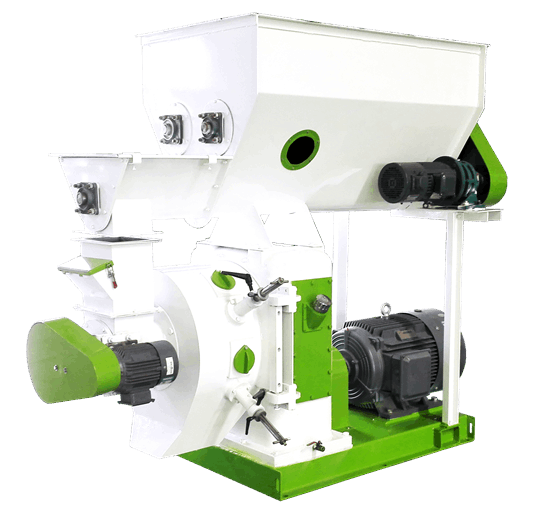

Biomass Pellet Press

Biomass pellet press is mainly suitable for the production of biomass pellets with sawdust, straw, rice husk, peanut shell, coconut shell, palm shell and other agricultural waste, economic crop waste and log materials as the main raw materials. This equipment is widely used in thermal power generation, industrial boiler fuel, fuel plant, feed plant, chemical plant, etc.

The MZLH350 biomass pellet press machine can handle motor power up to 37 kW. In this small model of pellet press machine, customers can get the right balance between costs and benefits. It is an excellent model for working wood, ensuring high quality biomass pellets.

- Capacity: 0.5-6T/H

- Power: 37KW

- Price: FOB 20,000-30,000 USD

Why use biomass pellet press to make biomass pellets?

The biomass pellets processed by biomass pellet press are granular products made of agricultural waste as raw materials through crushing, mixing, drying, extrusion and other processes. It is a new type of clean fuel that can be directly burned.

Biomass pellets are classified by raw material source, including sawdust, straw, rice straw, rice husk, peanut shell, corn cob, tea shell, cottonseed shell, etc.; according to specifications, they can be divided into granular products with diameters of 8 mm, 6 mm, 10 mm, 12 mm, etc.

Biomass pellets have the characteristics of low cost, high added value, high density, convenient storage and transportation, high efficiency and energy saving, wide application and strong applicability, green energy, clean and environmentally friendly, and enjoy the reputation of “green coal”.

Biomass pellet fuel can be used for heating, heating, cooking, gasification combustion, drying, drying, power generation, etc.

With the gradual depletion of non-renewable fuels such as coal, people’s awareness of energy crisis has gradually begun to sprout and awaken, and the development and rise of new energy has become a general trend.

Technical features of biomass pellet press

- This biomass pellet press machine is small in size, low in power consumption, low in noise, and adjustable in feeding speed. It has the characteristics of compact structure, beautiful appearance and stable performance. The main transmission box is a casting with large load-bearing capacity, good stability and long service life.

- The main drive adopts high-precision gear rotation, and the efficiency is about 15% higher than that of the belt drive type. The ring die adopts a quick-release hoop type.

- The transmission part of the whole biomass pellet press machine uses high-quality imported bearings and oil seals to ensure efficient, stable and low-noise transmission, and ensure the reliability and service life of the main machine.

- The internationally advanced level of compensation type serpentine spring coupling has novel structure, compactness, safety and low fault performance.

- The working intensity of the main working parts is strengthened from the material, heat treatment and other processes to meet the pelletizing requirements of biomass pellets.

- There are many innovative designs on the ring die, which mainly improve the problems of anti-cracking of the ring die, increase of hourly output and total output.

- Equipped with overload protection device to improve the service life of the biomass pellet press equipment;

- The door of the pelletizing room is made of stainless steel for durable use.

Advantages of biomass pellet press machine

- Simple structure, wide applicability, small footprint and low noise.

- The pellet fuel is compact and stylish, which is more conducive to storage.

- The biomass pellets made by the pellet press have high hardness, smooth surface, full combustion, high calorific value and no pollution. Biomass pellets can compress the raw material density from 130kg/m3 to more than 1100kg/m3, which brings convenience to transportation and storage and improves combustion performance.

- Large output, beautiful pellets and stable operation.

- RICHI biomass pellets press is easier to press for materials that are difficult to bond and difficult to form, so it is a wise choice for investors to start a business.

