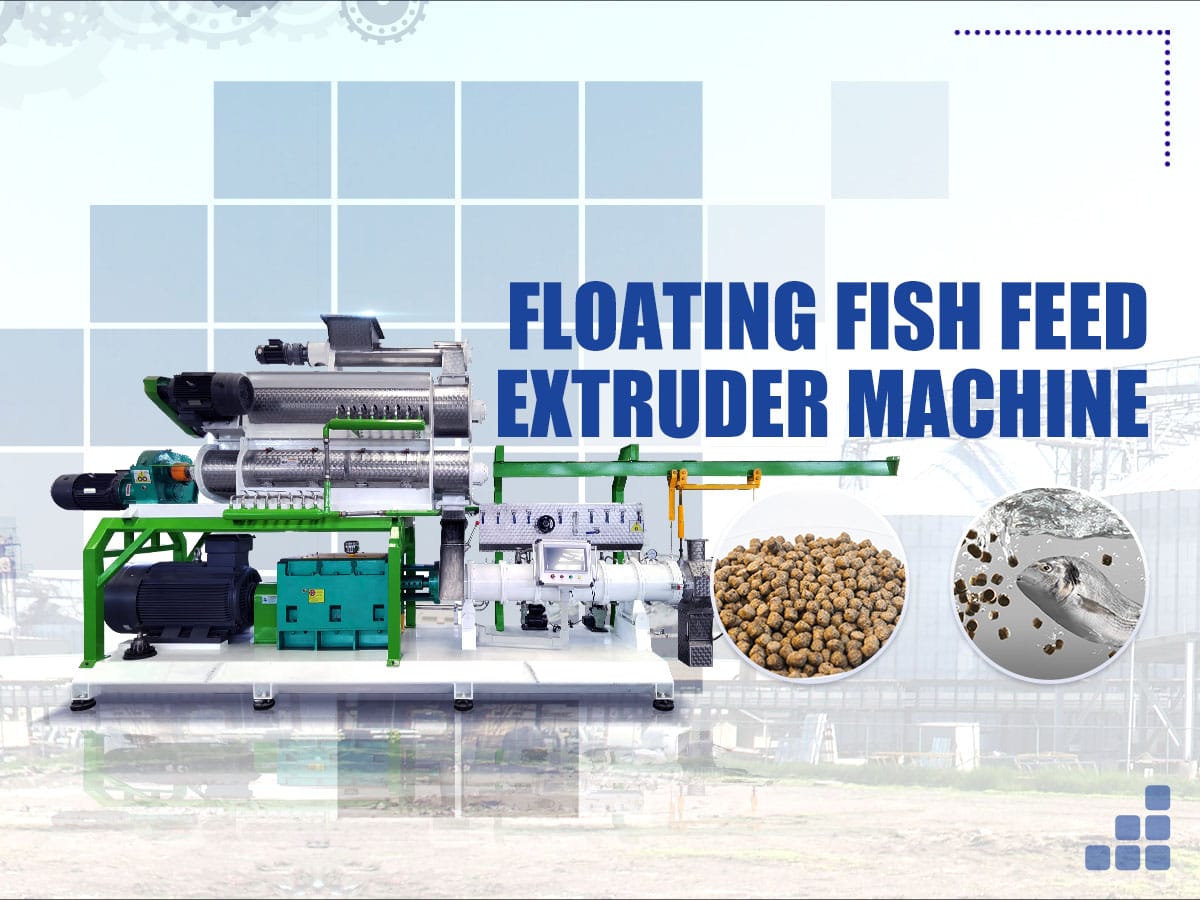

floating fish feed extruder machine

Floating fish feed extruder machine is a commonly used equipment and technology in the floating fish feed processing industry. It is widely used in the development of floating fish feed resources, the processing of special animal feed and aquatic feed.

Based on the power of knowledge and experience, we are strong enough to satisfy the production demand for various floating fish feed of all customers globally. You shall never worry whether your floating fish extruder demand exceeds our capacity, whether we can offer the floating fish feed mill design you require, or whether we have adequate experience in the field you are involved. In a word, no matter what you need, Richi Machinery is here for you.

+86 13838389622

Extruded aquatic feed is a high-quality and environmentally friendly feed with high processing efficiency and low pollution. With the development of the aquaculture industry in the direction of green, ecological and low-carbon, new requirements are put forward for the processing of aquaculture feed, so there is an urgent need for a floating fish feed extruder that is more suitable for floating fish.

Advantages of floating fish feed extruder

Floating aquafeed needs to have the characteristics of high expansion degree and low bulk density.

We use the known bulk density, water absorption and dissolution loss rate, we continue to optimize the floating feed extruder machine and extrusion production process, and continue to provide advanced aquatic extruded feed equipment for the processing of high-quality floating aquatic feed.

- A new type of conditioner has been equipped to make the final feed maturing degree and uniformity better than the traditional ways.

