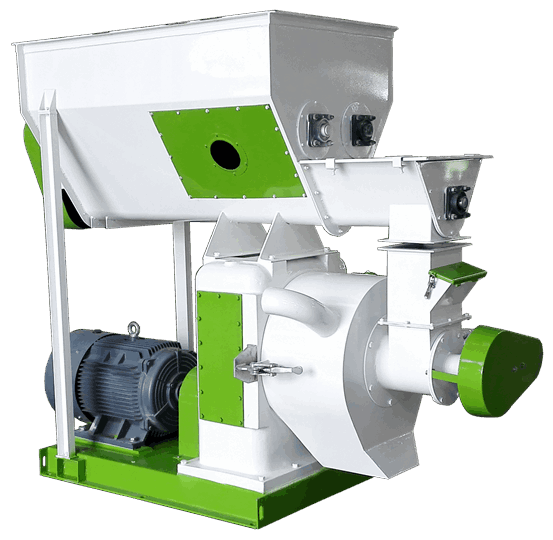

Small Biomass Pellet Machine

MZLH320 small biomass pellet machine is the key equipment for pelletizing biomass raw materials. With power of 22 kw and 6/8 pole-motor it was designed thinking to customers who want to install small biomass pellet plants, having mainly crop waste and forest waste to pelletize.

- Model: MZLH320

- Capacity: 0.3-4T/H

- Power: 22KW

- Price: FOB 10,000-20,000 USD.

The ring die compression pelletizing technology adopted by the small biomass pellet machine compresses the biomass raw materials into pellets with a diameter between 2-12 mm, which greatly improves its density and is easy to store and transport.

At the same time, the small biomass pellet maker has extremely high production efficiency, and the pellet fuel produced has stable quality and good combustion effect.

The pellet machine made by RICHI Machinery can not only replace traditional fossil fuels, but also be used for heat supply in various fields, such as boilers, water heaters, power plants, etc.

Application of MZLH320 small biomass pellet machine

The MZLH320 small biomass pellets machine has broad application prospects in many fields:

- Heating field: Biomass pellets can be used to replace traditional fuels such as coal to provide clean heat for homes, factories, etc.

- Power generation field: Biomass pellets can be used as fuel in biomass power plants to reduce dependence on fossil fuels.

- Animal husbandry: Biomass pellets can be used as raw materials for animal husbandry feed processing to achieve the recycling of waste.

- Industrial field: Biomass pellets can be used to replace traditional industrial fuels such as petroleum to reduce production costs. Applicable to various processing plants.

Technical features of MZLH320 small biomass pellet machine

- The main drive adopts high-precision gear rotation, and the efficiency is about 15% higher than the belt drive type. The ring die adopts a quick-release hoop type;

- The main shaft system adopts a double-support structure, the main shaft will not shake, and can provide a greater ring die extrusion force;

- The ring die roller adjustment device adopts an external structure, which can adjust the gap between the die rollers without stopping the machine;

- The roller adopts circulating water cooling, the bearing has a low working temperature and a long service life, which can reduce the consumption of grease;

- The main shaft and roller bearings are equipped with temperature measuring devices to monitor the working status of the bearings;

- The main shaft, transmission wheel, gears and other key parts are all made of high-strength forged alloy steel, and the gears are made of high precision gear grinding machine processing;

- The transmission part of the whole small biomass pellet machine uses high-quality imported bearings and oil seals to ensure efficient, stable and low-noise transmission;

- The internationally advanced level of compensation serpentine spring coupling has novel structure, compactness, safety and low fault performance;

- The working intensity of the main working parts is strengthened from the material, heat treatment and other processes to meet the pelletizing requirements of biomass pellets;

- Optional small biomass pelletizer operation report, cumulative working time, oil temperature alarm and lubricating oil replacement reminder and other intelligent systems;

- Adopt variable frequency motor feeding, equipped with overload protection device and magnetic plate iron removal device; high output, low noise, easy operation and maintenance.

