Broiler Feed Making Machine

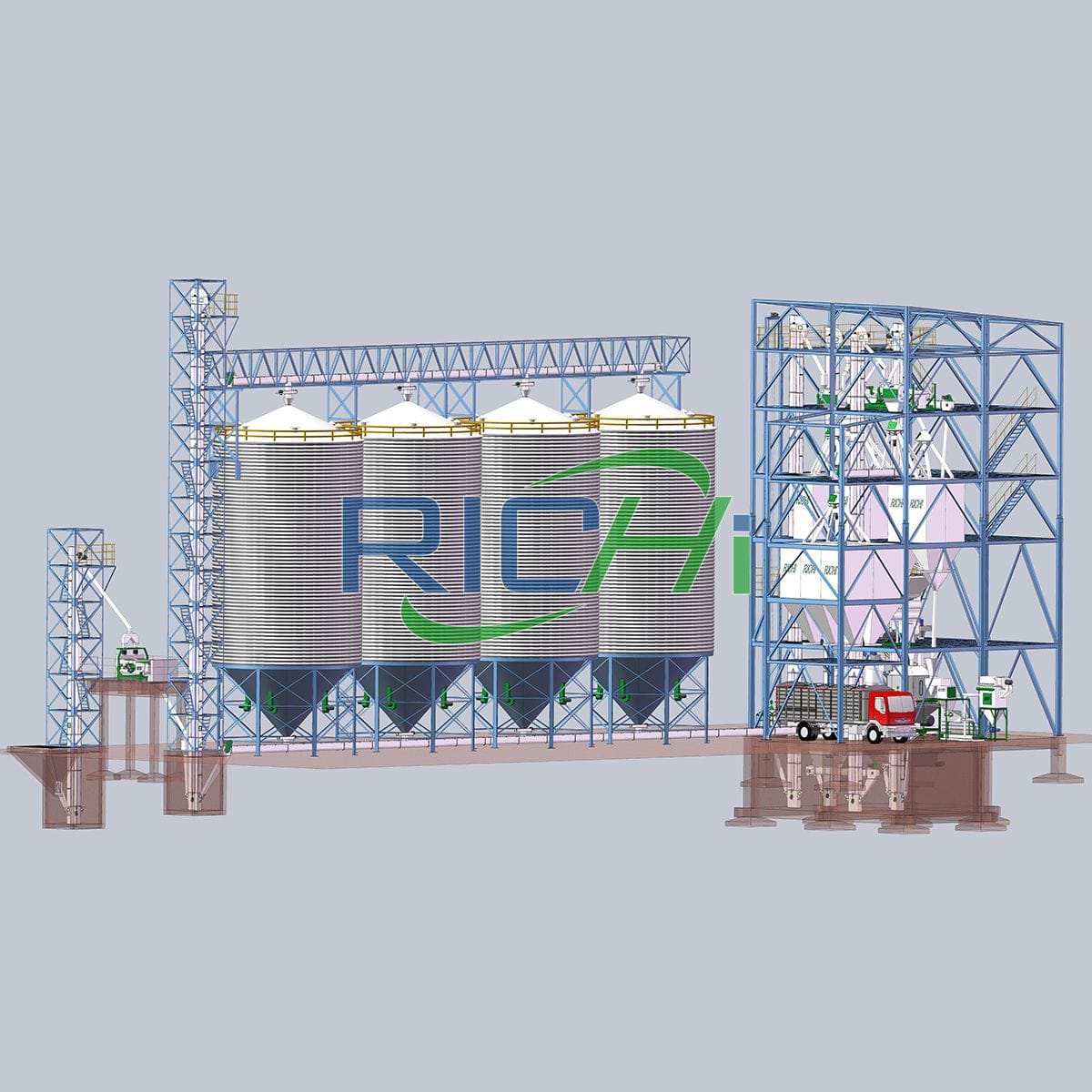

RICHI broiler feed making machine is equipment specially used for processing broiler feed, produced at our facilities in China, including: weighing and dosing systems, hammer mills, batch mixers, liquid mixers, conditioners, broiler feed pellet mills, counter-flow coolers, pellet crumblers, transport equipment and storage silos.