Working principle of biomass pellet press machine

The crushed biomass material enters the die cover by the forced feeding mechanism, and is fed evenly into the two pressing areas in the ring die, i.e. the wedge-shaped space formed by the two pressing rollers and the ring die, through the centrifugal force generated by the feeding device and the rotation of the ring die and the action of the feeding scraper.

Under the strong extrusion of the ring die and the pressure roller, the material is gradually compacted, squeezed into the die hole of the ring die and formed in the die hole.

Since the extrusion of the material between the ring die and the pressure roller is continuous, the formed material is continuously discharged from the die hole in a columnar shape, and then cut into biomass pellets of the required length by the cutter.

Technical specifications of biomass pellet press machine

| Type | MZLH350 |

| Output(t/h) | 0.5~6 |

| Main motor power(kw) | 37 |

| Main motor series | 6/8P |

| Forced Feeder (KW) | 1.5 |

| Conditioner Power(kw)(Optional) | 4 |

| Ring die diameter (mm) | 350 |

| Finished pellet diameter (mm) | 2-12mm |

Configuration of MZLH350 biomass pellet press

- Ring die material: 42CrMo

- Stainless steel feeder: with anti-caking function

- Door of pelleting room: 6mm /SUS304

- Forced feeding: Worm gear reducer

- Gear box: HT250

- Gear: 42CrMo

- Gear shaft: 42CrMo

- Spindle: 42CrMo

- Empty shaft: 42CrMo

- Bearings: The gear shaft and main shaft bearings are SKF, and the pressure roller bearings are domestic high-quality bearings

- Oil seal: Germany/Taiwan

- Overload mechanical protection: safety pin

- Serpentine spring coupling drive

- Lubrication system: Configurable automatic oil injection system

Cases of biomass pellet press

Biomass Pellet Press for sale Vietnam

- pelletizer selection: MZLH350

- Ingredients: wet corn Straw waste

- project cost: 180,000 USD

Biomass Pellets Press for sale India

- pelletizer selection: MZLH350

- Ingredients: bamboo, rice husk

- project cost: US$170,000

Biomass Pellet machine for sale United States

- pelletizer selection: MZLH350

- Ingredients: Miscanthus, Hay, flax straw

- project cost: US$350,000

Biomass Pellet Press for sale poland

- pelletizer selection: MZLH350

- Ingredients: palm waste, straw, husk, wood waste

- project cost: 410,000USD

Biomass Pellet Press for sale france

- pelletizer selection: MZLH350

- Ingredients: palm waste, Sawdust

- project cost: 190,000 USD

Biomass Pellet mill for sale brazil

- pelletizer selection: MZLH350

- Ingredients: Peanut shells, straw, rice husks

- project cost: 370,000 USD

Biomass Pellet maker for sale romania

- pelletizer selection: MZLH350

- Ingredients: Straw, hay, Sawdust, blocks, planks

- project cost: $110,000

Biomass Pellet Press for sale argentina

- pelletizer selection: MZLH350

- Ingredients: cotton stalk, sawdust

- project cost: $385,000 USD

How to process biomass pellets with whole set biomass pellet press system?

The biomass pellet press system process is the process of making biomass materials such as crop straw, cotton stalks, and wood chips into pelletized fuel through a series of processing. Let me introduce the production process of biomass pellets in detail.

- First, the raw materials are preliminarily processed.

The raw materials mainly include biomass materials such as straw, cotton stalks, and wood chips. First, the raw materials are crushed. Wood crushers, straw crushers and other equipment can be used to crush the raw materials into particles of appropriate size. Then, the crushed raw materials are placed in the material feeder. - Secondly, the materials are pre-treated.

Under the action of the material feeder, the raw materials are transported to the hopper. Then, the raw materials are transported to the drum through the screw feeder, and an appropriate amount of water is added for mixing. The purpose of this step is to increase the humidity of the raw materials so that they are easier to form particles during the pressing process. - Then, the pressing is performed.

The forming of biomass pellets is mainly completed by a biomass pellet press. Under the action of the biomass pelletizing machine, the raw materials are pressed into pellets of a certain shape and size after a series of filtering and pressurizing operations. In this process, the lignin and cellulose in the raw materials will polymerize with a certain temperature and pressure to form pellets with a tight structure. - Then, the drying process is performed.

Biomass pellets must be dried to reduce their moisture content. Through high-temperature drying equipment, the moisture in the pellets is evaporated to a certain degree of dryness. This helps to improve the combustion efficiency and storage stability of the pellets. - Finally, packaging and storage are carried out.

