Floating fish feed plant

4-5T/H

RICHI 4-5t/h floating fish feed plant is widely used in many parts of the world and can be used for the processing of floating fish feed and pet food. RICHI floating fish feed processing plant is carefully designed for customers according to on-the-spot investigation or actual requirements of customers. It can provide overall solutions and EPC general contracting services to meet the different extruded feed process requirements of customers.

4-5T/H floating fish feed plant

The quality of aquatic products will be the inevitable development of aquaculture in the new century, and the use of 4-5t/h floating fish feed mill plants to process extruded feed will be the main means of producing high-quality and safe animal products.

At present, a new model of processing and breeding with extruded pellet feed as the mainstream has been formed in many countries and regions around the world.

With the promotion and application of extruded feed in the aquaculture market, more and more compound feed factories have begun to introduce floating fishfeed plant and extruding equipment.

And many aqua feed companies are upgrading their floating fish feed manufacturing processes and production capacity through new construction, adding floating fish feed making plants, and technological transformation to meet the opportunities and challenges of market development.

The 4-5t/h high-end aquatic floating fish extruded feed plant solutions provided by Richi Machinery are based on modular design and are tailored according to customer needs. It can fully meet the customer’s demand for floating fish and other various extruded feed production, and meet strict hygiene standards to provide animals with green, clean and hygienic safe feed.