Advantages of MZLH320 small biomass pellet machine

- High efficiency and energy saving:

The pelletizing technology adopted by the small biomass pellet mill machine can efficiently convert biomass raw materials into pellet fuel, and its production efficiency is several times higher than that of traditional pelletizing methods. At the same time, biomass pellet fuel has high calorific value and high combustion efficiency, which can effectively save energy. - Environmental protection and energy saving:

Biomass pellet fuel can be widely used in industrial and civil fields. The waste gas and waste residue generated by its combustion can be effectively treated and utilized, causing less pollution to the environment, which meets the requirements of sustainable development. - Wide application:

The biomass pellets machine can convert various biomass raw materials into pellet fuel, such as wood chips, straw, reeds, hemp stalks, etc., and has a very broad application prospect, especially in rural areas and areas rich in forestry resources. - Low cost:

The production cost of small biomass pellet machine is low, and the production is simple, easy to operate and maintain, so it has become an important equipment in the field of biomass energy conversion.

In short, small biomass pellet machine is a biomass energy conversion equipment with the advantages of high efficiency and energy saving, environmental protection and energy saving, wide application and low cost.

It has broad application prospects and is of great significance for promoting sustainable development and realizing energy structure transformation.

Working principle of MZLH320 small biomass pellets machine

The MZLH320 small biomass pellet making machine is mainly driven by the main motor to drive the reducer.

The reducer reduces the motor speed through the speed ratio and drives the pressing roller to rotate through the connected main shaft.

The outer periphery of the pressing roller is a ring mold, and biomass materials such as wood chips, straw powder, and wood powder enter the pressing chamber.

The roller squeezes the material out of the small hole of the die through mechanical extrusion, and the extruded pellet is cut by the cutter.

Technical specifications of MZLH320 small biomass pellet machine

| Type | MZLH320 |

| Output(t/h) | 0.7-4 |

| Main motor power(kw) | 22 |

| Main motor series | 6/8P |

| Forced Feeder (KW) | 1.1 |

| Conditioner Power(kw)(Optional) | 2.2 |

| Ring die diameter (mm) | 320 |

| Finished pellet diameter (mm) | 2-12mm |

Configuration of MZLH320 small biomass pellet machine

- Ring die material: 42CrMo

- Stainless steel feeder: with anti-caking function

- Door of pelleting room: 6mm /SUS304

- Forced feeding: Worm gear reducer

- Gear box: HT250

- Gear: 42CrMo

- Gear shaft: 42CrMo

- Spindle: 42CrMo

- Empty shaft: 42CrMo

- Bearings: The gear shaft and main shaft bearings are SKF, and the pressure roller bearings are domestic high-quality bearings

- Oil seal: Germany/Taiwan

- Overload mechanical protection: safety pin

- Serpentine spring coupling drive

- Lubrication system: Configurable automatic oil injection system

Small biomass pellet machine projects

Small biomass pellet machine project In Vietnam

- pelletizer selection: MZLH320

- Ingredients: wet corn Straw waste

- project cost: 180,000 USD

small biomass pellets machine project In India

- pelletizer selection: MZLH320

- Ingredients: bamboo, rice husk

- project cost: US$270,000

small biomass pellets machine project In United States

- pelletizer selection: MZLH320

- Ingredients: Miscanthus, Hay, flax straw

- project cost: US$250,000

small biomass pellet machine project In germany

- pelletizer selection: MZLH320

- Ingredients: palm waste, straw, husk, wood waste

- project cost: 210,000USD

small biomass pellet machine project In indonesia

- pelletizer selection: MZLH320 small biomass pellet maker

- Ingredients: palm waste, Sawdust

- project cost: 190,000 USD

small biomass pellet machine project In poland

- pelletizer selection: MZLH320 small biomass pellet maker

- Ingredients: wood, leaves, straw

- project cost: 370,000 USD

small biomass pellets machine project In canada

- pelletizer selection: MZLH320 small biomass pellet maker

- Ingredients: Straw, hay, Sawdust, blocks, planks

- project cost: $90,000

small biomass pellet machine project In brazil

- pelletizer selection: MZLH320 small biomass pellet maker

- Ingredients: cotton stalk, sawdust

- project cost: $285,000 USD

How to process biomass pellets with complete small biomass pellet machine plant?

