Mesh Belt Dryer

The mesh belt dryer is a continuous drying equipment. It is most suitable for assembly line operations and is mainly used for drying animal pet and aqua feed, food, vegetables, fruits, grain, biomass, wood and other granular, strip-shaped, flake-shaped, spherical and irregular block materials.

RICHI’s belt dryer machines offer excellent drying performance, ensuring evenly dried products and cost-effective operation. The mesh belt dryer is specially designed by the RICHI engineering team and can be used in drying processes in multiple industries and has a wide range of applications.

- Capacity: 2-12T/H

- Model: WDWS

- Mesh belt dryer price: 100,000-250,000 USD

- Applicable materials: pet food, aquatic feed, cereals, snacks and nuts, vegetables, fruits, chemical products, mineral products, pharmaceutical products, etc.

Suitable customers: animal feed mill plants, aqua feed mill, pet feed mill, food mills, grain processing plants, chemical plants, pharmaceutical plants, wood pellet production line, biomass pellet plants, lumber mills, sawdust plants, wood chip plants, straw pellet plant, etc.

Each of our belt drying machines is built from scratch in our own factory. Beginning with sheet metal and culminating in a finished, cutting-edge dryer, our team of experts oversees every intricate detail. This hands-on approach ensures unparalleled quality and precision making even the toughest engineer smile.

Application scope of mesh belt dryer

Mesh belt dryers can be used in various feed mills, food factories, grain processing plants and planting fields. RICHI belt dryer machine is reliable in use, has good drying quality and high production efficiency. It is very beneficial to the drying process needs of aquatic feed, pet feed, puffed feed, grain crops, various vegetables, fruits and chemical products.

At present, our industrial belt dryer equipment is not only widely used in the feed processing industry and agricultural product processing industry, it is also an ideal dryer equipment in the building materials, ceramics, fertilizer, chemical and other industries. In addition, the mesh belt dryer can be used in conjunction with other equipment or alone.

So, according to different application fields, belt dryers can be called animal feed dryer machine, pet food dryer, fruit dryer machine, belt dryers for biomass, fish feed dryer machine, vegetable dryer machine, industrial conveyor dryer, etc.

- Feed and grains: The mesh belt dryer can be used as a pet feed dryer, aquatic feed dryer, pasture dryer, alfalfa dryer, grain dryer and straw dryer, suitable for feed pellets production, corn, soybeans, sorghum, wheat, barley, oats, cassava, sweet potatoes, walnuts, Chinese medicinal materials, etc.

- Biomass: various types of wood and various forms of wood, straw, grass, rice husk, coconut shell, peanut shell, palm shell, sunflower shell, bamboo chips, bagasse, etc.

- Vegetables: tofu, bamboo shoots, broccoli, lettuce, shiitake mushrooms, fungus, fungus, white fungus, chives, shredded carrots, yam, cucumber, pepper, lily slices, turmeric, ginger slices, pepper, etc.

- Fruits: lychee, kiwi, persimmon, mango, apple, pear, strawberry, grape, etc.

- Meat: Beef, mutton, chicken, pork, duck, meat products, etc.

- Seafood: All fish and shrimps such as dried shrimp, dried fish, squid, cod, sardines, cod, etc., and all seafood. Such as kelp, seaweed, seaweed, etc. are all suitable.

- Industrial product: soap, coiled incense, mosquito coils, Buddhist incense, printing, leather, ceramics, cloth, paper tubes, sludge, coal, air purifier, cat litter, bentonite clay, rat poison, etc.

- Others: Tobacco, mineral products, glass drying, plastics, etc.

- …

Based on the structure and working principle, the mesh dryer can also be called continuous belt dryer, conveyor belt dryer, continuous vacuum belt dryer, horizontal fluidized bed dryer, horizontal dryer, etc.

If you have needs for mesh belt dryer machine and complete drying systems, please contact Richi Machinery. In addition to mesh belt dryers, we can also provide drum dryers. We will choose the most suitable equipment type and specification model for you based on the materials you want to dry!