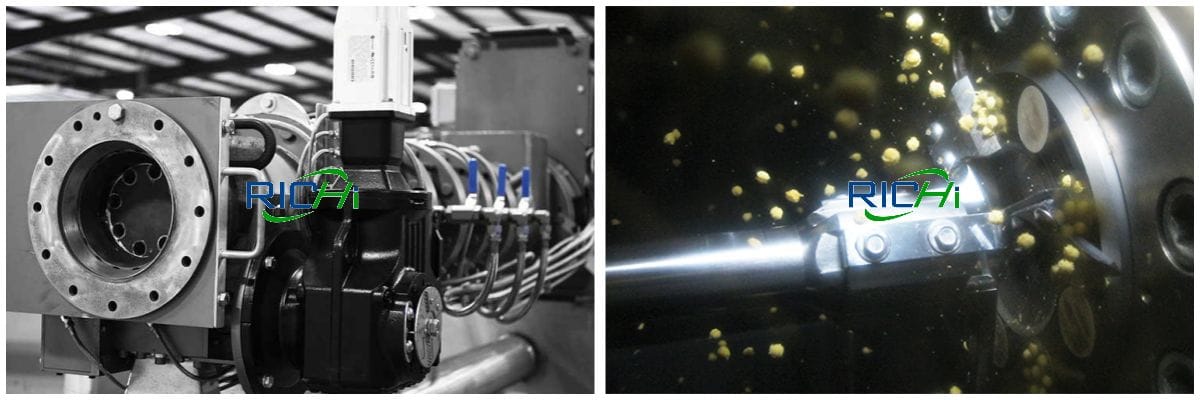

- The floating feed extruder machine adopts with multi-screw coaxial extruding, feed output is increased obviously, abrasion of wearing parts is more uniform, discharging is smoother and pellet uniformity is better.

- When producing different pellets, the quantity and speed of cutter can be adjusted according to needs, and cutting quality is easier to control.

- The self-adjusting constant gap cutting system ensures the appearance quality of the products, solving the appearance quality problems caused by cutter abrasion.

- The adaptability of different feed formulations is improved compared with the conventional condition in the industry, and the formula sensitivity is low.

- Easy to disassemble and assemble ring die, fast cleaning, save operation time and reduce cross contamination.

- Touch screen control system reduces the dependence on the operators’ skills.

At present, people have increasingly recognized the advantages of using floating fish feed extruder machine to process aquatic feed, and floating feed extruder itself has incomparable advantages over other equipment. It can produce aquatic feed with different characteristics according to the feeding habits of fish.

The floatingfeed extruder machine can control the floating characteristics of the particles. The floating characteristics of the pellets mainly include four types of fast-sinking feed, slow-sinking feed, suspended feed and floating feed.

The ability to control the long-term stability of pellets in water is also another major advantage of the floating fish pellet feed extruder machine. The long and short stability time of the pellets determines the utilization rate of the feed.

For the feed with short stabilization time and low utilization rate, it will also bring about the problem of water environment pollution. Today, when the use of aquatic fish feed extruder machine is more popular, everyone’s requirements for floating fish feed equipment are getting higher and higher.

To satisfy customers’ requirements for high profits, low costs, and energy saving, and to overcome the shortcomings of floating fish feed extruder equipment such as complex operation procedures and low extrusion efficiency, Richi Machinery has developed the new generation of high-efficiency floating fish pellet machine – RCPH floating fish feed machine. This floating fish feed extruder is the ideal upgrading product of conventional floating fish feed making machines.

Types of floating fish feed extruder Machine

At present, many floating fish feed mills still use ring die pelleting machine to produce floating fish feed. The hard pellet feed produced by ring die granulation sinks into the bottom of the water for 10 to 20 minutes and then collapses, with poor feed intake, and part of it remains in the water environment, causing serious water pollution.

By through floating feed extruder machine, it can produce high quality and environmentally friendly feed with less waste and high conversion rate. Therefore, aquatic extruded feed has gradually replaced hard pellets as the mainstream of aquatic feed.

The production process of aquatic extruded feed generally includes raw material pulverization, mixing, secondary micropowder, fish feed extruder extrusion, drying, cooling and other processes.

Among them, floating fish feed pellet extruder machine plays a very important role in the whole fish feed making process, and has a significant impact on the quality of feed and production efficiency.

To this end, Richi Machinery introduces the working characteristics and reasonable selection of single-screw and twin-screw floating fish feed extruder in detail, and provides a reference for manufacturers to correctly apply floating extruder machines, so that extrusion technology can really play a role in production.

It can achieve the purpose of increasing production, reducing consumption, and improving nutrient digestibility and energy utilization during feeding.

Twin-screw floating fish feed extruder machine

Twin-screw floating fish feed extruders are generally used in the production of high value-added aquatic and pet feeds, such as eel, soft-shelled turtle and juvenile feed production, because these products are sold in the market at a price that is sufficient to repay the twin-screw technology. Other special aquatic feeds, such as particulate aquatic feeds (0.5-1.5mm in diameter), high-fat aquatic feeds and feeds with small production volumes but often changing formulas, also need to be produced by twin-screw floating fish feed extruders.

- Capacity: 1.5-12 T/H

- Fish feed extruder machine prices: 70,000-200,000 USD

The twin-screw floating fish feed extruder is relatively late in development. For the twin-screw feed extruder above medium size, due to the wide range of raw material characteristics, the screw speed needs to be adjusted within a wide range, because its working principle is different from that of the single-screw floating feed extruder machine.

Extrusion machines have great differences in specific structure, especially the arrangement of barrel, screw, thrust bearing and gear box is more complicated.

