aqua feed mill

We are experts in aqua feed mill equipment. Whether in traditional markets in China and Asia, or emerging markets in Latin America and Africa, Richi Machinery has extensive experience in aqua feed mill construction solutions.

How to choose high-quality, low-cost high-grade fish feed, high-grade shrimp feed, crab feed, aqua feed mill technology solutions? How to make the conditioner better control the maturity of the feed? How to control the sinking and floating characteristics of the extruded material more accurately?

Richi Machinery helps customers improve the efficiency and sustainability of aqua feed production through continuous technological innovations in aqua feed extrusion, pelleting systems, drying and spraying systems, research and application of different raw materials and the growth performance of aquatic species.

aqua feed mill equipment

We offer a wide range of aqua feed mill equipment and are able to meet your specific needs for any fish and shrimp feed production. With decades of experience in designing cleaning, grinding, milling, mixing, extrusion, screening, cooling, coating and bagging equipment for any aqua feed milling plant, you can rely on our expertise to get you the aquatic feed production line solution best suited for you. Need more information on our aqua feed mill equipment? Please the equipment below.

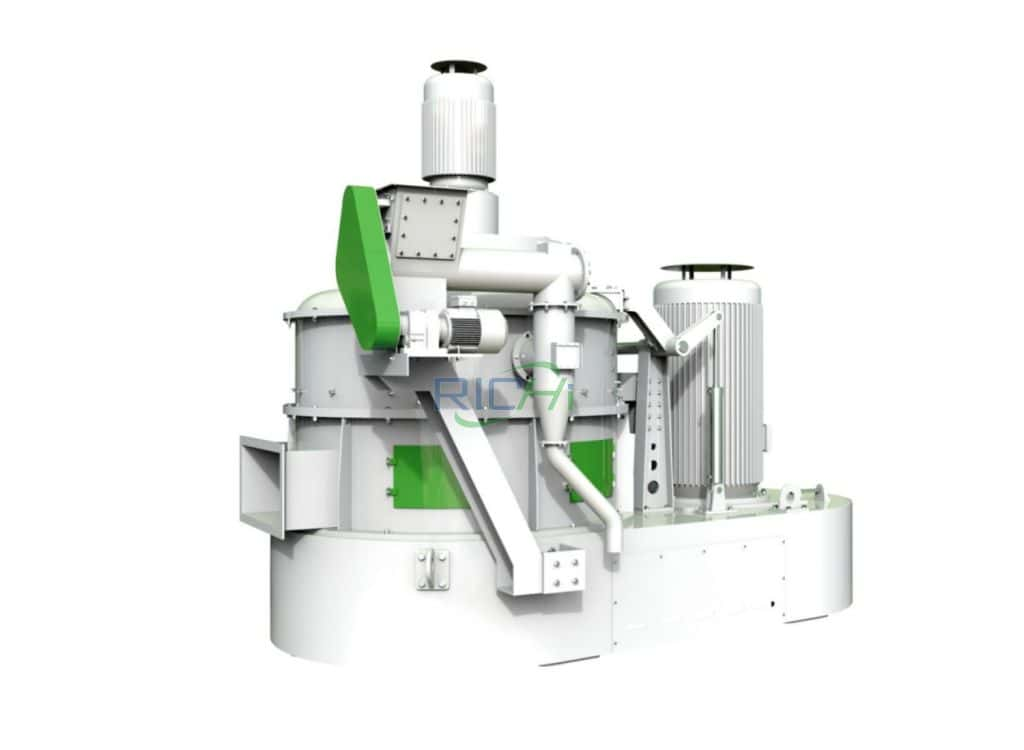

Floating Fish Feed Extruder Machine

Floating fish feed extruder machine can be used for production of various floating, sinking and slow-sinking aquatic extruded feeds. It can meet the needs of various customers such as 0.6mm die hole floatability and 0.8mm die hole sinkability small particles, low starch formula, high protein and high fat California perch, and large particle size grouper.

Capacity: 0.3-4.5T/H

Power: 37-280kw

shrimp feed pellet machine

Shrimp feed pellet machine can produce both sinking and floating shrimp feed. Service time of the die with hole diameter Ø1.8mm is up to 8500t, with continuous production of 2500h and output of over 4.5t. Three-layer jacket insulation conditioner and double-shaft differential conditioner. Optional hygienic conditioner, better maturing performance.

