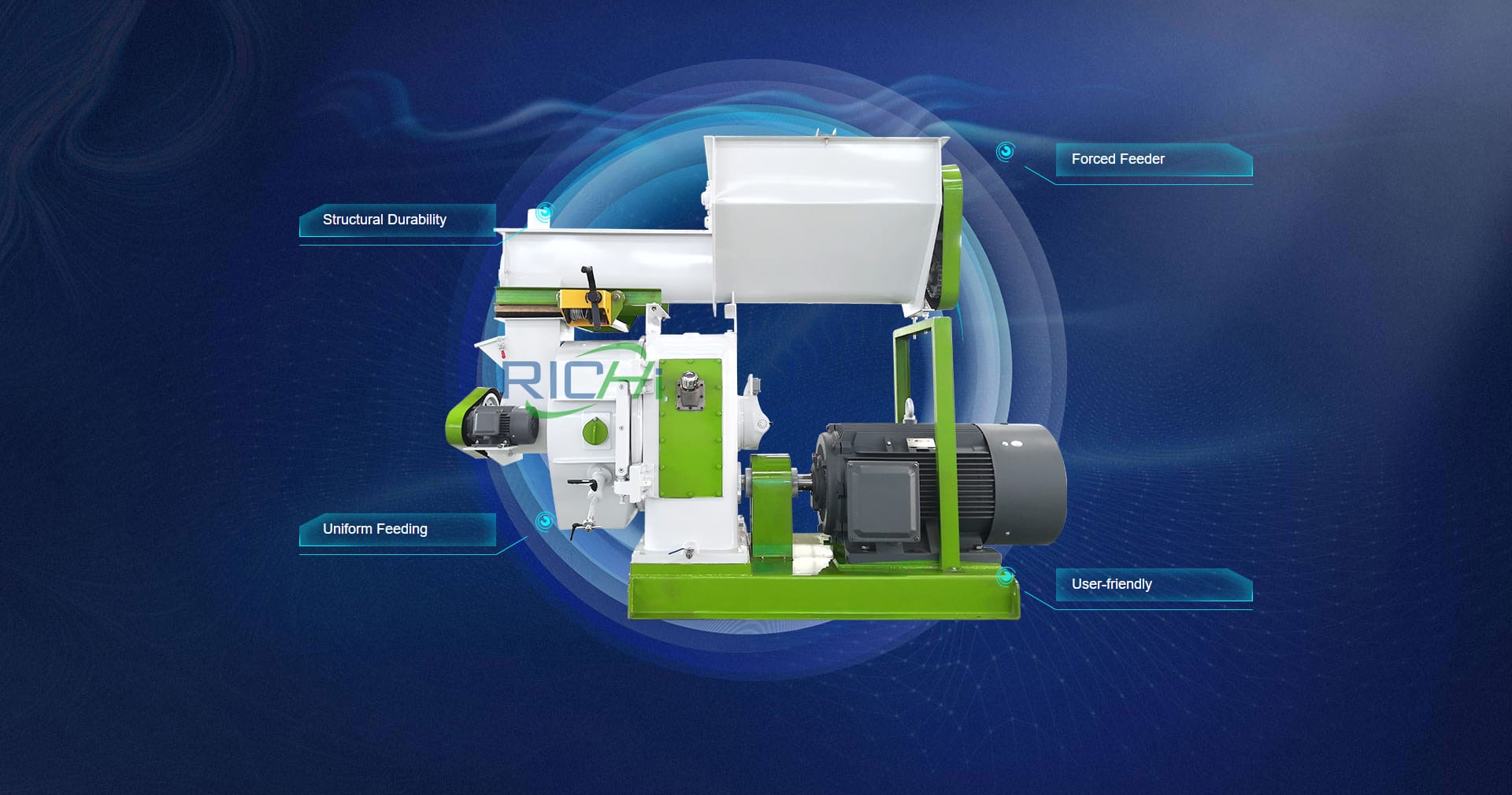

RICHI manufactures MZLH520 compost granulating machine with high quality materials and advanced designs.