With the expansion of the application field of the twin-screw extruder machine, the twin-screw extruder for fish feed is also used in the production of pet food, aquatic feed, special economic animal feed, and feed for young animals during lactation. (Related post: Fish Feed Extruder Machine)

| NAME | CAPACITY | MODEL | POWER(KW) | NAME | CAPACITY | MODEL | POWER(KW) |

|---|---|---|---|---|---|---|---|

| Anti-caking bin | 1.5-2T/H | PGC900/700 | 1.5 | Anti-caking bin | 3-4T/H | PGC900/750 | 1.5 |

| Inverter feeder | WLQ219×1200 | 1.5 | Inverter feeder | WLQ219×1200 | 1.5 | ||

| DDC-conditioner | DC400*300-244 | 11 | DDC-conditioner | DC400*300-244 | 11 | ||

| Twin screw extruder | RCPH120*2 | 75 | Twin screw extruder | RCPH120*2 | 90 | ||

| PLC Controlling System | / | PLC Controlling System | / | ||||

| Anti-caking bin | 4-5T/H | PGS900/800 | 1.5+0.3 | Anti-caking bin | 6-7T/H | PGS900/800 | 1.5+0.3 |

| Inverter feeder | WLQ219-1300 | 1.5 | Inverter feeder | WLQ219-1300 | 1.5 | ||

| DDC-conditioner | DC500/244 | 11 | DDC-conditioner | DC500/244 | 11 | ||

| Twin screw extruder | RCPH150*2 | 160 | Twin screw extruder | RCPH150*2 | 200 | ||

| PLC Controlling System | / | PLC Controlling System | / | ||||

| Anti-caking bin | 8-10T/H | PGS900/800 | 2.2+0.3 | Anti-caking bin | 10-12T/H | PGS900/800 | 2.2+0.3 |

| Inverter feeder | WLQ219-1300 | 2.2 | Inverter feeder | WLQ219-1300 | 2.2 | ||

| DDC-conditioner | DC600/300 | 15 | DDC-conditioner | DC600/300 | 15 | ||

| Twin screw extruder | RCPH185*2 | 315 | Twin screw extruder | RCPH185*2 | 355 | ||

| PLC Controlling System | / | PLC Controlling System | / |

Single-screw floating fish feed extruder machine

The single-screw fish feed extruder has a relatively simple structure and relatively low price. Its development is relatively early, the technology is relatively mature, and the equipment is stable. It has been used as the main equipment in the production of extruded aquatic feed for more than 40 years and is widely used in many coutries, for the production of low-protein adult fish feed for non-fish, channel catfish, grass carp, common carp, etc.

- Capacity: 0.03-4 T/H

- Fish feed extruder machine prices: 2800-40000 USD

This trend is more obvious when the moisture and oil content of the material are higher. In order to avoid these problems, most single-screw extruder machines now use segmented, single- and double-screw, pressure rings and kneading rings staggered arranged screw and inner wall grooved barrel to adapt to the change of materials in the machine cavity.

In addition, in the production of low-grade feeds such as fish feed for pond polyculture, the single-screw floating fish feed extruder has obvious advantages. The raw materials do not need to go through ultrafine powder, and 95% of the particle size can pass through 30-50 mesh, which greatly reduces equipment investment costs. Improved production efficiency.

| Model | Capacity(TPH) | Main Motor Power(kw) | Feeder Motor Power(kw) | Screw diameter(mm) | Cutter power(kw) | Conditioner power(kw) |

|---|---|---|---|---|---|---|

| DSP60-B | 0.18-0.2 | 15 | 0.4 | Φ60 | 0.4 | 0.75 |

| DSP70-B | 0.25-0.30 | 18.5 | 0.6 | Φ70 | 0.6 | 0.75 |

| DSP80-B | 0.35-0.40 | 22 | 1.1 | Φ80 | 0.8 | 1.1-1.5 |

| DSP90-B | 0.50-0.60 | 37 | 1.1 | Φ90 | 1.1 | 2.2 |

| DSP120-B | 0.70-0.80 | 55 | 1.1 | Φ120 | 1.5 | 2.2-3.0 |

| DSP135-B | 1.0-1.2 | 75 | 1.5 | Φ135 | 2.2 | 3.0-4.0 |

| DSP160-B | 1.8-2.0 | 90 | 2.2 | Φ155 | 2.2-3.0 | 4.0-5.5 |

| DSP200-B | 3.0-4.0 | 132 | 2.2 | Φ195 | 3.0-4.0 | 5.5 |

| DSP200-B | 3.0-4.0 | 132 | 2.2 | Φ195 | 3.0-4.0 | 5.5 |

In the floating fish feed production industry, Richi Machinery focuses on the extrusion equipment of twin screw extruder machine and single screw floating fish feed extruder machine, on the basis of which, we have developed over 40 models of machines in 5 series which are assorted into high , medium and low level to fully satisfy the customer’s production demand for various tons and types of floating fish feed.

Price of floating fish feed extruder

The price of RICHI floating fish feed extruder is generally before 5,000-200,000USD. Richi Machinery has rich experience in fish feed extrusion. Twin-screw floating fish feed extruder equipment and wet extruder are also one of the star products produced by the company.

The floating fish extruder machine can be flexibly configured according to the actual production, with large output and many models. If you are investigating the construction of a floating fish feed extruder, you may come to Richi Machinery to have a look. We have technical staff to recommend a suitable floating fish feed extruder and design a floating fish feed production line for you. If you have any questions, please consult online customer service personnel!

