Pellet Stove Pellet Making Machine

The pellet stove pellet making machine is used to process heating stove pellets. The raw materials are mainly various agricultural and forestry wastes, mainly wooden materials.

what’s Pellet Stove Pellet Making Machine?

Pellet stove pellet making machine is a specialized equipment used to process heating pellets, it is the last stage of raw material formation. The processed pellets can be used for heating of entire home, an apartment, condo, garage, or cabin. The working principle of the pellet stove pellet maker machine is to process biomass waste into granular materials through physical compression and high-temperature heating.

This industrial device comes in many models produced for different purposes. The efficiency of the machine depends on the size of the input material, the type of the machine, and its settings.

Whether you are looking to produce Premium Wood Pellets, Standard Wood Pellets, or other types of heating pellets, RICHI offers a selection of highly rated pellet stove pellet machines perfect for your production needs!

- Capacity: 0.3-5 T/H (single machine)

- Price: 10,000-100,000 USD

- Applicable customers: biomass pellet plants, wood pellet factory, wood chips plant, lumber mills, farms, power plants, farms, industrial enterprises, panel factory, and any other companies and individuals who want to start pellet processing business.

RICHI offers the largest selection of models to complement your pellet production business. RICHI is proud of our reliable pellet machine design that is suitable for commercial or industrial scale pellet production.

Whether you are looking for a wood stove pellet making machine insert for your wood pellet factory or a complete wood pellet plant, we have plenty of solutions to fit your needs!

Pellet stoves are a highly cost effective way of heating home – encased in a range of shapes, sizes and stylish designs, stove pellets are mainly made of compressed wood which is known as biomass.

In fact, there is no need to think of a pellet stove pellet making machine too special, because this is just a wood pellet mill machine. Whether it is used to process pellet stove pellets or fuel pellets and heating pellets for other purposes, this equipment is used .

All manufacturers are the same.

Therefore, when purchasing a wood pellet maker for pellet stove, what customers really need to examine is the quality of the equipment, operating parameters, and whether the final pellet quality can meet the European Union, the United States, Canada and other wood pellet standards.

Applicable raw materials

The raw materials of pellets are usually sawdust, wood chips, wooden pallets, branches, trunks, wood scraps, etc. These raw materials in different physical states mainly come from the following tree species:

- Cherry

- Hickory

- Apple

- Hamer Hot Ones

- Mesquite

- Douglas fir

- Oak

- Pecan

- …

In addition to wood-based raw materials, many customers currently use a variety of raw materials to pellet together. Whether it is pure wood pellet processing or biomass mixed pellet processing, as long as you are sure that the final pellet product has a market and can make you profitable, you are always welcome to contact us to customize your pellet stove pellet making machine and pellet processing plan!

