micro pulverizer

Micro pulverizer is a typical fine pulverizing equipment, which is mainly used in feed, feed additive, chemical, pharmaceutical, food, dye and other powder industries. With the development of special aquatic feed, the particle size requirements of feed raw materials are getting finer and finer, and ultrafine grinders have been used in aquatic feed, deep processing of aquatic products and pet feed industries.

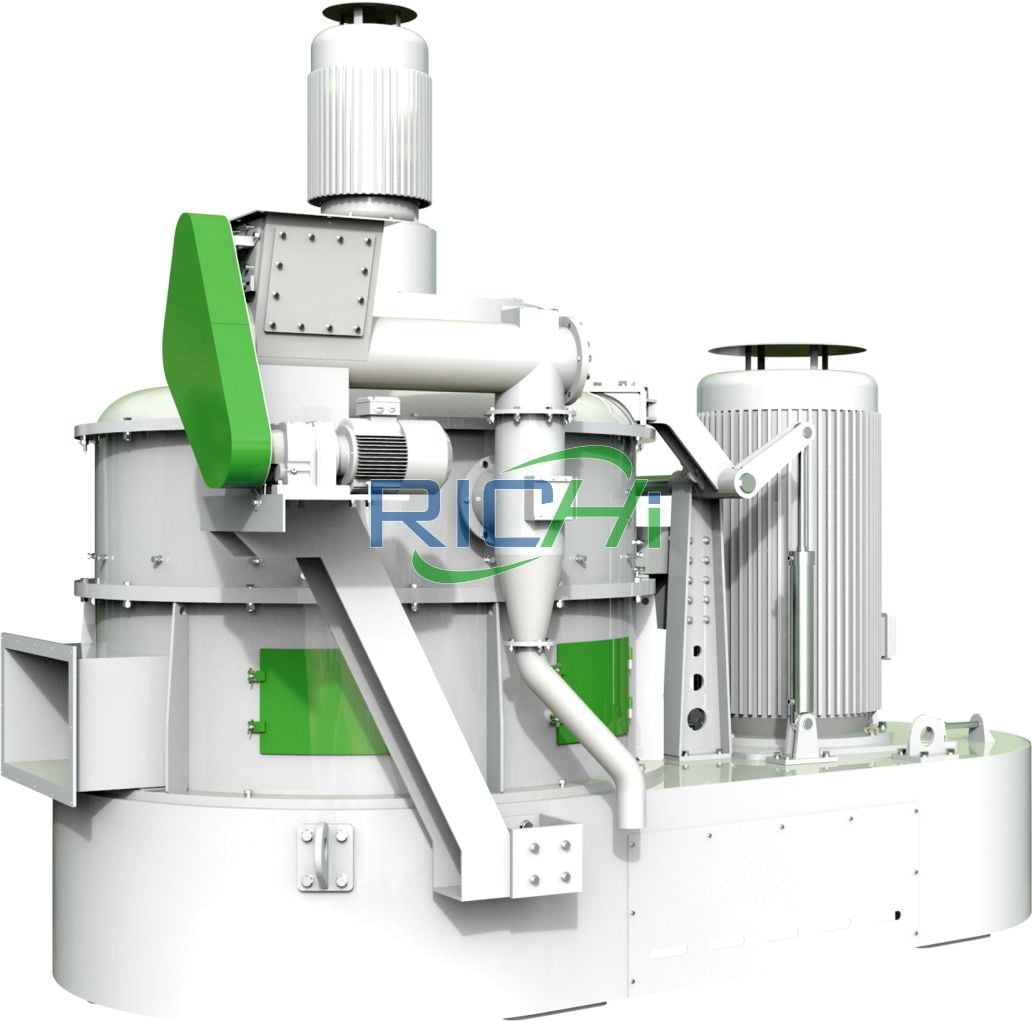

The vertical micro pulverizer is a new ultra-fine pulverizing technology that Richi Machinery has absorbed on the basis of more than ten years of research and development experience, and has a special structural design. The micro pulveriser with large capacity and low energy consumption is also the preferred equipment for large-scale construction of aquatic feed processing plants of various scales and environmental protection and intelligent production.

The RICHI fine powder grinding machine is equipped with the technical achievements of the RICHI engineer team in recent years, with higher output, lower power consumption per ton, longer life of accessories, and lower user cost.

Characteristics of micro pulverizer

- Mesh structure, enhance the strength of the body, reduce noise and vibration;

- The unique internal optimized structure increases the probability of material collision and thus increases the hourly output;

- The hydraulic cover opening system reduces labor intensity, facilitates maintenance, improves safety, and shortens maintenance cycle;

- The heavy object removal system can effectively remove 98% of raw material impurities (such as stones, iron blocks, stainless steel parts, etc.). The feeding system feeds evenly and improves the generation of large current during initial feeding.

- The unique arch breaking device prevents the material from arching during feeding.