RICHI MACHINERY

floating fish feed extruder machine cases

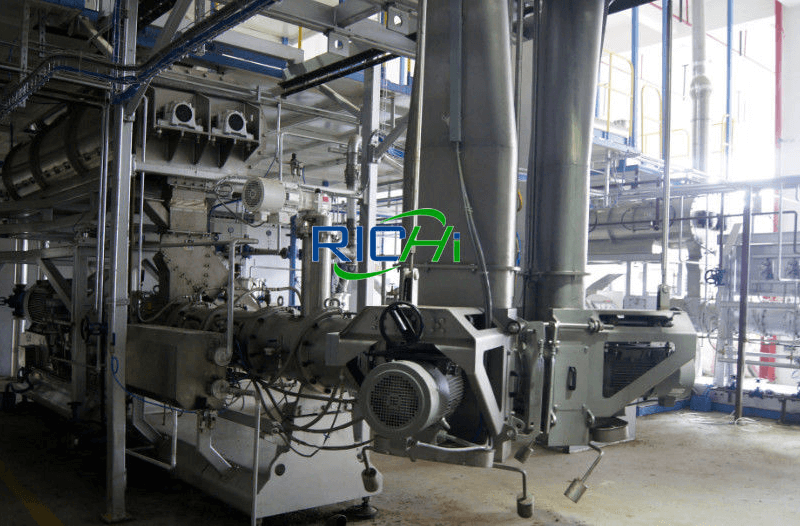

RICHI has many successful fish feed extruder machine projects in floating fish feed production, sinking fish extruded feed production and Ornamental fish feed processing fields, including 5-6T/H Russian fish feed processing line, Russia 10-12T/H fish feed extruder project, 1.5 -2T/H Iranian aquatic food production line, 5-T/H Russia floating fish feed extrusion line, Honduras 1T/H wet extrusion feed production line, Senegal 1T/H floating fish feed line, Nigeria 1T/H fish feed pellet extruder, Congo 1T/H floating fish feed mill…(Related case: Fish Food Production Line In Iran)

5-6 t/h floating feed extruder machine for sale Russia

5 t/h floating fish feed extrusion machine for sale Iran

10-12 t/h fish feed extruder machine for sale Russia

Economic benefits of extruder machine for Floating Fish Feed

Why is the twin-screw floating fish extruder more economical? The most direct reason is to save money. The twin-screw floating fish feed extruder equipment can effectively reduce the investment in process equipment and production and processing costs.

The biggest feature of the twin-screw floating fish feed extruder is that the two combined screws rotate in the same direction and are fully meshed to have the function of a positive pressure pump. It can mix various raw materials regardless of their composition.

Diverse components such as protein, animal protein, fresh meat pulp, fat, high fiber, starch and wet fish residue can be easily processed, suitable for high-viscosity materials, low-viscosity materials or high-moisture, high-fat formula products.

It can adapt to the processing of floating, fast sinking, slow sinking and other kinds of aquatic feed, such as fish, shrimp, river eel, crab, turtle, bullfrog, ornamental fish and other high-grade feeds, etc., all need to use twin-screw fish feed extruder machine, especially for microparticles. Aquatic feeds (0.5mm to 1.5mm in diameter), high-fat aquatic feeds and feeds with small production volumes but constant formulations must be produced by twin-screw extruders. The screw extruder has obvious advantages.

- The adaptability of raw materials is wider, and it can be adapted to the processing of high viscosity, low viscosity, high oil content, high moisture or viscous, oily, very wet and other materials that will slip in a single screw;

- There are fewer restrictions on the particle size of the raw materials, and it can be adapted to the processing of raw materials with a wide particle size or from fine powder to coarse powder particles and the processing of raw materials with a particle size outside the specific range of single-screw floating fish feed extruder machine processing;

- The material flow is more uniform and stable in the barrel, which can make the addition of steam, water and other auxiliary processing to obtain a more accurate ratio;

- The material flow mixing effect is better, the homogeneous state is better, and the molecular structure of the material is evenly arranged, the surface is smooth during the extrusion process, and the product pellet has high uniformity;

- The effect of ripening and homogenization is better. Usually, the starch ripening degree can reach more than 95%, so that the processed aquafeed can be kept stable in water and the nutrient components of the product will not be lost, and it is easy to digest and absorb;

- The floating fish feed extruder output is higher under the same power, and the good mixing performance makes the heat obtained by the material uniform in time, accelerates the degree of maturation of the material, reduces the fluctuation of material temperature, and improves the output of extruded products, which is usually higher than that of single screw extrusion. The floating fish feed extruder increases the output by more than 20%;

- The product diversity and adaptability are wider, and it can process particulate aquatic feed, high-oil formula, high-moisture, high-cohesion products and multi-color, sandwich, and special-shaped products;

- The floating fish feed extruder machine process operation is simpler, the spindle speed can be adjusted according to the needs of the processed products, the product varieties can be changed or the floating and submerged feed can be produced without stopping the machine and without changing the screw parameter settings. The operation is particularly convenient and completely satisfactory. Due to the self-cleaning feature, cleaning is very convenient, and there is no need to disassemble and assemble the equipment after each processing;

- Wear parts are lighter. Usually a misconception thinks that the wear of the single screw is less. In fact, during the twin-screw floating fish pellet extruder machine extrusion process, due to the characteristics of stable material conveying and material flow, the material is affected by the screw and the inner sleeve of the barrel. The wear and tear of the screw is smaller than that of the single screw, although there is one more set than the number of screws, the cost of its accessories is still lower than that of the single screw;

- Lower production cost. Due to the good operation stability of the twin-screw model floating fish feed extruder, in the fish feed making process, the startup cost is less, the waste of water and gas is less, the labor cost is less, the heat transfer efficiency is high, the yield is high, and the kWh output index High, and the cost of floating feed extruder machine accessories is also low, the final production cost is still much lower than that of a single screw.

As long as the advantages and characteristics of the twin-screw floating fish feed extruder machine are fully utilized and utilized in the design and production operation of aquatic feed processing technology, equipment investment and production and processing costs can be effectively reduced.

