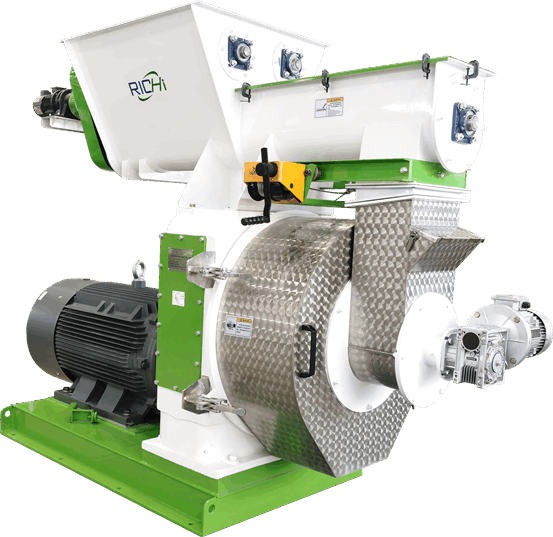

Biomass Pellet Making Machine

Biomass pellet making machine can use agricultural and forestry waste such as wood chips, straw, rice husks, bark and other biomass as raw materials, and solidify them into high-density pellet fuel through pretreatment and processing.

It is an ideal fuel to replace coal, natural gas, electricity and oil. It can save energy and reduce pollution emissions, and has good economic and social benefits.

- Model: MZLH768

- Capacity: 2.5-30T/H

- Price: FOB 50,000-70,000 USD

This MZLH768 model biomass pellets making machine was often used in the production of husk, straw, shell and leaves but after a restyling the machine is able to work extremely difficult products as wood waste.

It can stand up to comparison with any competitive models in the same range and melds the construction simplicity and characteristics of all our models with a stiffness guaranteed by a heavy duty cast-iron base. Can handle motors up to 250 kW.

Technical features of biomass pellet making machine

- The main drive adopts high-precision gear rotation, and the efficiency is about 15% higher than that of the belt drive type. The ring die adopts a quick-release hoop type; The gear transmission has high efficiency, large transmission torque, and the roller does not slip, which increases the production capacity by 15%; the working intensity of the main working parts is strengthened from the aspects of materials, heat treatment and other processes, so as to meet the requirements of biomass pellets pelleting;

- The transmission part of the whole biomass pellets making machine uses high-quality imported bearings and oil seals to ensure efficient, stable and low-noise transmission;

- The internationally advanced level of compensation type serpentine spring coupling has novel structure, compactness, safety, low failure and other performances;

- The working intensity of the main working parts is strengthened from the aspects of materials, heat treatment and other processes, so as to meet the requirements of biomass pellets pelleting;

- There are many innovative designs on the ring die, which mainly improve the problems of anti-cracking of the ring die, increase of hourly output and total output;

- Overload protection device is configured to increase the service life of the biomass pellet making machine;

- The feeding auger, conditioner and door cover are made of stainless steel to avoid pollution of raw materials due to equipment corrosion, and have a longer service life.

- Forced feeding ensures uniform and smooth feeding; the spiral feed plate design in the die cover ensures uniform intake of sawdust from the left and right rollers and balanced extrusion force.

Advantages of biomass pellet making machine

- High degree of automation, strong applicability, suitable for pelletizing and molding of all biomass raw materials.

- Ring die pelletizing technology with world-leading technology, large gears, sturdy ring die, and large production capacity.

- Protect the biomass pellets making machine from long-term high-load and stable operation;

- Frequency conversion drive mode, set the ring die speed according to different raw materials.

Working principle of biomass pellets making machine

The crushed material enters the die cover by the forced feeding mechanism, and is fed evenly into the two pressing areas in the ring die, i.e. the wedge-shaped space formed by the two pressing rollers and the ring die, through the centrifugal force generated by the feeding device and the rotation of the ring die and the action of the feeding scraper.

Under the strong extrusion of the ring die and the pressure roller, the material is gradually compacted, squeezed into the die hole of the ring die and formed in the die hole.

Since the extrusion of the material between the ring die and the pressure roller is continuous, the formed material is continuously discharged from the die hole in a columnar shape, and then cut into biomass pellets of the required length by the cutter.