Thus, if you choose RICHI’s machine, it will be helpful for you to make organic fertilizer pellet with high production capacity. Meanwhile, the pellets will be high quality, too.

In addition to being used to press cylindrical organic fertilizer granules, the organic fertilizer pellet making machine system can also be equipped with a rounding device based on the granule press, so that the cylindrical granules can be rolled into balls at one time without returning to the granules, with a high balling rate and good strength, beautiful and practical, it is the ideal equipment for producing spherical granules from organic fertilizers today.

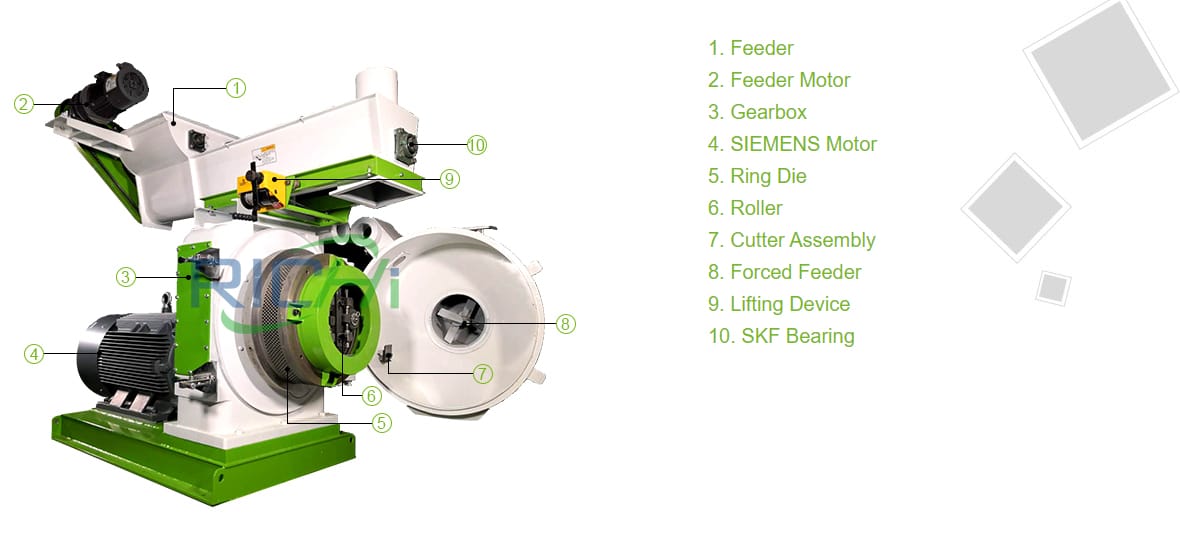

Technical characteristics of MZLH520 compost granulating machine

- Using brand bearings to ensure the operational stability and long working life of the equipment;

- The main transmission adopts a multiple combination sealing structure to ensure the sealing reliability of the transmission box;

- The feed port is equipped with an adjustable soft sealing structure to effectively prevent steam and dust from leaking;

- The door cover is equipped with a mechanical opening protection mechanism and an emergency stop switch to ensure stable operation;

- The automatic control system of the granulator can be configured, making it easier to use;

- The door cover adopts a new door shaft mechanism, which has strong support and easy adjustment;

- Equipped with an automatic grease lubrication system to achieve regular and quantitative refueling;

- Equipped with an electric mold roller disassembly and assembly device, the ring mold roller disassembly and assembly is quick and convenient;

- The optional oil circulation cooling and lubrication system makes the equipment more adaptable to continuous operation in high-temperature environments.

MZLH520 compost granulating machine advantages

- High granulation rate: the dry powder is produced at room temperature without drying, and the product is extruded in one go and meets the technical requirements of organic fertilizers.

- Large output: reasonable design, used in conjunction with corresponding equipment, can meet the continuous production of the production line.

- Low energy consumption: advanced technology, compact structure, novel and practical, low energy consumption.

- Wide scope of application: The extrusion force can be adjusted through hydraulic pressure, and the operation is flexible. It is suitable for various industries such as fertilizer, biomass, feed, medicine, chemical industry, and feed.