The design of floating fish food processing technology and the selection of equipment are important ways to produce feed efficiently. The impact of feed processing on animal nutrition has always been a common concern of feed processing technologists and nutritionists, and it is the guarantee for the realization of scientific formulas.

The organic combination of processing technology and animal nutrition will greatly improve animal production performance, body health and the quality of animal products.

Standard production flow and high-end CNC machine are our first safeguard for manufacturing high-end mining machine; strict inspection procedures and precise test instruments are our second safeguard for excellent product quality; perfect float fish feed extruder machine operation test and packing and transportation mechanism are the final reputation safeguard we promised to each customer.

How to choose floating fish feed extruder machine?

—— Richi Machinery ——

Floating fish feed manufacturers often ask these questions:

For dry extrusion and wet extrusion, single-screw extrusion and twin-screw extrusion, which one is better? There is no definite answer to this question. The best answer depends on its practical application. As far as the nutritional quality of the extruded feed is concerned, it does not make much difference whether it is produced by dry extrusion, wet extrusion, single-screw extrusion or twin-screw extrusion. Each method can produce a high-quality feed if the fish feed processing conditions and process controls used are suitable.

For those companies that want to try feed extruder machine extrusion technology, the first questions to consider before making a decision are: what kind of extrusion feed is produced by the fish feed company, financial status, personnel and skills required for floating fish feed machine operation and maintenance, feed market demand and enterprise development planning, etc.

After making the decision to use extrusion technology, a business or company must understand the details of the floating fish feed extruder machine: type of feed extruder, production capacity, adaptability of the feed extruder, operation of the extruder, original cost, operation expenses, capital turnover space, maintenance and repair costs, training programs, technical support items, customer service items and sales systems, etc.

In order to ensure the production of good aquafeed by extrusion technology, it is necessary to have a good understanding of extrusion technology and process, including floating fish feed extruder manufacturers, nutritionists, quality inspectors, operators and raw material purchasers. Knowing and collaborating, only their joint efforts can truly produce a good extruded aquafeed.

The floating fish feed pellet extruder is like the heart of the floating fish feed mill, and is the fundamental guarantee for the operation of the floating fish feed mill. So, Richi Machinery has been spending a lot in the development of the floating feed extruder machine so that the floating fish feed mill plant production system, centered on twin screw series of fish feed extruder machine in combination with all-round development of multiple series and multiple styles, has been formed and widely used in various fields like extrusion in pet feed mill , sinking fish feed mill and shrimp feed mill.

Choose single-screw or twin-screw floating fish feed extruder

Usually, aquatic feed manufacturers choose single-screw or twin-screw floating fish feed extruders with investment funds. Since the price of twin-screw extruders (especially imported models) is much higher than that of single-screw models, they often choose higher prices.

The low-end domestic single-screw floating feed extruder machine can only be used to produce low-grade floating feed for freshwater fish in aquatic feed processing due to its simple structure and insufficient technical level and manufacturing level, and it is difficult to produce submerged feed and other High-grade aquatic feed products.

The choice of floating fish feed extruder machine model should not only see that the price of twin-screw extruder is higher than that of single-screw fish extruder, but should also consider the comprehensive cost performance and the cost of producing per ton of product. (Related product: Twin Screw Extruder For Sale)

In recent years, RICHI twin-screw extruder machine’ technical performance has approached or basically reached the level of twin-screw extruders of internationally renowned brands, but its price is only half of the price of imported products.

And it can achieve a high cost performance, should be the best choice for the current aquafeed processing industry. The table below gives a list comparison of the characteristics of single-screw and twin-screw floating fish extruder machines:

From the comparison of the characteristics of the single-screw extruder machine and the twin-screw extruder machine, you can easily choose the model according to your own needs for the product. The screw extruder machine, economic benefits brought by it are much higher than that of the single-screw extruder.

Working principle of floating fish feed extruder machine

01 Principle of twin-screw floating feed extruder

The twin-screw extruder is one of the multi-screw extruders. It is developed on the basis of the single-screw extruder. In the barrel of the twin-screw floating feed extruder machine, two screws are arranged side by side. Therefore, it is called a twin-screw floating feed extruder machine.

The characteristics of forced conveying and self-cleaning of twin-screw make the material stay in the barrel for a short and uniform time; the good mixing performance of twin-screw makes the heat obtained by the material uniform in time, which accelerates the degree of maturation of the material and reduces the fluctuation of material temperature. The yield and quality of puffed products are improved.

02 Principle of single screw floating fish feed extruder machine

The screw of the single-screw floating fish feed extruder is composed of a shaft connecting screw units of various structures. The whole screw consists of three sections: feeding section, kneading section and melting and homogenizing section. After the material enters the barrel from the feeding port, it undergoes the process of solid conveying, melting and homogenization in the screw, so that the material changes from a loose state to a continuous plastic dough.

In the single-screw floating fish feed extruder machine extrusion cavity, the material is basically closely surrounded by the screw, in the shape of a continuous spiral. When the screw rotates, the material moves forward along the screw like a nut, but when the friction between the material and the extruder screw is greater than the friction between the material and the barrel, the material will co-rotate with the screw, which cannot realize the forward extrusion and conveying of the material.

In order to optimize the extrusion processing parameters of floating aquatic feed, RICHI combined the domestic and foreign aquaculture extrusion technology, took the expansion degree, bulk density, water absorption and dissolution rate as the evaluation indicators of fish feed processing quality, and used the response surface analysis method to study the screw speed,

The influence of barrel temperature and material moisture content on the quality of feed processing in the discharge section, a floating fish extruder with leading technology was designed and developed.

