Paper Pellet Making machine

RICHI paper pellet making machine is the workhorse and go-to paper pellet machine for many applications. Whether it is used for making paper cat litter pellets, dog litter paper pellets, rabbit paper pellet litter or paper fuel pellets, the paper pellet mill is known for its dependability and versatility.

The paper pellet machine’s superior construction quality makes the machines durable and problem-free while ensuring high-performance and efficient processing around the clock. The machine is our independent development and contains many national patent. It mainly improves the ring die to craze so as to keep high yield and long service life.

- Capacity: 0.3-5T/H

- Pellet size: 2-12mm

- Power: 37-315KW

It can be said that the paper granulator can be mainly used as a cat litter making machine and a fule biomass pellet mill machine at present.

Based on detailed customers requirements, we can always offer satisfying paper pellet press and solutions for pellet production projects.

Application of Paper pellet making machine

The paper pelletizer is suitable for meeting the requirements of customers who need to compact large quantities of scrap.

Paper pellet maker machine is suitable for processing:

01

- paper pellet cat litter

- Waste paper fuel pellet

- Paper wood pellet fuel

- recycled paper pellets

- naturals paper pellet litter

- paper pellet litter for rabbits

- paper pellets dog litter

- recycled newspaper cat litter

- shredded newspaper cat litter

02

- exquisicat paper crumble litter

- special kitty paper pellets

- non clumping paper cat litter

- fresh news post consumer paper pellet cat litter

- unscented paper pellet litter

- paper pellets for guinea pigs

- compressed newspaper pellets

- cardboard pellets

- …

In general, paper pellet machines are mainly used to process cat litter pellets, animal bedding and paper pellet fuel. The equipment can also be used for material processing and conversion in biomass pellets, wood pellets, straw pellets, agricultural and forestry waste pellets and other industries.

During the processing of the pellet machine, people can adjust the size of the discharge port according to different needs in order to obtain particles of different shapes and sizes. At the same time, due to its simple structure, easy operation, high efficiency and low energy consumption, the pellet machine is widely used in production in different industries.

Features Of Paper pellet making machine

MZLH series high-grade paper pellets machine is the main item of equipment for producing paper pellet with application to small, large and medium scale paper pellet plant.

- The paper pellet maker machine features compact structure, fine appearance, low noise, high output with low power consumption, it is convenient in operation and reliable in performance.

- The machine can be fitted with dies of Ø2 – Ø12 hole diameter, which can be chosen by user according to requirements.

- The machine adopts frequency conversion speed-adjusting motor for feeder and large door conditioner access, with axial liquid addition.

- Feeder is fitted with strong magnetic safety device, press overload protection device and external discharging mechanism.

RICHI paper pellet mills are built to operate 24 hours a day under tough running conditions to match the output requirements.

Structure Of Paper pellet making machine

The paper pellet mill machine is mainly composed of feeding system, compression system, separation system, lubrication system, starting system, control system, etc.

- The feeding system mainly consists of a feeding port, a speed regulator and a feeding device.

- The compression system is mainly composed of a rotating screen, mesh ring, pressure wheel, and pressure wheel adjustment device.

- The separation system mainly includes a screen device, a discharge port, a vibrator, etc. The lubrication system generally uses an oil pump or grease lubrication device.

- The starting system adopts response equipment according to the driving motor of the pellet machine, such as an electronic starter and a corresponding isolator.

- The control system mainly consists of commutator, protection device and detection device.

Working principle of paper pellet machine:

Input the pretreated waste paper materials into the paper pellet making machine through the feed port. Under the action of the high-speed rotating mesh ring and the gear pairs around the mesh ring, the material gradually becomes paper pellets through multiple actions such as extrusion, shearing and friction.

The discharge port of the pellet machine can be configured according to different needs. At the same time, the feeding, discharging and motor mixing interlocking devices of the pellet machine can play a safety role.

paper pellet making machine Parameters

| Model | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH768 | MZLH858 |

| Output (t/h) | 0.3~0.5 | 0.5~0.7 | 1.0~1.5 | 2.0~2.5 | 2.5~4 | 4~5 |

| Main motor power (kw) | 22 | 37 | 90 | 132 | 250 | 280 |

| Main motor series | 8P | |||||

| Ring die diameter (mm) | 320 | 350 | 420 | 520 | 762 | 858 |

| Finished pellet diameter (mm) | 2-12 | |||||

| Device Configuration | Ring die material: 42CrMo Stainless steel feeder: with anti-caking function Door of pelleting room: 6mm /SUS304 Forced feeding: Worm gear reducer Gear box: HT250 Gear: 42CrMo Gear shaft: 42CrMo Spindle: 42CrMo Empty shaft: 42CrMo Bearings: The gear shaft and main shaft bearings are SKF, and the pressure roller bearings are domestic high-quality bearings Oil seal: Germany/Taiwan Overload mechanical protection: safety pin Serpentine spring coupling drive Lubrication system: Configurable automatic oil injection system | |||||

CE Paper pellet machine Price

Paper pellet machine Price: 10000 – 100000USD

There are many options available in the market and they come with different price tags. It is important that you have a clear idea about how much money you are willing to spend on buying a paper cardboard pellet machine.