Characteristics of pellet stove pellet maker machine

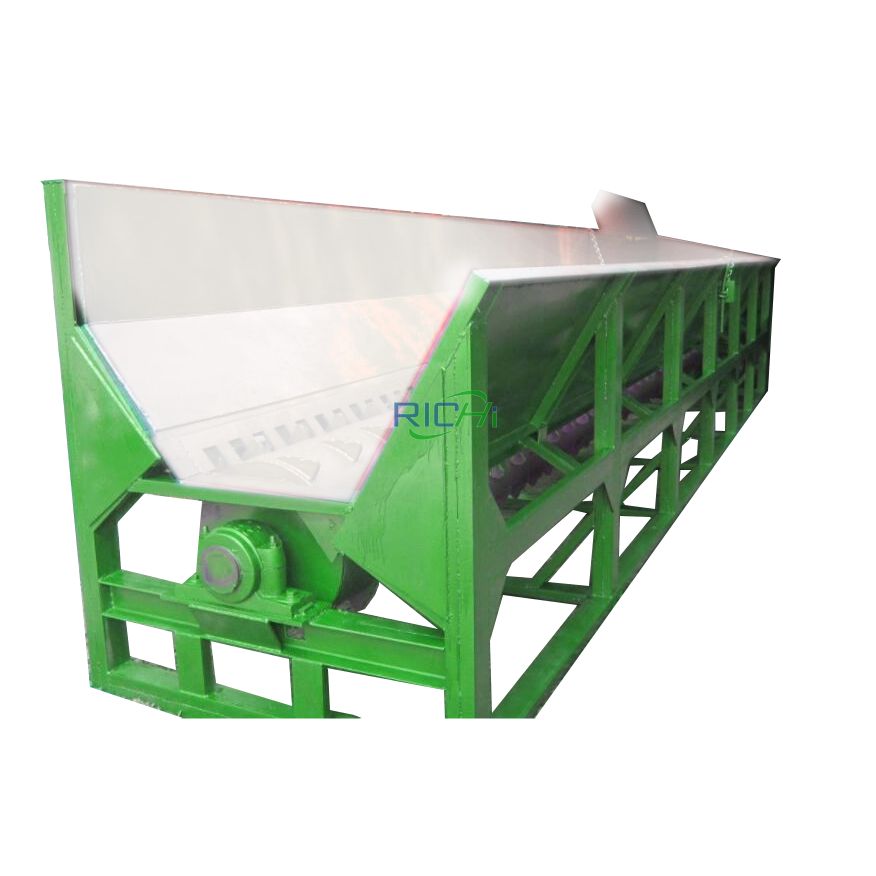

- Since raw materials such as sawdust have low density and poor fluidity compared to feed, they will not enter the pressing chamber for granulation under the action of gravity. Therefore, they need to be given a certain amount of power, thus requiring a forced feeder. The forced feeder adopts auger type conveying.

- The conjoined hollow shaft and main shaft in the wood stove pellet maker machine are forged parts, which increases the service life of the equipment.

- Adopts horizontal spindle transmission. The specially designed spindle is made of forging material, which has a longer service life and higher transmission efficiency;

- Creatively adopts a bidirectional ring die design structure with dual apertures and dual compression ratios to meet the special requirements of different raw materials, different apertures, and different compression ratios, and exponentially improves the ring die life and raw material adaptability;

- The customized gear transmission box is designed as a separate main and auxiliary oil tank to effectively avoid gear wear;

- The transmission part uses high-quality bearings imported from Europe, making the operation safer and more stable;

- Equipped with an automatic butter filling system and thin oil circulation cooling system, which avoids the uncertainty of manual maintenance and improves the degree of automation and the stability of pellet stove pellet maker equipment operation.

- Pellets forming is relatively difficult. It requires the moisture content of the raw materials to be controlled at 13% to 18% before granulation. The ring die speed cannot be too fast during granulation, and the material must have a slight residence time in the ring die hole to form.

- The pressure generated by the material during the pressing process is 50 to 100 MPa, which requires a high-torque, low-speed main motor. Currently, the commonly used motor is an 8-level motor with a speed of about 750 r. The torque is enhanced, and the ring die speed is about 141 r. According to the customer’s process needs, a 10-level main motor can also be configured.

Order from our customized pellet stove pellet making machines range today and enjoy amazing prices that you won’t find anywhere else, plus take advantage of our free services!

Advantages of pellet stove pellet making machine

- RICHI pellet maker for wood stove has the characteristics of high efficiency and can complete production and processing work quickly and accurately. It can greatly improve production efficiency, shorten production cycle, and improve product quality and output.

- The wood stove pellet machine has high precision and can ensure the stability of product quality during the processing process. The use of production equipment can accurately process granular products so that the size and shape of the products meet customer requirements and improve product reliability and safety.

- The pellet making machine for pellet stove has a high degree of automation, which can reduce manual labor intensity and reduce the risk of safety accidents. Through the automated control system, the process parameters and processing procedures are preset to realize automated production and improve production efficiency and product quality.

- The stove pellet making machine is energy-saving and environmentally friendly, which can reduce production consumption and waste emissions. At present, various countries have increasingly higher requirements for environmental protection. Using energy-saving and environmentally friendly pellet machines can greatly reduce production costs and improve the social image and credibility of pellet processing enterprises.

In short, pellet stove pellet mills play an important role in modern pellet processing and production, with the advantages of high efficiency, high precision, high degree of automation, energy saving and environmental protection.

Before purchasing pellet stove pellet maker equipment, pellet processors should select suitable equipment based on process requirements, pellet product specifications and market demand to ensure final pellet quality and production efficiency.

Working principle of pellet stove pellet making machine

The material is fed into the pressing chamber of the main machine by the spiral feeder, and is evenly distributed between the ring die and the pressure roller under the action of the leveler.

The ring die is rotated by the main motor, and is rotated and extruded through the pressure roller installed in the ring die.

