Wood Pellet Making Machine Price

The wood pellet making machine price is generally between 10,000-100,000 USD. Our wood pellet machine prices include pellet machine and on-site electric control cabinet. (There is no additional charge for on-site electric control cabinet)

Our wood pellet machine uses different kinds of wood waste to make pellets as fuel, cat litter or animal bedding. Because of its environmental-friendly and high-return features, this kind of machine has been widely applied. RICHI offers six models wood pellet mill to process 0.3-4.5 tons of wood pellets. Besides, fast shipment and installation are available.

In addition to the sales of single wood pellet machines, we also provide customized design, manufacturing, installation, commissioning and training services for a complete set of wood pellet mill plant systems. If you are interested in our equipment and wood pellet production lines, feel free to contact us to get the wood pellet making machine price!

What’s wood pellet making machine?

Ring die wood pellet machine is generally large wood pellet production equipment because of its large capacity as compared to small flat die pellet mill. It is usually used for industrial or commercial wood pellet production. For example, investors who want to make pellets for sale or demand for 0.3-90 tons per hour wood pellets capacity would prefer to buy ring die pellet mill to build a complete wood pellet plant.

Due to the strong pressure of compression, ring die wood pellet making machine is able to process various wood materials, especially materials that is difficult to bond and form, so it is the ideal wood pelletizer to produce high quality woods pellets that are widely used in power plants, carpentry factory and other chemical plants.

What needs to be emphasized is that today, our wood pellet mill has helped hundreds of wood pellet manufacturers obtain ENPlus Certification, USA PFI Wood Pellets Standards Certification, ISO Wood Pellet Standard Certification, and Canada CANplus wood pellet certification.

Types of wood pellet making machines

Wood pellet making machine is designed to make pellets fuel from wood chips, sawdust, shavings, tree branches, wood barks, etc. It is also suitable for other biomass materials, such as rice straw, rice husk, corn stalk, bamboo, peanut shells, bagasse, palm fiber, coconut shells, hay, hemp, hops, cotton stalk, etc.

- Sawdust pellet machine

- Wood chip pellet machine

- softwood pellet mill

- hardwood pellet mill

- Wood Shaving Pellet Machine

- Wood Log Pellet Mill Machine

- Wood Board Pellet Mill

- …

The end products, biomass wood pellets are widely used heating fuel for commercial or residential use, cooking, and power generation. If you are interested in the promising wood pellet production business, please contact RICHI for wood pellet making machine price, operation and installation site videos.

Wood pellet making machine price on different models

RICHI MZLH320, MZLH350, MZLH420, MZLH520, MZLH768, MZLH858 wood pellet making machine are designed to meet different customers’ demands. They are applicable for large scale business and small scale business. So, you would obtain the proper model from RICHI Machinery.

If you need us to help you to choose the wood pellet mill machine, leave us your message and describe your situation and demands, such as raw material, output, factory area, destination, etc. Then, we would give you professional suggestions and reasonable wood pellet machine price.

MZLH320 Wood Pellet Machine For Sale

- Wood pellet machine price:10,000-20,000USD

- Power: 37KW

- Capacity: 300-400KG/H

- Final Pellet: 6-12 mm

- Weight(KG): 2500

MZLH350 wood pellet extruder machine

- wood pellet mill price: 20,000-35,000USD

- Power: 55KW

- Capacity: 500-700KG/H

- Final Pellet: 6-12 mm

- Weight(KG): 3500

MZLH420 Wood Pellet Maker For Sale

- wood pellet mill cost: 35,000-45,000USD

- 90KW

- Capacity: 1.0-1.2 T/H

- Final Pellet: 6-12 mm

- Weight(KG): 4000

MZLH520 Wood Pellet Press for sale

- wood pellet machine cost: 40,000-50,000 USD

- Power: 132KW

- Capacity: 2.0-2.5 T/H

- Final Pellet: 6-12 mm

- Weight(KG): 4500

MZLH768 Wood Pelletizer for sale

- wood pellet machine Price: 50,000-70,000 USD

- Power: 250KW

- Capacity: 2.5-4 T/H

- Final Pellet: 6-12 mm

- Weight(KG): 5000

MZLH858 Wood Pelletizer machine

- wood pellet machine cost: 70,000-90,000USD

- Power: 280KW

- Capacity: 3-4.5 T/H

- Final Pellet: 6-12 mm

- Weight(KG): 5500

wood pellet machine price types we can offer:

The wood pellet mill quotes we can provide mainly include the following:

- FOB price: FOB price, that is, the price before leaving the port of Qingdao, China. (We usually ship from Qingdao Port, China)

- EXW price: ex-factory price, that is, the price when departing from RICHI.

- CIF price: cost + insurance + freight, that is, the total price of the wood pellet mill arriving at the customer’s destination port.

Generally speaking, most customers inquire about FOB quotations. You can inform our technical consultants of the type of wood pellet making machine price and destination you want during consultation, and our technical consultants will send you an accurate quotation.

Customized price of wood pellet making machine:

Richi Machinery can customize the wood pellet making machine according to the actual needs of customers, including voltage, electrical components, door opening method, product color matching, etc. Some of these customized contents are paid and some are free. The wood pellet machine price needs to be finalized according to customer needs.

You can trust us because we don’t have to rely on others. We are offering all manufacturing, assembling, testing and after sales services from a single source by proven RICHI quality!

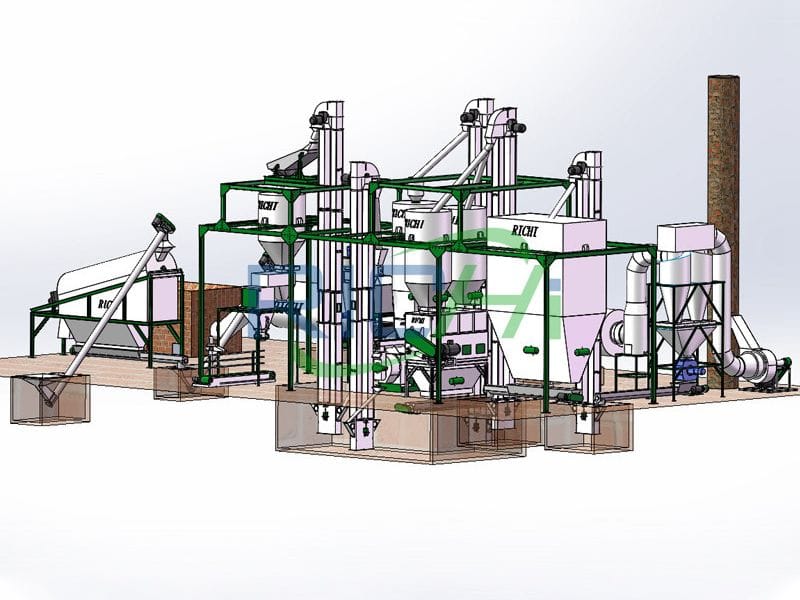

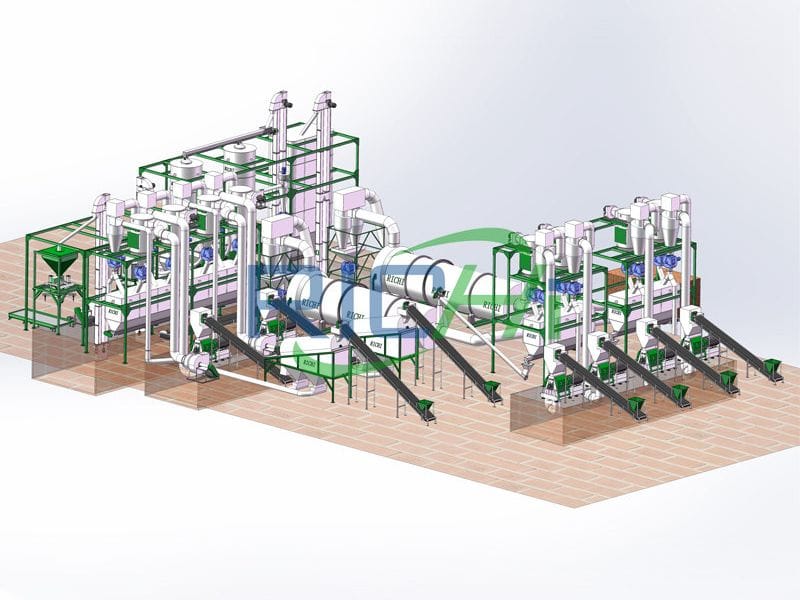

Customized whole set wood pellet making machine prices

The complete whole set wood pellet making machine price is 50,000-3,000,000 USD. The complete wood pellet making machine plant here refers to a complete system, not only a single wood pellet machine.

- The wood pellet mill price is fixed and is available to global customers at the same price.

- The complete wood pellet production line price changes with the customer’s process needs and raw materials.

Generally speaking, a wood pellet machine cannot support the entire wood pellet production process. Therefore, from the processing stage of wood waste raw materials to the formation of wood pellets, different processes and equipment are required to form a complete wood pellet processing system, and then form a complete production process.

- The complete wood pellet making process includes wood raw materials crushing, drying, pelletizing, cooling, and packaging. This process is relatively complete, but not every customer needs it, and it can be customized according to actual needs.

- Accordingly, the equipment needed in the whole set wood pellet making system includes wood crusher or chipper, woo dryer, wood pelleting machine, cooling system, and packing system. Depending on the type, shape, and moisture of the raw materials, You can choose the process and equipment according to your needs.

To facilitate understanding, the following is an list of several typical situations:

- If your raw material is clean, dry sawdust without impurities: you can directly skip the crushing and drying stages and directly put the sawdust into the wood pelletizing machine for processing through the conveying equipment; if you want to sell processed wood pellets, then Cooling, screening and baling processes need to be added; if you want to save money and your factory is large, you can consider stacking the processed wood pellets in the open space for natural cooling, and then packaging them directly through conveying equipment , then you only need a wood pellet granulator, a baling scale and some conveying equipment (conveyors, forklifts).

- If your raw material is wood chips with a moisture content of more than 30% and requires a complete process, then you need to dry the wood chips, then crush the wood chips, and then enter the granulation, cooling, screening, packaging and other stages. Then the equipment you need includes wood pellet hammer mill, pellet machine, cooling machine, screening machine, bagging machine, etc.

- If your raw material is a very thick tree trunk and the moisture content of the tree trunk is very high, then this requires a lot of “pre-treatment equipment”. The required equipment includes wood splitters, slicers, wood flour machines, dryers, and trommel screens. After pre-treatment, it can then enter the granulation, cooling, screening and packaging sections.

- If your raw materials include wood chips, reeds, hay, etc., depending on the shape and moisture content of your raw materials, you will also need to add equipment such as haymakers and trommel screens.

- …

One hundred customers represent one hundred needs, and what RICHI Machinery has always done is to transform these needs into process plans and final equipment configuration plans to realize what customers want.

No matter how many kinds of raw materials you use, no matter how your raw materials need to be processed, RICHI can provide you with the most suitable solution and matching high-performance equipment.

Different projects, different Wood pellet making system prices

At present, RICHI wood pellet mills and complete wood pellet systems have been exported to all continents around the world, including the United States, Canada, Indonesia, Thailand, Russia, Malaysia, Australia, New Zealand, the United Kingdom, Germany, Poland, South Africa, and Angola. More than 5 pellet production line projects have been built in more than 80 countries.

wood pellet making machine project In United States

- Capacity: 10 T/H

- Pellet Size: 6-8 mm

- The install period: 60 Days

- Complete set wood pellet machine cost: 1,300,000 USD

- Main Raw material: wood waste from furniture factories, paper mills and other factories

- Main Machines: Wood chipper, wood hammer mill, rotary dryer, wood pellet mill, Pellet cooling machine, Screener machine, packing machine, Sewing machine,etc.