Technical features of mesh belt dryer

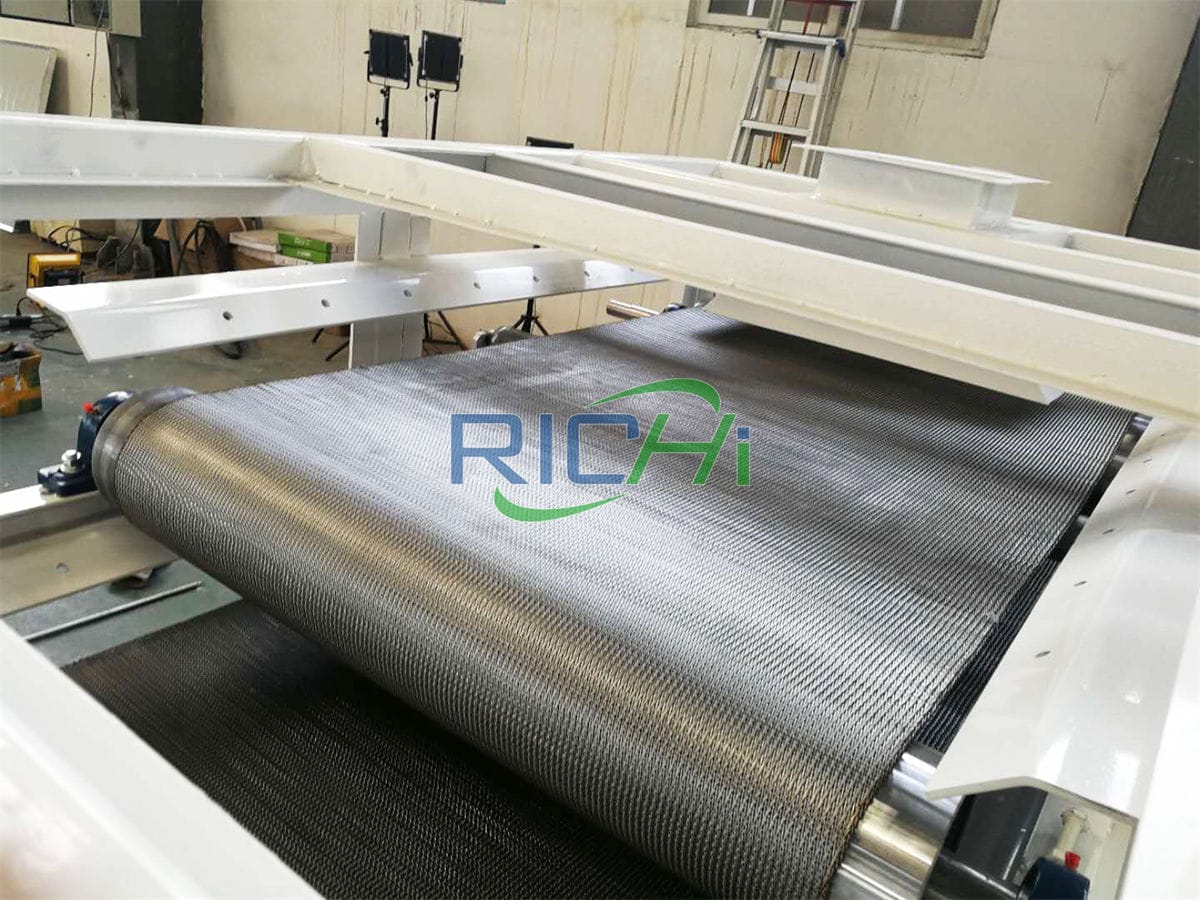

The belt dryer machine is mainly composed of a box, mesh belt, transmission device, feeding and distributing equipment, air inlet duct, moisture discharge duct, fan, heat source equipment, conveying equipment, control cabinet, etc.

- Durable mesh belt material:

Imported PET woven mesh belt is used, which has high transportation and ventilation efficiency, and the drying efficiency is increased by more than 25%. The dried materials will never be damaged or deformed. - Circulating hot air:

The drying hot air in the drying section adopts left and right directions and up and down convection circulation. Therefore, the material particles are dried evenly up and down, left and right, and the moisture error rate is within 2%. The dry hot air is recycled and utilized to greatly improve the heat exchange efficiency and save a lot of steam energy. - Precisely control the moisture content of the material:

The drying time is adjusted steplessly by frequency conversion, making it easy to control the moisture content of the product to within the standard range. The distributor adopts a swing distributor, which ensures uniform distribution and good moisture uniformity. - Strong heat exchange function:

The mesh belt dryer heat exchanger is equipped with a high-efficiency drain valve to effectively remove air and condensed water in the steam pipe. After the steam pipe (air, condensed water) is removed, the heat exchange function can be improved by 10%. - Automatic temperature control system:

According to user needs, an automatic temperature control device is optional. The drying temperature control adopts a microcomputer PID automatic temperature control system, combined with a proportional pneumatic control valve, and the temperature control is accurate with a plus or minus error of within 3°C.