Capacity: 0.3-4.5T/H

Power: 37-280kw

Sinking Fish Feed Machine

Sinking fish feed machine is specially designed for processing sinking fish pellet feed. A new type of conditioner has been equipped to make the final feed maturing degree and uniformity better than the traditional ways. It can improve the fish pellet feed intake and digestion utilization rate and the growth performance and quality of aquatic animals.

Capacity: 0.3-4.5T/H

Power: 37-280kw

supporting equipment for aqua feed mill

For every piece of aqua feed mill equipment at RICHI you have many choices of various auxiliary equipment to add. Besides RICHI’s ability to customize aqua feed mill pellet/extruder machines or complete aqua feed production lines for your requirement, the many add-on possibilities enable you to tailor-make your equipment for any purpose. The auxiliary equipment allows you to embed your aquatic feed mill line operation with many add-ons, enhance it, or make your machine more dynamic.

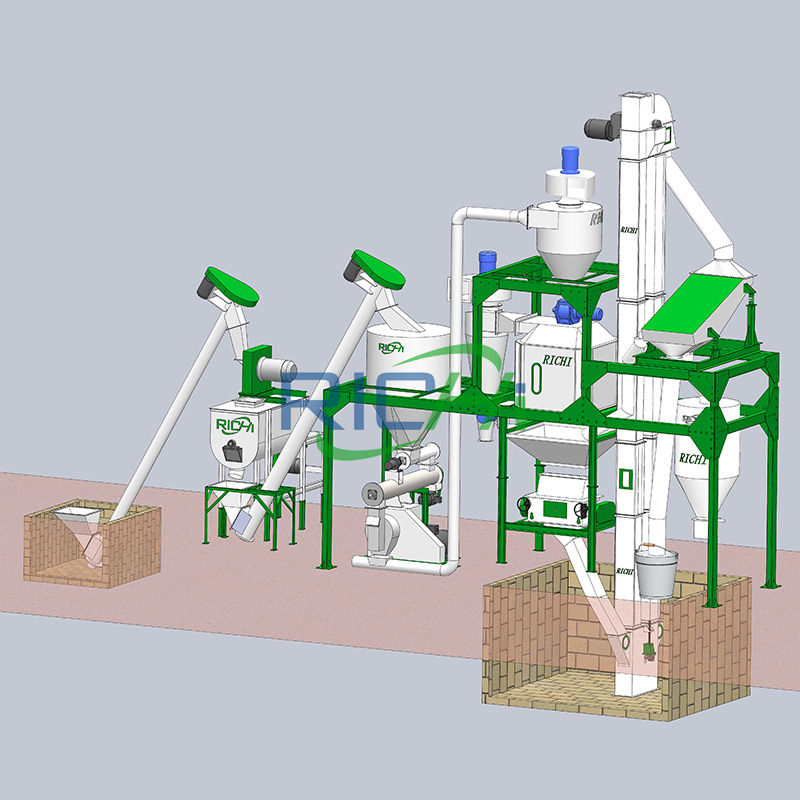

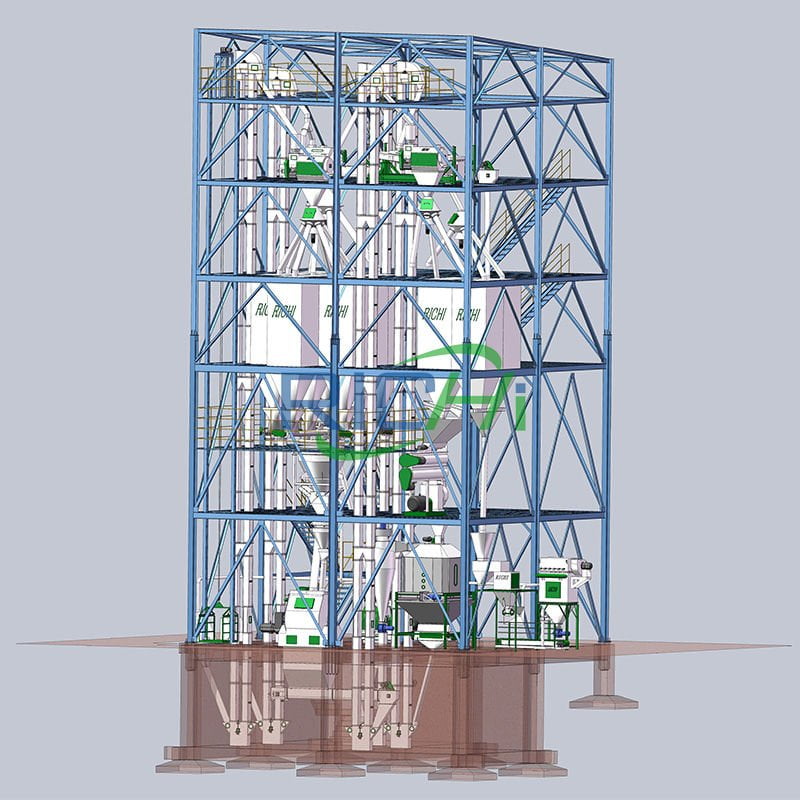

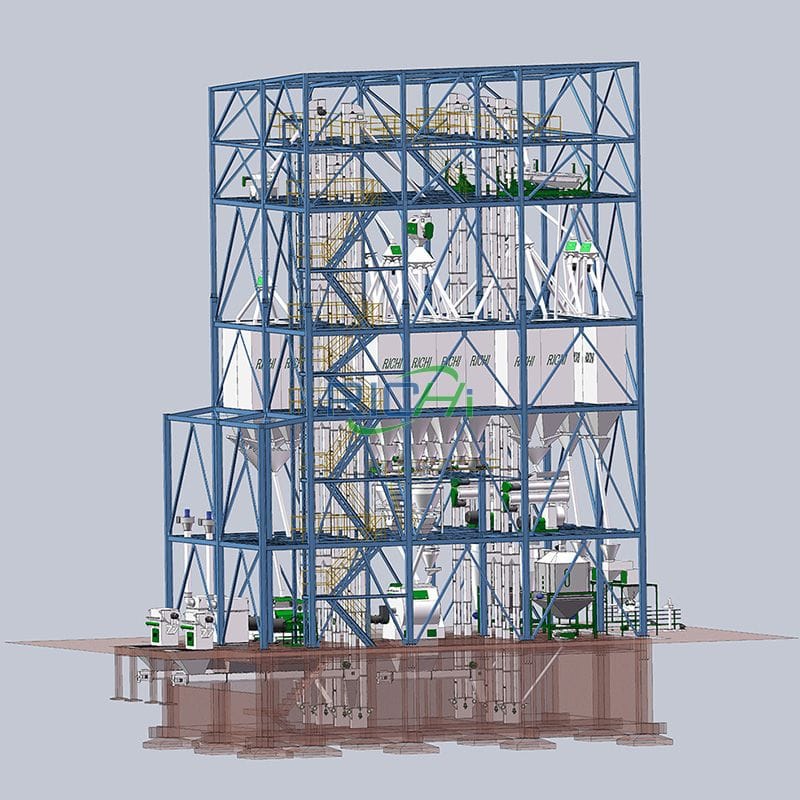

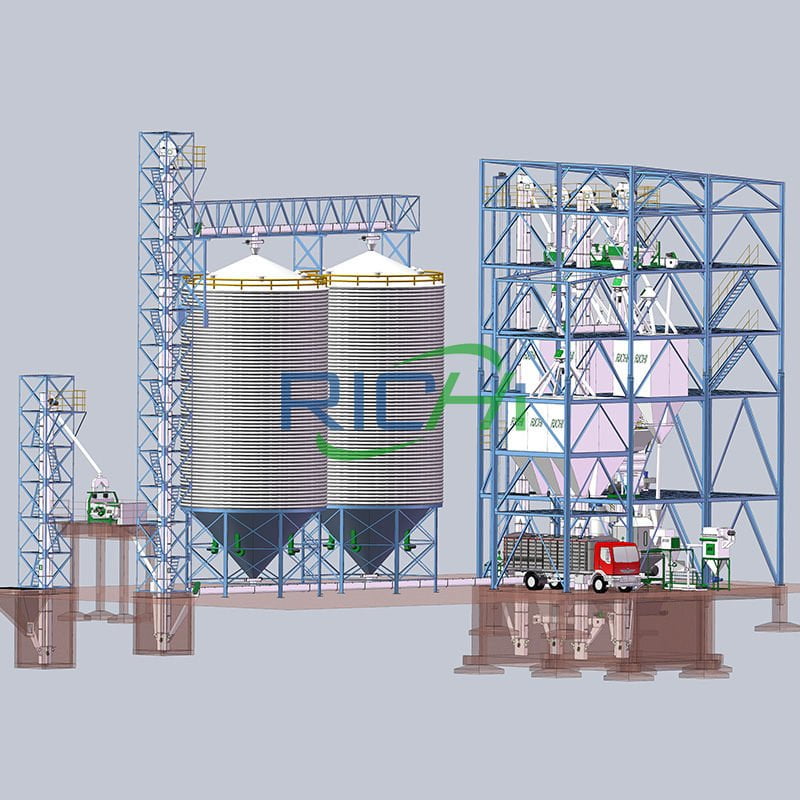

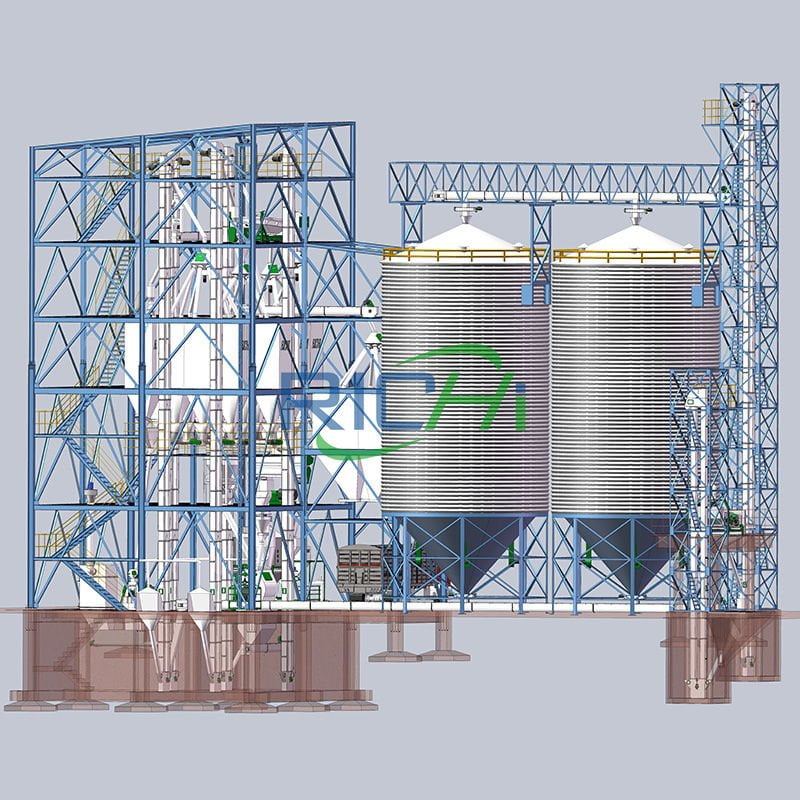

