cattle feed production line

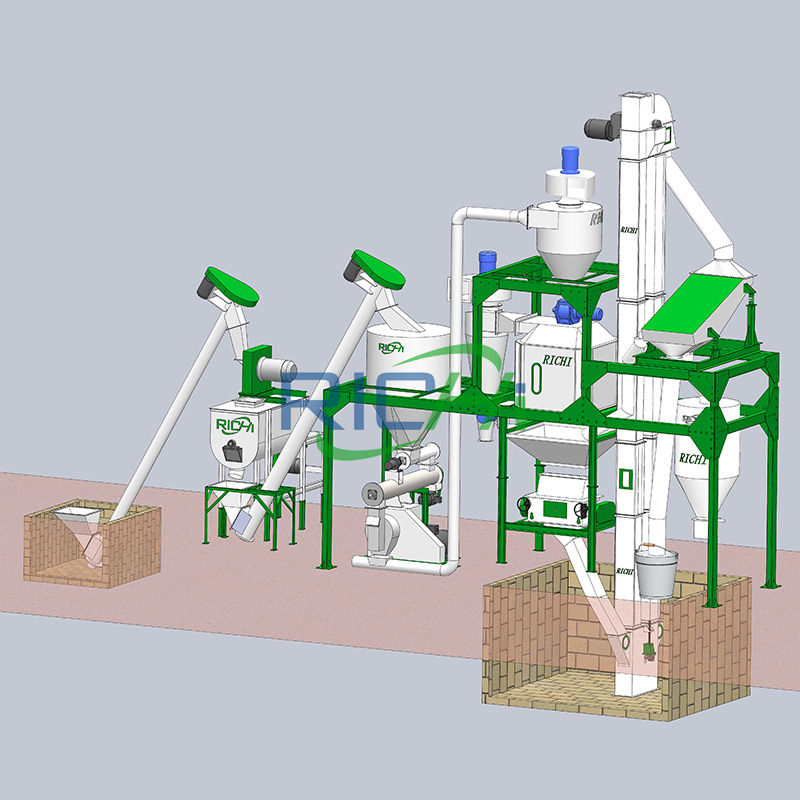

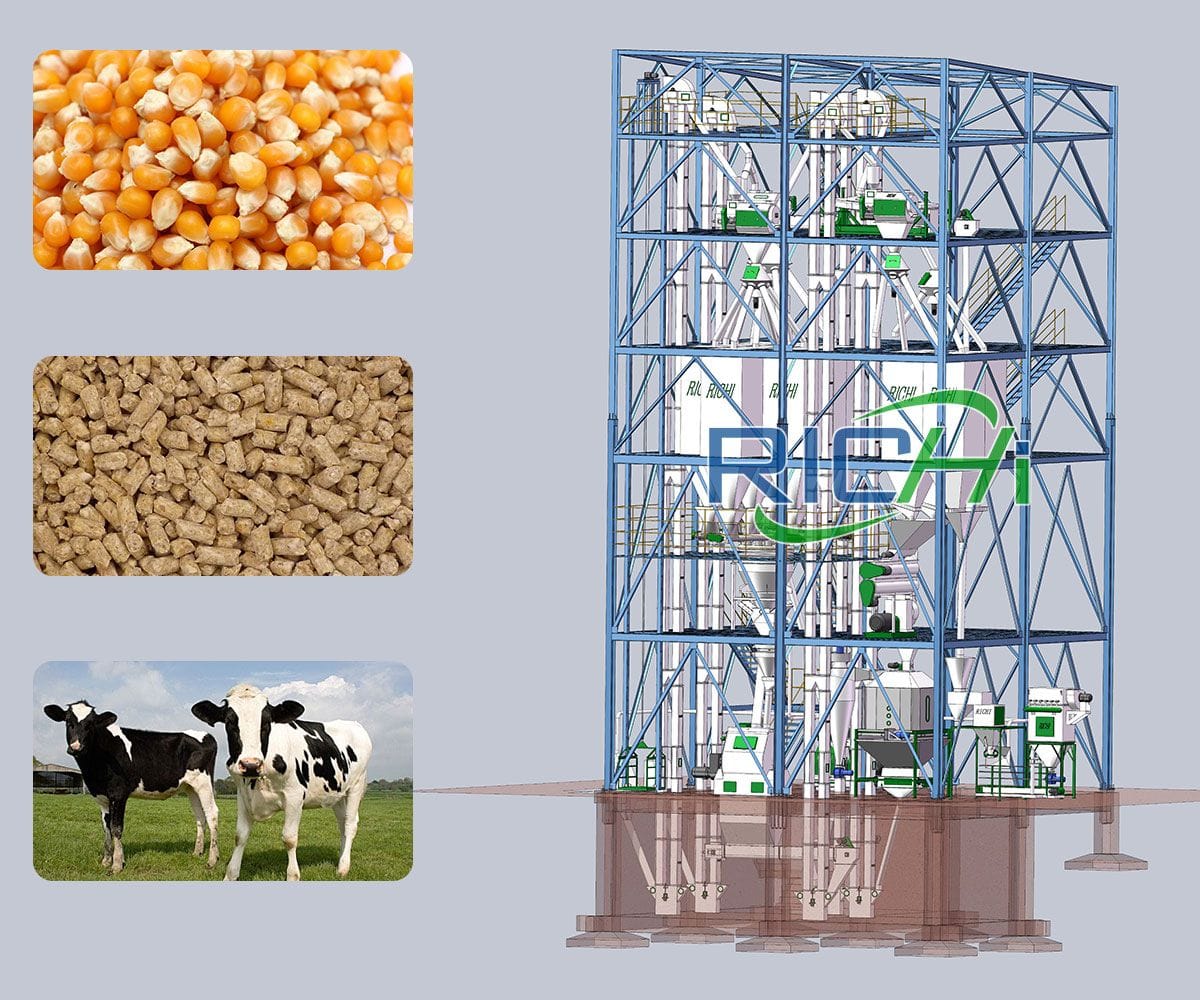

The cattle feed production line is a feed processing system for cattle feed with different growth stages. The feed production line is composed of a variety of machinery and can be customized with different outputs and specifications according to the different needs of customers.