After the temperature is set, the steam volume is automatically adjusted to effectively stabilize the moisture content of the finished product and reduce unnecessary steam waste during the production process.

In order to obtain the best drying effect and appropriate output from mesh belt dryer, the moisture content of the material, the linear speed of the mesh belt, the air volume and the air temperature must be appropriately, reasonably and organically combined.

RICHI’s balanced dehydration concept is to effectively control the dehydration rate and improve the quality of the dried materials through appropriate temperature and humidity control during the different stages of material drying and dehydration.

Advantages of belt dryer machine

The mesh belt dryer is a common automatic drying equipment. Compared with traditional sun drying and other automatic drying, the mesh belt dryer adopts a multi-layer mesh belt structure.

Not only does it have a large drying area, but it can also be used for drying while feeding and discharging materials to achieve large-volume continuous drying production. It has high production efficiency and is very suitable for manufacturers and growers who dry large quantities of materials.

- Customizable: The box length of the belt conveyor dryer machine is composed of standard sections. In order to save space, the dryer can be made into a multi-layer type. Common ones include double-layer, three-layer, five-layer, and six-layer. Length 6-40m, effective width 0.6-3.0m.

- Wide applicability: Suitable for large-volume continuous production, processing and rapid drying of various feed pellets, grains, foods, flowers, fruit slices, stem root slices, agricultural and sideline product slices, medicinal slices, and industrial products. Universal.

- Low energy consumption, unique structure, high thermal energy utilization, energy saving and environmental protection.

- Circulation drying process, small moisture difference in finished granules, long drying time, large output, and good drying effect.

- Horizontal layout, simple structure and convenient operation.

- Variable frequency motor controls the speed, and the drying quality can be flexibly adjusted.

Working principle of mesh belt dryer

The continuous conveyor dryer is a batch and continuous production drying equipment. The main heating methods include steam heating and heat pump hot air heating.

The main principle of the industrial belt dryer is to spread the materials evenly on the mesh belt. The mesh belt is made of 12-60 mesh PET woven mesh belt, which is driven by the transmission device to move back and forth in the dryer. The hot air flows between the materials. Then, the water vapor is forced to be dehumidified and discharged through the dehumidification fan, thereby achieving the purpose of hot air drying.

The drying process of materials is generally divided into two stages, the constant speed stage and the speed reduction stage.

- In the constant-speed drying section, the speed at which moisture inside the material diffuses to the surface can keep the surface of the material fully moist, that is, the moisture content on the surface is greater than the maximum moisture absorption capacity of the drying medium, so the drying speed depends on the surface vaporization speed.

- The moisture in the deceleration stage is vaporized inside the material, and then diffuses to the surface in the form of steam. Therefore, the drying rate in the deceleration stage completely depends on the diffusion rate of moisture and steam inside the material. Therefore, the deceleration stage is also called the internal diffusion control stage.

technical parameters of Mesh belt dryer

| model | WDWS150-4/2 | WDWS200-4/4 | WDWS200/5-4 | WDWS220/5-4 |

| Processing capacity (t/h) | 2~3 | 3-4 | 5-7 | 8-12 |

| Steam consumption (t/h) | The steam consumption per ton of floating feed is 140-160kg. Steam pressure 0.5-0.6MPa | |||

| Material drying unevenness (%) | >2% | |||

| Total power(kw) | 44.3 | 49.8 | 53.2 | 71.8 |

| Number of sections in the middle section of dryer | 4 | 4 | 5/4 | 5 |

About the dryer configuration:

The whole mesh belt dryer machine is made of stainless steel (except the frame and chain), independent temperature display in each zone, independent speed adjustment of mesh belt, internal circulation coil (aluminum rolled fin), steam supply/drainage valve group (pressure regulating valve, filter valve, inverted bucket trap), hard tooth surface reducer.

mesh belt dryer projects

mesh belt dryer for sale new Zealand

mesh belt dryer for sale Russia

mesh belt dryer machine for sale Australia

mesh belt dryer for sale Malaysia

Mesh belt dryer price

The mesh belt dryers currently on the market have different specifications and models, and the prices are also different. Therefore, when consulting the price of mesh belt dryers, you must first determine your own needs, and secondly, consider the heat source method and material of the equipment.