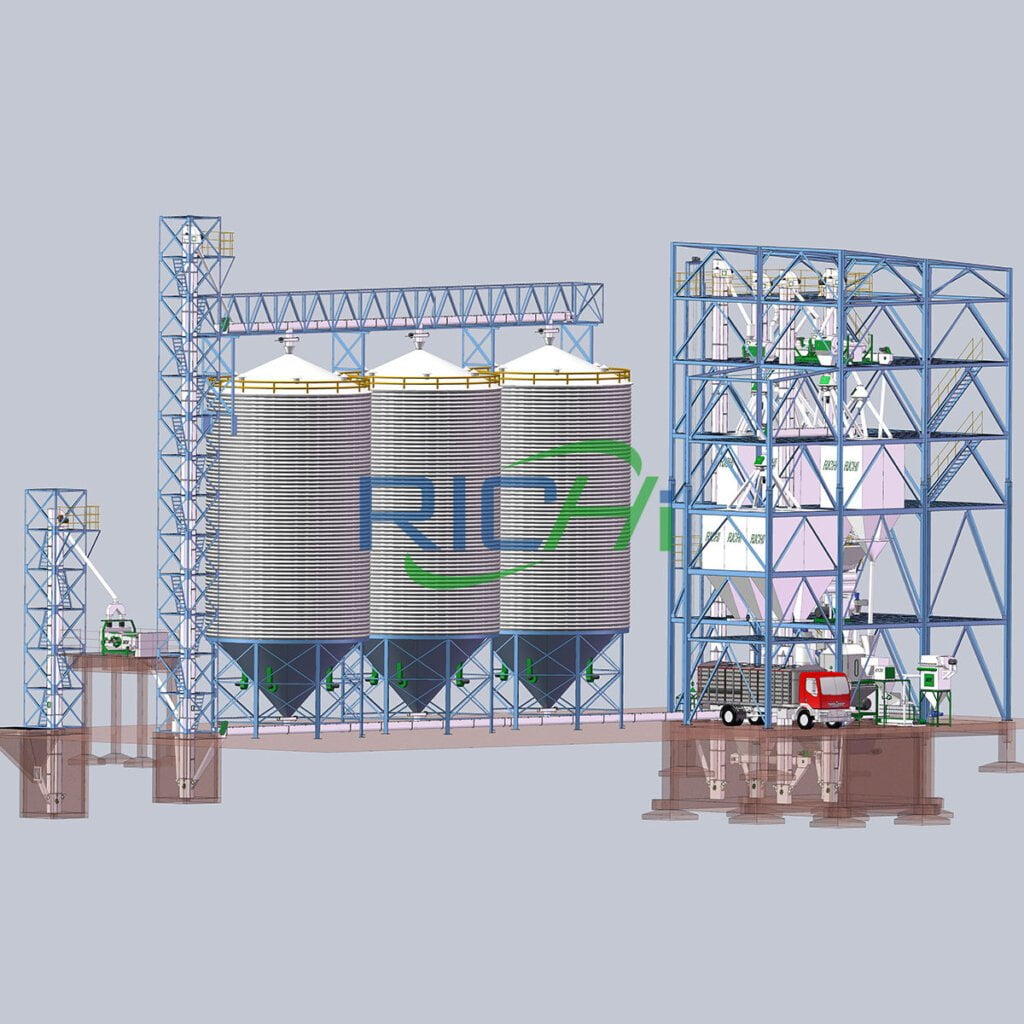

aqua feed mill solution

Creating the perfect aqua feed is essential, tailored to the specific needs of different fish and shrimp at various stages of their lives. At Richi Machinery, we excellent in helping you achieve the ideal balance between aqua feed quality and cost-efficiency. By combining your requirements with our engineering expertise and process knowledge, we design your aqua feed mill configuration to give you a competitive edge in the fish and shrimp feed industry.

auqa feed mill design with different scale

Fish Feed Processing Line

Richi Machinery develops customized 1-2 t/h fish feed processing line solutions for fish feed producers that optimize the production procedure and increase productivity.

Floating Fish Feed Production Line

Feed produced by 3-4 t/h floating fish feed production line is formulated to meet specific animal nutrition requirements for different species of aqua fish at different life stages.

Floating Fish Feed Plant

Complete sets of equipment are the ideal machinery for 4-5 t/h floating fish feed plant, feed company can choose this solution to produce fish feed with high degree of automation.