- Capacity: 1-160T/H

- Price: 7,000-100,000 USD

- Feed Type: 2-6,mm pellet feed

- Compliant standards: Our equipment fulfills to standards like CE, ISO, ATEX, GMP and HACCP.

- Equipment features: Minimizing maintenance, Minimizing energy consumption, Maximizing food safety, Maximizing easy and safe operation

In addition to stand-alone broiler feed equipment, we provide complete broiler feed mill systems to customers around the world. At RICHI, we design, develop, manufacture and install custom-built solutions, from complete broiler feed processing lines to large turnkey projects with highly advanced automation and management information systems.

broiler feed making machine list

There are many feed equipment that can be used in a broiler feed factory. The main broiler chicken feed making machines required for broiler feed production is as follows:

Cylindrical primary cleaning screen

It is suitable for the raw material receiving part of broiler feed mills, flour mills, grain silos and other industries. It is mainly used to remove large impurities, such as straw, wheat straw, hemp rope, paper, soil blocks, corn leaves, corn cobs, etc. Similar waste can prevent equipment and conveying devices in the next process from malfunctioning or being damaged.

- Capacity: 15-50 T/H

- Power: 0.75-1.5 KW

Powder cleaning sieve

It is suitable for the raw material cleaning section of the broiler chicken feed mill plant, so that the materials can pass through other equipment smoothly, effectively ensuring the normal operation of the subsequent processing equipment and conveying equipment. The screen can also be used to screen, break or remove the materials after the mixer. Lumpy material ensures the quality of compound feed.

- Capacity: 10-30 T/H

- Power: 5.5-7.5 KW

broiler feed hammer mill

An economical crushing equipment suitable for crushing materials of various sizes. It is also used in grain processing, brewing, biochemistry and other fields, as well as for crushing materials after expanded corn raw materials. The main accessories remain common with other hammer crushers and are easy to maintain.

