Wood Pellet Plant Construction

Currently, our wood pellet plant construction projects cover all continents, and the processed wood pellet products are mainly used for heating, fuel, cat litter, horse bedding, etc.

As the world increasingly turns towards renewable energy sources, the quality of wood fuels becomes pivotal.

We offer complete wood pellet plants for the treatment and production of high quality wood pellets. According to the requests of the Client and of the constructive characteristics, our plants have different construction characteristics and production capacity.

Pellet production is not a simple process so our support systems are designed to ensure product education and quick adoption of the technology. With over 30 years industry experience, we can provide the best advice on a broad spectrum of wood pelleting solutions.

- Output: 0.3-90 T/H

- Wood pellet plant construction cost: 50,000-3,000,000 USD

- Applicable raw materials: various types of wood waste (different moisture content), including sawdust, wood chips, tree trunks, branches, wooden pallets, wooden boards, wooden strips, etc

- Business scope: Newly built pure wood pellet production line or compound agricultural and forestry waste pellet production line

RICHI wood pellet plant construction in global

Richi Machinery is the world leader in supplying industrial wood pellet making machines and full wood pellet plants. We specialize in providing our customers with turnkey wood pellet plant construction system solutions catered to their specific needs and uses.

Currently, you can find our wood pellet factory construction projects in the United States, Canada, Russia, Indonesia, India, Australia, Poland, Germany, Netherlands, Argentina, Brazil, Japan, South Africa, etc.

wood pellet plant construction In United States

- Capacity: 10 TPH

- Pellet Size: 6-8mm

- The install period: 60 Days

- Guiding Price: 1,300,000USD

- Main Raw material: wood waste from furniture factories, paper mills and other factories

- Main Machines: Wood chipper, wood hammer mill, rotary dryer, wood pellet mill, Pellet cooling machine, Screener machine, packing machine, Sewing machine,etc.

wood pellet plant construction In canada

- Capacity: 2-2.5T/H

- Pellet Size: 8mm

- The install period: 45 Days

- Guiding Price: 330,000USD

- Main Raw material: wood off cuts, wood chip and sawdust different types of wood sizes

- Main Machines: Wood sawdust making machine, Mixing machine, MZLH520 sawdust pellet press, Wood pellet cooler, Wood pellet screener, Wood pellet bagging machine, etc.

wood pellet plant construction In Vietnam

- Capacity: 4T/H

- Pellet Size: 6-10 mm

- The install period: 90 Days

- Guiding Price: US$390,000

- Main Raw material: Sawdust, Bamboo chips, Corn stamens, corn stalks, bran powder, etc.

- Main Machines: Slicer, wood granulator, wood waste Grinder, wood sawdust dryer machine, Bag filter, Cyclone, Conveyor, Forklift, Truck, etc.

wood pellet plant construction In Thailand

- Capacity: 10-12T/H

- Pellet Size: 6-10 mm

- The install period: 70 Days

- Guiding Price: US$770,000

- Main Raw material: Scrap wood blocks, Sawdust, Wood shavings

- Main Machines: Slicing machine, Belt conveyor, wood chip silo (10m*3m*1.5m), Crusher, wood pellet mill (MZLH420), Cooling screening machine (Φ800), packaging machine, etc.

wood pellet plant construction In Argentina

- Capacity: 4-5T/H

- Pellet Size: 8 mm

- The install period: 50 Days

- Guiding Price: US$430,000

- Main Raw material: tree branches, Sawdust, wood pallets, Wood shavings

- Main Machines: Wood crusher, Pulse dust collector, U-screw conveyor, Drum dryer, wood fuel pellet mill MZLH520, Belt conveyor, Cooling machine, Vibrating screener, Packing machine, etc.

wood pellet plant construction In Indonesia

- Capacity: 1-2T/H

- Pellet Size: 10 mm

- The install period: 40 Days

- Guiding Price: US$ 350,000

- Main Raw material: various discarded wooden pallets

- Main Machines: Pallet shredder, Wood hammer mill, Wood pellet mill machine, Wood pellet cooler, Screening machine, Bucket elevator, Conveyor, Automatic weighing and baling machine, etc.