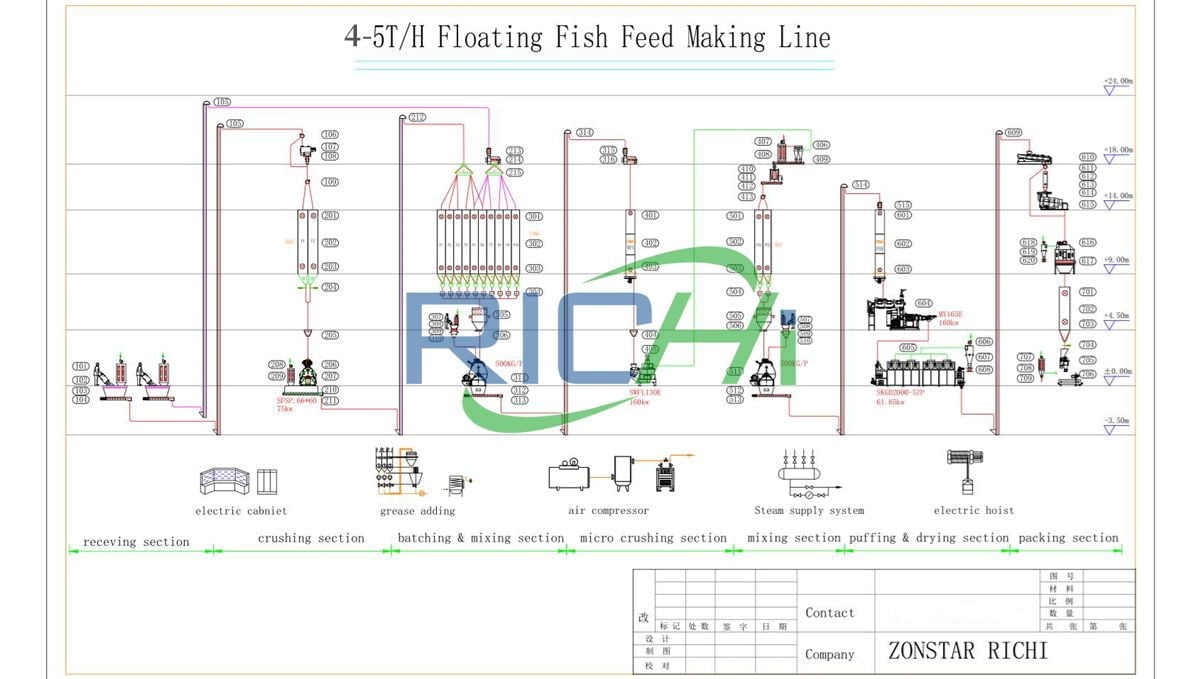

Process design of 4-5 t/h floating fish feed plant

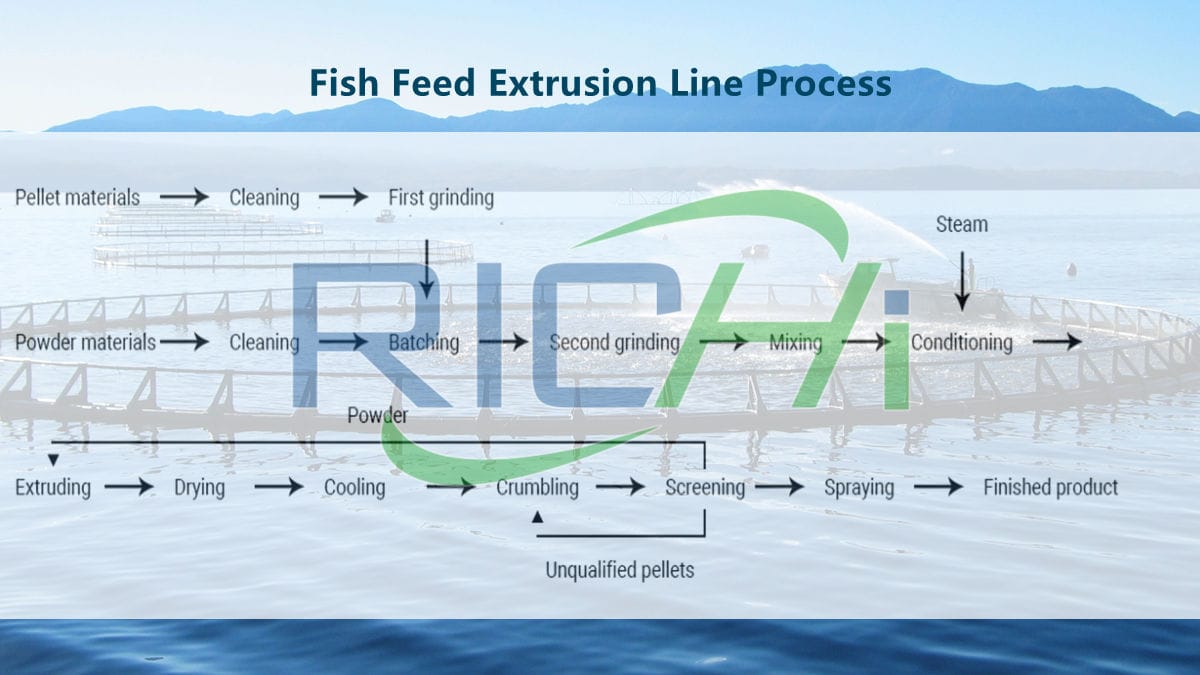

The 4-5t/h floating fish feed manufacturing process mainly includes the receiving of feed raw materials, the removal of impurities and iron from the raw materials, grinding or micro-grinding, ultra-fine grinding, batching, mixing, transportation, weighing and packaging, etc. For extruded aquatic feed, it also includes puffing, drying, coating, cooling, screening bagging, etc.

The reception of feed raw materials and the removal of impurities and iron from the raw materials are the same as the production process requirements of general livestock and poultry feed, and no special requirements are required.

But the requirements for crushing and mixing are higher. And because the aquatic feed contains more protein and oil, it increases the difficulty of crushing and mixing.

For example, 80% of the raw materials of shrimp feed pass through 0.25mm sieve hole and 97% through 0.425mm sieve hole after crushing, and the raw materials of eel feed and soft-shell turtle feed should reach 80-120 mesh after crushing.

Crushing is one of the key processes in the 4-5t/h floating fish feed plant. High quality aqua feed should use micro-grinding equipment, and ultra-fine grinding process should be arranged in the production process of eel feed and soft-shelled turtle feed.

For the one-time micro-pulverization that cannot all meet the pulverization requirements, it is necessary to match the micro-powder classification or ultra-fine powder classification equipment, so that the unqualified coarse particles after being pulverized by the classification equipment are re-pulverized.

The classifier should be adjustable to suit different fineness requirements. The smaller the content of a certain ingredient in the feed, the higher the fineness requirement, so that the ingredients of the mixed feed are consistent.