The material existing between the ring molding rollers is continuously embedded into the inner hole of the working surface of the ring die, extruded through the die hole and then formed, and finally cut into uniform size specifications by the cutting system installed on the door cover.

Technical parameters of pellet stove pellet making machine

| Model | Main Power(kw) | Anti-caking Feeder(kw) | Capacity |

|---|---|---|---|

| MZLH320 | 37 | 1.5 | 300-2000 kg/h |

| MZLH350 | 55 | 1.5 | 500-4000 kg/h |

| MZLH420 | 90 | 1.5 | 1-6 t/h |

| MZLH520 | 132 | 2.2 | 2-8 t/h |

| MZLH768 | 250 | 3 | 2.5-10 t/h |

| MZLH858 | 280 | 3 | 3-12 t/h |

pellet stove pellet making machine projects

Benefit from our expertise in pellet stove pellet maker machine manufacture and pellet plant construction! We provide you with the perfect solution for every stove wood pellet manufacturing plant section, whether it’s a customized complete solution or an expansion of an existing plant. We accompany you throughout the entire process from concept, planning, development/production, delivery, installation and commissioning.

pellet stove pellet maker machine in australia

- raw material: wood chips

- project date: 2023.09.01

- Pellet Size: 6-10mm

pellet stove pellet maker machine in Canada

- raw material: wood sawdust

- project date: 2022.9.21

- Pellet Size: 8-10mm

pellet stove pellet maker machine in uSA

- raw material: wood log & chips

- project date: 2020.10.19

- Pellet Size: 8mm

pellet stove pellet maker machine in italy

- raw material: wood sawdust

- project date: 2020.06.18

- Pellet Size: 10mm

pellet stove pellet making machine in germany

- raw material: wood sawdust

- project date: 2023.07.17

- Pellet Size: 6-10mm

pellet stove pellet making machine in romania

- raw material: wood sawdust

- project date: 2020.07.20

- Pellet Size: 8-10mm

pellet stove pellet making machine in poland

- raw material: wood sawdust

- project date: 2023.05.10

- Pellet Size: 8mm

pellet stove pellet making machine in spain

- raw material: wood sawdust

- project date: 2022.07.23

- Pellet Size: 8-10mm

pellet stove pellet making machine price

The price of a pellet stove pellet maker machine is usually between 10,000-100,000 USD.

The wood stove pellet maker machine price is not static. It is affected by many factors, such as configuration, manufacturer, competitiveness, etc. Depending on the influencing factors, the market quotation of the equipment will also be very different.

- Configuration factors:

Since the specific circumstances of each manufacturer are different, the pellet stove pellet maker equipment they configure is also different. Generally speaking, the larger the equipment model and capacity, the higher the market price of the equipment will be. High, and the smaller the pellet stove pellet making machine model and capacity configured, the lower the market price will be. - Equipment manufacturer factors:

Different pellet stove pellet machine manufacturers have different strengths, scales, production experience, and production materials. Therefore, the cost of their production equipment is also different, which affects the quotation of the equipment. If the equipment manufacturing cost is high, the price will be high; if the sand making cost is low, the price will be relatively low. - Competitiveness factors:

With the current economic downturn, there is great competition in various industries, and the same is true for manufacturers of pellet machine equipment. The greater the competition, the lower the price of the equipment produced, and the competition is not great. The price of pellet stove pellet machine will be relatively high. - Materials used:

Materials also have a certain impact on the price of wood pellet maker for pellet stove. Since the quality of materials directly affects the performance of pellet machine equipment and the quality of pellets, if the equipment materials are good, then the pellet machine equipment produced will be of high quality and performance. Well, it has a long service life, but of course the price is high. Therefore, the different materials used in pellet maker for wood stove will also have a certain impact on its price. - Market demand:

When the market has high requirements for pellet machines, but there are few such equipment on the market, the price of pellet making machine for pellet stove will be relatively high. On the contrary, if the market demand is not large, but the more equipment circulating in the market, the price of the pellet machine will be lower.

No matter whether you require general information about RICHI pellet stove pellet making machine products, need advice on machine operation or have questions about new or expansion projects – we will help you!