6-7 T/H wood pellet plant construction in australia

—— RICHI MACHINERY ——

- Annual output: 15000 t/a (1250 t/m,50 t/d)

- Raw materials: wood waste powder, straw powder

- Project construction period: 8 months

- Project construction land: 1000m²

- Wood pellet plant construction cost: 0.57 million USD

- Production process: Mixing-drying-feeding-granulation-natural cooling-packaging

| No | Main Equipment | Model | Quantity |

| 1 | Sawdust rotary dryer | ф1800*180000 | 1 |

| 2 | Ring die wood pellet extruder machine | MZLH-520 | 3 |

| 3 | wood pellet Cooling machine | SKLN17*17 | 1 |

| 4 | Vibrating screening machine for wood pellets | TDZS63 | 1 |

| 5 | Packing machine(with belt and sewing machine) | DCS-50 | 1 |

| 6 | MCC Control Center; Mimic control panel | / | 1 |

| More auxiliary equipment:U-screw conveyor*TLSSU35, Bucket elevator*TDTG50/28, Upper level indicator*KF1500, Storage bin*20m³, Lower level indicator*KF1500, Cyclone*ф600, Belt conveyor*PDS-500, Pneumatic gate valve*TZMQ30A,etc. | |||

1-1.2T/H wood pellet plant construction in romania

—— RICHI MACHINERY ——

- Annual output:3000 tons (250 tons per month ,10 tons per day)

- Raw materials: wood chips

- Project construction period: 4 months

- Project construction land: 1100m²

- Wood pellet plant construction cost: 120,000 USD

- Production process: Purchased raw materials-screening-crushing-drying-pelletizing-cooling-packaging

| No | Main Equipment | Model | Quantity |

| 1 | Wood hammer mill for sawdust | SFSP 66*60 | 1 |

| 2 | drum rotary dryer for wood chips and sawdust | ф1200*120000 | 1 |

| 3 | wood pellet maker machine for biomass | MZLH-420 | 1 |

| 4 | Cooling machine | SKLN11*11 | 1 |

| 5 | Vibrating grading machine | TDZS63 | 1 |

| 6 | wood chip pellets Packing machine(with belt and sewing machine) | DCS-50 | 1 |

| 7 | MCC Control Center ;Mimic control panel | / | 1 |

| More auxiliary equipment:Buffer bin*2m³, Cyclone*ф1000, Pulse dust collector*TBLMa.36b, Draught fan*9-19-5.6a, U-Screw conveyor*TLSSU30, Bucket elevator*TDTG40/23, Storage bin*4m³, Anti-caking equipment, Bucket elevator*TDTG36/18,etc. | |||

25-30T/H large scale wood pellet plant construction in Russia

—— RICHI MACHINERY ——

- Annual output:70000 tons (5800 tons per month, 230 tons per day, 28 tons per hour)

- Raw materials: wood waste, rice husk

- Construction period: 12 months

- Project construction land: 7500m²

- Wood pellet plant construction: 0.76 million USD

- Production process: Wood waste-chipping-crushing-drying-pelleting(add rice husk here) -finished product

| No | Main Equipment | Model | Quantity |

| 1 | heavy duty drum wood chipper for log and chips | JLBX-2113 | 2 |

| 2 | Wood pellet hammer mill | SFSP-Y60132Q1 | 4 |

| 3 | rotary dryer for wood | ф2400*100000*3 Layer | 4 |

| 4 | Wood pellet press machine | MZLH-520 | 12 |

| 5 | MCC Control Center ;Mimic control panel | / | 1 |

| More auxiliary equipment:Storage bin*4m³, Silencer for hammer mill*XY-132Q1, Connection piping system*FWY-350, Cyclone*SK1400, Pulse dust collector*FZMC6*12, Screw conveyor (air locked)*TLSS40, U-Screw conveyor*TLSSU40, etc. | |||

4-5T/H wood pellet plant construction in brazil

—— RICHI MACHINERY ——

- Annual output:10000 tons (833 tons per month, 33 tons per day, 4 tons per hour )

- Raw materials: wood waste

- Project construction period: 14 months

- Project construction land: 18 acres

- Wood pellet plant construction cost: 370,000 USD

- Process flow: Raw material- chipping – crushing – impurity removal – screening – -pelletizing -drying -cooling – packaging – storage- delivery

| No | Main Equipment | Model | Quantity |

| 1 | Commercial wood chipping equipment | JLBX-218 | 1 |

| 2 | Wood hammer mill crusher | SFSP66*80 | 2 |

| 3 | Good selling drum rotary dryer | ф2400*100000 *3 Layer | 1 |

| 4 | Wood pellet granulator machine | MZLH-520 | 2 |

| 5 | Cooling machine | SKLN17*17 | 1 |

| 6 | Vibrating screen equipment | TDZS80 | 1 |

| 7 | Packing machine for fuel pellets | DCS-50 | 1 |

| More auxiliary equipment:Bucket elevator*TDTG40/23, Belt conveyors*PDS650, Buffer bin*2m³, Cyclone*ф1000, Draught fan*9-19-5.6a, Pneumatic three-way*YSTZ22A, Lower level indicator* KF1500, U-screw conveyor*TLSSU32, Anti-caking equipment,etc. | |||