Mixing is also one of the key processes in 4-5t/h fish feed plant. Whether the mixing is uniform or not directly affects the stability of feed quality. The purpose of blending is to mix the various nutrients evenly so that the subject gets all the nutrients they need in each ingestion.

Compared with other mixers, the double-shaft horizontal mixer has the advantages of uniform mixing, less mixing residue, easy cleaning, more oil can be added, and shorter mixing time. Belt mixer. Since the raw materials of aquatic feed are finely crushed and contain more protein and oil, it is easy to cause arching during transportation, storage and processing.

In the extrusion process of 4-5t/h floating fish feed factory, a floating fish feed extruder machine should be used. Aquatic feeds with high requirements on water stability, such as shrimp feed, should be selected with appropriate binders added to the raw materials, which also helps to improve the stability of the feed in water.

The pellets after extrusion contain high moisture content, and they must be cooled (some must be aged, dried, and cooled) to obtain qualified feed. During ripening, heating the feed to keep warm and moisturizing is beneficial to further gelatinization of starch.

During drying, heating and dehumidifying the feed is also conducive to starch gelatinization, reducing the moisture content and obtaining a more solid feed. Rapid cooling after drying reduces moisture content to safe storage requirements and lowers feed temperature.

After sieving, the finished pellet feed can be obtained, which can be sold after weighing and packaging by automatic bagging machine.

RICHI series 4-5t/h floating fish feed plant adopts batching, secondary mixing, micro-grinding, curing, drying, cooling, crushing and screening, etc. The investment is not large, and the product quality is guaranteed.

It not only focuses on the production of floating fish feed, but also can be customized design, taking into account the production of sinking fish feed, shrimp feed, livestock and poultry feed.

- Maximum extruded fish feed production

- Process knowledge and experience

- Reliability and cost efficiency

- Reduced life cycle costs

- Short and effective shutdowns

- Improved energy efficiency

Due to the adoption of the latest maturing, countercurrent drying and countercurrent cooling technologies, the produced aquatic feed can ensure that it does not dissolve in water for a long time, does not collapse, reduces water pollution, and is suitable for aquatic animals to eat. This 4-5t/h floating fish feed system process is suitable for use in various countries, and is a relatively advanced and practical process for producing aquatic feed.

In line with the benign development needs of global fishery feed for low pollution, low waste, high efficiency and high conversion, aquaculture extruded feed made from 4-5t/h floating fish feed unit is gradually being accepted and recognized by the market, and has become a new trend in the development of the industry.

01 4-5T/H Floating Fish Feed Plant Price

300,000-1,500,000 USD

02 Application

4-5T/H floating fish feed mill can process floating fish feed, pet feed, and can also be upgraded to a combined feed production line, and can process shrimp feed, special feed, livestock and poultry feed, premix and other products at the same time.

03 4-5T/H Floating Fish Feed Plant Can Be Customized

- ① The entire 4-5t/h floating fish feed processing plant adopts a modular design, which can be customized according to the actual needs of customers, formula, plant structure, floor space and other requirements;

- ② 4-5T/H floating fish feed lines with various forms (extruded pellet, powder, pelletized feed), various raw materials and formulas can be customized;

- ③ In addition to floating fish feed, if customers also want to process shrimp feed, livestock and poultry feed, pet feed, premix and other types, they can customize the complete production line plan according to the customer’s product plan;

- ④ If the customer wants to reserve the possibility of expanding the 4-5t/h floating fish feed production plant capacity in the future, we will customize the plan according to the customer’s plan.

- ⑤ In addition to the program customization of the process flow and equipment layout, we can customize the layout and program of the whole 4-5t/h floating fish feed making plant according to customer needs, including the layout of laboratories, central control rooms, office buildings, boiler rooms, restaurants, etc.

- ⑥ All 4-5t/h floating fish feed equipment and electrical component laboratory equipment can be configured according to customer requirements, and motor and electrical component brands can also be changed according to customer needs.