During the production process, biomass pellets need to be packaged and stored for transportation and sales. Plastic bags, woven bags and other packaging forms are usually used, and the pellets are stored in a dry and ventilated warehouse to avoid moisture and oxygen affecting the quality of the pellets.

In summary, the production process of biomass pellets mainly includes raw material processing, material pretreatment, pressing and molding, drying, packaging and storage.

The completion of these steps requires corresponding biomass pellet manufacturing equipment, and it is necessary to control appropriate parameters such as temperature, humidity and pressure to ensure that the produced biomass pellets are of high quality and high combustion efficiency.

At the same time, attention should be paid to environmental protection requirements to reduce the impact on the environment.

Auxiliary equipment for biomass pellet press machine

According to different requirements, different types of auxiliary equipment can be equipped for biomass pellet plant system: such as crusher, dryer, cooler, packing machine, screening machine, conveyors, elevators, etc.; combined production equipment can also be used: that is, a biomass pellet production line consisting of a main machine with several auxiliary machines and ancillary equipment.

Bale breaker

Capacity:

1-20T/h

Main Power:

30-90KW

biomass Hammer Mill

Capacity:

3-25T/H

Main Power:

30-160 KW

Straw Grass Crusher Machine

Capacity:

0.3-3T/H

Main Power:

22-93KW

Mixing Machine

Capacity:

250-2000KG

Main Power:

4-55KW

biomass Dryer

Capacity:

Customized

Rotate Speed:

3-8 R/Min

RICHI Machinery develops biomass pellet line equipment in accordance with market demand, which is suitable for drying and molding wood chips, sawdust, bamboo chips, wood chips, wood shavings, barley straw, oat straw, wheat straw, rye straw, rice straw, sorghum straw, corn straw, potato vines, bean stems, peanut vines and other materials with a moisture content of 35-65%.

The drying and molding process technology is optimized according to the characteristics of each biomass material, output size, application requirements, cost control, degree of automation, on-site working conditions, etc.

video of biomass pellet press machine

FAQs of biomass pellet press

How much is the MZLH350 biomass pellet press?

The biomass pellet press price is generally between FOB 20,000-30,000 USD.

What are the factors affecting the price of a biomass pellet press machine?

When choosing equipment, many people are more concerned about the price of biomass pellet press machines. So what are the factors that affect the price of biomass pelletizer?

1. biomass pellet press model

The price of biomass pellets machine equipment ranges from several thousand to tens of thousands of dollars. Different models have different prices. Generally, the larger the model, the higher the price.

2. Equipment cost

The materials of biomass wood pellet press machines include carbon steel, manganese steel, and stainless steel. Different materials have different prices. In addition, the price of steel varies in different periods, and the price of biomass pellet machines will also vary a lot.

3. Equipment technology

Advanced technology and mature technology can not only create high-quality biomass pelleting machines, but also reduce costs while ensuring quality. Therefore, the production process has a relatively large impact on the price of biomass pellet machines.

4. Source manufacturer

As an industrial equipment, biomass pellet presses must be inspected on the spot to examine the comprehensive strength of the manufacturer and check whether they are source manufacturers. Source manufacturers of biomass pellet machines have no middlemen to make a profit and have more advantages in price.

How to choose a biomass pellet press?

In industrial production, biomass pellet extruder machine is a commonly used pellet forming equipment, which is widely used in biomass, energy, wood, feed, organic fertilizer, waste recycling and other industries.

Choosing a suitable biomass fuel pellet making machine is of great significance to improve production efficiency, reduce energy consumption and reduce maintenance costs. So, what factors should be considered when choosing a biomass pellet machine?

First of all, you need to pay attention to the performance parameters of the biomass pellet press. These parameters include crushing capacity, crushing ratio, particle size distribution, energy consumption, etc.

When choosing a biomass pellet machine, you need to determine the required pelletizing capacity and compression ratio according to production needs. At the same time, particle size is also an important consideration, which directly affects product quality and production efficiency.

In addition, energy consumption is also a factor that cannot be ignored. Low-energy biomass pellet machines help reduce production costs.

Secondly, the material and structure of the equipment are also factors that need to be considered when choosing a biomass pelleting pressor. High-quality materials and reasonable structural design can ensure the stability and durability of the equipment.

When choosing a biomass pelletizer press, you should pay attention to whether its material is wear-resistant and corrosion-resistant, and check whether its structure is reasonable, so as to reduce failures and maintenance costs during long-term use.

In addition, the operation and maintenance convenience of the biomass pellet press is also a factor that needs to be considered. The operation interface of the equipment should be simple and easy to use.