300-500 KG/H small wood pellet plant construction in New Zealand

—— RICHI MACHINERY ——

- Annual output:1000 t/a (83 t/m, 3 t/d)

- Raw materials: wood scraps, crop waste (rice stalks, peanut shells, walnut shells, etc.)

- Project construction period: 2 months

- Project construction land: 19314m2

- Wood pellet plant construction cost: 100,000 USD

- Process flow: Raw material-chipping-screening-crushing-drying-pelleting-packaging

| No | Main Equipment | Model | Quantity |

| 1 | Wood shredder chipper machine | JLBX-215 | 1 |

| 2 | Wood hammer mill for wood chips | SFSP66*60 | 1 |

| 3 | Wood sawdust rotary dryer | ф1200*120000 | 1 |

| 4 | wood pelletizer machine | MZLH-320 | 1 |

| 5 | Vibrating screening machine | TDZS63 | 1 |

| 6 | Wood pellet bagging machine | DCS-50 | 1 |

| 7 | MCC Control Center ;Mimic control panel | / | 1 |

| More auxiliary equipment:Buffer bin*2m³, Cyclone*ф1000, Pulse dust collector*TBLMa.36b, Draught fan*9-19-5.6a, U-Screw conveyor*TLSSU30, Bucket elevator*TDTG40/23, Storage bin*4m³, Anti-caking equipment, Bucket elevator*TDTG36/18,etc. | |||

15-20 T/H industrial wood pellet plant construction in USA

—— RICHI MACHINERY ——

- Annual output:50000 tons (4166 tons per month, 166 tons per day, 20 tons per hour )

- Raw materials: forest wood waste (branches, leaves), agricultural waste

- Project construction period: 11 months

- Project construction land: 50861.6 m2

- Wood pellet plant construction cost: 0.9 million USD

- Process flow: Raw material-sieving-crushing-drying-pelletizing-cooling-packaging

| No | Main Equipment | Model | Quantity |

| 1 | Wood chipper machine for waste | JLBX-2113 | 2 |

| 2 | Sawdust hammer milling equipment | SFSP-Y60132Q1 | 4 |

| 3 | Rotary dryer for wood chips/sawdust | ф2400*100000*3 Layer | 4 |

| 4 | Industrial wood pellet machine | MZLH-520 | 8 |

| 5 | Cooling machine | SKLN24*24 | 2 |

| 6 | Vibrating screening machine | TQLZ150x200 | 2 |

| 7 | MCC Control Center ;Mimic control panel | / | 1 |

| More auxiliary equipment:Belt and sewing machine*DCS-MTB,Storage bin*4m³, Silencer for hammer mill*XY-132Q1, Connection piping system*FWY-350, Cyclone*SK1400, Pulse dust collector*FZMC6*12, Screw conveyor (air locked)*TLSS40, U-Screw conveyor*TLSSU40, etc. | |||

8T/H wood pellet plant construction in indonesia

—— RICHI MACHINERY ——

- Annual output:20000 t/a (1666 t/m, 66 t/d)

- Raw materials: miscellaneous wood

- Project construction period: 7 months

- Project construction land: 3000m2

- Wood pellet plant construction cost: 520,000 USD

- Process flow: Miscellaneous wood—slicing—crushing—pelleting—finished product

| No | Main Equipment | Model | Quantity |

| 1 | Commercial drum wood chipper | JLBX-218 | 2 |

| 2 | Wood material hammer mill | SFSP66*80 | 2 |

| 3 | Rotary dryer for sawdust | ф2400*100000 *3 Layer | 2 |

| 4 | Biomass energy sawdust pellet machine | MZLH-520 | 4 |

| 5 | MCC Control Center ;Mimic control panel | / | 1 |

| More auxiliary equipment:Belt conveyors*PDS650, Buffer bin*2m³, Cyclone*ф1000, Pulse dust collector* TBLMa.36b, U-screw conveyor*TLSSU32, Bucket elevator*TDTG60/23, Storage bin*20m³, Anti-caking equipment, Belt conveyor*PDS-500, etc. | |||