If you have sufficient funds and are very sure of the huge economic benefits of paper pellet processing, it is recommended to choose the equipment output and paper pellet production line scale that match the budget.

If you do not have any idea about this, then it is better to start with something small and economical. You can always upgrade later if your business grows bigger and more profitable. You will also need to calculate how much it cost to run the machine per day or per week. This way, it will be easier for you to decide whether or not it’s worth buying one for your business.

If you have any questions about paper pellet machine price and paper pellet processing costs, please feel free to contact us for consultation!

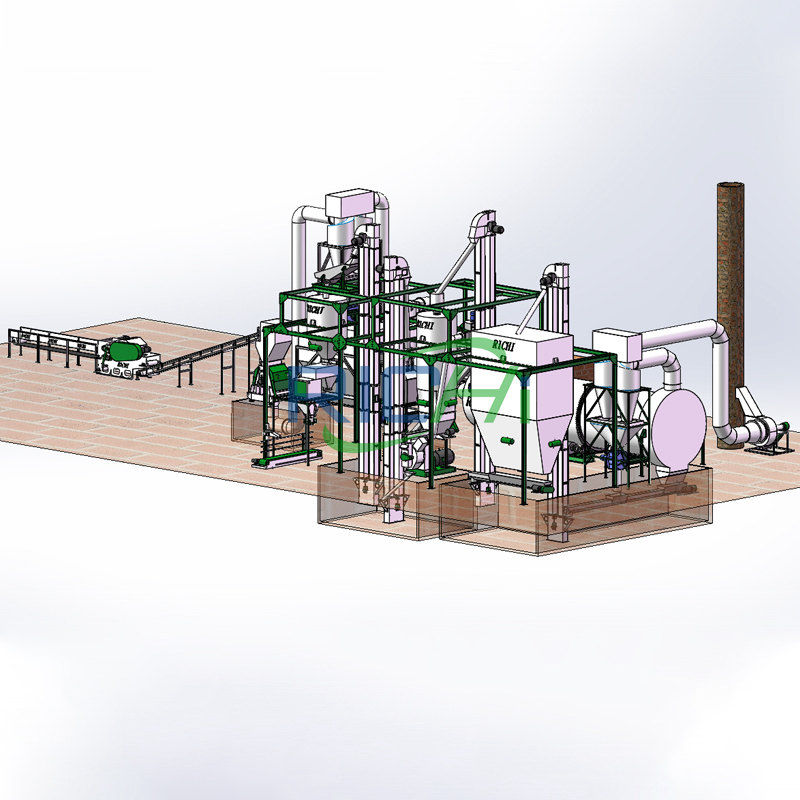

Complete paper pellet machine plant supplier

Based on different materials, we have suitable paper pellet making process. The whole paper pellet plant process include Material Crushing Section, Drying Section, Pelletizing Section, Pellets Cooling Section, Screening Section and Pellets Packing Section. The production capacity can be 300 kg/h to max 40 t/h.

- Raw material preparation

The main raw materials of waste paper particles are cardboard, newspapers, office paper, cartons and other paper products. First, the raw materials must be screened and crushed to ensure that there are few impurities and uniform particle size. - Pre-processing

The crushed raw materials need to be pre-processed, including impurity removal and drying. With proper moisture, hay is not needed. The purpose of impurity removal is to remove impurities in the raw materials so as not to affect the subsequent pelleting process. - Pelleting by paper pellet machine

The paper pellet making machine is the core equipment for the production of waste paper pellets. Its function is to compress and pellet the pretreated raw materials. There is a pressure roller and a mold inside the pellet machine. The raw materials form granular products through extrusion and friction. When granulating, the paper granulator needs to be adjusted according to different raw materials and product requirements, including adjusting the pressure, temperature, humidity and other parameters of the paper pellet press. - Cooling and screening

The granulated waste paper particles need to be cooled and screened. The purpose of cooling is to lower the temperature of the particles and avoid spontaneous combustion of the particles during storage and packaging. Screening is to separate particles into products of different specifications according to different particle sizes to meet market demand. - Packaging and storage

The screened waste paper particles need to be packaged and stored. When packaging, attention should be paid to sealing and corrosion resistance to ensure that the quality of pellet fuel is not affected by the external environment. When storing, choose a dry, ventilated, and moisture-proof environment to prevent pellet fuel from absorbing moisture or getting damp. - Quality inspection and sales

The produced pellet fuel needs to be tested for quality, including testing of calorific value, moisture content, ash content and other indicators. Qualified products can be sold through energy companies, industrial enterprises and household users.

Featured paper pelletizing line projects

2-2.5 t/h waste paper pellet machine in Kazakhstan

300-400 Kg/H Paper Granulator In Mauritius

300-400 Kg/H Paper Granulator In Ukraine

Why Choose Richi Machinery?