wood pellet making machine Project In canada

- Capacity: 2-2.5 T/H

- Pellet Size: 8mm

- The install period: 45 Days

- Complete set wood pellet machine price: 330,000 USD

- Main Raw material: wood off cuts, wood chip and sawdust different types of wood sizes

- Main Machines: Wood sawdust making machine, Mixing machine, MZLH520 sawdust pellet press, Wood pellet cooler, Wood pellet screener, Wood pellet bagging machine, etc.

wood pellet making machine project In Argentina

- Capacity: 4-5T/H

- Pellet Size: 8 mm

- The install period: 50 Days

- Whole set wood pellet making machine price: US$430,000

- Main Raw material: tree branches, Sawdust, wood pallets, Wood shavings

- Main Machines: Wood crusher, Pulse dust collector, U-screw conveyor, Drum dryer, wood fuel pellet mill MZLH520, Belt conveyor, Cooling machine, Vibrating screener, Packing machine, etc.

wood pellet making machine project In Indonesia

- Capacity: 1-2T/H

- Pellet Size: 10 mm

- The install period: 40 Days

- Whole set wood pellet making machine price: US$ 220,000

- Main Raw material: various discarded wooden pallets

- Main Machines: Pallet shredder, Wood hammer mill, Wood pellet mill machine, Wood pellet cooler, Screening machine, Bucket elevator, Conveyor, Automatic weighing and baling machine, etc.

Following, RICHI will show you three wood pellet production lines with an annual output of 10,000 tons. However, the same output, different projects, different customers, different needs, different raw materials, different processes, and ultimately, different complete sets wood pellet making machine price.

4T/H complete wood pellet making machine system

—— RICHI MACHINERY ——

- Annual output: 10,000 tons of wood pellets

- Whole set wood pellet making machine price: 110,000 USD

- Total building area: 400m2

- Employees: 6 people

- Working system: The production shift is one shift, 8 hours, and annual working day is 300 days.

- Annual electricity consumption: 6000 kwh

- Annual water consumption: 90 tons

- Main raw materials: sawdust*16,000 t/a

- Main equipment: 1 wood crusher, 1 wood pellet making machine, 1 dryer, 1 belt conveyor

4T/H Production Process design:

- Crushing: Due to the large size of various types of raw materials, they need to be crushed to 600mm by a pulverizer, and then directly transported to a closed molding machine to be directly pressed and formed by pressure.

- Drying: Since the moisture in the raw materials may not meet the production requirements, the raw materials need to be dried. The drying process of this project uses biomass pellet fuel as energy.

- Pressing and molding: The dried straw material and sawdust are fed into the pellet machine in a certain proportion and pressed into pellet shape in the pellet machine without any additives. The granulator machine is sealed.

- Packing and storage: The qualified finished products are bagged, weighed, packed, and stored in storage.

1.5-2.5 t/h complete wood pellet making machine plant

—— RICHI MACHINERY ——

- Annual output: 10,000 tons of biomass pellet fuel

- Whole set wood pellet making machine price: 230,000 USD

- Total area: 1000m2

- Electricity consumption: 210,000kWh/a

- Water consumption: 282.3m3

- Number of employees: 10

- Work system: 330 days a year, 16 hours a day.

- Main raw materials: furniture factory waste wood, scraps*1666.7t/a, sawdust & straw*11875t/a

- Main equipment: crusher, dryer, drum screen, new biomass pellet machine, bag sewing machine, conveyor

Production process design:

- Raw material reserves: The raw materials of this product are mainly waste wood, straw and sawdust.

- Raw material pretreatment: The raw material straw and waste wood need to be manually sent to the crusher to be crushed into particles with a diameter of less than 6 mm. The crushed materials are sent to the drum screen for screening, and the large pieces of materials are sent to the crusher again for crushing. Since the moisture in the product may not meet the production requirements, the product needs to be dried, using a belt conveyor and the material enters the drying system.