10T/H wood pellet plant construction in india

—— RICHI MACHINERY ——

- Annual output:25000 tons (2083 tons per month, 83 tons per day, 10 tons per hour )

- Raw materials: wood pallet, wood sawdust, straw

- Project construction period: 8 months

- Project construction land: 5333m2

- Wood pellet plant construction cost: 0.6 million USD

- Process flow: Raw material wood and straw-Chipping-Crushing-Drying -Sieving-Pelleting-Cooling-Packing

| No | Main Equipment | Model | Quantity |

| 1 | Hot sale wood chipper crusher | JLBX-218 | 2 |

| 2 | High capacity straw pulverizer | SFSP66*80 | 2 |

| 3 | Biomass wood chips rotary dryer | ф2400*100000 *3 Layer | 2 |

| 4 | Ring die straw wood pellet press machine | MZLH-520 | 4 |

| 5 | Cooling machine for fuel pellets | SKLN20*20 | 1 |

| 6 | Vibrating screen machine for pellets | TDZS80 | 1 |

| 7 | Packing machine(with belt and sewing machine) | DCS-50 | 1 |

| More auxiliary equipment:Belt conveyors*PDS650, Buffer bin*2m³, Cyclone*ф1000, Pulse dust collector* TBLMa.36b, U-screw conveyor*TLSSU32, Bucket elevator*TDTG60/23, Storage bin*20m³, Anti-caking equipment, Belt conveyor*PDS-500, etc. | |||

Each wood pellet plant construction project is uniquely configured according to individual needs. Our sales team is well equipped to customize your Plant to your needs with a wide range of equipment options which can be upscaled, or used in isolation.

Contact Richi Machinery and discuss your wood pellet construction project with RICHI engineers.

wood pellet plant construction process

The wood pellet plant construction process usually includes the following key stages:

- Planning:

This is the first step in wood pellet plant construction, involving the positioning and planning of product types, production quantities, production processes, etc. After the planning is completed, a wood pellet production line design plan needs to be formulated, including production line layout, equipment selection, logistics plan, etc. At the same time, construction costs and benefits need to be evaluated to ensure that it is economically feasible. - Equipment procurement and installation:

After planning is completed, equipment procurement and installation are carried out. Select an appropriate equipment supplier, determine the wood pellet making equipment model and quantity, and sign a contract with the supplier. After the equipment arrives, installation and debugging are carried out to ensure that the wood pellet plant equipment operates normally and meets production requirements. - Material supply and inventory management:

After the wood pellet plant construction is completed, a supply chain and inventory management system will be established to ensure adequate supply of raw materials and inventory. Optimize the distribution and inventory management of raw materials through logistics solutions to ensure production efficiency and cost control. - Employee training and management:

After the wood pellet plant construction is completed, workers will be trained and managed to ensure production efficiency and production quality. Excellent production lines rely on skilled operators. - Operation monitoring and improvement:

After the wood pellet plant construction is completed, monitor and improve the production operation. Through data analysis and production process monitoring, we can identify production inefficiencies and quality problems and make improvements and optimizations to improve operational efficiency and production quality.

In addition, there are other key steps, such as wood pellet mill project process flow design, equipment selection, construction, trial production and debugging, production workshop construction and power distribution, drainage system, etc.

These steps together constitute the complete process of wood pellet plant construction and ensure the smooth construction and operation of the production line.

wood pellet plant construction cost

The wood pellet plant construction cost mainly includes preliminary preparation, civil construction cost, equipment purchase cost, operating cost, etc.

- In the early preparation stage, a certain amount of funds need to be invested in market research, feasibility studies, and production plan formulation.

- During the construction stage, the wood pellet plant construction cost needs to be determined based on factors such as factory size, site selection, and design plan.

- In the equipment procurement stage, you need to purchase machinery and equipment, tools, testing instruments, etc. Depending on the size of the factory and equipment selection, the equipment purchase cost is approximately between US$100,000 and US$3 million.

- In the operation stage, fixed costs such as personnel wages, electricity and water bills need to be paid, and expenses such as raw material procurement and product transportation also need to be considered.

It should be noted that the specific wood pellet plant construction costs will also be affected by various factors, such as region, market demand, competition, etc. Before making investment decisions, investors need to carefully evaluate their financial strength and risk tolerance to ensure that they can bear the corresponding expenses and risks.