- ⑦ In addition to new construction, it can also undertake technical renovation projects for floating fish feed production. There are several benefits to be gained from continuous upgrades, optimizations, and services on your equipment:

04 Composition of complete 4-5 t/h floating fish feed plant

The following is only the composition of the standard 4-5t/h floating fish feed system, which can be designed according to the actual product type, process, formula and investment budget.

| Silo system |

| Raw materials revieving and crushing system |

| First-time crushing system |

| First-time batching and mixing system |

| Fine crushing system (Second-time crushing system ) |

| Second-time mixing system |

| Extruding and pelleting system |

| Drying system |

| Crumbling system |

| Liquid adding & coating system |

| Cooling system |

| Screening system |

| Packaging system |

| Stacking |

| MCC Control Center; Mimic Control Panel (CPP Computer System, Batching System (Computer controlled), Cables & Cable Bridge Tube) |

05 List of 4-5 t/h floating fish feed equipment

The following is only the core fish food processing machine list of the standard 4-5t/h floating fish feed plant, and the equipment can be configured according to the actual product type, process, formula and investment budget.

| Pulse dust collector | Scraper conveyor |

| Bucket elevator | Pnenmatic three-way |

| Drum pre-cleaner | Permanent magnet drum |

| Storage bin | Hammer mill |

| Air-locked conveyor | Batching bins |

| Batching scale | Premix scale |

| High efficiency mixer | Buffer bin |

| Double cyclone | Ultrafine grinder |

| Screw conveyor | Square plansifter |

| Twin screw extruder | Coating machine |

| Fish feed dryer machine | Rotary screener |

| Screening system | Cooling machine |

| Automatic packing machine | Sewing machine |

Cases of 4-5 t/h floating fish feed plant

Richi Machinery continuously develops and improves technologies and processes, and adopts the production process of floating fish feed factory solutions, which can produce animal feed with a larger ratio of feed to meat, while ensuring the economic interests of fish feed manufacturers, they pay more attention to the health of animals, so as to ensure the green safety of downstream products in the food chain.

For a long time, RICHI has market-leading production technology and integrates it into products and floating fish feed production engineering.

4T/H

4 t/h floating fish feed mill plant

5T/H

5 t/h floating fish feed making plant

Selection of 4-5 t/h floating fish feed equipment

Crushing process and equipment

The crushing particle size of raw materials affects the digestibility and utilization rate of feed, and also directly affects the mixing uniformity, conditioning effect and water resistance of the finished product. In order to achieve the ideal pulverization effect, the secondary pulverization process is often used for 4-5t/h floating fish feed plant.

The first pulverization (that is, the coarse pulverization) reaches 20-36 mesh, and the second pulverization reaches the fine pulverization particle size (40-60 mesh) or the ultra-fine pulverization particle size (greater than 80 mesh).

The first grinding section has two modes:

- First crush and then ingredients: raw material crushing (primary crushing) – batching bin – first batching – first mixing – second crushing, this method is a single raw material crushing method commonly used for livestock and poultry feed production.

- Ingredient first and then crushed: raw materials – ingredients – first mixing – first crushing – second crushing.

At present, the models used for the first pulverization of 4-5t/h floating fish feed plant include water drop hammer mill feed grinders, horizontal-width vibrating pulverizers, etc., which are characterized by large output and small particle size, and can satisfy high-fiber corncob and high-fat soybeans. Work under load without blocking the screen. The second pulverization: fine pulverization or ultrafine pulverization.

The crushing that exceeds the particle size requirement of 80 meshes is completed by an ultrafine pulverizer. At present, most of the ultrafine pulverization adopts a meshless ultrafine pulverizer. The crushing particle size requires 40-60 mesh, which can be done by a micro-grinder.

There are two types of micro pulverizers, one is a horizontal pulverizer with a mesh, its main engine speed is about 1600r/min, and the screen apertures vary from 0.8mm, 1.0mm, 1.2mm; the other is a coarse pulverizer. On the basis of pulverization, go through a horizontal-width vibrating pulverizer once, and the screen aperture can also be between 0.8 and 1.2 mm.

Mixing process and equipment

The factors that affect the mixing uniformity during 4-5t/h floating fish feed plant processing include fish feed mixer machine type, mixing time, loading factor and material characteristics.

The production of aquatic feed often uses a horizontal double-shaft paddle high-efficiency feed mixing machine or a double-shaft double-screw mixer. The former has a mixing time of 2 to 3 minutes and a CV of less than 5%; the latter has a mixing time of 5 to 6 minutes and a CV of 5% to 6%. .