- Pelleting: The dried wood chips are sent to the molding machine through a belt conveyor for pressing and granulation. A total of 4 molding machines are installed. Through granulation by a wood pelletizer, biomass pellet fuel with certain shapes and specifications is formed.

- Cooling: The temperature of the molded material can reach 60-80°C, and natural cooling is used to cool down;

- Packaging: The products enter the finished product warehouse for packaging and are packed in bags. The finished products are stored temporarily and then sold out.

3.5-4T/H wood pellet mill plant

—— RICHI MACHINERY ——

- Annual output: 10,000 tons of biomass pellets

- Whole set wood pellet making machine price: 270,000 USD

- Covered area: 1500㎡

- Annual water consumption: 270 tons

- Annual power consumption: 600,000kwh

- Number of employees: 6 people.

- Working system: There are 330 production days in the year and 8 hours of work per day.

- Main raw materials: furniture factory sawdust & scraps*4000t/a, straw&10000t/a

- Main equipment: drum chipper, pulverizer, cyclone dust collector, wood chip dryer, granulator, belt conveyor, screw conveyor

Brief Description Of Process Flow Design

- The sawdust, scraps and straw purchased by the project are transported by truck to the raw material workshop in the factory for temporary storage. The raw material workshop adopts a fully enclosed color steel structure.

- Manual selection and removal of impurities: The purchased sawdust, scraps and straw may contain scrap iron, earth and rocks and other debris, which must be manually sorted and removed by workers.

- Slicing: Use a slicer to slice the scraps and straw. The dimensions after slicing are about 5cm × 5cm and 2cm thick.

- Drying: The raw materials sawdust, scraps and straw have a high moisture content, generally 30-40%. To ensure product quality, the sawdust needs to be further dried. The impurity-free materials are transported to the dryer via a belt, and the dryer uses electric heating for drying.

- Crushing: The dried raw materials are transported to the crushing section through the belt, and crushed into a powder of about 2mm by the crusher.

- Granulation: It is sent to the granulation section through a screw conveyor. The working principle of the wood pellet press is that the raw materials are added from inside the ring die, and are rolled out of the ring die by the pressure roller to form granules.

- Cooling: After the pellets are made, cool to normal temperature.

- Packaging: After the qualified pellets are manually bagged and packaged, they are sealed by a sealing machine and then entered into the warehouse for storage and sales.

From the above three wood pellet plant construction projects, we can see that although they have the same annual output, their hourly output is different. Moreover, the raw materials they use are different, the ratio of raw materials is also different, and their processes are also different. In the end, we designed different solutions for customers based on their needs, with different equipment configurations and different prices for the entire set of wood pelleting system.

In addition, you can also see that the price of a production line with larger output is not necessarily higher, because this is determined by the equipment configured. A simple configuration of a large-volume production line is sometimes cheaper than a complex configuration of a small-volume production line.

If you also want to buy wood pellet machine or buy wood pellet mill plant, feel free to contact us to get a reasonable wood pellet making machine price!

Cost of setting up a whole Wood Pellet Making plant

In addition to the price of a complete set of equipment for the production line, operating a wood pellet production line also requires many cost estimates. But the complete wood pellet making system construction cost would be various in different regions around the globe. Main costs for starting a complete wood pellet making machine plant are placed as follow:

- Wood Pellet Plant Project Setup Cost

- Pellet warehousing, rail car loading facility cost

- Daily Operating Cost

- Labor cost

- Energy cost

- Maintenance cost

- Repairs and life cycle maintenance cost

- Transportation for bulk shipments cost

RICHI Machinery can also provide you turnkey solutions with other kinds of approach if the above capitals does not suit your requirements. And our customized biomass machinery would greatly reduce the cost to set up a wood pellet production line.