At the same time, biomass pellet industry investors also need to formulate reasonable financial plans and plan the use of funds and financing methods to reduce investment risks and financial risks. (Find RICHI on YouTube)

Different wood pellet plant construction projects, different process design

No single wood pellet plant construction project may be the same as customer’s needs differ. Our sales team are well equipped with a range of products to customize wood pellet mill plans to your needs.

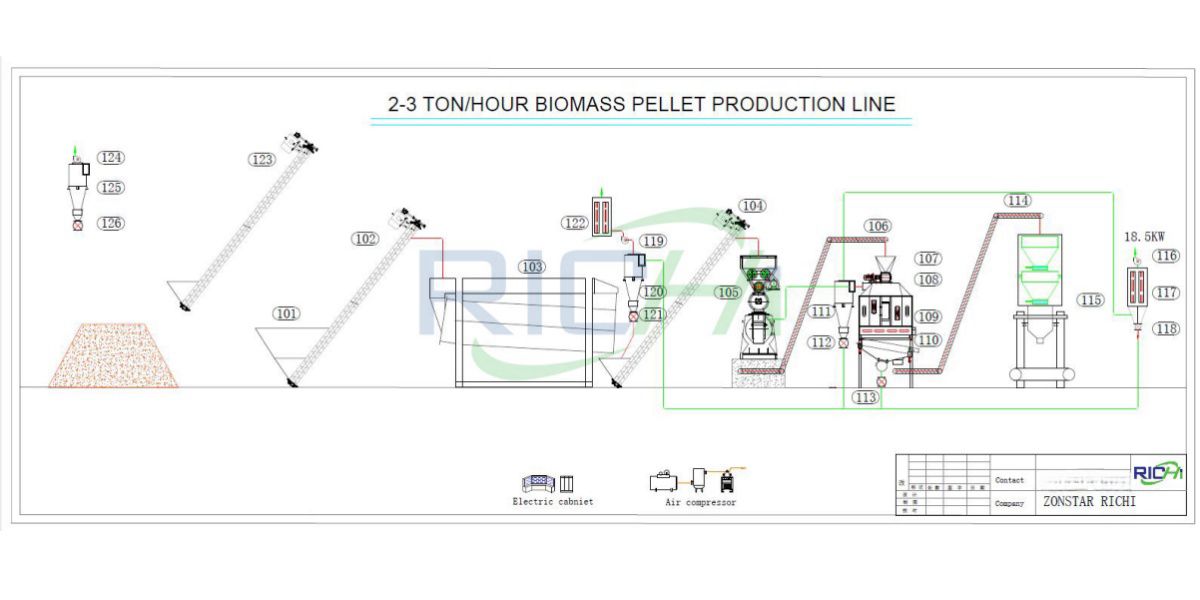

2-3T/H wood pellet plant construction project design

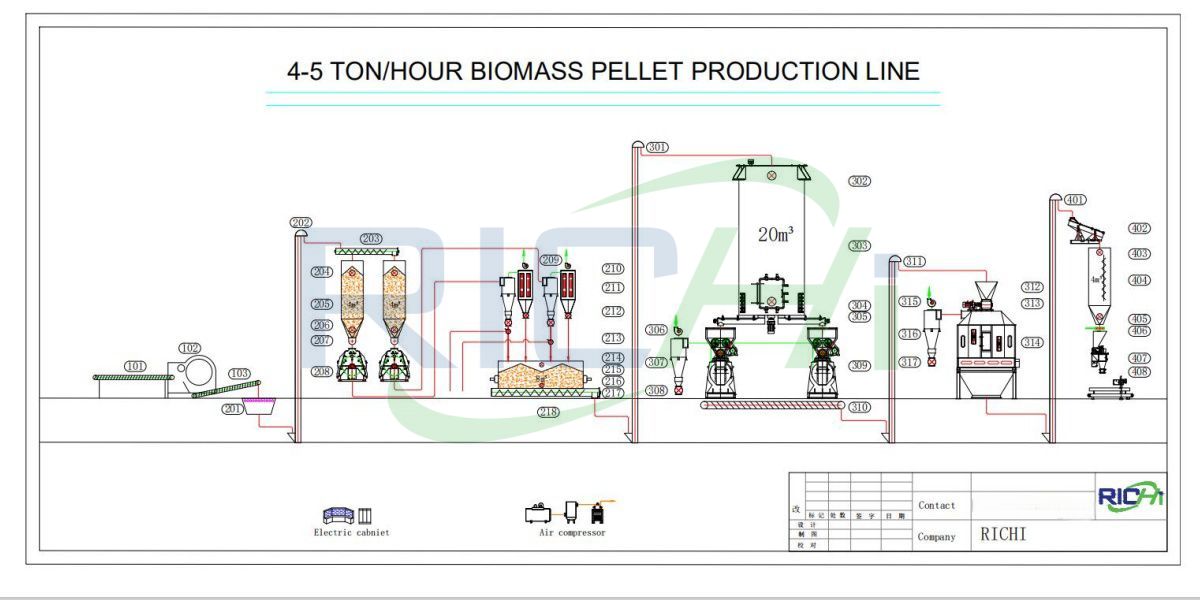

4-5 T/H wood pellet plant construction project design

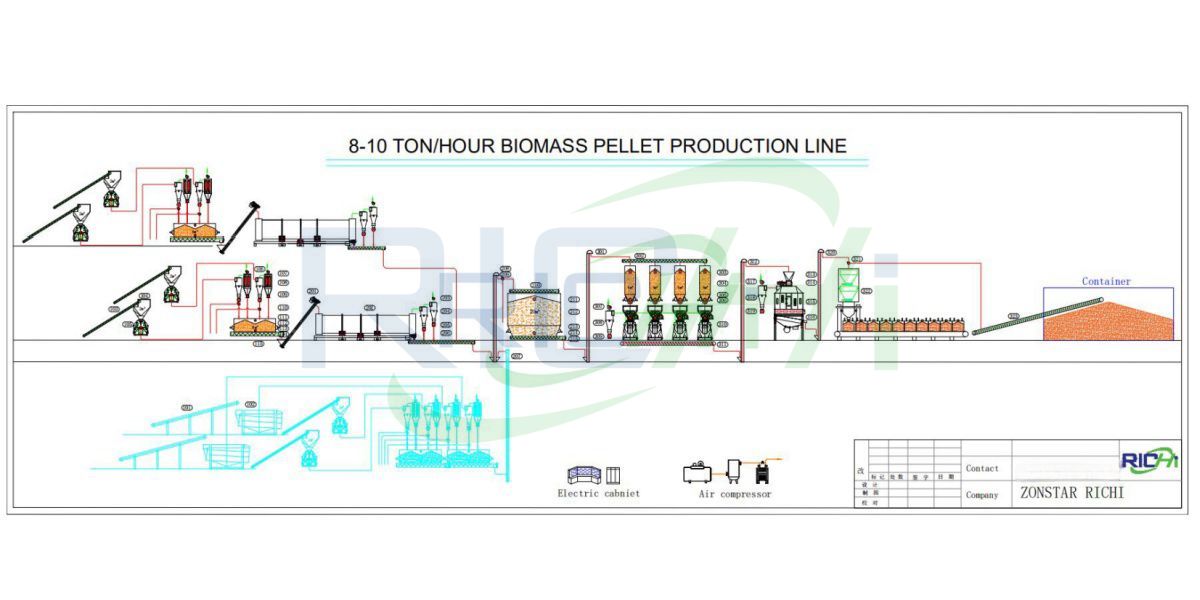

8-10 t/h wood pellet plant construction design

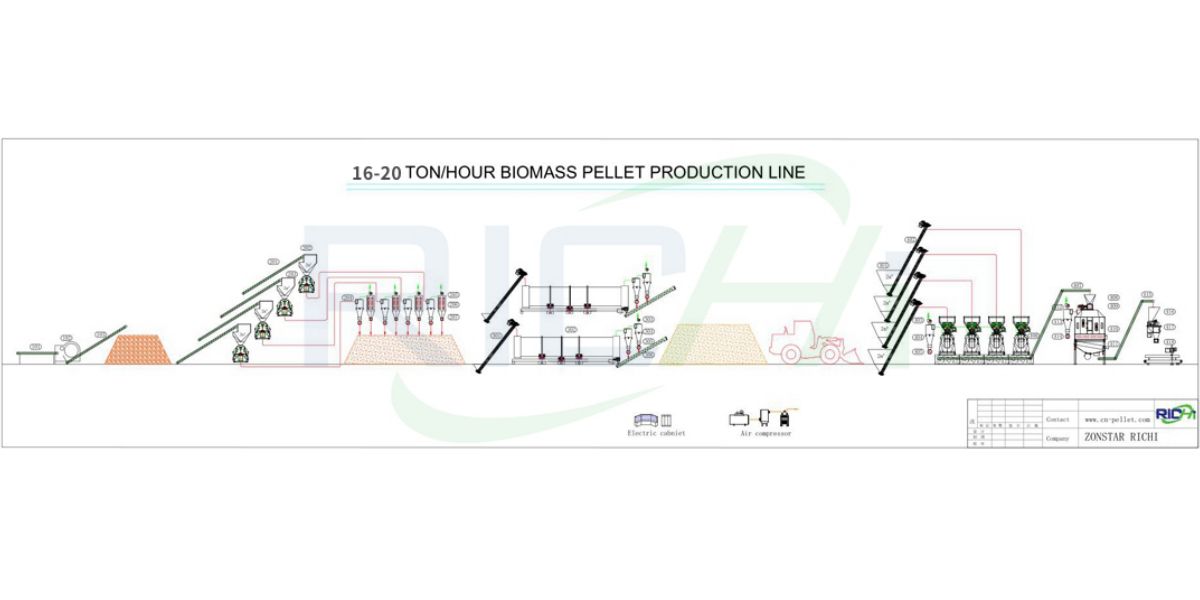

16-20 t/h wood pellet plant construction design

If you have any needs for wood pellet project construction design, contact us for technical support!