4-5T/H floating fish feed plant often uses two mixing processes:

- The first time: the raw materials are coarsely crushed – the first batching – the first mixing – the second crushing.

- The second time: the secondary crushing of materials (micro crushing, ultra-fine crushing) – the second batching (including liquid addition, premix addition) – the second mixing – granulation bin.

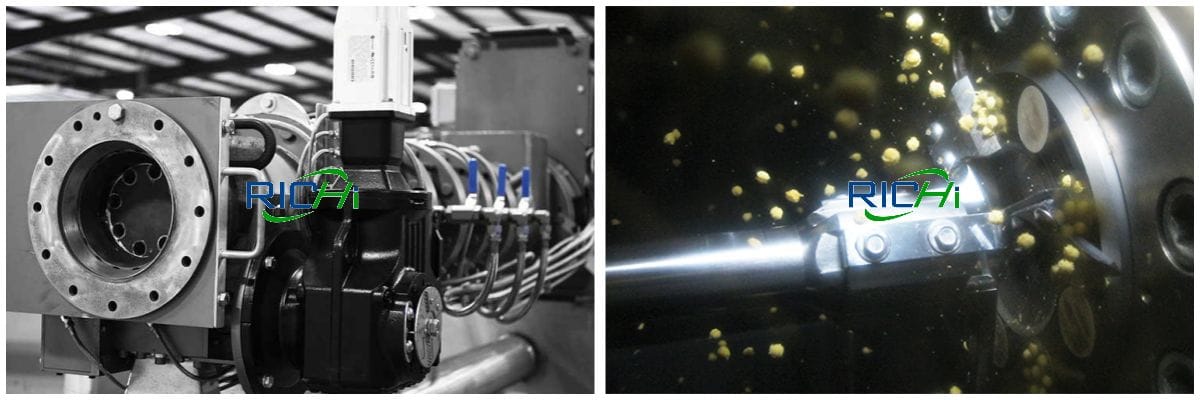

Extrusion

In recent years, extruded aquafeed has been widely used in the breeding of sea and freshwater fish and frogs, and is considered to be a very promising aquafeed. There are single-screw fish feed extruder and twin-screw extruder used in 4-5t/h floating fish feed extrusion system.

It is generally believed that the performance and economic benefits of twin-screw fish food extruders are superior to those of single-screw extruders. And in medium and large floating fish feed mill factoies, only twin screw extruders can better achieve large output.

Cooling and drying

In the 4-5t/h floating fish feed making process, the heat treatment time is long, the temperature is high, and the moisture content is large, so the cooling and drying capacity is required to be greater than that of livestock and poultry feed. The instant moisture of the extruded aquatic feed out of the die hole is about 25%, and the drying of the extruded feed is carried out in two steps, namely, hot air drying and cold air drying.

Hot air drying is usually carried out in a circulating drying oven, which is specially designed for the puffing process of 4-5t/h floating fish feed plant. It draws hot air from the heat exchanger through a high-power fan, and the hot air moves rapidly in the drying oven to take away the hot particles and volatilize. In order to achieve the purpose of drying, hot air drying can reduce the moisture content of pellets to 14% to 18%.

Cold air drying is also a process of cooling and drying extruded pellets. It can reduce the moisture by 2% to 3%, so that the moisture content of the finished product is between 11% and 12%. It is usually completed by a pellet cooler machine.

The wind flow and the feed flow move relative to each other, the wind flow is from bottom to top, the feed flow is from top to bottom, and the wind flow takes away moisture upward.In order to achieve the effect of cooling and drying, the design of the counterflow cooler should pay attention to the following aspects:

- Shorten the length of the entire air duct system as much as possible, reduce the number of elbows, and prevent powder deposition;

- Shorten the length of the horizontal air duct as much as possible to prevent the generation of condensed water;

- Reasonably select the diameter of the air duct to ensure that the wind speed in the air duct is 13-16m/s, and the wind speed less than 13m/s will cause powder deposition and condensate water. (Related product: Fish Feed Dryer Machine)

4T/H floating fish feed plant Project Report

The customer’s existing feed plant engineering products are mainly pig feed, common fish feed, chicken feed, duck feed, etc. In order to adapt to the changes in market demand, the customer invested 500,000 US dollars to adjust the existing engineering product structure. The specific contents are:

- Reduce the existing pelletized pig feed products by 10,000 tons, add new equipment such as feed pulverizers, fish feed extruders, fish feed dryers, feed pellet coolers, etc., and build a new 10,000-ton extrudedfloating fish feed plant. After the transformation is completed, the whole plant feeds’ total production capacity remains unchanged;

- In order to facilitate production, a powder pre-mixing production line is added to the existing spare warehouse on the north side of the plant to pulverize and pre-mix raw materials with less demand such as methionine and lysine;

- For the convenience of production, four 150t small silos are newly added this time, and the small particle raw materials of the existing project are temporarily stored in the small silos and then enter the feed pulverizer;

- Due to the increase in the steam consumption after the completion of this technical renovation project, the existing 2t/h gas-fired boiler will be replaced with a 4t/h low-nitrogen condensing waste heat recovery boiler.

It is worth mentioning that all the engineering content was undertaken by Richi Machinery. The feed mill works 300 days a year, 8 hours per shift.

There are many highlights of this extruded aquatic 4t/h floating fish extruded feed plant project. During the construction process, not only the advanced RICHI extruded feed technology was introduced into the local area, but also the utilization of resources and energy was considered, so as to save electricity and steam and be assured of the floating fish feed making plant project.

Not only that, during the 4t/h floating fish feed plant construction process, RICHI can find problems in advance, solve them in time, and strictly control the details, so that the project finally passes the acceptance. The customer also praised the work attitude and professional strength of the three commissioning engineers, and presented them with pennants to express their gratitude.

In the future, Richi Machinery will, as always, adhere to the corporate culture of “focus, stability, integrity, innovation, and heart, do value, and focus on results”, pioneering and innovating, and creating “a very economical floating fish feed mill plant” for more customers!

construction content

| Name | QTY | Building area (m²) | Structure |

|---|---|---|---|

| Expanded Fish Feed Workshop | 1 | 300 | Steel Structure |

| Premix Workshop | 1 | 800 | Steel Structure |

Main raw materials

| Name | Annual consumption (t/a) |

|---|---|

| Peanut meal | 850 |

| Flour | 900 |

| Rapeseed meal | 2500 |

| Rice bran | 500 |

| Wheat germ | 8500 |

| Soybean Oil | 850 |

| Fish meal | 1700 |

| Puffed soybeans | 1700 |

| L-Threonine | 50 |

| L-Lysine | 40 |

| DL-methionine | 10 |

| choline chloride | 30 |

| Salt | 20 |

Main fish feed manufacturing machine

| Name | QTY | Name | QTY |

|---|---|---|---|

| Scraper conveyor | 2 | Permanent Magnetic Cartridge | 2 |

| To be superfine grinding bin | 1 | Vertical Shaft Pulverizer | 1 |

| Two-way screw conveyor | 1 | High Square Sieve | 3 |

| Bucket elevator | 2 | Closed Air Screw Conveyor | 1 |

| To be puffed bin | 1 | Twin screw extruder | 1 |

| Fish feed dryer machine | 1 | Cooler | 1 |

| Belt Conveyor | 2 | Rotary Classifier | 2 |

| Grease Addition Tank | 1 | Grease Sprayer | 1 |

| Seam Conveyor Assembly | 1 | Double Scale Packing Scale | 1 |

Production Process of 4 t/h floating fish feed plant

The production process mainly includes the processes of particle preparation, powder preparation, mixing, magnetic separation, crushing, screening, magnetic separation, puffing, drying, adding oil, cooling, screening, packaging and other processes.

Among them, the 4t/h floating fish feed mill plant processes such as particle preparation, powder preparation, and mixing rely on existing projects, and will not be introduced here. Some of the new production processes are as follows:

01 Magnetic separation and crushing:

The materials mixed by the existing engineering feed mixer machine are sent to the permanent magnet drum by the scraper conveyor for iron removal, and then sent to the vertical shaft ultrafine pulverizer by the scraper conveyor for pulverization.