The biomass pellet processing technology mainly includes raw material crushing, drying, conveying, mixing, feeding, molding, cutting, cooling, metering and packaging. It can be divided into three sections, namely raw material pretreatment section, solid molding section, and auxiliary supporting section, as follows:

01 Raw material pretreatment section

The raw material pretreatment section includes raw material receiving, crushing, drying, mixing and other processes.

- Raw material receiving: biomass raw materials are transported from the stockyard to the feeding shed, and are stcked in sequence along the feeding conveyor belt to prepare for feeding. At the same time, some raw materials are temporarily stored to ensure that the raw materials are continuously and sufficiently supplied in one shift.

- Coarse crushing: Since biomass raw materials such as crop straw are large in size and cannot be directly used for molding processing, the main task of the coarse crushing process is to crush the larger straw into short and fine granular raw materials for secondary fine crushing.

- Scraper conveying: The raw materials are transported from the crushing process to the fine crusher. After secondary crushing, the particle size is less than 5mm and transported to the raw material warehouse. At the same time, the raw materials can also be naturally dried.

- Lifting and mixing: Use a hoist to temporarily store the raw materials in the raw material bin, install a lifting plate in the bin, stir and mix the raw materials, ensure smooth feeding, and continuous production.

- Screw conveyor: Ensure continuous and uniform feeding.

02 Biomass pelleting section

The solid molding section includes tempering feeding, pelleting , cutting and other processes.

- Tempering feeding: Temper and mix the powder in the raw material bin, and continuously and stably convey it to the small biomass pelletizing machine.

- Solid molding: The raw materials are extruded and molded by the small biomass pellet machine.

- Cutting: A cutter with adjustable gap is installed in the small pellet machine, and the extruded fuel is cut according to user needs for easy packaging, storage and transportation.

03 Auxiliary supporting section

The auxiliary supporting section includes cooling, dust removal, air compression, water addition, metering and packaging and other processes.

- Cooling: The temperature of the molded fuel just out of the small biomass pelletizer machine is 75-85℃, which is easy to break and not suitable for storage and transportation. The task of the cooling process is to cool down the high-temperature fuel after processing and molding so that its temperature can reach the conditions for packaging and storage. The whole process is equipped with a combined cooler to remove the heat and moisture of the solid molding fuel through the cooling process.

- Dust removal: Cyclone separation and pulse dust removal are used to remove dust during the production and processing process to meet national standards.

- Adding water(Optional): According to the characteristics and moisture content of the raw materials, appropriate water is added to adjust the humidity to meet the requirements of biomass pelleting.

- Measuring and packaging: The finished product is measured to achieve machine packaging.

Supporting equipment for small biomass pellet system

The small biomass pellet machine line mainly includes the following equipment:

Bale breaker

Capacity:

1-20T/h

Main Power:

30-90KW

biomass Hammer Mill

Capacity:

3-25T/H

Main Power:

30-160 KW

biomass Crusher Machine

Capacity:

0.3-3T/H

Main Power:

22-93KW

biomass Mixing Machine

Capacity:

250-2000KG

Main Power:

4-55KW

biomass Dryer

Capacity:

Customized

Rotate Speed:

3-8 R/Min

1. Raw material preparation equipment

The biomass pellet raw material preparation equipment mainly includes silos, conveyors, crushers and dust collectors. The function of these equipment is to collect, transport, crush and remove dust from biomass raw materials so that they can enter the next process better.

When selecting raw material preparation equipment, it is necessary to select the appropriate equipment model and configuration according to the characteristics of the raw materials and the production capacity of the pellet machine.

2. Small biomass pellet machine

The small biomass pellet making machine is the core part of the complete set of biomass pellet line equipment. It can compress the processed biomass raw materials into pellets of various specifications.

The small pellet machine usually includes parts such as pressing rollers, molds, transmission devices and heating systems. When selecting a small pellet machine for biomass, factors such as the specifications, output, and quality and efficiency of the pellets need to be considered.

3. Cooling equipment

The pressed biomass pellets have a high temperature and need to be cooled by cooling equipment for better storage and use. Commonly used cooling equipment includes natural coolers and forced coolers. Select the appropriate model and configuration according to your needs.