How does the MZLH520 compost granulating machine work?

- When the powdery material is guided by the feeding scraper in the pressing chamber and enters the pre-compression zone between the actively rotating die and the driven rotating pressure roller, the material has a certain degree of looseness and pores of varying sizes are formed inside. At the same time, they are driven and squeezed by the rotating die, causing movement (sliding and rolling) between the powdery particles.

- The pores between the powdery particles gradually decrease with the rolling of the die and the pressure roller, the internal pressure and material density increase, and the point contact between the powdery materials changes from point contact to surface contact.

- When the pressure reaches a certain value, the material reaches a predetermined density. The material with higher density enters the extrusion zone from the pre-compression zone, and changes from elastic deformation to plastic deformation. The material shows flow characteristics inside and begins to enter the die hole.

- Since the extrusion between powder particles is mechanical meshing, the increase in the contact area between powder particles, the characteristics of the material itself and the cohesiveness produced after conditioning, cause the material to maintain pressure in the die hole for a certain period of time, reaching pellets of predetermined density and strength are extruded out of the die hole and cut by a cutter to form pellets of the required length.

Specifications of MZLH520 compost granulating machine

| Model | MZLH520 |

| Output (t/h) | 7-8 |

| Main motor power (kw) | 132 |

| Main motor series | 8P |

| Ring die diameter (mm) | 520 |

| Finished pellet diameter (mm) | 2-12 |

| Device Configuration | Ring die material: 42CrMo Stainless steel feeder: with anti-caking function Door of pelleting room: 6mm /SUS304 Forced feeding: Worm gear reducer Gear box: HT250 Gear: 42CrMo Gear shaft: 42CrMo Spindle: 42CrMo Empty shaft: 42CrMo Bearings: The gear shaft and main shaft bearings are SKF, and the pressure roller bearings are domestic high-quality bearings Oil seal: Germany/Taiwan Overload mechanical protection: safety pin Serpentine spring coupling drive Lubrication system: Configurable automatic oil injection system |

MZLH520 compost granulating machine price

The price of MZLH520 compost granulating machine is generally 40,000-50,000 USD

There are many factors that affect the price of compost granulators. These factors cover everything from the quality of the equipment to market demand. The following are some of the main factors that affect the price of manure granulator:

- Equipment standards and models: Organic compost pellet making machines of different standards and models have different performances and capacities, so the prices will also be different. Generally speaking, the price of large and high-capacity organic fertilizer granulators will be higher than that of small equipment.

- Manufacturing process and materials: The manufacturing process and materials used in the fertilizer granulator machine will directly affect the quality and life of the equipment. High-quality craftsmanship and durable materials will increase the price of the device.

- Technological innovation and automation level: The machines with newer technology and higher automation levels generally have higher production efficiency and lower failure rates, so the price will increase accordingly.

- Brand and reputation: Organic fertilizer granulation machines produced by well-known brands and manufacturers with excellent reputation may be more expensive, but they generally mean more reliable quality and excellent after-sales service.

- Market demand and competition: Market demand and competition will also directly affect the price of organic fertilizer granulator. In a highly competitive market, prices may decrease due to competition; in a market with strong demand, prices may increase.