- Capacity: 3-25 T/H

- Power: 30-160 KW

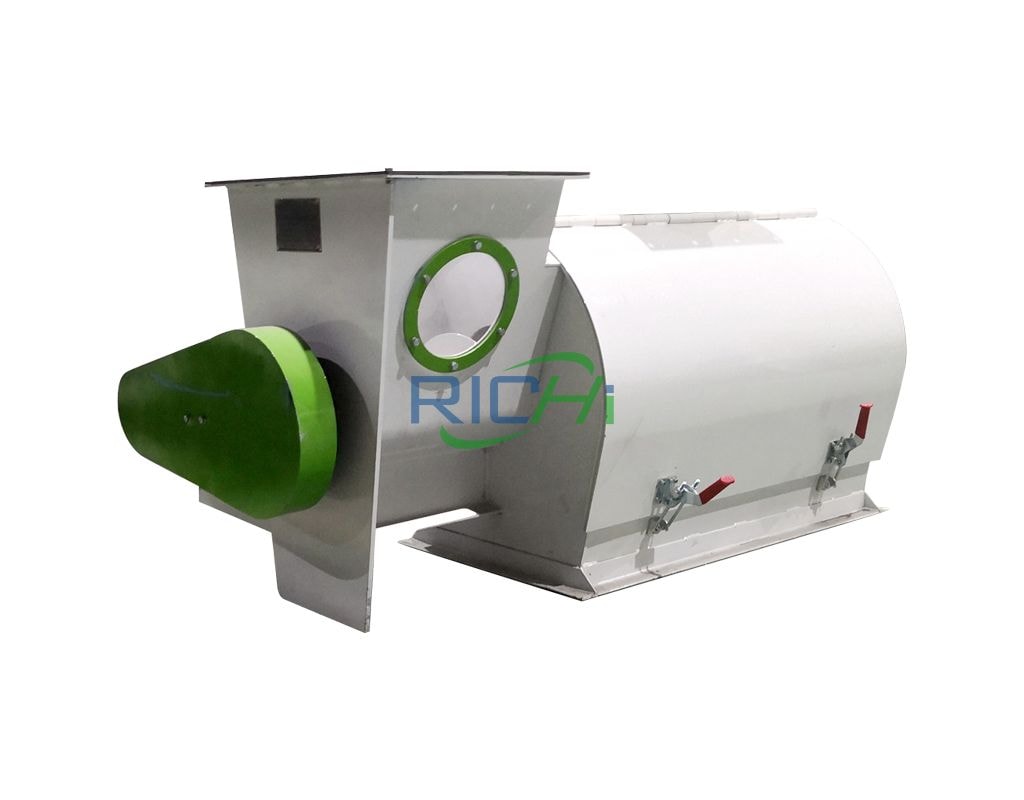

broiler Feed mixing machine

The product specifications and models are comprehensive and suitable for mixing feed raw materials in a variety of industries. The effective volume of the machine body is large; a variety of liquids (such as water, molasses, grease, etc.) can be added; the equipment operates stably for a long time and has few failures; the mixing uniformity will not be affected by the use time.

- Capacity: 250-3000 KG/P

- Power: 4-55 KW

Liquid addition system

Liquid addition system is an indispensable link in broiler feed processing. It can improve broiler feed quality and processing performance; it has high adding accuracy, reliable use, and easy operation and maintenance.

- Adding Rate: 50-200 L/Min

- Power: 2.2-5.5 KW

Broiler feed pellet mill

This broiler chicken feed pellet making machine model adopts a gear system and has an ideal transmission ratio, large driving torque, stable transmission, high output, low noise, and easy operation and maintenance. It has an ideal transmission ratio, large driving torque, stable transmission, high output, low noise, and easy operation, easy to maintain.

- Capacity: 1-42 T/H

- Power: 22-315 KW

broiler pellet Cooler machine

The broiler pellet cooler machine and unloading device adopt a variable frequency impeller unloader; it can automatically clean materials to avoid cross-contamination; it is widely suitable for cooling of various pellet feed.

- Capacity: 1.5-18 T/H

- Power: 0.75-2.05 KW

Pellet crumbler machine

Used in the pellet crumbling stage, it is an economical method introduced to avoid using a ring die with a smaller aperture on the pellet machine to produce small pellet feed, resulting in a reduction in the overall production capacity.

- Capacity: 2-20 T/H

- Roller: 2-3

vibrating screening machine

Adopting a V-belt driven biased balance mechanism and an elastic tail support mechanism, the materials rotate on the working surface of the horizontal rotary body, resulting in high screening accuracy and low vibration. No oil lubrication is required, thus avoiding oil leakage.

- Capacity: 3-20 T/H

- Power: 1.5-5.5 KW

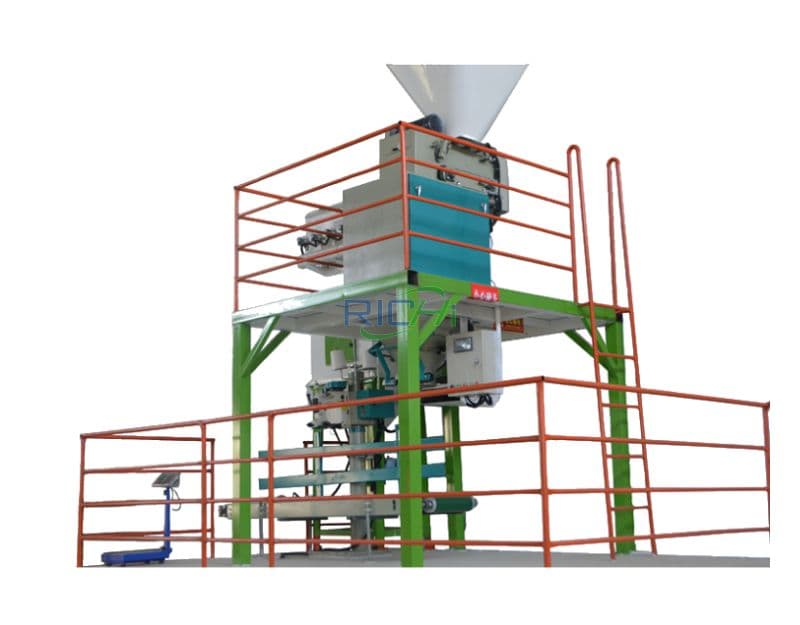

Automatic Bagging Machine

The fully automatic packaging machine is easy to operate, simple to maintain and has a small installation space. It is especially suitable for industrial materials such as powder and granular feed. In addition, according to the characteristics of the material, the packaging machine can be equipped with a net weight or gross weight quantitative packaging scale.