Our core value of development is integrity-based, quality-oriented and client-centered. Based on these concepts, we’ve also set up professionally established departments for paper pellet making machine and other equipment.We have set up overseas agencies, and with ISO and CE certifications, RICHI Machinery is a renewable machinery manufacturer that enjoys national encouragement policies. We also have domestic offices in Zhengzhou and Kaifeng of China.

- 25+ Years Factory With CE IS09001 Certificate

- 1000+ Happy Customers Worldwide

- Shipped To Over130+ Countries

- Pellet Machine Made With Enhanced Top Level Steel

- Easier To Start Your Pellet Production Plant

- 24*7 Hours Online Service

Faqs of paper pellet making machine

In addition to paper materials, our paper pellet machine can also process various materials from forest and agricultural waste. For example wood logs, branches, wood chips, tree leaves, log stump, waste furniture, sawdust, mushroom, rice husk, rice straw, corn stalk, peanut shell, EFB, bamboo etc.

We have different machines and specification which can meet your various materials production requirements, you can contact with your experts team to know more. Or you click here to visit our product:sawdust pellet machine, straw pellet machine, rice husk pellet machine, alfalfa pellet machine, grass pellet machine, hay pellet machine, hops pelletizer machine, etc.

1. Negotiation

We will negotiate with you about your requirement, including what’s your material for making pellets? how much moisture content? how much capacity per hour? budget for the project? plant landing size available etc. Based on them we will customize the solution with our experience and introduce to you.

2. Order Confirmation

After we conclude the paper pellet production line solution and quotation, we will sign contract and proceed with payment. We accept 40% T/T after confirm the order, and 60%T/T balance before shipment.

3. Manufacturing Process

After we get your deposit payment, we will arrange production accordingly, based on different capacity, our manufacturing time are different. Normally speaking, we need 30-45days for whole pellet line capacity under 5t/h, and 45-60days for capacity over 5t/h. For single set machine need about 25-30days based on our manufacturing plan.

4. Machine commission and delivery

After all the paper pellet making machine and other supporting machines finished manufacturing, we will test and run all the machines before delivery, make sure the machine can achieve best performance before delivery, during that time we will send customers the testing videos for confirmation

5. Balance payment and delivery arrange

After customer accept the machines performance, customer should arrange the balance payment to us, after we get the balance, we will arrange to book the ship and arrange delivery for customers. All the machines will be well packed for long distance shipment.

6. Customs documents handover

After all the paper pellet making machine and other equipment arranged customs in China, we will send all the documents to customers including Bill Of Lading ,Invoice, Packing List, Country Of Origin, etc. We will help customers on the customs clearance smoothly.

We are pellet machinery manufacturer since the year 1995, we can offer complete pellet production machinery based on your requirement. Factory landing size 50000m² and 100+ employees. And more than 1000+ customers domestic and abroad. We have seperate team to arrange sales and after-sales service.

In order to serve you better, please try to provide the below information:

(1) What kind of paper material are used to make pellets? Better if you can share us some pictures.

(2) Hardness of your material?

(3) Moisture content?

(4) Maximum diameter of the material to be processed?

(5) The capacity per hour you want to get for the pellet production.

(6) Then we will recommend suitable model based on your actual needs.

To make pellets, we should control the sawdust entering the paper pellet making machine moisture content 10-15%, too wet or too dry will affect the pelletizing result. If you material is too wet, you need a dryer machine to remove the moisture.

Our warranty for paper pellet making machine machinery are one year after sale, not including the wear parts. The main wear parts are the ring die and roller.

Before delivery, we will also test all the machines to make sure it can achieve best performance, and we will make detailed video to show customers how to install them, and the installation manual will be sent together with the machine. Our after-sales will be ready 24hours to support customers for the whole installation process.

(1) How does a paper pellet maker work?

(2) Need to buy additional equipment for paper pellets machine?

(3) What is the size of premises where the paper pellet mill will be located?

(4) What are your capacity requirements?

(5) What is your source material? Is it moist enough to be pelletized?

(6) What kind of power source will the machine run on?

(7) Will there be regular maintenance? How much and how often?

If you are serious about buying a paper cardboard pellet maker, you need to consider the important factors we’ve outlined above. Paper cardboard pellet mills are making a big splash in the cat litter and fuel industry, however you need to understand that there is more to consider when buying one than meets the eye. Remember, doing your research can save you a lot of time, energy, and money.

When it comes to choosing the right paper pellet making machine for your business, you need to confirm whether or not you need a complete paper cardboard pellet mill plant or just one machine.

If you’re looking for a single machine, then you should consider how much space you have available for installation, as well as how much power you need for operation. You’ll also want to make sure that the machine can handle the type of materials that you plan on using in your paper pellet production process.

If you’re thinking about going with an entire paper pellet mill plant instead of just one machine, then consider whether or not there will be any downtime during installation and operation of your new system.

You’ll also want to make sure that the paper pellet making machine manufacturer’s warranty covers any potential issues with installation or operation before making your final decision on which option is best for your needs! (Find us on Facebook)