Technical specifications of MZLH768 biomass pellet making machine

| Type | MZLH768 |

| Output(t/h) | 2.5~30 |

| Main motor power(kw) | 250 |

| Main motor series | 6/8P |

| Forced Feeder (KW) | 2.2 |

| Conditioner Power(kw)(Optional) | 11 |

| Ring die diameter (mm) | 762 |

| Finished pellet diameter (mm) | 2-12mm |

Configuration of biomass pellet making machine

- Ring die material: 42CrMo

- Stainless steel feeder: with anti-caking function

- Door of pelleting room: 6mm /SUS304

- Forced feeding: Worm gear reducer

- Gear box: HT250

- Gear: 42CrMo

- Gear shaft: 42CrMo

- Spindle: 42CrMo

- Empty shaft: 42CrMo

- Bearings: The gear shaft and main shaft bearings are SKF, and the pressure roller bearings are domestic high-quality bearings

- Oil seal: Germany/Taiwan

- Overload mechanical protection: safety pin

- Serpentine spring coupling drive

- Lubrication system: Configurable automatic oil injection system

biomass pellet making machine projects

biomass pellet making machine In Vietnam

- pellet making machine selection: MZLH768

- Production: 6500 t/a

- Ingredients: wet corn Straw waste

- biomass pellet project cost: 180,000 USD

biomass pellet making machine In India

- pellet making machine selection: MZLH768

- Production: 10,000 T/A

- Ingredients: bamboo, rice husk

- biomass pellet project cost: US$270,000

biomass pellet machine In United States

- pellet making machine selection: MZLH768

- Production: 50,000 T/A

- Ingredients: Miscanthus, Hay, flax straw

- biomass pellet project cost: US$550,000

biomass pellet making machine In argentina

- pellet making machine selection: MZLH768

- Production: 35,000 T/A

- Ingredients: palm waste, straw, husk, wood waste

- biomass pellet project cost: 410,000USD

biomass pellets making machine In indonesia

- pellet making machine selection: MZLH768

- Production: 10,000 T/A

- Ingredients: palm waste, Sawdust

- biomass pellet project cost: 190,000 USD

biomass pellet making machine In Thailand

- pellet making machine selection: MZLH768

- Production: 55,000 T/A

- Ingredients: Peanut shells, straw, rice husks

- biomass pellet project cost: 470,000 USD

biomass pellet making machine In canada

- pellet making machine selection: MZLH768

- Production: 6,000 T/A

- Ingredients: Straw, hay, Sawdust, blocks, planks

- biomass pellet project cost: $160,000

biomass pellet making machine In brazil

- pellet making machine selection: MZLH768

- Production: 30,000 T/A

- Ingredients: cotton stalk, sawdust

- biomass pellet project cost: $585,000 USD

How to process biomass pellets with complete biomass pellet making machine plant?

The biomass pellet making machine plant process is to process biomass materials through mechanical processing, crushing, mixing, granulation and other steps to make pellets with a certain shape and size that can be used as fuel or feed.

The biomass pellet production line mainly includes raw material preparation, pelleting processing, drying, cooling, screening and packaging.

- Raw material preparation: The raw materials of biomass pellets mainly include waste such as straw, weeds, wood chips, sawdust and energy crops such as corn stalks. In the raw material preparation stage, these materials need to be chopped, impurities removed and humidity adjusted to ensure the quality of subsequent pelleting and drying.

- Pellet processing: After the raw materials are processed by the biomass pellet making machine, granular biomass materials are formed. The main process of pelletizing is to heat and press the raw materials through the mold orifice plate to form pellets. The selection and operation technology of the biomass pellets making machine have an important influence on the quality of the pellets.

- Cooling: The biomass pellets after pelleting contain high humidity, which needs to be reduced to a suitable moisture content by cooling equipment. The cooling method can be hot air cooling, natural air cooling or other forms of heat source cooling. During the coolng process, the temperature and humidity should be controlled to avoid deformation or cracking of the biomass pellets.

- Screening: The cooled biomass pellets may have a certain amount of fragments or uneven particle size. The screening equipment can remove unqualified particles to improve the uniformity and quality of the particles.

- Packaging: After screening, the biomass pellets can be packaged. Common packaging methods include bagging and bulk. The packaging should pay attention to moisture-proof, flame-proof and permeability.

Equipment needed in a complete biomass pellet making machine system

The complete set of biomass pellet making equipment mainly includes the following categories:

Bale breaker

Capacity:

1-20T/h

Main Power:

30-90KW

biomass Hammer Mill

Capacity:

3-25T/H

Main Power:

30-160 KW

biomass Crusher Machine

Capacity:

0.3-3T/H

Main Power:

22-93KW

biomass Mixing Machine

Capacity:

250-2000KG

Main Power:

4-55KW

biomass Dryer

Capacity:

Customized

Rotate Speed:

3-8 R/Min

1. Crushing equipment

The crushing equipment is the most basic equipment on the biomass pellet manufacturing plant. Its main function is to crush the raw materials into smaller sizes for subsequent transportation and processing. There are many types of crushing equipment, including wood chippers, high-efficiency crushers, multi-functional crushers, rotary cutter crushers, etc. Different biomass pellet machines are suitable for different raw materials and should be selected according to actual conditions.