- Moderate screw speed, barrel temperature in the discharge section and low moisture content of the material are conducive to the formation of a higher degree of feed puffing;

- High screw speed and high barrel temperature in the discharge section are conducive to the formation of lower feed bulk density, water absorption and dissolution rate;

- The optimized extruding processing parameters of floating aquatic feed are screw speed 130r·min-1, barrel temperature in the discharge section 150℃, material moisture content 10%, and the extruded degree, bulk density, water absorption and solubility of the processed feed. The loss rates were 1.223, 0.398g·mL-1, 214.803%, and 4.297%, respectively;

- The microscopic surface of the optimized floating aquatic feed is relatively smooth and round, the melting effect of the material is better, the structure is dense, and the overall quality of the feed extrusion processing is better.

The twin screw floating feed extruder machine, single screw floating feed extruder machine, wet type floating feed extruder machine, dry type floating feed extruder cover all requirements of extruded fish feed in the floating feed production field. Production of free combination from 1 to 10mm can be realized. No matter which industry you are in, aqua feed or pet food field, Richi Machinery will always meet all your demands.

Different design of sink and floating fish feed extruder machine

Our floating fish feed extruder can process not only floating fish feed but also sinking fish feed.

Commercial fish feed is produced by single or double screw extruder machines. For fish feed, extruding is more suitable than pelleting. Because the degree of starch gelatinization in the floating feed extruder machine is higher, it is beneficial to improve the cohesion of feed particles and the stability in water. Extruded feed can be divided into three types: floating, slow settling and rapid settling.

The same float fish feed extruder machine can be used to produce flotation feed and settled feed. The settled feed should be high-density, fully cooked pellets. For feeds with high starch content, it is difficult to extrude non-expanded cooked pellets, especially when the fat content is less than 12%.

In order to produce granules that meet the requirements, an extrusion head with a vent is usually used to decompress before puffing, so as to reduce the temperature, humidity and pressure of the final product, and obtain fully matured high-density granules.

Add water instead of steam to the preconditioner, the moisture content of the mixed material leaving the preconditioner should not exceed 25%, and the moisture content of the feed should be 27% to 30% before cooling.

At present, about 80% of fish feed is settled feed. Shrimp, salmon, salmon, and yellowtail tuna prefer settled feed, while catfish, tilapia, and eel require floating feed.

Some fish like sinking feed and floating feed equally, such as catfish, tilapia. Juveniles prefer floating feed in ponds, but feeding on the surface can expose small fish to attack by birds. The temperature of the extrusion tube is different when producing settled feed than when producing floating feed.

When extruding the settled feed, the curing temperature is 115-125℃, and the temperature at the outlet can be controlled by the cooling water flowing to the mouth of the sleeve.

The inner pressure of the tube near the die is 25 to 30 atmospheres, and the bulk density of sedimentary feed is generally in the range of 450 to 550g/L. The floating fish feed extruder machine with ton-level capacity usually requires an opening area of 550 to 650 mm² to produce sedimentary feed.

A preconditioner is an essential component for floating feed production.

In the preconditioner, the starch begins to gelatinize, and the friction force of the powder in the tube is reduced. Spray steam into the preconditioner to facilitate the puffing of the material.

In order to achieve the required density and shape of the floating feed, the temperature in the middle of the extrusion tube should be the highest, and it can be lowered near the die. In order to add steam and water, there must be screw holes.

During puffing with floating fish feed extruder machine, about 8% to 10% of the dry material is added with water, and the pressure in the tube at the die is usually 33 to 40 atmospheres. The recommended curing temperature is 124-140℃, which varies with the different feed components.

The water content of the floating feed before cooling should be close to 24% to 30%, and the ideal bulk density is 320 to 400g/L. The floating feed extruder machine with ton-level production capacity usually requires an opening area of 300mm² when producing floating feed.

The nutritional formula and processing technology of aquatic extruded feed will be continuously improved and perfected, and the use of extruded feed with high conversion rate, low pollution and low cost will become an inevitable trend in the development of the feed industry.

Floating fish feed extruder is a new crushing machine developed by Richi Machinery, the floating fish feed extruder machine manufacturer, after the release of traditional fish feed extruder. This floating feed extruder machine is a perfect combination of modern science and technology and the production practice, which can better satisfy the automatic production demands of vast customers.

Process flow after floating fish feed extrusion

Drying section

Most extruded aquafeeds have a moisture content of more than 25%. The pelleted feed after leaving the extruder machine must be dried to remove some moisture.

Drying of extruded feed is usually carried out in two steps: hot air drying and cold air drying. The hot air drying equipment used with the small floating fish feed making machine can be selected as “vibrating fluidized bed”. The vibrating fluidized bed has low energy consumption, uniform drying and low equipment price.

But the output is small. Large and medium-sized floating fish feed extruder machines use mesh belt dryers for hot air drying. The extruded pellets stay in the box-type circulating fish feed dryer machine for a long time, the drying strength can be adjusted in a wide range, and the particles are less broken during the drying process. The suitable hot air temperature is 120℃~130℃, the drying efficiency is high in this temperature range, and the material is not easy to coking. Hot air drying reduces the moisture content of the material to 14% to 18%. The small particle selects the large value, and the particle selects the small value; the density selects the small value, and the density selects the large value.