Common cattle feed line includes cattle pellet feed plant, cattle grass feed plant, cattle mash feed plant, maize cattle feed plant, cattle premix feed production line.

RICHI cattle feed line can process cattle feed of various specifications and formulas for dairy cattle feed and beef cattle feed. The entire cattle feed mill line has the advantages of high degree of automation, low operating cost, large output, less pollution, and easy maintenance.

- Capacity: 1-160T/H

- Price: 10,000-5,000,000 USD

- Feed Type: cattle pellet feed, cattle mash feed, cattle grass feed, maize cattle feed, cattle premix feed, fermented cattle feed

- Feed size: 2-12mm cattle pellets feed and mash/powder feed

- Suitable cattle type: cows and beef cattle in different growth stages

- Applicable customers: Cattle feed processors, cattle feed mills, cattle farms

cattle feed production line types

According to the type of feed output, the cattle feed pellet production lines we can provide can be divided into the following types:

compound cattle feed production line

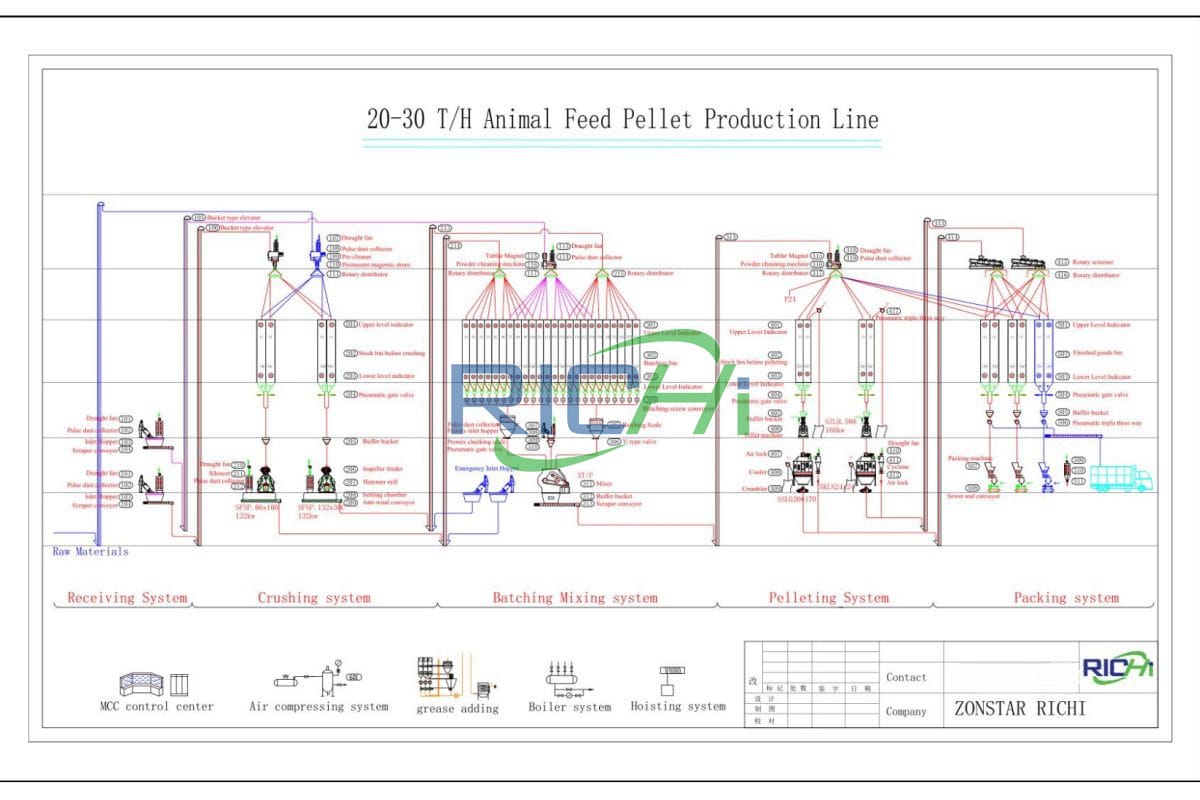

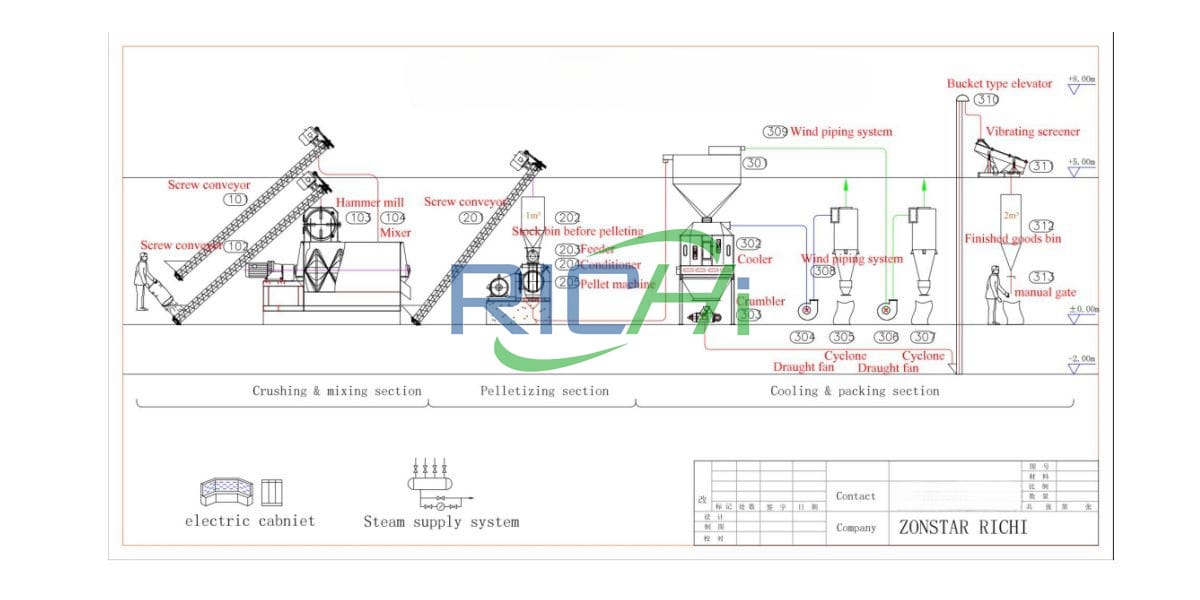

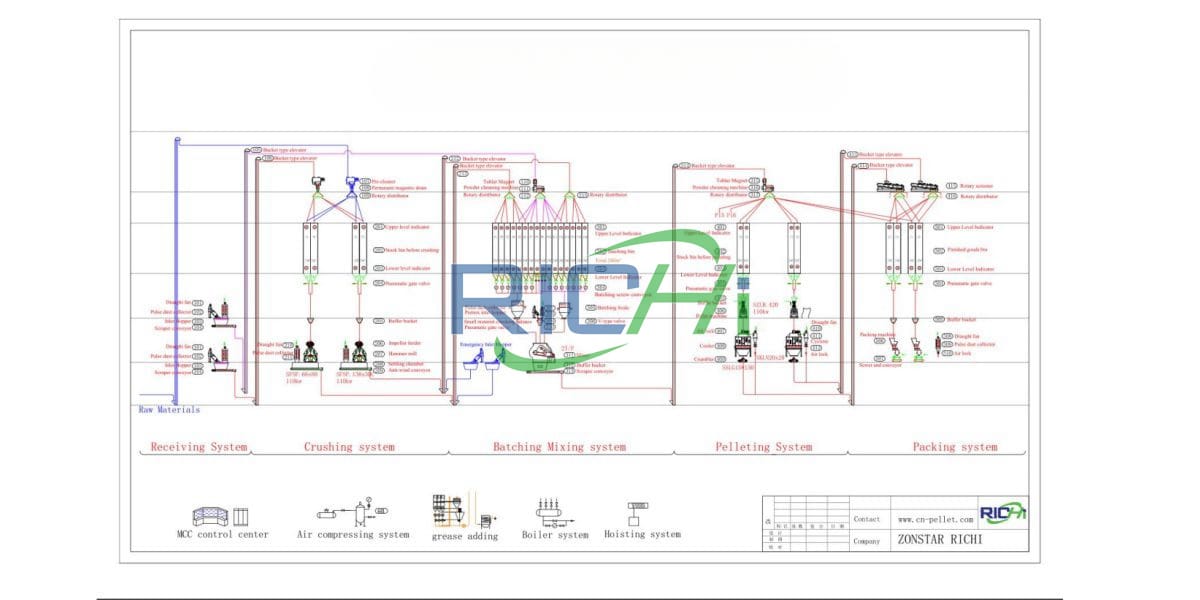

Used to produce compound feed. It must be a feed that contains all nutrients in a balanced proportion and meets the various nutritional needs of cattle. This is one of the most common cattle feed processing systems. The process flow mainly includes: cleaning-crushing-mixing-granulation-cooling-screening-packing.

cattle grass feed production line

Used to process cattle feed made from only grasses, such as hay, fresh grass, alfalfa, timothy, elephant grass, giant grass, straw and other similar raw materials. This is another common cattle feed system. The process flow mainly includes: bale breaking/drying-forage crushing-granulation-cooling-screening-packaging.

Fermented cattle feed production line

Using advanced biological fermentation technology, feed raw materials are converted into fermented feed integrating microbial protein, active amino acids, probiotics, and complex enzyme preparations. While supplementing animal nutrition, it promotes digestion and absorption and improves animal immunity.

Cattle Premix feed production line

Cattle premix feed production line is used to process cattle premix feed. The cattle premix is composed of a carrier that mixes one or more different trace raw materials, such as vitamins, minerals, trace elements or drugs, and they do not contain protein feed. The amount of premix used in feed is usually 1% or less.