- Speed: 6-12 Bags/Min

- Power: 1.1-5 KW

Our positioning The vital link…also stands for the technology we offer – the broiler feed manufacturinig machines and operating systems that we deliver. For maximum benefit to the broiler feed manufacturers, farmer and poultry chicken, giving broilers the feed they need, to grow and live healthy.

If you want to know more about the complete set of broiler feed making machine needed by the broiler feed mill plant, contact us to get product information and quotation of the broiler feed equipment!

broiler feed making machine projects

1-2T/H broiler feed machine in Nigeria

- Date: June 15, 2020

- Feed type: broiler pellets

- project cost: 25,000-29,000 USD

- main broiler feed equipment in this project: Feed grinder, mixer, broiler feed pellet mill, cooler, pellet crumbler, packing scale, screening machine, etc.

15-20T/H broiler feed machine in Vietnam

- Date: December 05, 2020

- Feed type: broiler feed

- project cost: 500,000 USD

- main broiler feed equipment in this project: Feed crusher, mixer, broiler feed pellet mill, cooler, baling scale, screening machine, silo system, etc.

5-7 t/h broiler feed machine in Ethiopia

- date: 2022.08.09

- Feed type: broiler pellet feed

- project cost: 97160 USD

- main broiler feed equipment in this project: Feed crusher, mixer, broiler feed pellet machine, cooler, baling scale, screening machine, silo system, etc.

10T/H broiler feed machine in the Philippines

- Project date: 2018.07.13

- Feed type: broiler feed

- project cost: 460,000 USD

- main broiler feed equipment in this project: Feed crusher, mixer, broiler feed pellet press, cooler, baling scale, screening machine, silo system, boiler system, etc.

5 t/h broiler feed machine in Argentina

- Project date: 2021.10.14

- Feed type: broiler & cow feed pellets

- project cost: 184500USD

- main broiler feed equipment in this project: broiler feed grinder, feed mixer, batching scale, broiler feed pelletizer machine, cooler, screening machine, baling scale, silo system, etc.

5-10 t/h broiler feed machine in angola

- Project date: 2022.10.12

- Feed type: broiler & cattle & goat feed

- project cost: 131820 USD

- main broiler feed equipment in this project: grass crusher, corn crusher, feed mixer, broiler feed granulator, broiler feed pellet cooler, screening machine, packaging scale, etc.

15 T/H broiler feed machine In Uganda

- Project date: 2022.06.10

- Feed type: broiler & fish feed pellets

- project cost: 159070 USD

- main broiler feed equipment in this project: Feed grinder, ultra-fine grinder, feed mixer, broiler feed granulator, fish feed extruder, cooler, screening machine, packaging scale, etc.

10T/H broiler feed machine in Afghanistan

- Project date: 2019.09.10

- Feed type: broiler & ruminant cattle feed

- project cost: 550000 USD

- main broiler feed equipment in this project: Bale breaker, broiler feed crusher, feed mixer, broiler feed pellet mill, cooling machine, screener, baling scale, oil adding system, etc.

2 * 3-5 T/H broiler feed making machine in Algeria

- Date: Sep 23th, 2019

- Feed type: broiler and cattle feed pellets

- project cost: 80,000-400,000 USD

- main broiler feed equipment in this project: Feed crusher, mixer, broiler feed granulator, cooler, granulator, baling scale, screening machine, silo system, etc.

10-15T/H broiler feed making machine in Uzbekistan

- Date: July 11th, 2022

- Feed type: broiler and cattle feed pellets

- project cost: 150,000-400,000 USD

- main broiler feed equipment in this project: Feed grinder, grass grinder, mixer, broiler feed pelletizer, cooler, baling scale, screener, silo system, boiler, etc.

5T/H broiler feed making machine In Peru

- Date: February 1st, 2021

- Feed type: broiler and cattle goat feed

- project cost: 220,000-250,000 USD

- main broiler feed equipment in this project: Feed grinder, pulser, distributor, mixer, broiler feed pelletizer, cooler, baling scale, screening machine, boiler, etc.

3-5T/H broiler feed making machine In Malaysia

- Date: October 08, 2021

- Feed type: broiler and ruminant feed

- project cost: 60,000-65,000 USD

- main broiler feed equipment in this project: broiler Feed grinder, mixer, broiler pellet mill, cooler, pellet crumbler, baling scale, screening machine, etc.