Featured compost granulating machine project

compost granulating machine In Vietnam

- Country: Vietnam

- Production: 2500 t/a

- Ingredients: industrial waste

- project price: 80,000 USD

compost granulating machine In Mexico

- Country: Mexico

- Production: 10,000 T/A

- Ingredients: livestock manure

- project price: US$110,000

compost granulating machine In United States

- Country: United States

- Production: 50,000 T/A

- Ingredients: poultry litter

- project price: US$430,000

compost granulating machine In Lithuania

- Country: Lithuania

- Production: 35,000 T/A

- Ingredients: food waste

- project price: 410,000USD

compost granulating machine In Thailand

- Country: Thailand

- Production: 55,000 T/A

- Ingredients: chicken manure

- project cost: 570,000 USD

compost granulating machine In indonesia

- Country: indonesia

- Production: 10,000 T/A

- Ingredients: animal manure, straw

- project cost: 190,000 USD

compost granulating machine In canada

- Country: canada

- Production: 6,000 T/A

- Ingredients: livestock manure

- project cost: $160,000

compost granulating machine In Pakistan

- Country: Pakistan

- Production: 30,000 T/A

- Ingredients: cow manure, Bagasse

- project cost: $385,000 USD

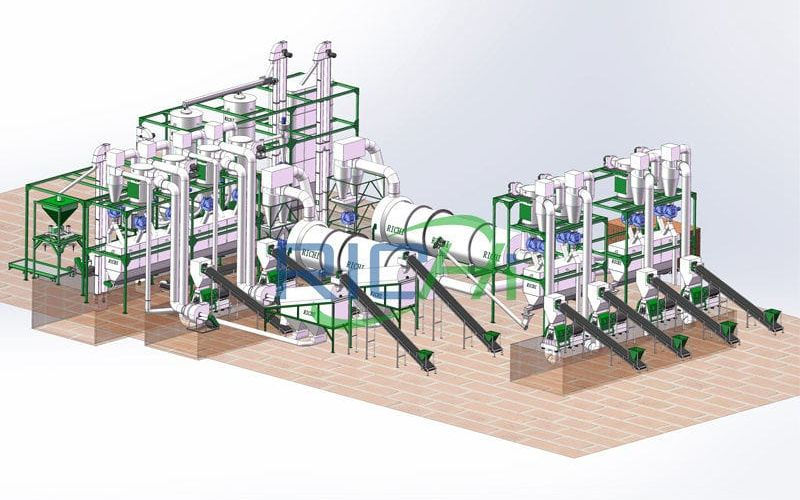

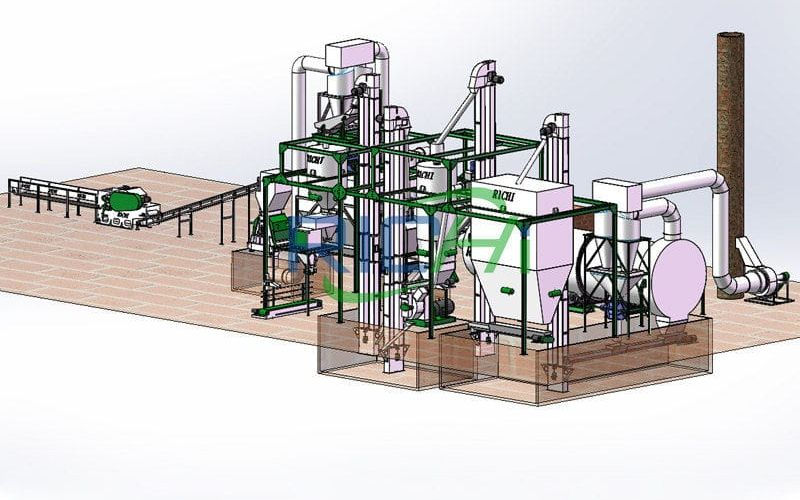

How to process organic fertilizer granules? Complete 7-8 T/H fertilizer granulation process

Organic fertilizer is an organic fertilizer made from fresh animal and plant materials (such as livestock and poultry manure, plant straw, etc.) through a series of processes. It is an environmentally friendly, safe and efficient fertilizer that has great effects on improving soil and improving the quality of agricultural products.

The following introduces the process flow of organic fertilizer production line:

- First, prepare raw materials. The raw materials of organic fertilizer mainly include livestock and poultry manure, plant straw, waste vegetable leaves, etc. These raw materials need to be processed, such as crushing, soaking and fermentation, to make them easy to decompose and utilize.

- Secondly, compost fermentation. The processed organic raw materials are first mixed in a certain proportion and then composted. When composting, attention should be paid to controlling the temperature, humidity, ventilation and other conditions of the compost to ensure that organic matter is suitable for biological fermentation. Compost usually requires multiple turnings to speed up the decomposition and fermentation of organic matter.