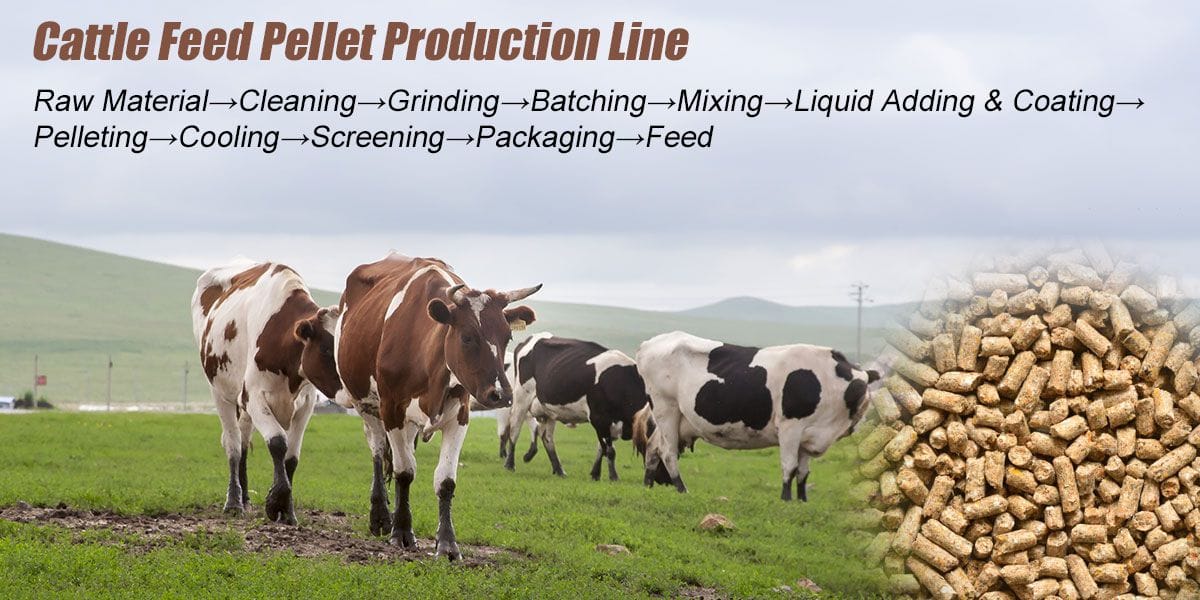

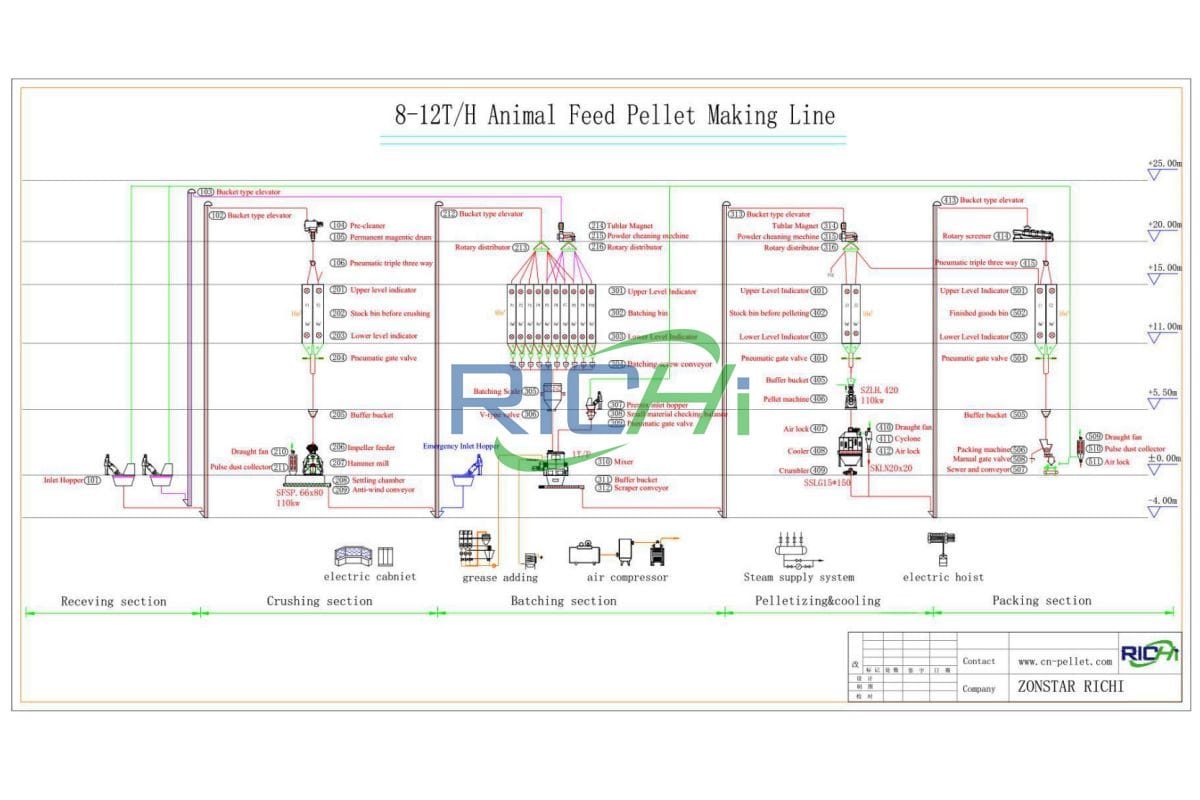

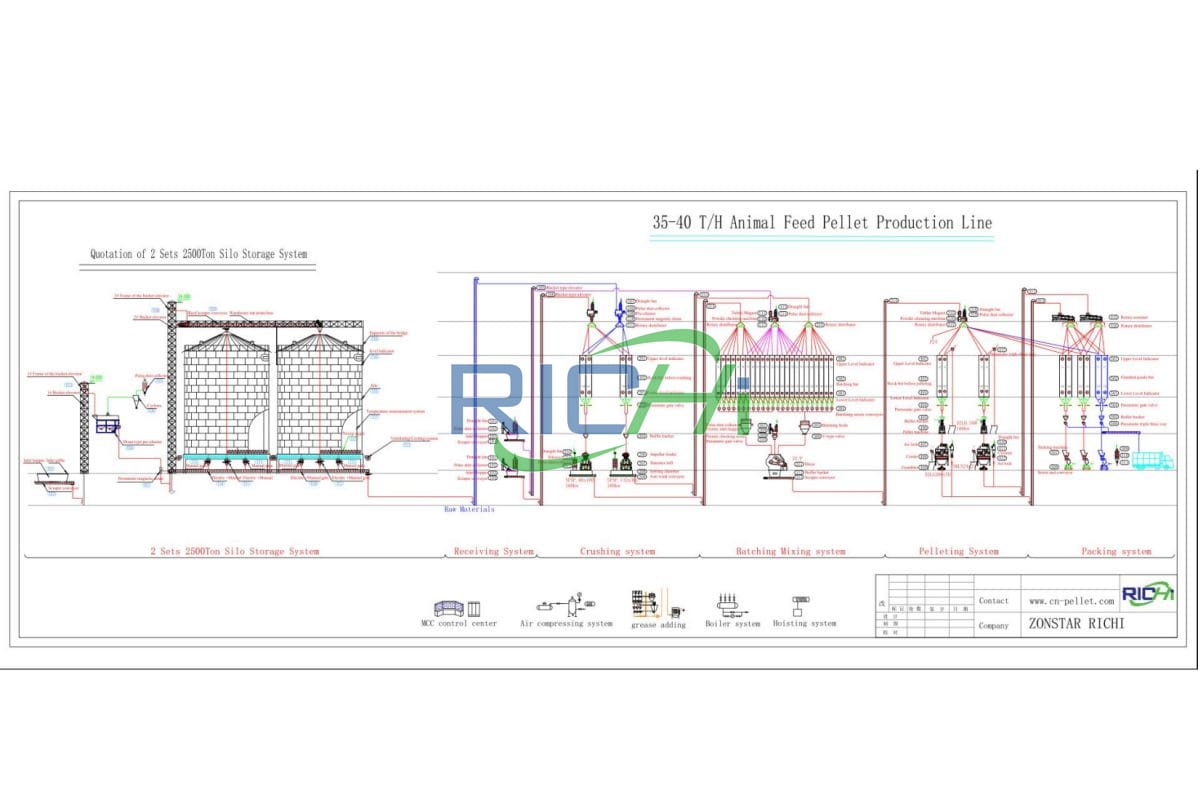

How is cattle feed made? cattle feed production process

The cattle feed production process technology can be briefly summarized as: raw material reception and cleaning → crushing → batching → mixing → forming → measurement and packaging and other main processes.