5 T/H broiler feeds making machine In El Salvador

- date: 2022. 03.13

- Feed type: broiler premix

- project cost: 480,000 USD

- main broiler feed equipment in this project: Feed grinder, stainless steel mixer, stainless steel batching scale, packaging scale, stainless steel silo system, boiler system, etc.

10 T/H broiler feeds making machine In Thailand

- date: 2021. 09. 22

- Feed type: broiler premix

- project cost: 120,000 USD

- main broiler feed equipment in this project: Ultrafine pulverizer, stainless steel mixer, stainless steel batching scale, packaging scale, silo system, boiler system, etc.

50T/H broiler feeds making machine in russia

- Date: June 17, 2019

- Feed type: broiler & ruminant

- project cost: 960,000USD

- main broiler feed equipment in this project: Feed crusher, feed mixer, batching scale, broiler feed pellet mill, pellet cooler, screening machine, baling scale, boiler system, etc.

30T/H broiler feeds making machine in Kazakhstan

- Date: December 02, 2018

- Feed type: broiler & stock feed

- project cost: 1,250,000 USD

- main broiler feed equipment in this project: Feed crusher, feed mixer, batching scale, broiler feed pellet mill, feed pellet cooler, screening machine, packing scale, silo system, etc.

Broiler feed making machine Videos

broiler feed making machine price

01 Single broiler feed equipment price

The main broiler feed equipment prices are as follows:

- broiler feed grinder: 5300-35000 USD

- broiler feed Mixer: 2800-36500 USD

- broiler feed pellet machine: 7000-100000 USD

- broiler feed pellet Cooler: 4000-20000 USD

- Vibrating screener: 2000-10000 USD

- Packing scale: 5000-10000 USD

02 complete set broiler feed mill machine price

The price of a complete set of broiler feed equipment is as follows:

- 1-2 t/h broiler feed machine price: 10000-50000 US dollar

- 3-4 t/h broiler feed machine price: 50000-120000 US dollar

- 5-7 t/h broiler feed machine price: 70000-250000 US dollar

- 8-10 t/h broiler feed machine price: 150000-300000 US dollar

- 12-20 t/h broiler feed machine price: 250000-580000 US dollar

- 25-40 t/h broiler feed machine price: 450000-850000 US dollar

- 50-60 t/h broiler feed machine price: 900000-1400000 US dollar

- 60-80 t/h broiler feed machine price: 1450000-1800000 US dollar

- 80-100 t/h broiler feed machine price: 2000000-2800000 US dollar

The broiler feed making machine price on the market ranges from a few thousand to tens of thousands of dollars, because there are many factors that affect the price, such as different equipment types, equipment output, model selection, and different purchase manufacturers, including second-hand, middlemen, and self-produced ones.

There are differences in broiler feed mill equipment quality and performance, as well as prices among other channels. It is recommended that users focus on finding well-known feed equipment manufacturers and direct sales manufacturers, first consult online, and then conduct on-site inspections and consultations to save time and purchase machines cheaper.