If you are interested in opening a wood pellet manufacturing factory with 0.3-90 t/h production capacity, we are happy to offer your customized quotation! (Maybe you are interested in our post:how to start a wood pellet business)

Wood pellet auxiliary equipment price

As can be seen from the above, in a complete wood pellet system, in addition to the wood pellet making machine, many other wood pellet processing equipment are needed to assist in the processing of wood pellets. Let’s list the prices of the following 6 common auxiliary equipment:

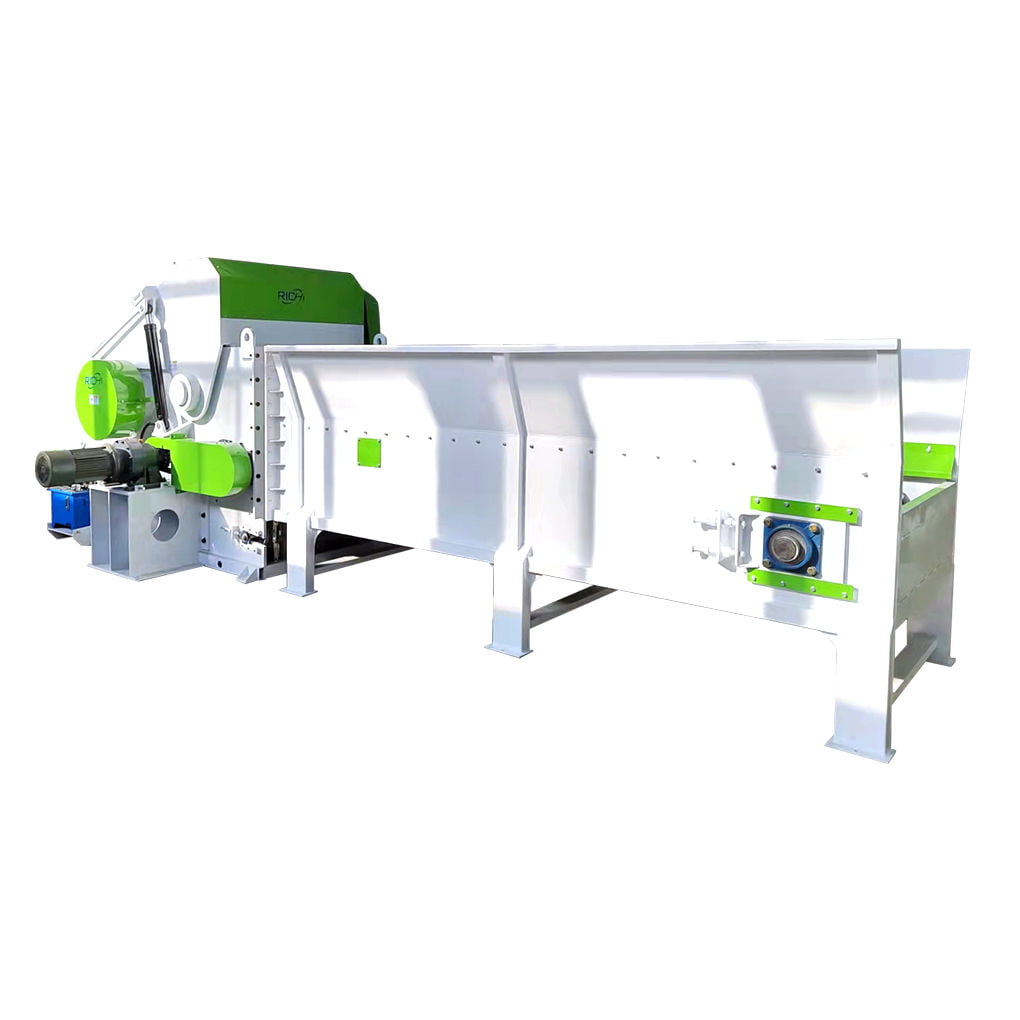

Wood Chipper Machine

wood chipper Price: 12,000 – 25,000 USD

Processing big size materials into smaller chips size, 3-5cm length and width, 10mm thickness

Capacity:

3-18 T/H

Main Power:

4-110 KW

Wood pellet Hammer Mill

Wood grinder Machine Price: 5,300-35,000 USD

Further crushing the chips size material into smaller sawdust size, 3-5mm size sawdust.