2. Conveyor

Conveyor is an important auxiliary equipment in the biomass pellet making plant. Its main function is to transport the crushed raw materials to the next process. There are many types of conveyors, including belt conveyors, screw conveyors, bucket elevators, etc. When choosing a conveyor, you should choose according to the characteristics of the material and the production process requirements.

3. Dryer

The moisture required for making biomass pellets should be around 15%, so it is necessary to dry the raw materials with high moisture. The commonly used dryer is a drum dryer, a long large cylinder, and the heat source has a hot air furnace. It can burn coal, wood chips, or electricity, but the cost is higher. It depends on your own needs.

4. Biomass pellet making machine

The biomass pellet making machine is the core equipment in the biomass pelletizing plant. Its main function is to process the processed materials into regular shapes. Biomass pellet machines include flat die pelletizers and ring die biomass pelletizers. Among them, the horizontal ring die biomass pellets making machine is a commonly used model. When choosing a molding machine, factors such as material characteristics, output requirements, and production process requirements should be considered.

5. Cooler

Coolers are mainly used in the cooling process of biomass pellet machine lines. Their main function is to cool down the biomass pellets that have just been processed to prevent cracking and other problems. There are many types of coolers, such as forced circulation coolers and natural coolers. When choosing a cooler, factors such as material characteristics, output requirements, and production process requirements should be considered.

6. Screening machine

Screening machines are mainly used in the screening process of biomass pellet mill lines. They can be used to screen raw material impurities in the early stage, and can also be used to screen pellets in the later stage. Common screening equipment includes drum screens, vibrating screens, etc.

7. Packaging machine

The packaging machine is the last link in the biomass pellet mill plant. Its main function is to package the classified biomass pellets. There are many types of packaging machines, including ton packaging machines, automatic sewing machines, etc.

The above are the main types of complete sets of biomass pellet equipment. Different equipment plays different roles in different processes. When choosing equipment for biomass pellet plant, it is necessary to choose according to the actual situation to ensure that the quality of the produced biomass pellets is better.

Video of biomass pellet making machine

FAQs of biomass pellet making machine

What is the cost of MZLH768 biomass pellets making machine?

The MZLH768 biomass pellet making machine price is generally between FOB 50,000-70,000 USD.

The biomass pellets making machine price vary greatly in the market. So, what determines the biomass pellet machine price?

1. Technical cost

Different biomass pellet mill machines have different technical levels, which leads to different prices. High-end biomass pellet machines generally have more lean pelletizing technology and higher stability, so their technical costs are also relatively high.

2. Material cost

Different materials and specifications also have a certain impact on the price of biomass pellet press machines. For example, biomass pellet machines made of high-grade stainless steel are relatively expensive, while those made of general carbon steel are relatively cheap.

In addition, the quality of components, bearings, motors and other parts used in biomass pellet machines produced by different manufacturers is also different, which further leads to price differences.

3. Brand premium

Like other industrial equipment, the brand of a biomass pellet making machine also has a certain impact on the price. Well-known brands of biomass pellet machines tend to have high visibility and good reputation, so their prices are generally higher. Some small brands or emerging brands of biomass pellet machines are relatively cheap. Consumers can choose the right brand according to their own needs and budget when purchasing.

4. Service and function

In addition to the basic pelletizing function, some biomass pelleting machines also have other additional functions, such as remote monitoring, PLC touch screen control, etc. These additional functions and services will also have an impact on the price. The more functions and more comprehensive services a biomass pellet machine has, the higher the price.

In summary, the price determining factors of biomass pellet making machine mainly include technical cost, material cost, brand premium, and service and function. When purchasing a biomass pellet machine, biomass pellet processors can choose the right product according to their own needs and budget.

How to choose a biomass pellet machine?

It is very important to choose a suitable biomass fuel pellet machine. It can not only improve production efficiency and reduce the production cost of biomass pellets, but also ensure product quality and market competitiveness.

- When choosing equipment, you can make a comprehensive consideration based on factors such as brand, model and purchase channel, and conduct detailed market research and price comparison.

- In addition, you can also refer to some experience summaries and tips, such as communicating with people in the same industry to understand their choices and usage experience; you can also search the Internet or consult professionals to obtain more information about the performance and price of biomass pellet making machines.

- Finally, after purchasing the biomass pellets making machine, pay attention to correct use and maintenance, and arrange the production plan reasonably to give full play to the role of the equipment. Only by using the equipment scientifically and efficiently can its value be maximized and better economic benefits be obtained.