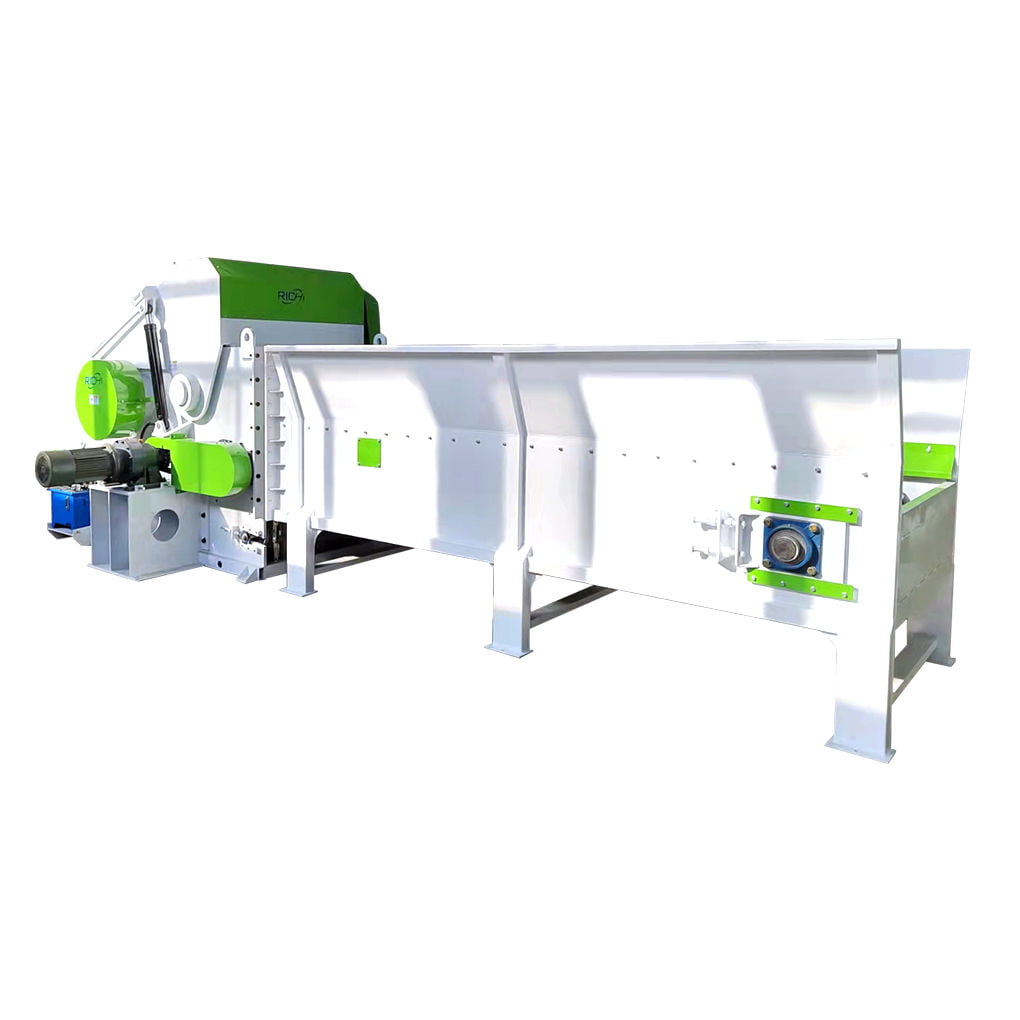

Equipment for starting wood pellet plant construction project

Our range of wood pellet processing equipment can be configured into full wood pellet plant construction layouts; or stand-alone units which are powered by tractor-driven options, or single- and three phase motors. Our clients are guided by our industry knowledge and a passionate focus on after sales service that supports our RICHI Brand.