On the one hand, the moisture content of the dried product depends on the material properties such as moisture, shape and size, and density before drying, and on the other hand, it depends on operating parameters such as air temperature, air speed, hot air humidity, advancing speed of the drying bed, and material layer thickness.

The temperature of the feed after hot air drying is about 80℃, followed by cold air drying and cooling. Make the temperature of the product 4℃ to 5℃ higher than the workshop temperature, and the moisture content is between 10% and 11%.

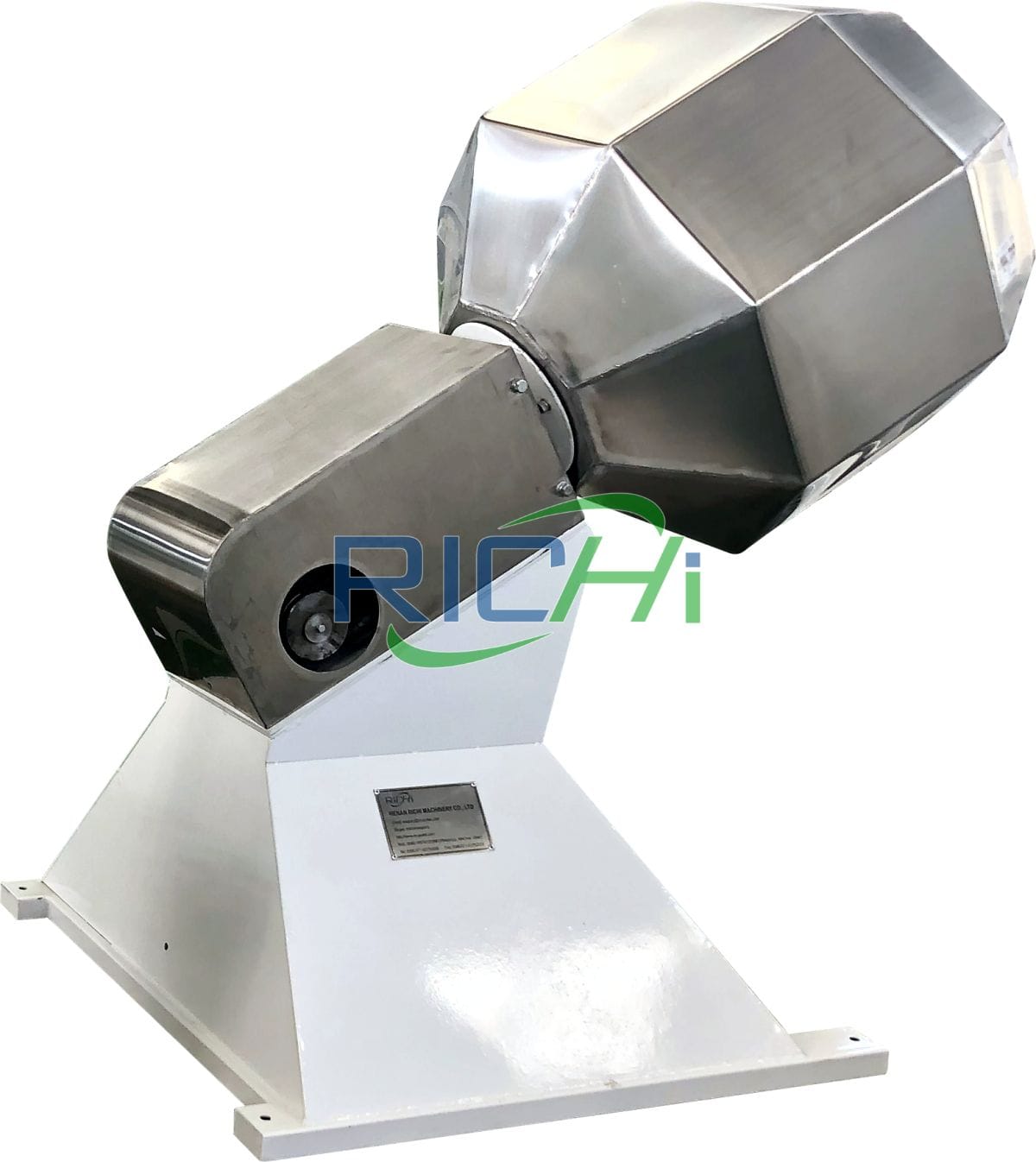

Coating section

Most extruded aquafeeds have a moisture content of more than 25%. The pelleted feed after leaving the fish feed extruder must be dried to remove some moisture.

Coating is also known as grease coating, is limited to grease. Excessive grease during extrusion can affect product processing quality. Grease is one of the contents of external coating. However, with the development of feed research and the improvement of breeding standards, for extruded products, a wide variety of heat-sensitive substances need to be coated into the feed.

The application of enzyme preparations in aquafeed is gradually revealed, and the application prospect is promising. Except for a small amount of amylase which can withstand high temperature, the loss rate of most feed enzymes in the extrusion process is greater than 90%. The types and quantities of heat-sensitive substances used in aquafeed are expanding. The high loss rate of heat-sensitive materials such as vitamins and enzymes in the extrusion process makes external coating gradually become a necessary supporting section for the floating fish feed extruder machine.

The coating equipment is divided into two types: atmospheric pressure external coating and negative pressure external coating. Atmospheric pressure coating equipment is simple in structure and large in output. At present, there are several types of rotary table type, drum type and box plate type. Negative pressure coating facilitates the penetration of the coating liquid into all parts of the pellets. Existing negative pressure coating machines operate intermittently, with long operating cycles and limited output.