4. Packaging equipment

The biomass pellet packaging equipment includes packaging machines, weighing devices and conveyor belts, which are used to measure, package and transport the cooled biomass pellets. When selecting packaging equipment, factors such as pellet specifications, packaging materials and packaging methods need to be considered.

5. Auxiliary Equipment

The complete set of small biomass pellet machine plant also includes some auxiliary equipment, such as dust removal equipment, safety equipment, electrical control system, etc.

The role of these equipment is to ensure the smooth progress of production and environmental protection requirements. When selecting auxiliary equipment, factors such as production process, environmental protection requirements and the need for safe production need to be considered.

In short, the configuration of the complete set of biomass pellet machine equipment needs to be selected according to specific production needs and conditions.

Reasonable configuration can improve production efficiency, reduce costs, and ensure product quality. At the same time, it is also necessary to pay attention to environmental protection and safe production requirements.

video of small biomass pellet machine

FAQs of small biomass pellet machine

How much does a small biomass pellet machine cost?

The price of a MZLH320 small biomass pellet maker machine is generally between FOB 10,000-20,000 USD.

Factors affecting the price of a super small biomass pellet machine:

- Brand and model: The prices of biomass fuel pellet making machines of different brands and models vary greatly. Well-known brands and high-end models are usually more expensive, but the quality and performance are also more guaranteed.

- Function and technology: The function and technical level of the equipment directly affect the price. Equipment with more advanced technologies and functions, such as intelligent control, PLC control, etc., will have a correspondingly higher price.

- Output and power: The output and power of a small biomass pellet mill machine determine its heating and cooling capacity. Generally speaking, the greater the output and power, the higher the price.

- Materials and manufacturing process: High-quality materials and fine manufacturing processes can ensure the durability and performance of the equipment. Therefore, the price of equipment using high-quality materials and processes will be relatively high.

- Market supply and demand: The price of a small biomass pelleting machine is also affected by market supply and demand. When demand is high and supply is tight, prices may rise.

How to choose a small biomass pellet machine?

In the construction of a biomass pellet production line, choosing a suitable small biomass pellet granulator machine requires considering multiple factors, including the type of raw materials, requirements for biomass pellet products, output requirements, working environment, operating costs, etc.

The following are some suggestions to help you choose a suitable biomass pellet machine in the construction of a biomass production line:

- Understand the characteristics of raw materials:

Before choosing a small biomass pelleting machine, you need to have a detailed understanding of the raw materials to be used. This includes the moisture content, thermal conductivity and other characteristics of the raw materials, which will directly affect the selection of the biomass pellet machine and the pelletizing effect. - Determine the pelleting requirements:

clarify the requirements for biomass pellets after pelleting, output requirements, and pelleting efficiency. These requirements will help you choose the appropriate type and configuration of biomass pellet machines. - Choose the right type of biomass pellet machine:

Choose the right type of small biomass pellet machine according to the characteristics of the raw materials and the pelleting process requirements.

For example, for raw materials such as rice husks, palm shells, sawdust, peanut shells, and bamboo, if they are used to process biomass fuel pellets, you need to choose an MZLH biomass pellet machine (without a conditioner); for raw materials such as forage, straw, alfalfa, and elephant grass, if you want to process biomass feed pellets, you need to choose a forage biomass pellet machine (need to be equipped with a conditioner). - Consider the working environment:

Consider the working environment of the small biomass pelletizing machine, such as temperature, humidity, dust, etc. These factors will affect the service life and maintenance cost of the biomass pellet machine, so you need to choose a biomass pellet machine that can adapt to harsh working environments. - Evaluate operating costs:

When choosing a small biomass pellet press machine, in addition to considering the purchase cost of the equipment, you also need to consider the operating costs of the equipment, such as maintenance costs, energy consumption costs, and replacement costs of wearing parts. Choosing a biomass pellet machine with good cost-effectiveness will help reduce operating costs. - Reference experience and technical support:

When choosing a small biomass wood pellet machine, you can refer to the experience and technical support of other similar projects. Understand the after-sales service and technical support capabilities of the biomass pellet machine manufacturer to ensure that you can get timely technical support and maintenance services during use.