- After compost fermentation, impurity removal treatment is required. There may be some impurities in the compost, such as wood blocks, stones, plastics, etc., which need to be screened and cleaned. To ensure the purity and quality of the final organic fertilizer.

- Next, the compost needs to be finely crushed. The compost is finely crushed through a fine crusher to make the particles of organic fertilizer even in size, making it easy to use and utilize.

- Then, prepare the formula. Determine the formula proportion of organic fertilizer according to the needs of different crops and soil types. During the preparation process, some trace elements and biological agents can be added to improve the fertilizer efficiency of organic fertilizer.

- Next, perform granulation processing. The organic fertilizer is granulated through a compost granulating machine to facilitate storage and use. Granulation treatment can also increase the nutrient content of organic fertilizer and reduce volatilization and loss.

- Finally, package and store. According to market demand, the granulated organic fertilizer is packaged and stored in a cool, ventilated, and dry place to maintain the quality and stability of the organic fertilizer.

To sum up, the process flow of organic fertilizer mainly includes the steps of raw material preparation, compost fermentation, impurity removal, fine crushing, formula preparation, granulation, packaging and storage.

This series of processes can fully decompose, ferment and refine the organic matter in the raw materials to produce efficient, environmentally friendly organic fertilizers and promote sustainable agricultural development.

Equipment o strat whole compost granulating machine system

Compost Turner

Turning height:

0.5-2.0 m

Motor:

32-300 KW

Compost Grinder

Capacity:

3-25T/H

Main Power:

30-160KW

organic Fertilizer Mixer

Capacity:

250-2000 kg/P

Main Power:

4-30 KW

organic fertilizer Dryer machine

Capacity:

Customized

Rotate Speed:

3-8 R/Min

compost granulating machine

Capacity:

1-12T/H

Main Power:

37-280KW

How to choose compost granulating machine?

Today, when green and organic agriculture are receiving increasing attention, the demand for organic fertilizer manufacturing equipment is also growing. So, how to choose an organic fertilizer manufacturing equipment with reasonable price and high quality?

1. When choosing compost granulating machine, you must not only consider the price, but also consider the following factors:

- Applicability: Choose the appropriate organic fertilizer pellet mill model and size according to your own needs to avoid being too large or too small.

- Production capacity: Select appropriate equipment production capacity based on expected production scale and market demand.

- Finished product quality: Ensure that the finished product quality of the equipment meets the requirements, such as moisture content, nutrient content, etc.

- Energy consumption and maintenance costs: Consider the energy consumption and maintenance costs of the equipment, and try to choose energy-saving and easy-to-maintain equipment.

- Reliability: Choose brands and models with advanced technology and reliable quality to ensure the stability and durability of the compost granulating machine.

- After-sales service: Choose brands and manufacturers with good after-sales service so that problems can be solved in time.

2. Here are some suggestions for purchasing compost granulating machine:

- Understand market information: Before purchasing equipment, fully understand the market information, compare the fertilizer granulation equipment prices and performance of different brands and models, and be aware of it.

- Budget and return on investment: Develop a reasonable budget and consider the return on investment cycle to avoid blindly pursuing low prices and ignoring long-term benefits.

- Manufacturer direct sales are preferred: Choose to purchase equipment directly from the manufacturer to avoid middlemen and get more favorable prices and better after-sales service.

- Inspect prototypes and cases: Go to the compost granulating machine manufacturer to inspect prototypes and cases to understand the actual situation of the equipment and increase trust.

- Signing the contract and retaining the balance: When signing the contract, clarify the rights and obligations of both parties, and retain a certain proportion of the balance as a quality deposit.

- Purchase accessories and services: Purchase relevant accessories and services as needed, such as dust collectors, control systems, etc., to improve the overall performance of the equipment.

- Gradual upgrade and optimization: Based on actual production experience and technological development, gradually upgrade and optimize equipment to improve production efficiency and product quality.

- Follow policy and industry trends: Pay attention to relevant policy support and industry trends to keep abreast of market changes and new technology applications.