Capacity:

3-25T/H

Main Power:

30-160KW

wood pallet crusher

Pallet Shredder Cost: 20,000-20,000 USD

Pelletizing the ready dried sawdust into pellets. Single set machine capacity can reach 20t/h.

Capacity:

3-12T/H

Main Power:

50-110KW

wood chip Dryer

Chips dryer machine price:10,000-300,000 USD

Drying the wood chips or sawdust to standard 15% moisture content.

Capacity:

Customized

Rotate Speed:

3-8 R/Min

Pellet Cooler Machine

pellet cooler price: 5000-10000 USD

Cooling down the hot pellets into standard temperature.

Capacity:

1.5-18T/H

Main Power:

0.75-2.05 KW

Automatic Bagging Machine

Wood pellet bagger price: 5000-10,000 USD

Packing the pellets into bags, small 20-50kgs/bag or jumbo bag.

Speed::

6-12 Bags/Min

Main Power:

1.1-5KW

Richi Machinery has witnessed the vigorous development of global wood pellet industry and we also grow up along with its development. We guarantee it is definitely profitable and has great potential to starting wood pellet manufacturing business.

How does a wood pellet making machine plant save costs?

How does a wood pellet plant save costs? The following are some suggestions given by RICHI.

Choose the lowest cost raw materials

The lowest-cost raw materials, literally speaking, means that the cost of purchasing raw materials is as low as possible. Everyone should know this. But from the above content, we can know that if possible, choose raw materials that are easy to handle as much as possible.

For example, tree trunks with large moisture content and thick shapes require more pre-treatment equipment. If you have sufficient funds, or you only have this kind of raw material to choose from, then you must carefully select a wood pellet making machine manufacturer to ensure the high quality of the equipment.

Material input

The smooth operation of a wood pellet machine plant depends on the consistency of the material. Energy consumption is a key indicator of production line efficiency at a pellet plant. Every time a wood pellet line is started, energy consumption soars.

In order to reduce energy consumption, it is crucial for pellet plants to minimize the frequency of cold starts. It is also necessary to maintain a stable input of materials. The consistency of raw materials not only helps maintain the quality of the pellets, but also improves the overall efficiency of the process.

Unscheduled stopping and starting of production line equipment has a negative impact on the overall efficiency of the factory and the life of the machine. Each start-up cycle affects the uniformity and integrity of the pellets. Additionally, repeated starts place additional stress on equipment, leading to wear, increased maintenance requirements and reduced productivity.

Therefore, wood pellet machine plants need to have enough and stable raw materials to keep the line running for a period of time, ideally for a full eight-hour shift.

Equipment amortization and energy supply

Another important challenge for wood pellet processing plants is the cost of basic equipment, such as the wood pellet making machine price. Although the price of some equipment, such as granulators, pulverizers, and crushers, is directly proportional to production capacity, the cost of their wearing parts also needs to be taken into consideration.

For example, the cost of wearing parts of a pellet machine with an output of 5 tons per hour can be equivalent to or lower than the cost of wearing parts of a pellet machine with an output of 2 tons per hour, which is more conducive to reducing costs for pellet plants.

The main purpose of any pellet plant is to produce energy, however the plant itself also requires energy to operate. Specifically, each stage of the production line consumes a lot of energy, and how to reduce energy consumption is a challenging issue for pellet plants.

This problem usually has a different approach to each case. It is generally recommended that pellet factories purchase more energy-saving wood pellet machines and other production equipment. The distance between large energy-consuming equipment and transformers can be shortened as much as possible.

Energy usage can also be reduced in the production process. If conditions permit, they can cooperate with neighboring companies for cheap energy.

Regardless of the size of the wood pellet plant and the cost investment, as long as it is run properly, it is bound to be a profitable investment. Of course, raw materials and energy are crucial aspects of the operation of a pellet plant, and they need to be handled by the pellet plant based on its own environmental conditions.

So if you are planning to set up a wood pellet manufacturing business, please contact RICHI Machinery Co., LTD. for a detailed business plan, and complete wood pellet making machine price.