In summary, choosing a suitable small biomass pellet mill machine requires comprehensive consideration of multiple factors, including raw material characteristics, pelletizing requirements, product requirements, working environment, operating costs, etc.

By understanding these factors and referring to professional advice and experience, you will be able to choose a biomass pellet machine suitable for your project and provide strong support for the construction of a biomass pellet manufacturing plant.

How to choose a small biomass pellet machine manufacturer?

Biomass pellet mill machines are increasingly widely used in the industrial field, but facing the numerous small biomass pellet machine manufacturers on the market, how can you choose a manufacturer that suits your needs? The following will answer this question for you and provide some professional advice.

1. Clear business needs and budget

Before choosing a small biomass pellet maker machine, you should have a clear understanding of your business needs and budget. This includes the type of raw materials that need to be pelletized, the power of the equipment, and the size of the equipment. After understanding this information, you can more accurately find a biomass pellet machine manufacturer that suits your needs.

2. Preliminary selection of manufacturers

Based on market research and peer recommendations, select several manufacturers with strength and scale for inspection. Specifically include details such as production scale, delivery cycle, transaction method, delivery instructions, training methods, after-sales matters, etc.

3. Investigate the performance and configuration

When inspecting small biomass pelleting machine manufacturers, you need to pay attention to important accessories such as ring dies, rollers, bearings, motors, feeders, conditioners, and the brands of these accessories.

These parts directly affect the pelletizing effect of the small biomass pelleting machine, and the prices of different brands are also very different. Avoid being deceived by bad manufacturers using inferior accessories to impersonate imported accessories.

4. Pay attention to the strength and experience of the manufacturer

A strong manufacturer usually has a standardized production workshop, many years of production experience and continuous research and development capabilities.

These factors can guarantee the quality and performance of the biomass pellet machine. When choosing a small biomass pellet machine manufacturer, be sure to pay attention to their strength and experience.

5. Understand the processing technology

The processing technology of small biomass pellet machines is closely related to various hardware equipment, power and other factors. When choosing a biomass pellet machine manufacturer, understand their processing technology and equipment configuration.

In addition, the proficiency of the operator will also affect the performance of the biomass pellet machine, so the manufacturer should provide professional training and technical support.

6. Pay attention to the after-sales service system

A complete after-sales service system is an important guarantee for user rights. A strong biomass pellet making machine manufacturer will provide customers with one-stop after-sales service from the user’s perspective, including equipment installation, commissioning, training, repair and maintenance.

When choosing a biomass pellet machine manufacturer, do not ignore the importance of after-sales service.

7. Understand customer evaluation

When choosing a small biomass pelletizer machine manufacturer, it is also very important to understand other customers’ evaluation and word of mouth of the manufacturer. You can learn about the performance and service quality of the manufacturer from peers, friends, or forums, social media and other platforms on the Internet.

This will help you more accurately evaluate the level and reputation of the manufacturer.

8. Visit the site and actual operation

Before purchasing a small biomass pellet press machine, you can ask the manufacturer to arrange for you to visit the site and observe the actual operation process of the biomass pellet machine.

In this way, you can more intuitively understand the performance, stability and ease of operation of the equipment. If possible, try to operate the equipment and conduct actual pelleting tests to ensure that the purchased biomass pellet machine can meet your needs.

9. Compare quotations and comprehensive cost performance

After collecting quotations from multiple small biomass pellet machine manufacturers, you can make a comprehensive comparison, weighing factors such as equipment performance, brand, after-sales service, and choose the one with the highest cost performance.

Please note that you should not blindly pursue low prices, because too low prices may mean unreliable equipment quality and after-sales service.

10. Sign a contract and ensure relevant terms

After determining the manufacturer to purchase the small biomass pellet processing machine, sign a formal contract and ensure that the relevant terms are clear.

These terms should include detailed specifications of the equipment, price, delivery period, payment method, after-sales service, etc. Before signing the contract, be sure to read it carefully to ensure that your rights and interests are protected.

Through the above considerations, you can more confidently choose a biomass pellet machine manufacturer that suits your needs. We hope you can find a suitable partner to provide strong support for your business development. (Find RICHI on youtube )