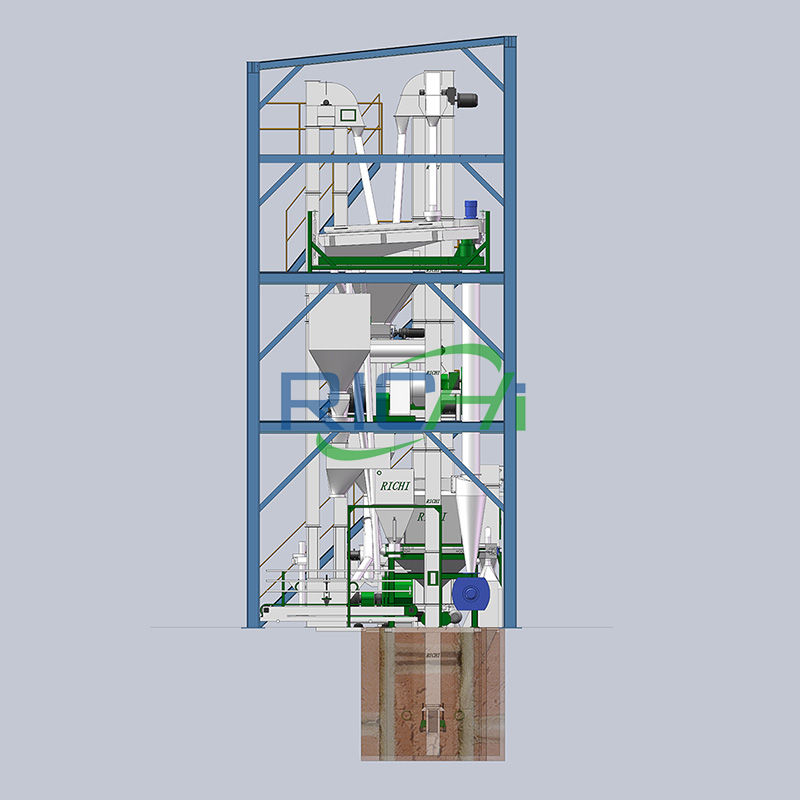

Fish Feed Plant

After years of innovative development, our 6-7 t/h fish feed plant with high efficiency and convenient operation, can cover extrusion and pelleting process in one system.

Fish Feed Mill

RICHI 8-10 t/h fish feed mill equipment provides the opportunity of grinding and proportioning feed for various fish, such as tilapia, catfish, trout, salmon, carp, cod, eel, etc.

Fish Feed Factory

RICHI is one of the largest producer of 10-12 t/h fish aqua feed mill in China and is associated with global fish feed manufacturers since 1995. We have done fish feed factory construction project in 50+ countries.

Fish Feed Manufacturing Plant

We design and build complete 12-14 t/h fish feed manufacturing plant for a wide range of aqua fish species. It can help you produce top quality fish feed and make economical use of energy and raw materials.

Fish Food Factory

We have formed various kinds of 16-20 t/h fish food factory equipment with relatively complete varieties, serialization, standardization. The process can be customized for large, medium and small projects.

Fish Feed Mill Plant

Perfect customized solution, optimal fish feed mill plant equipment configuration. This way we ensure that all components of fish feed factory run at peak performance and by the best available technology.

Aqua Feed Plant

Looking to start an aqua feed business for fish or shrimp prawn feed processing? RICHI Machinery can offer comprehensive 24-28 t/h fish and shrimp feed production solutions for turnkey aqua feed plants in the worldwide.

aqua feed mill with different application

fish feed production line

No matter what your formula is, no matter what your aqua feed mill structure is, no matter what your process requirements are, through RICHI customized fish shrimp feed production line for you process, you will be able to process high-quality fish shrimp feed and obtain higher economic benefits.