The vertical shaft ultrafine pulverizer is a vertical shaft reflection type pulverizer, which can simultaneously complete the two processing procedures of pulverization and fine powder sorting. device and motor. The material crushing process is airtight, and after crushing is completed, it is sent to the high square screen by the screw conveyor and bucket elevator.

02 Screening, magnetic separation:

The materials are sieved through two-stage high square sieves, and the materials with particle size larger than 0.18mm (fineness of 80 mesh) are returned to the fish feed pulverizer for further pulverization. The elevator is sent to the twin-screw extruder for fish feed.

03 Puffing system:

The moisture content of the material before entering the 4t/h floating fish feed plant puffing process is about 10-12%. The material is extruded and formed after high temperature, high pressure, instant curing and shearing in the twin-screw fish food extruder. (Hot product: twin screw extruder for sale)

04 Drying, adding grease, cooling:

The extruded feed pellets enter the fish feed dryer machine from the chute for drying. The drying temperature is 100-125℃, the drying time is 20 minutes, and the moisture content of the feed after drying is 9-11%. The drying process uses the steam provided by the gas boiler as the heat source, and the heating process is indirect heating.

The dried feed is then sent to the grease adding tank through the belt conveyor, and the grease is pumped into the tank. At this time, the feed temperature is about 50-60℃. After that, the feed is sent to the pellet cooler machine through the bucket elevator, and after cooling to 30℃, it is sent to the finished product warehouse by the bucket elevator and screw conveyor.

05 Screening and packaging:

After the feed enters the finished product warehouse, it is sent to the rotary grading screen by the screw conveyor. The powdered feed that cannot be formed is returned to the crushing process for processing again. The formed feed is packaged by the baler and put into storage for sale. In the production process of 4t/h floating fish feed plant, the feed conveying equipment and fish feed manufacturing machine are fully enclosed.