- At the same time, with the continuous development of technology and the update and iteration of equipment, pay attention to timely understanding and mastering new technology and equipment information, and upgrade and update the equipment in a timely manner to maintain your position and advantage in market competition.

How to choose biomass pellet making machine manufacturers?

When users choose biomass pellet making machine suppliers, in order to avoid being deceived, they need to clearly understand their actual production needs, and then communicate with the manufacturer’s technicians. The manufacturer’s technicians recommend or formulate a suitable biomass pellet production plan for the user based on the information provided by the user. When the user chooses, the manufacturer’s economic strength, biomass pellet making machine quality, engineering cases and after-sales service are very important.

- The economic strength of the manufacturer refers to the production scale and the advancement of drying technology. 换行 The quality of the biomass pellet making machine determines the equipment performance, production efficiency and service life. After-sales service includes consulting, procurement, installation, commissioning, training, post-maintenance and other services. When purchasing a biomass pellet making machine, users should first consider the quality of the biomass pellet machine, because the quality directly affects the stability, production efficiency and production effect of the biomass pellet machine, and also affects the service life of the biomass granulator.

- Secondly, consider the manufacturer’s after-sales service, because after-sales service is related to the post-maintenance and upgrade of the biomass pellets making machine. 换行 In order to ensure better and stable production of the biomass pellets making machine, users can choose several biomass pellet machine manufacturers, visit them on site, understand the manufacturer information and equipment information, and select high-quality biomass pellet machine products through comparison.

What is the prospect of processing biomass pellets with biomass pellets making machines?

With the growing global energy demand, biomass pellets, as a renewable energy source, are gradually attracting people’s attention. Biomass pellets are solid fuels made from agricultural waste, forestry waste, etc. as raw materials and processed. It is not only environmentally friendly and renewable, but also generates high heat and low ash during combustion, so it is widely used in industrial and civil fields.

1. Current status of biomass pellets

At present, the production technology of biomass pellets has been relatively mature, and the production scale has been continuously expanded. In the domestic and foreign markets, the demand for biomass pellets has shown a steady growth trend.

Especially in some developed countries, biomass pellets made by biomass pellet making machine have become an important choice to replace traditional fossil energy. At the same time, the production cost of biomass pellets is gradually decreasing, which provides strong support for its popularity in the market.

2. Market prospects of biomass pellets

- With the transformation of the global energy structure and the improvement of environmental awareness, the market prospects of biomass pellets are very broad. First of all, as a clean energy, biomass pellets meet the requirements of sustainable development and will occupy an important position in the future energy field.

- Secondly, the raw materials for the production of biomass pellets are widely sourced. Not only can agricultural waste, forestry waste and other waste resources be used, but also urban garbage and other wastes can be used, which has huge development potential.

- Finally, the application field of biomass pellets will continue to expand. It can be used not only in industrial boilers, civil heating and other fields, but also in biomass power generation, biomass gas and other fields, providing a broad market space for the further development of biomass pellets.

In summary, biomass pellets, which are made by biomass pellet making machine, as a renewable energy source, have broad development prospects. With the transformation of the global energy structure and the improvement of environmental awareness, biomass pellets will occupy an important position in the future energy field.

What are the application fields of biomass pellets?

1. Industrial field

In the industrial field, biomass pellets can replace traditional fossil energy such as coal and fuel oil, and be used in industrial boilers, drying equipment, smelting furnaces and other equipment.

Biomass pellets have high combustion efficiency and low ash content, which can not only reduce the energy cost of enterprises, but also reduce the impact on the environment and achieve green production.

2. Civil field

In the civil field, biomass pellets made by biomass pellet making machine can be used for home heating, hot water supply and other aspects.

Compared with traditional energy such as coal and gas, biomass pellets produce fewer pollutants during combustion, which is conducive to improving indoor air quality. At the same time, the price of biomass pellets is relatively low, which also meets the actual needs of consumers.

3. Biomass power generation field

Biomass pellets can also be used for biomass power generation. By burning biomass pellets, high-temperature and high-pressure steam can be generated, which in turn drives turbines to generate electricity. Biomass power generation has the advantages of being renewable and environmentally friendly, and is one of the important development directions in the future energy field.

4. Biomass gas field

Biomass pellets made by biomass pellet making machine can also be converted into biomass gas through gasification, cracking and other technologies, and used in gas power generation, gas boilers and other fields. Biomass gas has the advantages of high calorific value, clean and environmentally friendly, and is an important choice to replace traditional fossil gas.

The production cost of biomass pellets continues to decrease, and the application field will continue to expand, providing strong support for its popularity in the market.

Therefore, we can foresee that biomass pellets will become an important force in the future energy field and make important contributions to the sustainable development of human society. (Find RICHI on youtube)