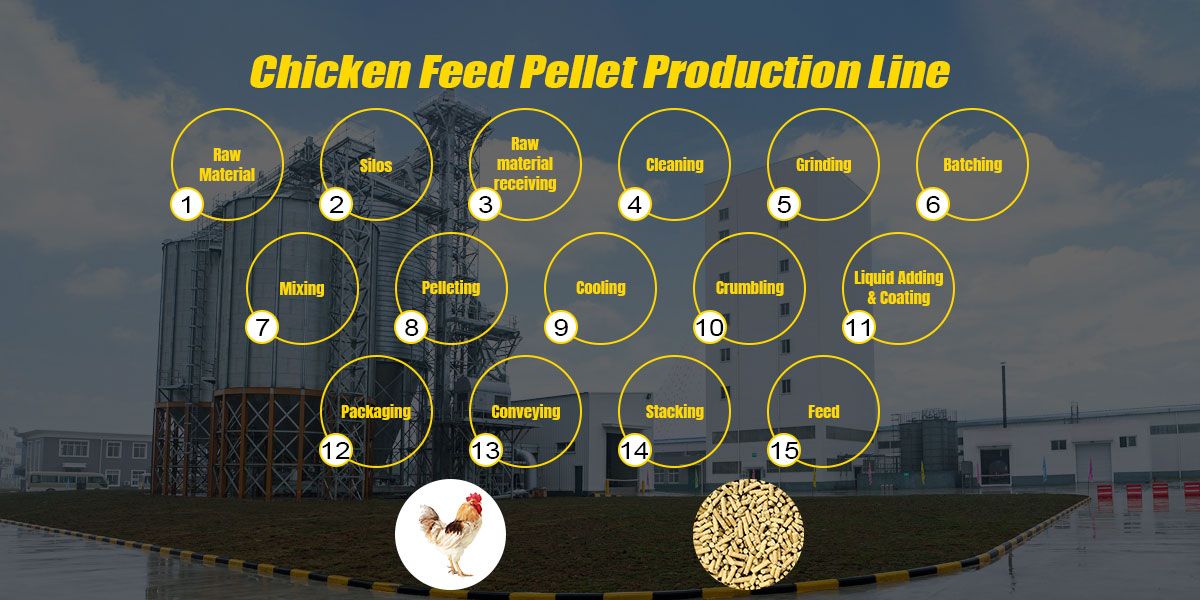

How to process broiler feed pellets?

- Feeding: put the broiler feed raw materials into the silo.

- Cleaning: Before the raw materials enter the warehouse, impurities and iron blocks in the raw materials are removed.

- Crushing: crush the raw materials that need to be crushed and then enter the batching bin, and the raw materials that do not need to be crushed directly enter the batching bin.

- Ingredients: After the raw materials are ready, use the computer to automatically batch the ingredients.

- Mixing: Put the prepared raw materials into the mixer and mix them evenly. If pellets are not needed, they can be directly packaged into powder for sale or use.

- Conditioning: The broiler feed that needs to be pelleted and formed enters the conditioner and uses steam conditioning to mature the feed.

- Pelletizing: Pelleting and shaping of powdered feed with chicken feed pellet machine.

- Cooling: Cool the pelleted feed (high temperature, high moisture) until its temperature and moisture meet the requirements.

- Screening: Use a grading sieve to screen out feed that does not meet the requirements (powder, large particles, blocks, etc.) and allow qualified products to enter the finished product warehouse.

- Packaging: Fill and package the qualified finished products and enter them into the finished product warehouse for sale or use.

Realizing excellence when it comes to performance in your broiler feed production facility starts with engineering. It takes the input of your requirements, our engineering expertise and process know-how to build your broiler feed mill in a configuration that will give you a competitive edge.

Leading broiler chicken feed mills worldwide have trusted us for over 30 years in developing the best solution for their specific situation, tailored to their needs and local conditions. We trust we can satisfy you, too.

Different capacity Broiler feed making machine configurations

Below are brief lists of several broiler feed equipment configurations for different production capacity:

1-2 t/h Broiler feed machine configurations

| broiler feed Hammer mill grinder | 15-200 | 1 |

| broiler feed Mixer | SLHY0.5A | 1 |

| Feeder | WLQ16 | 1 |

| Stainless steel condtioner | TZQ22*180 | 1 |

| broiler pellet feed machine | SKLH-250 | 1 |

| Conterflow cooling machine | SKLN1.0*1.0 | 1 |

| Crumbling machine | SSLG15*100 | 1 |

| Vibrating sifter | ZDS60*1 | 1 |

| Auto Packing machine | DSC-50 | 1 |

| Sewing+belt conveyor |

3-4 t/h Broiler feed mill configurations

| broiler feed Hammer mill | SFSP.56*40 | 1 |

| Mixing machine (Pneumatic door) | SLHY.1 | 1 |

| Feeder | WLQ22 | 1 |

| Stainless Steel Conditioner | TZQ32X200 | 1 |

| broiler feed Pellet machine | SZLH.320 | 1 |

| Cooling Machine | SKLN14x14 | 1 |

| Rotary screener | SFJH.80x2C | 1 |

| Final pellets storage bin | 2m³ | 1 |

| Auto Packing machine | DSC-50 | 1 |

| Sewing+belt conveyor | 1 |

5-7 t/h Broiler feed plant configurations

| broiler feed crusher | SFSP66*60 | 1 |

| Single-shaft mixer | SLHJ1A | 1 |

| Feeder | WLQ25 | 1 |

| 1-Layer Conditioner | TZ35*244 | 1 |

| broiler feed Pellet machine | SZLH350 | 1 |

| Cooling Machine | SKLN17x17 | 1 |

| broiler feed pellet Crumbler | SSLG15*100 | 1 |

| Rotary screener | SFJZ100*2C | 1 |

| Automatic Packing machine | DCS-50 | 1 |

| Sewing machine+conveyor | / | 1 |

10 t/h Broiler feed machine configurations

| Hammer mill for broiler feed | SFSP66*60 | 1 |

| Double Ribbon Mixer | SLHY2.5L | 1 |

| broiler feed Pellet making machine | SZLH420 | 1 |

| Stainless steel conditioner | TZ38*300 | 1 |

| Feeder | WLQ25 | 1 |

| Cooling Machine | SKLN20×20 | 1 |

| broiler feed pellets Crumbler | SSLG15X150 | 1 |

| Rotary screener | SFJH125*2C | 1 |

| Automatic Packing machine | DSC-50 | 1 |

| Sewing machine and belt conveyor | 1 |

20-30 t/h Broiler feed making plant configurations

| broiler feed Hammer mill | SFSP66*80 | 1 |

| broiler feed Hammer mill | SFSP138*40E | 1 |

| Batching scale | PLC1.0A | 2 |

| broiler feed Mixing machine | SLHJ4.0A | 1 |

| Pellet mill for broiler feed | SZLH420 | 2 |

| Cooling Machine | SKLN20x20 | 2 |

| Crumbler for broiler feed pellets | SSLG15*150 | 2 |

| Rotary screener | SFJZ125*2C | 2 |

| Automatic Packing machine | DCS-50 | 2 |

| Sewing machine&belt conveyor | / | 2 |

60-80 t/h Broiler feed making machine configurations

| broiler feed grinder | SFSP66*100 | 2 |

| broiler feed grinder | SFSP138*50E | 2 |

| Single-shaft mixer for broiler feed | SLHJ6.0A | 2 |

| Pellet machine for broiler feed | SZLH508 | 4 |

| 1-layer SS Conditioner | TZ42*3000 | 4 |

| Cooling Machine | SKLN24x24 | 4 |

| broiler feed Crumbler | SSLG20*170 | 4 |

| Rotary screener | SFJZ150*2C | 4 |

| Packing machine | DCS-50 | 4 |

| Sewing machine and conveyor belt | 4 |

The broiler feed production plant includes but is not limited to the above configurations. The surrounding environment, physical and chemical properties of raw materials, discharging requirements, etc. will affect the selection of broiler feed making machine.

Moreover, there are many models to choose from for the equipment configuration of each processing link, so basically the detailed configuration of the broiler feed mill will be different. If you also want to configure a broiler poultry animal feed production line that suits your needs, contact RICHI to customize a plan and get a detailed product quotation!

Advantages of broiler feed making machine system

The RICHI broiler poultry feed plant system has the characteristics of compact structure, fine production, short construction period, and small footprint. It can meet the needs of feed mills and poultry farms of different sizes.

01 Continuous production

The broiler feed plant system adopts a continuous production method, which can greatly improve production efficiency. At the same time, continuous production can also reduce production batches and handling times, thereby reducing production costs and losses.

02 High degree of automation

Broiler feed production systems usually use advanced automation technology, which can realize automatic batching, automatic mixing, automatic mixing, automatic pelleting, automatic packaging and other functions. This can not only improve production efficiency, but also reduce errors and defective products caused by manual operations.

03 High utilization rate

The broiler feed making machine plant uses precise feed control technology to minimize feed waste. At the same time, the feed can be recycled, further reducing production costs.

04 High efficiency and energy saving

Broiler feed making system usually use efficient energy utilization technology to reduce energy consumption. For example, the broiler feed production line can use energy-saving crushing, mixing, and granulating equipment and processes to reduce energy consumption and carbon emissions.

RICHI broiler feed making processing system, as an advanced chicken feed manufacturing system, has many advantages and advantages.