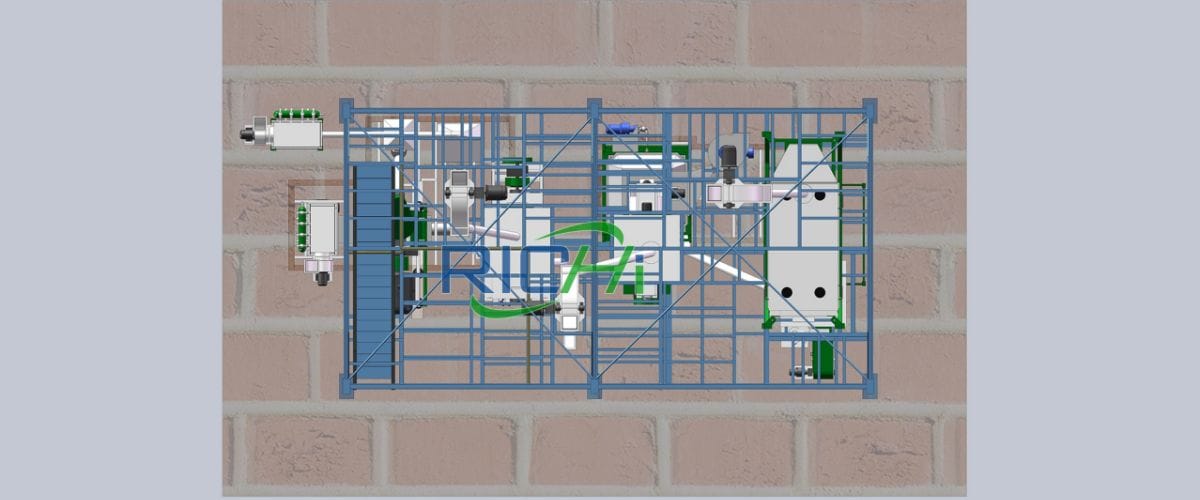

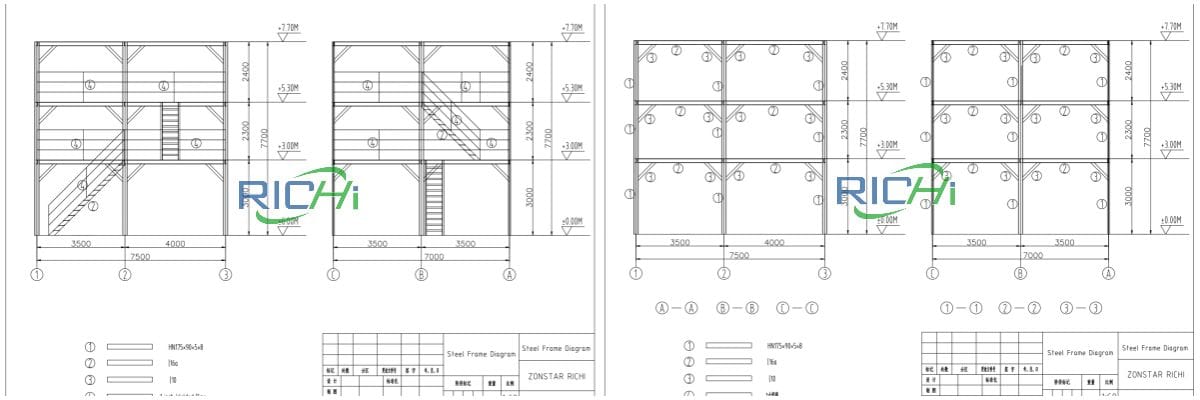

Layout of 4 t/h floating fish feed plant

The factory area where the 4t/h floating fish feed manufacturing project is located is rectangular as a whole. The gate is located on the south side of the factory area, allowing people to flow in and out of the factory. The roads in the floating fish feed factory area are smooth, which is convenient for logistics transfer.

After the completion of this technical renovation project, the spare warehouse on the north side of the 4t/h floating fish feed processing plant will be changed to premix workshop and premix warehouse, some raw material warehouses will be used as extruded fish feed workshop, and other buildings will remain unchanged from the existing project.

The 4t/h floating fish feed factory area is divided into living area and production area. Among them, the living area is located on the south side of the factory area, including offices, dormitories, restaurants, etc.; the production area is located on the north side of the factory area, from south to north: finished product warehouse, main workshop, extruded fish feed workshop and raw material warehouse, heat sensitive raw material room, maintenance room, boiler room, premix workshop and premix warehouse, etc.

The layout of the 4t/h floating fish feed production line project is reasonable, which is convenient for the flow of people and logistics.

Richi Machinery is always based on market trends and customer needs, constantly seeking changes and improving, timely innovation, and relying on standard floating fish feed making solutions, flexible and reasonable configuration of fish feed processing line equipment, to achieve stable performance and mature customized design.

If you have any needs or questions about the construction of floating fish feed plant, please leave a message and we will reply to you as soon as possible after receiving it! You can also contact us directly via WhatsApp (+86 138 3838 9622)!

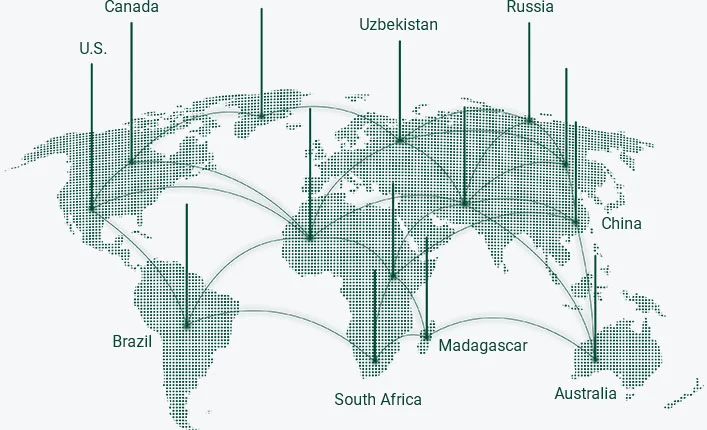

2,000+ /PROJECTS

In the past 30 years, as floating fish feed machines manufacturer, we have accumulated rich experience. We has exported floating fish feed equipment for sale the world, and has reached cooperative relations with more than 2,000 customers in more than 130 countries and regions, providing them with complete solutions and services covering the entire product life cycle.

130+ /COUNTRIES

Customer experience is the touchstone. Richi Machinery has benefited a lot from winning the market with connotative products and high-quality services. Richi Machinery specialize in floating fish feed equipment for sale, our floating fish feed plant machines are carefully designed for customers according to the actual feed production requirements.