How to make pellets for pellet stove? Complete pellet stove pellet plant process design

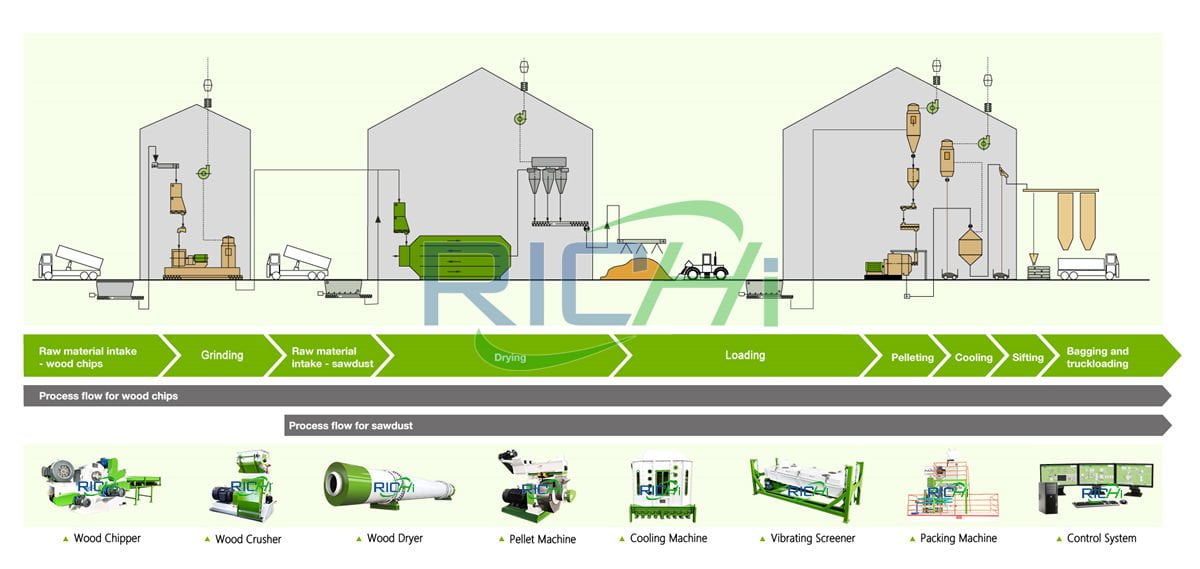

How are pellets for pellet stoves made? The complete pellet stove pellet system mainly converts raw materials such as sawdust and wood chips into products with higher density, no odor, and easy to store through processes such as crushing, drying, pressing, cooling, screening, and packaging of raw materials. and transported granular products.

Here’s how pellet stove pellet production line works:

- Cleaning: Clean the raw materials through cleaning equipment to remove impurities. If the raw materials are inherently clean, this section is not needed.

- Crushing section: Different raw materials are processed by suitable crushing equipment to break larger raw materials into smaller particles.

- Drying treatment: Send the raw materials into the wood chip dryer, and use hot air to flow to evaporate the moisture in the raw materials and reduce the humidity of the raw materials.

- Pelleting: The dried raw materials are fed into the pellet stove pellet making machine. There is a mold driven by a motor inside the pellet stove pellet machine, and the internal cavity is the pressing cavity. Through continuous rotation of the mold, the raw materials are gradually formed into pellets under the action of extrusion force. The mold in the pellet stove pellet maker machine presses the raw materials into granules through pressing force, and at the same time, the pressure inside the mold gradually increases.

- Cutting and cooling: There is a cutting knife at the outlet of the wood stove pellet making machine to cut the pellets formed inside the mold into the required length, and at the same time cool the pellets to solidify them.

- Screening and packaging: The solidified pellets are discharged from the discharge port, and the unqualified pellets are removed through screening equipment, and then the qualified pellets are sent to the packaging or finished product warehouse through the conveyor for packaging and storage.