- Establish cooperative relationships: Establish long-term cooperative relationships with excellent compost granulating machine manufacturers to jointly carry out technology research and development and product upgrades to achieve mutual benefit and win-win results.

- Environmental awareness: When purchasing manure pellet mill equipment, pay attention to environmental indicators and choose equipment that meets environmental requirements to reduce the impact on the environment.

- Personnel training and technical support: After purchasing equipment, timely personnel training and technical support are provided to ensure smooth operation and maintenance.

- Regular inspection and maintenance: Regularly inspect and maintain the equipment to ensure normal operation and extend service life of the equipment.

- Pay attention to waste utilization: When using compost granulating machine to process waste, pay attention to the utilization value of the waste and look for more application scenarios and business opportunities.

- Market development and promotion: In terms of product sales and promotion, actively explore the market, broaden sales channels, and increase product visibility and reputation.

How to choose compost granulating machine manufacturer?

Which compost granulator manufacturer is better and how to choose?

With the continuous promotion of organic fertilizers in agricultural production, the proportion of organic fertilizers in the fertilizer market is also increasing year by year. However, organic fertilizer manufacturers are still in the development stage, with a small number of manufacturers, small production scale, and relatively low quality organic fertilizers. Therefore, more and more investors are investing in the organic fertilizer industry.

The investment in an organic fertilizer production line is relatively large. How to choose a strong compost fertilizer equipment manufacturer and a high-quality organic fertilizer production line to ensure the stable and efficient production of organic fertilizer has become a problem that these investors need to consider. Let’s talk about this topic next.

When purchasing organic fertilizer granulator machine, it is best to conduct an on-site inspection. Only after passing the on-site inspection can you choose the correct manufacturer and product through your own observations.

- First of all, need to check the strength of the compost granulating machine manufacturer. Only a regular large manufacturer has the strength to produce professional organic fertilizer equipment or large-scale organic fertilizer production lines. After all, the cost of making these equipment is relatively high.

- Secondly, it depends on whether the manufacturer has advanced processing equipment or a group of professional engineers. Only professional and technical personnel can make the product’s functions perfect and minimize errors.

- Then it also depends on whether the manufacturer has successful cases and how many successful cases there are. Manufacturers with successful cases must have certain experience and can help you formulate and assist you in establishing an organic fertilizer factory.

- There is also after-sales service from the organic manure making machine manufacturer. The purpose of establishing an organic fertilizer factory is to ensure long-term and stable production. After any equipment has been running for a long time, some problems or failures will inevitably occur. Only perfect after-sales service can handle and solve these problems in a timely manner. problems or failures to ensure the normal and stable operation of the organic fertilizer factory.

In general, choosing a suitable organic manure making machine manufacturer is an important guarantee for the stable operation of the production line and improving production efficiency. If you have any questions about the organic fertilizer granulator, please feel free to consult Richi Machinery directly online!

Prospects for organic fertilizer processing

Long-term excessive application of chemical fertilizers has destroyed the soil structure and caused soil hardening and cracking. The demand for organic fertilizers is constantly growing. Many people want to know the prospects and market analysis of organic fertilizers.

01 Great growth potential

Data shows that in recent years, the organic fertilizer industry has grown at a growth rate of about 10%-15%. Although the number of companies involved in organic fertilizer production continues to increase, the organic fertilizer gap is still large due to problems such as technology research and development and insufficient funds among companies.

02 Emerging organic fertilizers dominate the market

The core of the development of organic fertilizer is technology and technology. With the support of agricultural policies in various countries and the gradual participation of enterprises, bio-organic fertilizers are ushering in new opportunities for industrial development.

The development of the bio-organic fertilizer industry has an increasingly obvious impact on the development of special fertilizers and even the entire fertilizer industry.

03 Policy support

At present, many countries are vigorously developing organic agriculture and have issued relevant policies and documents. This indicates that the organic fertilizer market will experience explosive growth.

Organic fertilizers made by compost granulating machine are upgraded from traditional chemical fertilizers and have many advantages. They are now widely used in crops and are in huge demand. (Find RICHI on YouTube)