catfish feed mill

crab feed mill

trout feed mill

aqua feed mill projects

Reinventing and optimizing the production of aquaculture fish shrimp feed

Countries

aqua feed mill equipment in russia

aqua feed mill equipment in Kazakhstan

aqua feed mill equipment in Indonesia

aqua feed mill equipment in India

aqua feed mill equipment in iran

aqua feed mill equipment in peru

Customer Visit

aqua feed mill videos

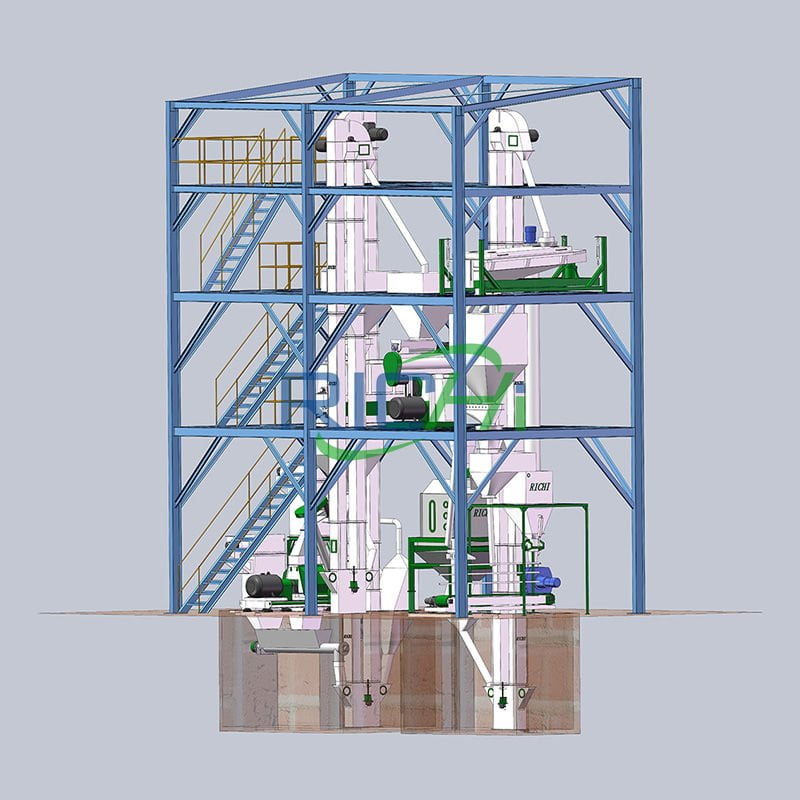

why choose RICHI aqua feed mill equipment?

RICHI tailor-made aquatic feed mill solutions make the difference for fish and shrimp feed

RICHI is a recognized leader in aqua feed mill engineering solutions, specializing in the design, production, and expert installation of custom aqua feed machines tailored specifically for aqua feed mill plant.

Our comprehensive approach revolves around enhancing efficiency and reducing production costs. We’re committed to assisting our valued customers in meeting their feed production goals while lowering their operational expenses.

In addition to high-end technology and the cutting edge fish and shrimp feed mill machinery and turnkey aqua feed factory project solution for aqua feed companies, we provide exceptional after sales service and all-inclusive training of feed mill operation.

Benefits of RICHI aqua feed making machines:

1

Easy-to-build solution / Reduced construction time

2

Can be built by local contractors / Superior flexibility & scalability

3

Easy to operate, upgrade and maintain / Better workflow & easy access to the entire aqua feed mill plant

4

Safer work environment / Improved employee retention

5

Superior performance & efficient production / Consistent feed quality & full traceability

About RICHI MACHINERY

Founded in 1995, Richi Machinery is mainly engaged in the R&D and manufacturing of pellet plant equipment required for industry projects such as animal & aqua & pet feed, biomass agricultural and forestry waste utilization, organic fertilizer, pet litter and urban waste.

All products have passed ISO international quality system certification, EU CE certification and Customs Union CU-TR certification.

At present, the marketing network of Richi Machinery has spread to more than 140 countries and regions in Asia, Africa, Europe, America and Oceania, and has established overseas offices in many countries.

Consultation and Tailor-made design

Equipment manufacturing and testing

Equipment packaging & delivery

Equipment installation & Training

1

What’s aqua feed mill equipment cost?

An aquatic feed mill plant contains a lot of equipment, and the prices of equipment used in different sections vary greatly, ranging from a few hundred dollars, a few thousand dollars, to hundreds of thousands of dollars. The price of a complete aquatic feed equipment system is usually between 20,000-5,000,000 USD (150 kg/h-100 t/h).

2

Are You aqua fish shrimp feed mill equipment Manufacturer?

We are fish shrimp feed plant equipment manufacturer, not a middleman. All aqua feed machines prices are ex-factory prices.

3

What’s an aqua feed mill?

Aqua feed mills are responsible for the production of aqua feeds, including those consumed by aquaculture feed machine, fish and shrimp feed production.

4

Can You Provide Installation Services?

We provide installation and commissioning services for all aqua feed mill plant equipment, and will be responsible for all after-sales technical support services!

5

Can You Test The aqua feed mill equipment Before Shipping?

All RICHI aquatic feed mill machine supports trial service. This is for customers and even more for the RICHI brand.