It can achieve continuous, automated and efficient production, improve production efficiency, product quality and feed utilization, reduce production costs and energy consumption, and can also save energy and protect the environment.

Therefore, RICHI broiler feed makingsystem has broad application prospects and market prospects in global chicken feed processing.

How to choose broiler feed making machine?

Choosing broiler feed processing machine of suitable scale is the key, which will directly affect production efficiency and cost. The following are key points and suggestions for selecting broiler feed machine of the right size:

- Determine the production scale: First, you need to determine the production scale of your farm or broiler feed mill. This includes how much feed needs to be produced to meet demand. This will be a key factor in equipment selection, as equipment of different sizes has different production capabilities.

- Consider production efficiency: You need to consider the production efficiency of the broiler chicken feed making machine, that is, how much feed can be produced per hour or per day. Efficient equipment saves time and labor costs, but is often more expensive.

- Consider the type and quantity of raw materials: Feed usually requires a mixture of multiple raw materials, including grain, soybean meal, additives, etc. Make sure the equipment can hold and mix the various ingredients you need and can handle your throughput needs.

- Consider the level of automation: The level of automation is another factor to consider. Broiler chicken feed making machine with a high degree of automation can reduce manual intervention and increase production efficiency, but they are generally more expensive. Choose based on your budget and staff availability.

- Consider equipment durability and maintenance requirements: Broiler chicken feed making machine durability is important because you want your investment to last for a long time. At the same time, it is also critical to understand the maintenance needs of the equipment to ensure that you can perform timely maintenance to maintain its normal operation.

- Seek professional advice: If you are not sure what type and size of equipment you should choose, you can consult a professional feed production equipment supplier or engineer. They can provide customized advice based on your needs and budget.

- Understand market standards: Then, understand the market standards and regulations in your area to ensure that the broiler feed making machine you choose meets the requirements.

Choosing chicken fee equipment of suitable scale is a key step to ensure smooth production and improve efficiency. Carefully considering the above factors and working with a professional can help you make an informed decision. (Find RICHI on YouTube)

Setup your broiler feed making machine system

- Step 1: Draft a broiler feed milling business plan

- Step 2: Choose a location

- Step 3: Acquire the land

- Step 4: Get the required approval and licenses to operate an animal feed mill plant

- Step 5: Draw the broiler feed mill architectural plans and have them approved

- Step 6: Hire a professional for constructing your feed mill

- Step 7: Find a broiler feed machine manufacturer, purchase the animal feed mill equipment

- Step 8: Install the broiler feed making machines and equipment

- Step 9: Hire broiler feed mill workers and other personnel

- Step 10: Purchase the supplies and raw materials required for broiler feed production

- Step 11: Start broiler feed production

- Step 12: Start marketing the broiler feed products

- Step 13: Improve on the broiler feed products

Whatever the challenge… you will benefit from a fully controlled broiler feed making project as a direct result of Richi Machinery, combining all disciplines under one roof. We recognize the importance of personal communication and provide a direct line of contact between your project site and our main office.

RICHI project management brings you peace of mind in the knowledge that all your requirements are taken care, providing you with the confidence that the broiler feed making plant project can deliver to: Time & Budget & Quality.

Why choose RICHI Machinery?

- Rich experience: A 30-year-old manufacturer, it has designed and installed more than a thousand animal feed production lines for countless feed processing plants, large-scale farms, and large-scale farmers, and has been well received by customers;

- Complete equipment: From silos, crushing, mixing, and granulation to cooling, screening, and packaging, all broiler feed making machine is available, and we can customize the production of forced feeders, quality preservers, and according to the actual processing needs of customers. Bucket elevators, spiral augers, etc., fully meet the needs of customers for broiler poultry feed production lines;

- Professional design and installation: A complete broiler feed production machine system has dedicated personnel responsible for and following up from drawing design, production ordering to loading and shipping, installation and commissioning, and maintenance to ensure product quality;

- Energy saving, consumption reduction and cost reduction: The broiler feed making machine system batching warehouse adopts computer automatic control, realizing fully automatic operation from feeding, crushing, weighing, oiling and mixing, reducing physical labor and labor costs;

- Excellent brand reputation: Product sales areas have spread to more than 140 countries and regions around the world, and many customer cases have become local project benchmarks.