Only by clearly understanding your needs, required equipment configuration, etc., can we provide customers with corresponding equipment quotation information, or provide customers with dryer customization services.

In fact, there are many factors that affect the price of belt dryer machines. Generally, the size, material, heat source matching, equipment quality, production efficiency, after-sales service, manufacturer strength, etc. of the mesh belt dryer need to be considered.

- Size of the continuous belt dryer: The larger the equipment, the greater the material drying output, and the more expensive the mesh belt dryer is;

- Material style: Currently, polyurethane, color steel, baking paint, stainless steel, etc. can be used to produce continuous vacuum belt dryers. We can also choose according to our own production needs;

- Heat source matching: There are many heat source methods for mesh belt dryers. They can use gas, steam, electricity, heat pump air energy, coal, firewood, biomass pellets, etc. Different heat source methods have different matching heat exchangers. Likewise, the cost of equipment will naturally vary.

- Equipment quality: Mesh belt dryers made by different manufacturers are very different in terms of performance and production efficiency, so the equipment prices will naturally be somewhat different.

- Manufacturer strength: Different belt dryer manufacturers have different strengths, and their technical levels are also very different. When we face mesh belt dryer manufacturers, generally large manufacturers have good equipment quality and strong manufacturer strength, but the equipment price will be a little more expensive. Equipment from small manufacturers is relatively cheap, so we still recommend that you choose drying equipment from large manufacturers so that you can have good protection.

- After-sales service: This is still related to the strength of the mesh belt dryer manufacturer. The after-sales service of large manufacturers is generally relatively complete, and the market reputation is naturally good.

Are you looking for belt dryer in feed industry, belt dryer in food industry, belt dryer in biomass industry? Contact us for quotations!

mesh belt dryer design

Here, RICHI will show you the principles and key elements of our engineer team’s design of mesh multi-layer belt dryers.

As drying technology accounts for an increasing proportion in life and production, people have put forward higher requirements for drying functions. Aiming at the common problems of existing drying equipment such as low heat utilization efficiency, serious pollution, and large floor space.

Therefore, in response to these problems, RICHI MACHINERY’s engineering team designed a mesh drying equipment with relatively complete functions. A versatile drying equipment should be able to meet the requirements of small footprint and easy maintenance.

RICHI mesh belt dryer can fulfill the above basic requirements to the greatest extent possible under the prerequisite of drying large quantities of feed, food, snacks, nuts and agricultural products.

So, how is a belt dryer with such obvious advantages designed and manufactured?

- First of all, an excellent mesh belt dryer should have an efficient hot air circulation system.

The design of the hot air circulation system directly affects the energy consumption and drying effect of the dryer. Through reasonable hot air circulation design, RICHI can make full use of the thermal energy of hot air, improve thermal energy utilization and reduce energy consumption. At the same time, good hot air circulation can also heat the materials evenly and improve the drying effect. - Secondly, the structural design of the mesh dryer is also very important.

RICHI mesh belt type multi-layer dryer usually consists of upper and lower multi-layer mesh belts. Materials enter from the upper mesh belt and go out from the lower mesh belt after passing through the drying area.

Therefore, the design and layout of the mesh belts have been carefully considered. Properly designed mesh belts can ensure smooth transportation of materials and avoid problems such as blockage and material leakage. At the same time, appropriate mesh belt tension adjustment can also ensure the stable operation of materials. - In addition, the temperature control of the continuous belt dryer is also a key element.

The control of hot air temperature directly affects the drying speed and quality of materials. RICHI engineers have reasonably set up the hot air temperature control system to ensure that the hot air temperature fluctuates within an appropriate range to avoid adverse effects on materials caused by excessively high or low hot air temperatures.

At the same time, the drying characteristics and needs of different materials should be taken into consideration and corresponding temperature adjustments should be made. - In addition, the durability and ease of maintenance of the mesh belt dryer are also important considerations.