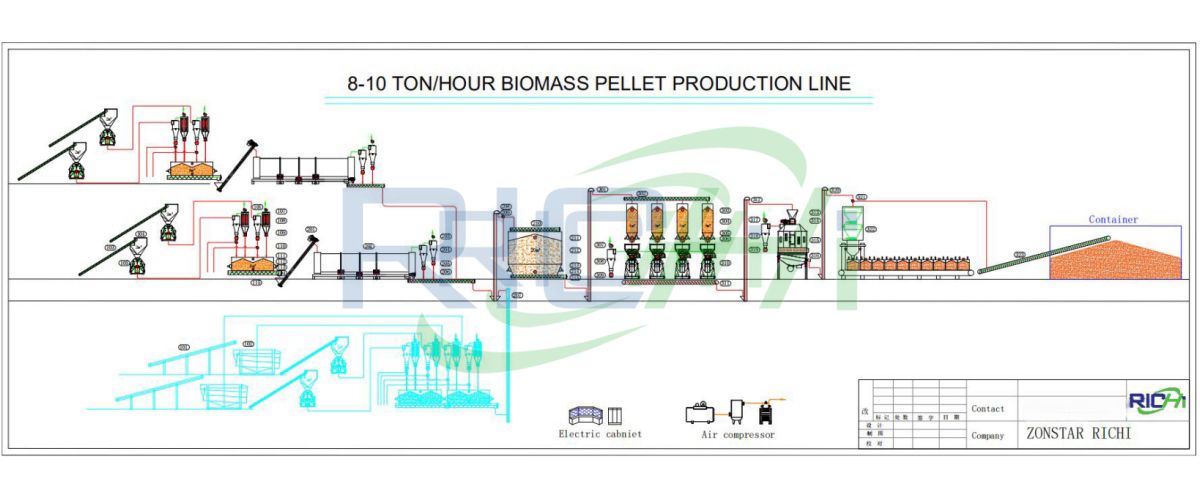

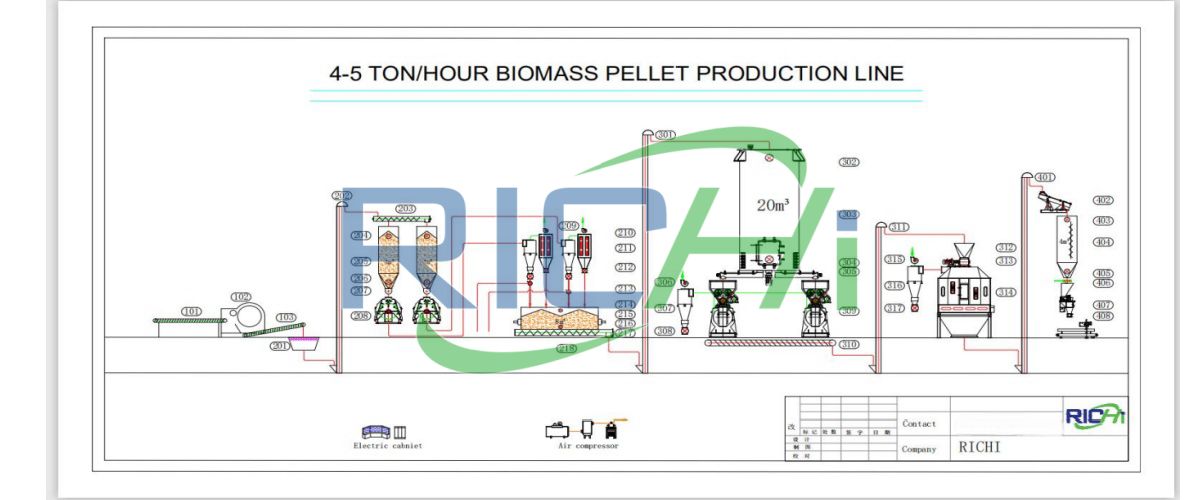

Below are two pellet stove wood pellet production line designs we have done:

pellet stove pellet production line for USA customer

pellet stove pellet production line for Poland customer

Please remember! From Concept to Commissioning – We are Your Reliable Partner!