At the same time, the maintenance requirements of the equipment should also meet the actual situation of the production site in order to reduce maintenance costs and improve production efficiency.

When choosing a biomass pellet making machine, you should also pay attention to its price and cost performance. The prices of biomass pellet presses from different manufacturers and models vary greatly. Users need to choose the right equipment according to their own budget and actual needs.

At the same time, when purchasing a pellet press for biomass, you should also pay attention to the cost performance of the equipment and choose those pellet machines with stable performance and reasonable prices to achieve a better return on investment.

In the actual selection process, it is also necessary to combine the specific production environment, raw material characteristics and production needs for comprehensive consideration.

For example, for different types of materials, different models of biomass agri pellet machinery may need to be selected to meet production requirements.

At the same time, it is also necessary to pay attention to the safety performance, environmental protection performance and after-sales service of the equipment to ensure that the equipment can give full play to its performance advantages during use and create more value for biomass pellet processors.

How to choose a biomass pellet press manufacturer?

The selection of biomass pellet press manufacturers should consider the manufacturer’s qualifications, equipment quality, usage time, production process, price, after-sales service and other aspects.

1. Manufacturer qualifications

The selection of biomass pellet making press manufacturers should consider the manufacturer’s qualifications. Manufacturers with complete qualifications are relatively more secure.

2. Equipment quality

The selection of biomass pellets press manufacturers should consider the equipment quality. Manufacturers with excellent equipment quality should be selected as much as possible.

3. Usage time

The selection of biomass fuel pellet press manufacturers should consider the equipment usage time. Manufacturers with long equipment usage time should be selected as much as possible.

4. Production process

The selection of biomass pellet press manufacturers should consider the production process. Manufacturers with mature and cutting-edge production processes should be selected as much as possible.

5. Price

The selection of biomass wood pellet press manufacturers should consider the price. Manufacturers with more affordable prices should be selected as much as possible.

6. After-sales service

The selection of biomass wood pellet mill press manufacturers should consider after-sales service. Manufacturers with good pre-sales and after-sales services should be selected as much as possible.

Application fields and development prospects of biomass pellets?

Biomass pellet mill machines are increasingly widely used in the industrial field, but facing the numerous small biomass pellet machine manufacturers on the market, how can you choose a manufacturer that suits your needs? The following will answer this question for you and provide some professional advice.

1. Application fields of biomass pellets

(1) Home heating

Biomass pellets made by biomass pellet press are widely used in home heating. By burning and heating the pellets, functions such as house heating and hot water supply can be achieved. In Western countries, the use of biomass pellets for home heating has already formed a scale, while in China, with the promotion of transportation, environmental protection and other systems, biomass fuel home heating has also become a new development direction.

(2) Power generation

Biomass pellets can also be used for power generation. Because it can generate heat energy after the combustion reaction, the power generation equipment can generate electricity through its heat-carrying effect. Compared with fossil fuel power generation, biomass pellet power generation has significant advantages in environmental protection.

(3) Industrial boilers

The application of biomass pellets in the industrial field is also gradually increasing. Biomass pellets are usually used as fuel in the boiler rooms of some small and medium-sized enterprises or factories. This is an environmentally friendly, economical and efficient fuel that can save energy consumption and reduce the production costs of enterprises.

(4) Biomass gas turbine

The application of biomass pellets in biomass gas turbines is gradually advancing. This is a new power generation method that combines biomass power generation with gas turbines. By burning pellets, high-temperature and high-pressure gases are generated, which are used to drive gas turbines to generate electricity.

(5) Biomass liquefaction

Biomass liquefaction refers to the conversion of biomass into liquid fuel. In this process, biomass pellets made by biomass pellet press are decomposed into liquid or semi-liquid substances, and biomass liquid fuel is produced by pressurization, vaporization and other methods. It can be used in transportation, chemical industry and other fields.

2. Development prospects

With the intensification of environmental protection and energy problems, biomass pellets will play an increasingly important role and have great market potential in the future.

At the same time, with the gradual maturity of the biomass pellet industry, new biomass energy utilization technologies will also emerge, and the industry development prospects are promising. Especially in the field of environmental protection, biomass pellets, as a green energy, will have more application scenarios.

As a renewable energy source, biomass pellets made by biomass pellet press are increasingly widely used in home heating, power generation, industrial boilers, biomass gas turbines, biomass liquefaction and other fields.

With the intensification of environmental protection and energy problems, biomass pellets will play an increasingly important role. In the future, the industry has great market potential. (Find RICHI on youtube)