How to configure a high-performance wood pellet plant construction project? Contact us to get wood equipment configurations and quotes for different capacities!

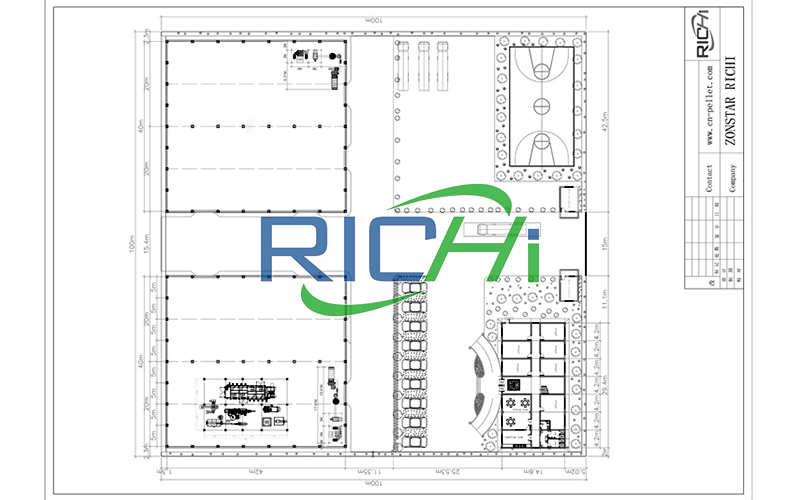

wood pellet plant construction layout

Our wood pellet plant construction projects differ in layout because of a few variable factors.

- The first factor is the physical space where the plant will be installed.

- The second is the use of the pelleting equipment which can range from single wood pelleting to many biomass waste which can become renewable energy pellets and even animal feed or fertilisers, to name a few.

- The third important layout decision is normally related to power supply and existing equipment that will be incorporated.

RICHI always aim to accommodate the client’s current situation to ensure the most cost effective wood pellet plant construction solution and optimal wood pellet project layout is suggested.

wood pellet plant construction project video

Customize your wood pellet plant construction project

RICHI is reliable partner in high-end equipment for pelleting and grinding a large variety of wood waste products. Our equipment processes hard and soft woods, torrefied wood worldwide.

Durability is crucial in this segment of the market where the load on the equipment can be extreme while using it 24/7, 365 days a year. With Richi Machinery, you have complete control over every step of production, and we offer tailored wood pellet plant construction solutions for the whole process: chipping, grinding, drying, pelleting, cooling, screening and bagging.

We consider as a primary factor to find the most appealing technical solutions for our customers, which are economical, effective and sustainable combined with high quality.

Get your hands on these solutions for building a wood pellet plant construction project below:

Why Richi Machinery?

At Richi Machinery, we believe there’s no substitute for experience. And we have well over 25 years of wood pellet plant construction.

We have been in business for 25+ years.

Our long-term business strategy lends stability to our client’s wood pellet plant construction projects.

We are innovators.

We don’t stand still—we are continually finding ways to improve the design and wood pellet plant construction process to add value and save you money.

We are a lean organization.

Our clients work with just one project manager and one wood pellet plant construction project superintendent who have the authority to make decisions. This minimizes mistakes and expedites jobs, saving everyone time and money.

We have key employees with significant experience in the industry

Our key employees have an average of 10 years with the company. As a result, we deliver our jobs faster and help our clients get a return on their investment sooner than other companies in our industry.

We understand the importance of communication

We want to make sure our clients know what’s going on at all times. We anticipate problems to minimize client risk, and we listen to ensure that client needs are accurately reflected from proposal to wood pellet plant construction project completion.

We understand customer satisfaction includes being cooperative

We work as a team with the owner, subcontractors, and suppliers. We strive to make the construction process a pleasant experience for the client.

We are committed to quality

We see each wood pellet plant construction project as a reflection of our values and build each one as though it were for ourselves. We strive to do it right the first time, improving the investment value of our client’s property.

We work safely

We have minimal lost time due to injuries and our insurance costs are lower, which saves our clients money.

We work in tough environments

We understand the challenges, maintain flexibility in our work schedule, and minimize errors in order to deliver your wood pellet manufacturing equipment on time and on budget.