Equipment needed in a pellet stove pellet machine plant

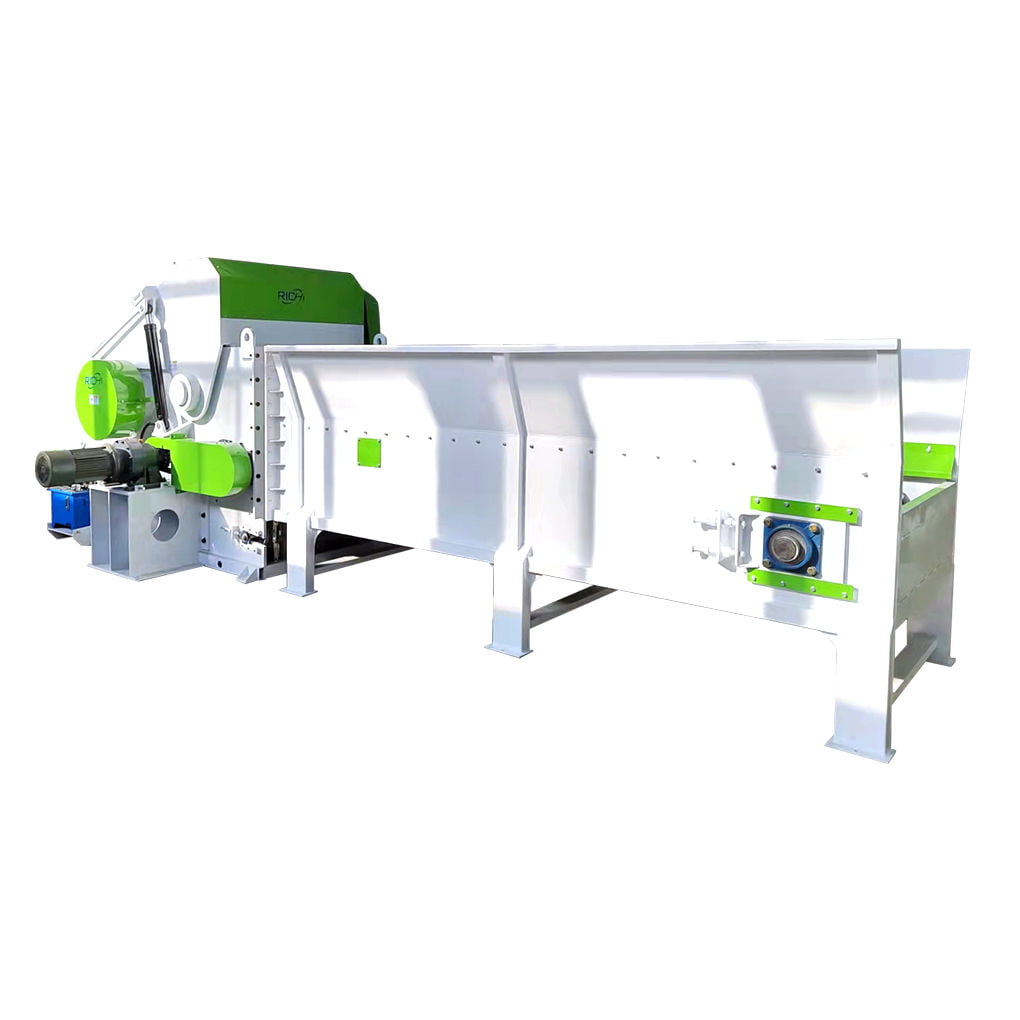

wood Debarker

Capacity:

5-15 T/H

Main Power:

7.5-11 KW

Wood splitter

Capacity:

3-12T/H

Main Power:

10-20 KW

Pellet types from the pellet stove pellet machine

RICHI pellet makers for wood stove are mainly used to process the following pellet types:

Premium Wood Pellets

The highest quality pellets are of premium grade. This fuel will generally be low in moisture and ash content, allowing pellet stove to burn pellets more cleanly and efficiently. The higher the fuel quality, the more heat appliance will give off.

These pellets will be more expensive, but they’re worth the investment in keeping pellet stove running effectively. For pellet processors, such pellets can be processed using better raw materials and process equipment.

Standard Wood Pellets

When premium wood pellets are outside the pellets users’ budget, they consider standard wood pellets. These pellets typically have slightly more ash content, so the fuel will leave behind more ash inside pellets stove.

This is still a quality wood pellet, but pellets users may need to clean out appliance more frequently to ensure it’s working efficiently. Like Premium Wood Pellets Production, pellet processors can process this kind of pellets as long as they use better raw materials and process equipment.

In addition, the after-sales service of the fuel pellet making machine is also one of the key factors in choosing a manufacturer. Good after-sales service can ensure the maintenance and upkeep of equipment during use, solve problems such as equipment failures, and provide customers with professional technical support.

Therefore, when choosing a stove pellet machine manufacturer, you can communicate with the manufacturer to understand its after-sales service system, including warranty policy, maintenance services, etc., to judge whether the manufacturer’s after-sales service is perfect.

Other type pellets

Peoples do have the option to burn other biomass fuels in pellet stoves, such as wood chips, rice husk, straw, corn kernels or nutshells, etc. However, not all pellet stoves can burn these types of fuel. Processing into pellets is also an option, which would be more environmentally friendly.

If your raw materials are non-wood, RICHI can also provide you with efficient biomass wood pellet processing solutions. But the suitability of these pellets for different pellet stoves requires you to conduct market research.