(If it is a cattle feed production line for processing grass-containing feed, depending on the different storage conditions of the grass, it is necessary to add equipment such as bale breakers, hay cutters, and grass grinders to the process. Eventually, the grass raw materials will appear in the form of grass powder in the mixing section. )

01 Raw material receiving

Receiving raw materials is the first process to ensure the quality of feed products. The settings of receiving equipment and processes must ensure the safe storage of raw materials. During the receiving process, raw material cleaning equipment must be reasonably combined.

02 Raw material cleaning

Impurities mixed in cattle feed ingredients, if not cleaned in advance, will affect product quality and even affect animal growth, damage equipment during processing, and affect production. Generally, the cleaning of animal-derived feed, minerals, trace elements and other raw materials is mostly completed in raw material processing plants.

Cereal raw materials and their processing by-products must be cleaned of ropes, cloths, plastic films, sand, metal and other debris. The usual method of cleaning raw materials is to first screen and then magnetically separate, supplemented by suction and dust removal facilities.

03 Crushing process

The crushing process is one of the main processes in the cattle feed production line. The quality of crushing directly affects the quality, output, power consumption and other comprehensive costs of feed production, and also affects the intrinsic quality and feeding effect of the feed. For crushing particle size control, just select the corresponding screen hole for the hammer crusher.

04 Dosing system

Ingredients are the core part of the feed processing technology, and the correct implementation of the formula is guaranteed by the ingredients process. The changes in the batching system are mainly to adapt to the increase in added varieties, the reduction in the amount added, and the improvement of weighing accuracy.

At the same time, the weighing cycle should be shortened and the production volume per unit time should be increased.

05 Mixing system

Mixing is an important link to ensure feed quality and improve feed returns. The key to the mixing process is how to ensure uniform mixing. There are three main aspects to consider: mixing time, mixer door and preventing grading after mixing. The mixing time is generally designed to match the batching time of the scale and the mixing time recommended by the mixer manufacturer.

06 Pelleting & Cooling Process

The granulation process includes: granulation and cooling. After the mixed materials are conditioned from the pelleting bin, they are sent to the compression chamber of the cattle feed pellet machine and compressed into pellet feed.

The newly made pellets are still in a state of high humidity and temperature and need to be cooled in a cooling equipment. After cooling in the cooling tower, it is screened by screening equipment to obtain standard pellets. We can also provide cattle feed extruder to process extruded cattle feed pellets.

07 Screening & packaging section

The feed is weighed from the finished product warehouse through a packaging scale, put into packaging bags, and then the packer inserts the label and seals it, and then is transported to the warehouse by a transport truck for stacking.

The above process is based on the processing of complete compound cattle feed as an example. If you want to process other types of cattle feed, contact us to customize your cattle livestock feed production line plan!

Basis for cattle feed production line process design

- The estimated scale of the cattle feed factory, the commercial radius of the product, and the customer’s product usage habits.

- Product varieties, specifications, and classification of product lines according to regulatory requirements.

- Types, quality specifications, physical properties (including density, fluidity, storage conditions, etc.) and receiving methods of raw materials.

- Product formula composition and expected dosage of cattle feed raw materials

- Specific indicators of cattle feed production process design, such as requirements for crushing, mixing, liquid addition, granulation, extrusion and puffing, etc.

Equipment for cattle feed production line

cattle Feed Grinder machine

Capacity:

3-25 T/H

Main Power:

30-160 KW

cattle Feed Mixer machine

Capacity:

250-2000 KG

Main Power:

4-55 KW

Bale breaker

Capacity:

1-20 T/H

Main Power:

30-90 KW

Grass crusher

Capacity:

0.3-3 T/H

Main Power:

22-93 KW

cattle Feed Extruder machine

Capacity:

1-12 T/H

Main Power:

0.75-355 KW

grass dryer machine

Capacity:

Customizable

Rotate speed

3-8 R/Min

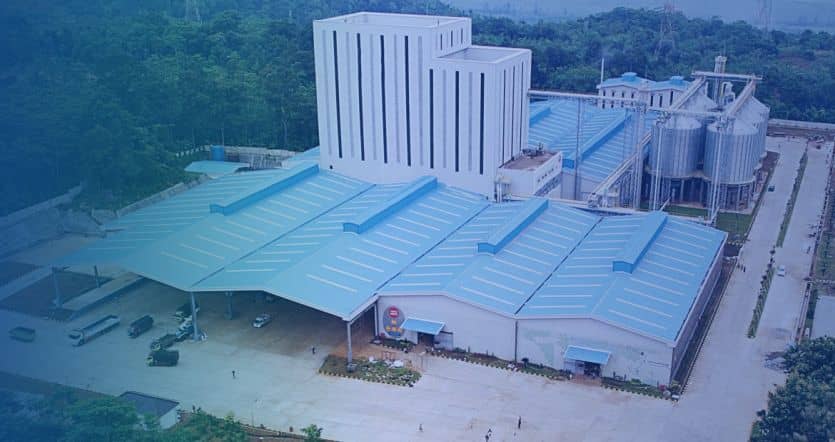

cattle feed production line projects

3-5T/H cattle feed line in Indonesia

- Date: April 9th, 2018

- Feed Type: cattle grass pellet feed

- The install period: 30 Days

- Workshop size(L*W*H): 10m*5m*12m

- cattle feed production line price: 110,000USD

3-4T/H cattle feed line in Vietnam

- Date: Nov 1st, 2019

- Feed Type: cattle grass pellet feed

- The install period: 45 Days

- Workshop size(L*W*H): 60m*24m*12m

- cattle feed production line price: 150,000 USD

15T/H cattle feed line in Saudi Arabia

- Date: March 30th, 2018

- Feed Type: cattle hay pellet feed

- The install period: 60 Days

- Workshop size(L*W*H): 16m*8m*12m

- cattle feed production line price: 480,000 USD

10-12 T/H cattle feed line in United States

- Date: May 2019

- Feed Type: cattle hemp pellet feed

- Feed Pellet Size: 4-8 mm

- The install period: 40 Days

- cattle feed production line price: 380,000 USD

40-42T/H cattle feed production line in russia

- Date:June 2019

- Feed Type: cattle pellet feed

- Feed Size:3-8mm pellets

- The install period:10 months

- cattle feed plant cost:1,800,000USD

5 t/h cattle feed production line in Argentina

- Date:2021.10.11

- Feed Type: alfalfa pellet feed

- Feed Pellet Size:6-8 mm

- The install period:50 Days

- cattle feed plant cost:184,500 USD

5 T/H cattle feed production line In El Salvador

- Date:2020.11.19

- Feed Type: cattle premix feed

- Control Mode:Full Automatic

- The install period:90 Days

- cattle feed line price:450,000 USD

0.8-4T/H cattle feed production line in south africa

- Date:May 19, 2021

- Feed Type: straw cattle pellet feed

- Pellet Size:6-8mm

- MAIN POWER:283KW

- cattle feed line price:85000-95000USD

cattle feed production line price

Based on our past cattle feed plant project experience and data, the cattle feed manufacturing plant cost usually conforms to the following price range:

| Capacity | cattle feed production line price (USD) |

| 1-2 T/H | 10,000-50,000 |

| 3-4 T/H | 50,000-120,000 |

| 5-7 T/H | 70,000-250,000 |

| 8-10 t/h | 150,000-300,000 |

| 12-20 t/h | 250,000-580,000 |

| 25-40 t/h | 450,000-850,000 |

| 50-60 t/h | 900,000-1,400,000 |

| 60-80 t/h | 1,450,000-1,800,000 |

| 80-100 t/h | 2,000,000-2,800,000 |

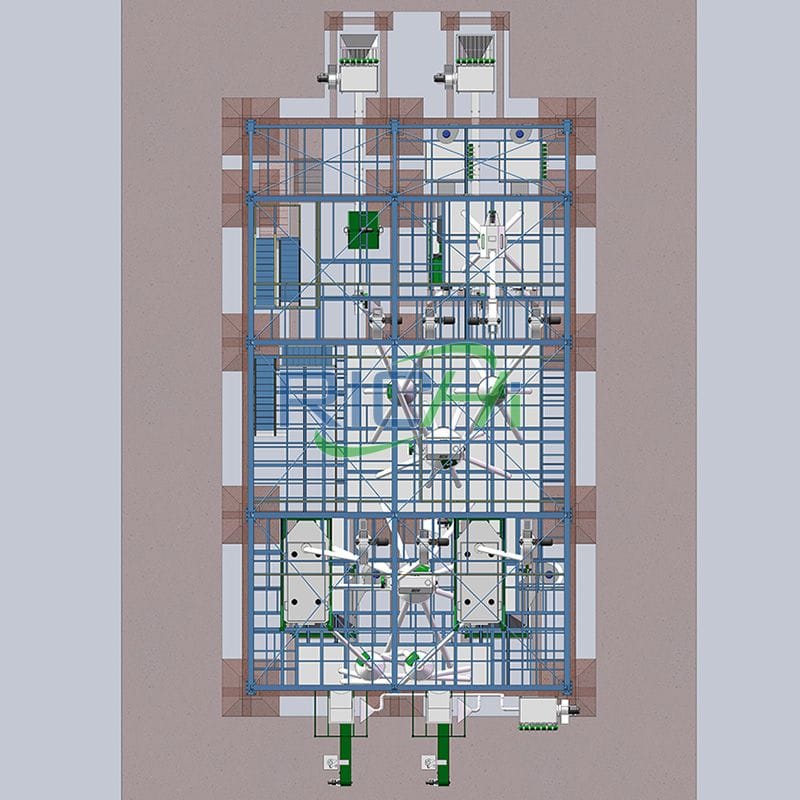

Customized cattle feed production line design and equipment configuration

For different customer needs, we will customize different cattle feed production line designs; for different fully automatic cattle feed plant designs, we will provide customers with the most suitable cattle feed equipment.

4-6 T/H cattle feed Line equipment (100% Dryed Bale Hay)

| cattle feed machine name | Model | QTY |

| Bale breaker | MPKJ170*225 | 1 |

| Belt conveyor | TDSJ120*400 | 2 |

| Straw/Grass crusher | 9FQ50-120 | 2 |

| Cyclone | ф1000 | 2 |

| Pulse dust collector | TBLMa.36b | 2 |

| Hay pellet machine | MZLH-520 | 2 |

| Belt conveyor | PDS-500 | 1 |

| Bucket elevator | TDTG36/18 | 1 |

| Vibrating screener | TDZS80 | 1 |

| Storage bin | 4m³ | 1 |

| Packing machine &Belt and sewing machine | DCS-50 | 1 |

equipment for 5-6T/H cattle Feed making Line (60% Alfalfa)