Coating requirements

Similar to livestock and poultry feed, the external coating of aquatic feed requires accurate ratio of coating liquid and particles, uniform distribution, and storage resistance. In addition, aquatic feed requires that the coating does not run off in water and does not affect palatability.

The satisfaction of these requirements requires not only the improvement of the overcoating equipment and the overcoating process, but also the further study and improvement of the physical and chemical properties of the overcoating liquid will be a necessary process to give full play to the overcoating effect.

In order to satisfy the new requirements of customers under the new market environment and solve the unavoidable problems in the normal fish feed production line construction, except for the development of single equipment, Richi Machinery has been active in developing various large-sized complete sets of equipment, including the efficient, environmental and high quality of full set of floating fish feed extruder machine represented by twin screw extrusion system, and the full set of crushing, mixing, dying, coating, cooling, screening and packaging equipment represented by the complete floating feed production line.

Establish a complete floating fish feed Mill

There are many kinds of floating fish feed mill plant— the 1-2t/h, 3-4t/h, 4-5t/h, 6-7t/h, 8-10t/h, 10-12t/h, etc., and these kinds have hundreds of customized designs in total. No matter what demands you put, we can always assemble a floating feed plant for you.

Floating fish feed mill cost:80,000-3,000,000 USD

Application of floating fish feed extruder

The floating fish feed extruder machine is widely used, not only for floating fish feed factories, but also for other types of aquatic feed and raw material processing.

01 Sea fish

At present, the majority of domestic and foreign marine fish culture use cages, and many cultured marine fish are not used to feeding on the water surface, nor can they go to the bottom of the sea to feed. The feed sinks from the water surface to the bottom of the net, which is the area where the fish eat.

To prolong the time available for feeding, the feed density needs to be slightly higher than that of seawater. So far, in the industrial feed production equipment, only the floating fish extruder machine can adjust the density of the product to a large extent.

02 Ordinary fishfish

Most of these feeds contain a high proportion of grain processing by-products and raw materials with high crude fiber content such as rapeseed meal and cottonseed meal. After floating fish feed extruder extrusion, part of starch and protein are freed from the bondage of fiber to improve digestibility, and part of cellulose is degraded and converted into nutrients from nutrient inhibitors.

Comprehensive calculation of feed cost and farming benefits, the extruded form of ordinary fish feed is being accepted by more farmers. (Related post: floating fish feed making machine)

At present, the majority of domestic and foreign marine fish culture use cages, and many cultured marine fish are not used to feeding on the water surface, nor can they go to the bottom of the sea to feed. The feed sinks from the water surface to the bottom of the net, which is the area where the fish eat.

To prolong the time available for feeding, the feed density needs to be slightly higher than that of seawater. So far, in the industrial feed production equipment, only the floating fish feed extruder machine can adjust the density of the product to a large extent.

03 Special fish

Although the breeding volume of special fish species such as sea bass and eel is much lower than that of ordinary fish, the price is high and the breeding income is large. These fish are accustomed to feeding on the water surface, and extruded floating feed is generally used at present.

Floating feeds can be produced in a number of ways, but no single method of producing a floating feed can compare to floating fish feed extruder machine extrusion in both yield and production cost.

04 Shrimp, crab, shellfish

Shrimp, crab, and shellfish are all benthic animals and are accustomed to feeding on the bottom of the water. The specific gravity of hard pellet feed is high and the speed of sinking to the bottom is fast, so it is used in shrimp, crab and shellfish aquaculture. So far, domestic and foreign shrimp feeds are mainly hard pellet feeds.

Another feeding habit of shrimp, crab and shellfish is “gnawing” or “licking”, which requires the feed to have good water resistance and be soft and easy to eat. Compared with hard pellet feed, extruded feed has obvious advantages in this regard. After some adverse effects of extruded feed are gradually solved, it is expected to fully enter the field of shrimp, crab and shellfish farming.

05 Raw material pretreatment

The use of floating fish feed extruder machine for aquafeed raw materials pretreatment can usually eliminate anti-nutritional factors, improve digestibility, and improve storage and transportation performance. For example, soybean extrusion, cottonseed extrusion, and fish foot extrusion can respectively eliminate antitrypsin, gossypol, thioaminase, etc.; wheat extrusion, feather meal extrusion, and blood meal extrusion can promote starch gelatinization.

The disulfide bond is broken, the blood cell wall is broken; the extrusion of the lower feet of the poultry inactivates the esterase, protease and some pathogenic bacteria, and removes the excess water and fat, so that the fresh and wet material can be stored and transported for a long time.

Owning advanced international floating feed extruder machine technologies, the RCPH Series floating fish extruder is a new-type intelligent feed extrusion equipment with big capacity and high efficiency. Compared with traditional floating fish feed machine, it boasts higher puffing efficiency, low using costs and convenient maintenance and adjustments, able to offer customers more efficient and intelligent floating fish food extrusion solutions.

Want to learn more about our floating extruder machines? Please submit your request!

2,000+ /PROJECTS

In the past 30 years, as floating fish feed extruder manufacturer, we have accumulated rich experience. We has exported fish feed extruder machine for sale the world, and has reached cooperative relations with more than 2,000 customers in more than 130 countries and regions, providing them with complete solutions and services covering the entire product life cycle.

130+ /COUNTRIES

Customer experience is the touchstone. Richi Machinery has benefited a lot from winning the market with connotative products and high-quality services. Richi Machinery specialize in floating fish feed extruder machine, our floating fish feed extruder is carefully designed for customers according to the actual requirements.