Overall, premium-grade pellets are your best choice for fuel. if you have many biomass waste resources, and are unsure which fuel is appropriate for specific pellet stove, start market research, consult the pellet stove manufacturer’s instructions. Remember, fuel with low moisture and ash content will burn the cleanest and most efficiently.

The cost of raw materials, pellet stove pellet making machine costs, processing costs and final pellet selling price will ultimately determine your profits. If you are ready to start a pellet processing business, you may wish to contact Richi Machinery to learn more about equipment information and obtain a complete set of pellet processing solutions.

pellet stove pellet making machine video

How to choose a qualified pellet stove pellet mill machine manufacturer?

Choosing a qualified pellet stove pellet making machine manufacturer is the first step in ordering equipment quality control from the manufacturer. Therefore, it is very important to do a good job in preliminary selection of manufacturers and on-site inspection before ordering a pellet stove pellet machine.

01 Preliminary selection of qualified suppliers

Identify alternative manufacturers by conducting horizontal comparisons among similar manufacturers. During the selection process, priority can be given to vendors that have had business dealings with them in previous wood pellet line engineering projects and have been proven to be fully cooperative. The content of preliminary selection of suppliers may include the following:

- Qualification review of suppliers. Review whether the wood stove pellet machine supplier’s business license, production license, and business scope cover the equipment to be purchased. For suppliers who need to design and manufacture special equipment or who are responsible for manufacturing and installing equipment, they should also review whether they have a design qualification certificate or installation qualification certificate.

- Equipment supply capability. Including the company’s production capacity, equipment conditions, technical level, process level, personnel composition, production management, quality stability, financial status, after-sales service and the company’s reputation, testing methods, personnel quality, and production plans scheduling and civilized production, implementation of process procedures, operation of the quality management system, procurement channels for raw materials and supporting parts and components, etc.

- The supply, production, and manufacturing of similar equipment in recent years, the status of pellet stove pellet making machine currently in production, the status of production and manufacturing equipment, and the quality of products.

- The situation of raw materials, supporting parts and components that need to be purchased separately.

- Various inspection and testing methods and laboratory qualifications.

- Relevant performance of suppliers in recent years.

02 On-site inspection

Conduct further on-site inspections and research on the manufacturers, take a look at the pellet stove pellet making machines on site, and even put forward test machine requirements and make inspection conclusions.

In general, when considering pellet stove pellet maker machine manufacturers and purchasing pellet stove pellet mills, it is necessary to consider the supplier’s qualifications, equipment supply capabilities, financial status, etc., and make horizontal comparisons.

During the on-site inspection stage, it is necessary to have an in-depth understanding of the manufacturer’s production, quality, technology, management system, etc., evaluate its strength, and finally draw conclusions. (Find RICHI on YouTube)

Why start a pellet stove pellet processing business?

Pellet stoves are highly efficient cleanburning devices that offer automatic operation and heat at very competitive prices. They can be purchased for 1 000 to 2 000 Euro and lead to annual savings of heating costs of 400 – 900 Euro, depending on the country and the replaced fuel.

If pellets replace electric heating or heating oil, a payback of 1- 2 years can be achieved. Pellet stoves were invented in the USA during the first oil crisis and are currently extensively used in the USA, Italy, France, Spain, Greece and a number of other countries.

In developing countries like India, pellets are being used for cooking. They are usually sourced from agricultural residues and they help replace the burning of firewood in rural communities.

This has many advantages including: cheap fuel, improving health and economic conditions of rural communities.

- Pellets cost only half as much as heating oil. This makes the conversion to pellet heating attractive, particularly for buildings with large heat demand.

- Pellet stove markets have been able to develop with or without financial incentives due to the low upfront investment cost.

The market for pellet stoves has great development prospects. Therefore, the pellet processing business for pellet stoves also has great room for development. If you also see this market, contact us to get professional pellet stove pellet making machine quotations and technical support!

Start your pellet stove pellet production business

Trust RICHI Machinery to provide the best pellet stove pellet making machine for all of your needs.

Whether you’re building a new pellet production plant, revamping an existing system, need engineering help on a wood stove pellet plant design project, or you’re upgrading your pellet machine—we can help.

Our knowledgeable and experienced design and build team of engineers will put together the right pellet processing system for your unique operation that maximizes your pellet stove use pellet production and reduces your cost.