| cattle feed machine name | Model | QTY |

| Straw/Grass crusher | 9FQ56-120 | 1 |

| Pulse dust collector | TBLMa.36b | 1 |

| Screw conveyor | TLSU30 | 1 |

| dairy feed mixer machine | SLHY2.5L | 1 |

| Storage bin | 4m³ | 1 |

| Force feeder | M-42 | 1 |

| Stainless steel conditioner | TZ42*300 | 1 |

| alfalfa Pellet machine | MZLH520 | 1 |

| Cooling Machine | SKLN20*20 | 1 |

| Vibrating screener | TDZS100 | 1 |

| Packing machine& Belt and sewing machine | DCS-50 | 1 |

Equipment list of 1-2 t/h maize cattle feed production line

| cattle feed machine name | Model | QTY |

| Screw conveyor | TLSS16 | 1 |

| cattle feed Hammer mill | 15-200 | 1 |

| cow food mixer machine | SLHY0.5A | 1 |

| Screw conveyor | TLSS20 | 1 |

| Storage bin for making pellet | 1m³ | 1 |

| Stainless steel condtioner | TZQ22*180 | 1 |

| cattle Pellet machine | SZLH-250 | 1 |

| Conterflow cooling machine | SKLN1.0*1.0 | 1 |

| Vibrating sifter | ZDS60*1 | 1 |

| Auto Packing machine &Sewing+belt conveyor | DSC-50 | 1 |

| Vibrating screener | TDZS100 | 1 |

| Packing machine& Belt and sewing machine | DCS-50 | 1 |

Equipment list of 3-4 t/h cattle feed pellet production line

| cattle feed machine name | Model | QTY |

| Screw conveyor | TLSS20 | 1 |

| Iron removing device | Z-Type | 1 |

| cattle feed grinding machine | SFSP.56*40 | 1 |

| Pulse dust collector | TBLMa.8A | 1 |

| cattle feed mixer (Pneumatic door) | SLHY.1 | 1 |

| Feeder | WLQ22 | 1 |

| Stainless Steel Conditioner | TZQ320X200 | 1 |

| cattle feed Pellet making machine | SZLH.320 | 1 |

| Cooling Machine | SKLN14x14 | 1 |

| Rotary screener | SFJH.80x2C | 1 |

| Final pellets storage bin | 2m³ | 1 |

| Auto Packing machine & Sewing+belt conveyor | DSC-50 | 1 |

Equipment list of 10 t/h cattle feed manufacturing line

| cattle feed Equipment Name | Model | QTY |

| Drum type precleaner | SCY63 | 1 |

| corn grinder for cattle feed | SFSP66*60 | 1 |

| cattle feed mixing machine | SLHY2.5L | 1 |

| Scraper conveyor(5m) | TGSU20 | 1 |

| Powder precleaner | SCQZ60*50*100 | 1 |

| cattle Pellet mill | SZLH420 | 1 |

| Stainless steel conditioner | TZ38*300 | 1 |

| Feeder | WLQ25 | 1 |

| cattle pellet Cooling Machine | SKLN20×20 | 1 |

| Rotary screener | SFJH125*2C | 1 |

| Final pellets stock bin | 4m³ | 1 |

| Automatic Packing machine& Sewing machine and belt conveyor | DSC-50 | 1 |

Equipment list of 20 t/h cattle feed production line

| cattle feed Equipment Name | Model | QTY |

| Drum type precleaner | SCY80 | 1 |

| corn grinder for cattle feed | SFSP66*80 | 1 |

| cattle feed grinder | SFSP138*40E | 1 |

| Batching scale | PLC1.0A | 2 |

| cattle feed Mixing machine | SLHJ4.0A | 1 |

| Feeder | WLQ25 | 2 |

| 1-Layer Conditioner | TZ42*3000 | 2 |

| cattle Pellets machine | SZLH420 | 2 |

| cattle pellet Cooling Machine | SKLN20x20 | 2 |

| Rotary screener | SFJZ125*2C | 2 |

| Automatic Packing machine& Sewing machine and belt conveyor | DCS-50 | 2 |

| Heating oil storage tank | SYTZ100 | 1 |

Equipment list of 30 t/h cattle feed making line

| cattle feed Equipment Name | Model | QTY |

| Pulse dust collector | TBLMa.12A | 2 |

| Scraper conveyor | TGSS25 | 2 |

| Permanent magnetic sleeve | TCXT30 | 1 |

| Rotary distributor | TFPX4 | 1 |

| Powder cleaning sieve | SCQZ90*80*110 | 1 |

| feed grinder for cattle | SFSP66*100 | 1 |

| cattle feed grinder machine | SFSP138*50E | 1 |

| cattle Pellet machine | SZLH508 | 2 |

| cow feed mixer machine | SLHJ6.0A | 1 |

| cattle pellet Cooling Machine | SKLN24x24 | 2 |

| Rotary screener | SFJZ150*2C | 2 |

| Packing machine | DCS-50 | 2 |

| Sewing machine and conveyor belt | 2 |

Equipment list of 60 t/h cattle feed processing line

| Equipment Name | Model | QTY |

| cattle feed grinding machine | SFSP66*100 | 2 |

| cattle grain Hammer Mill | SFSP138*50E | 2 |

| Batching scale | PLC1.5A | 4 |

| Single-shaft cattle feed mixing machine | SLHJ6.0A | 2 |

| cattle Pellet machine | SZLH508 | 4 |

| 1-layer SS Conditioner | TZ42*3000 | 4 |

| Variable-frequency Feeder | TWLL32 | 4 |

| cattle pellet Cooling Machine | SKLN24x24 | 4 |

| Rotary screener | SFJZ150*2C | 4 |

| Packing machine (& Sewing machine) | DCS-50 | 4 |

| Heating oil storage tank | SYTZ200 | 2 |

| Add oil line | 2 | |

| Weight oil system | 2 |

The above listed are only some of the main cattle feed mill equipment, and many auxiliary equipment are needed to form a cattle feed production line.

Each customer has different raw material formulas, different plant conditions, and the equipment, technology, and configuration of the production line will also be different. If you want to build a cow cattle feed production line, contact us to configure your production line equipment!

Advantages of cattle feed production line

The complete livestock feed production line is a production method that uses automated equipment and scientific feed formula to produce high-quality feed. It has the following advantages:

- Precise ingredients and waste reduction:

RCIHI cattle feed production line is equipped with a precise batching system that can accurately mix various raw materials according to needs. This not only improves the quality of feed, but also reduces the waste of raw materials and reduces production costs. - Optimize production process:

RCIHI cattle feed production line can monitor the production process in real time through an intelligent control system. Manufacturers can use data analysis to identify bottlenecks and inefficient links in production, optimize them, improve production efficiency, and reduce production costs. - Full utilization of raw materials:

RCIHI cattle feed production line can make full use of various raw materials, including the utilization of by-products or waste materials. This not only saves raw material costs, but also reduces waste disposal costs. - Automation reduces labor costs:

RCIHI cattle feed production line has a high degree of automation, reducing the need for manual operations. This reduces labor costs, reduces errors caused by human factors, and improves production efficiency and product quality. - Predictive maintenance reduces downtime:

Some RCIHI cattle feeds production lines are equipped with predictive maintenance systems that can predict equipment failures in advance and avoid downtime caused by sudden failures. This can maintain the continuity of production and increase output. - Flexible production adjustment:

The intelligent system of RCIHI cattle cow feed production line makes the production process more flexible. The feed formula and production scale can be adjusted at any time according to market demand, adapting to market changes, improving market response speed and reducing inventory costs. - Product quality assurance:

The precise control and quality monitoring system of the RCIHI cattle feed production line ensures the stable quality of the feed. High-quality products help improve market competitiveness, achieve better sales prices, and increase product added value.