RICHI engineers select high-quality materials and components for customers to ensure the stability and reliability of the dryer during long-term operation. In addition, the reasonable establishment of equipment maintenance facilities such as inspection openings and cleaning openings can facilitate daily maintenance and cleaning work and extend the service life of the equipment. - Finally, the safety of the belt drying machine cannot be ignored.

Reasonable safety protection facilities can prevent operators from accidents during operation. For example, RICHI engineers have installed overload protection devices, leakage protection devices, etc. to ensure the safety of the operation process. In addition, for flammable and explosive materials, corresponding fire prevention and explosion-proof measures should be taken to ensure the safety of the operating environment.

To sum up, the design elements of RICHI mesh belt dryer include efficient hot air circulation system, reasonable structural design, accurate temperature control, durability and ease of maintenance, as well as comprehensive safety protection.

Through reasonable and scientific design, the drying effect and production efficiency of the dryer can be improved to meet the drying needs of different materials.

How to choose a belt dryer machine?

As can be seen from the above content, the multi-layer mesh belt dryer is a commonly used continuous drying equipment. It can be widely used in the feed industry, food, agriculture, grain, building materials, chemical industry and other industries. It is especially suitable for air-permeable materials.

For the drying of sheet, strip, and granular materials, pasty materials such as filter cakes can also be dried after being formed by a pellet machine or extruder machine. The quality of the multi-layer mesh belt dryer is largely Affects product quality.

For this reason, it is important to choose high-quality multi-layer mesh belt dryers and dryer manufacturers. So, for enterprises, how should they choose the appropriate multi-layer mesh belt dryer and dryer manufacturer?

- Output of mesh belt dryer.

The customer first knows in his mind how much output he wants, and what is his hourly output requirement? Approximately what is the annual output? - The temperature of the mesh belt dryer.

The customer himself first tells the dryer manufacturer what he wants to dry? For example, drying feed and food is very different from drying fruits and vegetables. - Number of layers of mesh belt dryer.

The mesh belt dryer is a space-saving equipment. In order to meet the customer’s workshop requirements, we usually consider the size of the customer’s workshop to customize the number of layers of the dryer and try to save space. - The length, width and height of the mesh belt dryer.

When ordering a mesh belt dryer, customers should first measure the size of their workshop space and provide it to the manufacturer as one of the conditions for designing and manufacturing the dryer. - Material of mesh belt dryer.

The outer shell of the mesh belt dryer is generally made of carbon steel or stainless steel. Customers can choose the material of the dryer box according to their own situation. So far, hundreds of dryer equipment exported by RICHI are all made of stainless steel. - Heating method of mesh belt dryer.

When purchasing, customers should first consider whether they are suitable for electric heating and whether the electricity bill is appropriate? Is it a good deal? Are the environmental requirements high? Coal-fired heating? Natural gas heating or thermal oil heating? Steam heating? Hot air heating? . . . In short, customers should consider their own local energy conditions and even environmental protection requirements. Currently, the most common heat sources are natural gas and electricity. - Drying effect of mesh belt dryer.

Customers need to understand the drying purpose you want to achieve and what moisture content you want the materials to be dried to achieve.

After reading this, you must have an idea of how to choose a suitable multi-layer belt dryer machine.

If you have questions about the selection of dryers, don’t hesitate to contact Richi Machinery and tell our professional technical consultants about your questions and let them answer your questions and provide the most comprehensive drying system solution!

RICHI mesh belt drying machine system serves growing global demand for innovative low-temperature belt drying. Our highly efficient drying equipment enhances our ability to meet the burgeoning global demand for energy-efficient and sustainable drying solutions, particularly in vital sectors such as aqua feed and pet food processing, grain processing, vegetable and fruit processing, wood processing, renewable fuels, biomass and pellet production, pulp and paper…

As one of the industry leaders for belt drying , RICHI Machinery offers a smarter way to dry everything. With over 120 installations worldwide, we deliver custom drying solutions that not only drive greater efficiency but also significantly reduce your carbon footprint. Ideal for global manufacturers seeking environmentally friendly and cost-effective drying methods, our advanced mesh belt dryer technology delivers unparalleled performance across a broad range of applications.

Are you looking for mesh belt dryer, dryer for food, equipment for drying fruits and vegetables or other continuous belt dryer? Contact RICHI Machinery —— high level belt dryer manufacturer!