In summary, the RCIHI cattle feed production line has created economic benefits for breeding enterprises and provided a guarantee for sustainable development through its advantages in increasing output, reducing costs, and ensuring product quality.

cattle feed production line Videos

How to choose a suitable cattle feed production line?

In the agricultural field, the choice of animal feed production line is an important decision, which directly affects the growth effect and breeding efficiency of animals. Especially for cattle husbandry, the quality of feed is directly related to the growth rate and meat quality of the animals. So, how to choose a suitable cattle feed production line?

- Clarify the classification of cattle feed production lines.

Generally speaking, powder feed production lines are suitable for producing feeds with lower protein content, while pellet feed production lines are suitable for producing feeds with higher protein content. Therefore, when selecting a feed production line, it needs to be determined according to the type of feed produced. - Consider the production capacity of the cattle feed production line.

Production capacity refers to the amount of feed the production line can produce every day.

When selecting a feed production line, we need to determine the production capacity of the production line based on the scale of investment, the scale of the cattle feed factory, the size and demand of the breeding farm. If the investment is large or the scale of the farm is large and the demand is large, then you need to choose a large-capacity feed production line. - Consider the price of a cattle feed production line.

Price is an important factor affecting breeding costs. When choosing a feed production line, you need to choose a reasonably priced production line based on your own economic conditions.

At the same time, it is also important to note that although lower-priced production lines may save some costs on initial investment, in long-term operation, the overall operating costs may increase due to the costs of maintenance and replacement of parts. - Consider the stability and reliability of the cattle feed production line.

Stability and reliability are important factors to ensure the normal operation of the feed production line. When choosing a feed production line, you need to choose a production line with good stability and low failure rate. At the same time, we also need to regularly maintain and inspect the production line to ensure its stable operation.

In general, choosing a suitable cattle feed production line requires comprehensive consideration of many factors. We need to make a selection based on the type of feed produced, the size and needs of the farm, our own economic conditions, and the stability and reliability of the equipment.

How to build a cattle feed production line?

- Market analysis

Before setting up a cattle feed production line or cattle feed mill plant, it is necessary to conduct sufficient analysis and research on the market to understand the current market demand and competition.

Market research can be conducted to understand the supply and demand situation, consumer demand and quality requirements of the local animal feed market, and provide reference and support for production positioning. - Cattle feed making equipment investment

In the cattle feed production process, the selection and investment of animal feed mill equipment is a very critical link. You need to choose suitable production equipment based on your own economic strength and market demand to ensure the quality and efficiency of the cattle feed making process and save production costs as much as possible.

At the same time, issues such as spare parts, maintenance, and upgrades also need to be considered to ensure the long-term stability of cattle feed processing equipment. - Personnel Recruitment

People are also crucial in the cattle feed production line. It is necessary to consider the quantity and quality of employees, conduct vocational training and career planning for the positions, and determine employee salary policies and benefits.

During the personnel recruitment process, it is also necessary to pay attention to labor laws and related policies and regulations to ensure that legal, honest and high-quality employees are introduced to work in the cattle feed manufacturing plant. - Production process

After determining the market positioning, purchasing cattle feed mill equipment, and recruiting personnel, a complete cattle feed production process needs to be determined. This process should include raw material procurement, production, quality inspection, packaging and logistics. Imperfect processes can lead to problems such as reduced efficiency, material waste, and increased costs, so processes need to be carefully planned, implemented, and tracked. - Capital investment

Establishing a cattle feed production line requires a large amount of capital investment, including expenditures on equipment, personnel, materials, site rental, electricity bills, etc. When investing funds, it is necessary to do a good job in capital budgeting and risk assessment, and establish a reasonable investment plan to ensure the flexibility and efficiency of fund use.

At the same time, attention should be paid to agreements and communication with banks, investors and shareholders to establish good trust and cooperative relationships.

There are many more aspects to consider when setting up a cattle feed production line, but the above aspects have covered many of the major issues. Before setting up a feed mill, it is necessary to fully understand the market demand and formulate a reasonable plan.

At the same time, it is necessary to fully prepare funds and seek support in terms of talents, cattle feed equipment, and raw materials to successfully launch a cattle feed manufacturing business. (Find RICHI on YouTube)

Why invest in cattle feed production business?

The cattle feed market size is expected to grow from USD 84.5 billion in 2023 to USD 100.36 billion in 2028, at a CAGR of 3.50% during the forecast period (2023-2028).

Globally, the beef cattle market is expected to witness growth over the forecast period owing to factors such as increasing demand for quality beef and high growth in beef consumption in Western countries such as the United States, United Kingdom, and Asia. China is the largest consumer and producer of beef, and the number of beef cattle is also growing.

In 2021, the Food and Agriculture Organization of the United Nations (FAO) predicts that by 2050, demand for cattle products will increase by 1.7% year-on-year, with dairy demand expected to increase by 55% and beef demand by 70%.

Growing demand for milk and dairy products in developing countries will drive the global market over the forecast period.

Europe and North America currently account for a significant share of dairy and meat consumption, while the Asia-Pacific and Latin America regions are expected to grow rapidly. Increased demand for dairy products and beef has led to increased industrialization of the cattle industry.

This means increased herd size, increased use of compound feeds and better scientific management of cattle. This phenomenon contributes to the growth of the cattle feed market.

It is foreseeable that the market size of the cattle feed industry will expand year by year. With the growth of population and improvement of living standards, people’s demand for beef is also increasing. And these demands will eventually promote the explosion of the cattle feed production industry!

cattle feed production line manufacturer

RICHI Machinery offers a range of cattle feed machine as part of their turnkey cattle feed production line solutions. Our services include project design, process engineering, local manufacturing and installation, debugging and after-sales support. With meticulous attention to detail, RICHI Machinery aims to provide the best cattle feed line equipment, service, and business plan for global clients.

- Online and offline communication

- Confirmation of customer needs

- Customized solution design

- Professional transportation solutions

- On-site installation and commissioning

- Customer acceptance items

- Perfect after-sales service

- Complete accessories service