- The ultra fine powder grinder adopts a screenless structure, and the crushing and grading are placed in the same closed space, so that the crushing and grading can be completed at one time, and the energy loss caused by over-grinding is reduced;

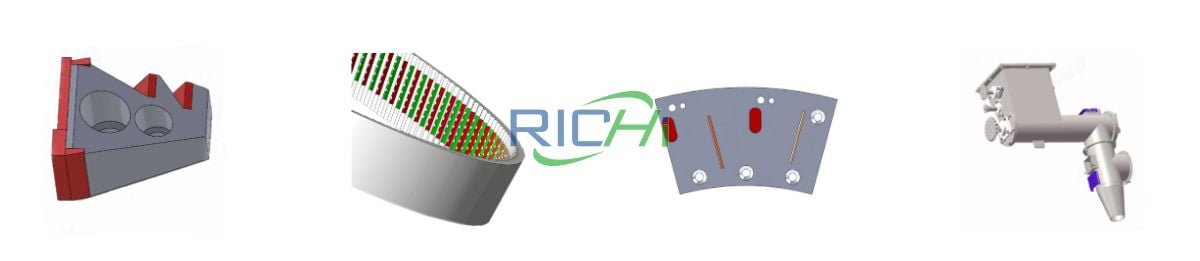

- The hammer head design of the new structure has strong wear resistance, prolongs the use time, and effectively reduces the cost of use; the unique hammer head installation method makes it faster to replace the hammer head;

- The crushing particle size from ultrafine mill is continuously adjustable from 60 to 300 mesh, which can meet the special requirements of ultra-fine crushing; air separation and transportation are adopted, and the material temperature rise is low.

While the vertical micro pulverizer highlights the RICHI brand characteristics, it pays more attention to the essence of complete functions, stable performance, strong practicability, and a wide range of uses. Compared with the aquatic feed pulverizing system of the same installed power, the performance and stability of the RICHI vertical series fine pulverizer are more reliable, more powerful and rich in functions, and the output is greatly improved.

Parameters of micro pulverizer

Micro pulveriser price: 30000-120000USD

| Item | Capacity:1-2T/H | Capacity:3-4T/H | Capacity:4-5T/H | Capacity:5-8T/H | Capacity:8-12T/H |

|---|---|---|---|---|---|

| MODEL | SWFL90 | SWFL110 | SWFL130 | SWFL150 | SWFL170 |

| POWER(KW) | 90+7.5+1.5 | 110+7.5+1.5 | 132+11+1.5 | 160+15+1.5 | 220+18.5+2.2 |

| Double cyclone | SK800*2 | SK800*2 | SK800*2 | SK800*2 | SK1000*2 |

| Draught fan | 9-19-7.1D | 9-19-7.1D | 9-19-7.1D | 9-19-7.1D | 9-19-7.1D |

| Pulse dust collector | TBLMa.24*3A | TBLMa.24*3A | TBLMa.24*3A | TBLMa.32*3A | TBLMa.32*4A |

| Screw conveyor | TLSS20 | TLSS20 | TLSS20 | TLSS20 | TLSS25 |

| Air lock | GFZY-13 | GFZY-13 | GFZY-16 | GFZY-16 | GFZY-25 |

| Square plansifter | SFSJ.100 | SFSJ.100 | SFSJ.100 | SFSJ.100 | SFSJ.100*2 |

Why use micro pulverizer?

—— RICHI MACHINERY ——

In recent years, with the rapid development of the aquaculture industry, the demand for aquafeed is also increasing. Since the raw material crushing particle size of aquafeed and the particle properties of the final product are different from livestock and poultry feed, higher requirements are put forward for the crushing section in aquafeed.

Different aquatic animals and different growth periods have different requirements for the particle size of their raw materials.

Under normal circumstances, the crushed particle size of raw materials for aquatic feeds such as adult eels, soft-shelled turtles and shrimps requires 90% to exceed 80 mesh (175μm), while 95% of the larvae need to exceed 90 mesh (160μm).

Larger fish require feed crushing particle size is 40 mesh (380μm), and the juvenile fish needs to have a feed crushing particle size of about 60 mesh (250μm). Such a small particle size makes the crushing workload of aquafeed raw materials larger and the classification requirements higher.

The hammer mill feed grinder is more efficient when using a sieve with a mesh size of 2.0mm to 3.0mm. After pulverization, the average particle size of the material is about 1.2mm to 1.5mm.

When using a 1mm mesh, the average particle size of the pulverized material is about 0.5mm to 0.6mm, which can only meet the requirements of larger adult fish feed, a finer crushing particle size will cause poor discharge or blockage of the screen.

At present, the crushing section of aquatic feed generally uses a micro pulverizer for raw material crushing work. The choice of a high-capacity vertical micro pulveriser machine is of great significance to enterprises that produce aquatic feed.

Working principle of micro pulverizer

—— RICHI MACHINERY ——

In order to meet the requirements of special aquatic feed crushing and processing, Richi Machinery has developed and developed a new type of ultrafine pulverizer on the basis of the combination of mature ultra-fine pulverizing technology, successful foreign experience and its own technological innovation and upgrading.

The crushing function of this series of micro pulverisers is performed by the vertical spindle, the crushing disc and the ring gear.

Working principle of micro pulveriser machine:

The crushing disc rotates at high speed, the material is hit and sheared by the hammer and knife on the disc, forming a crushing, the crushed material hits the ring gear at a high speed by the action of the airflow, and is crushed again, and friction and collision occur between the returning material and the material flying to the ring gear, shearing, further pulverizing, forming fine particles, and entering the air selection chamber under the action of the wind network.

There is a classification impeller in the air selection chamber for high-speed rotation, the unqualified debris is returned to the pulverizing chamber by centrifugal force, and the fineness qualified particles are subjected to high-speed rotation. The wind selection leaves the wind selection room and enters the warehouse. Therefore, the adjustment of the pulverization fineness is realized by adjusting the wind power and the rotating speed of the classification impeller, which can avoid excessive pulverization.

RICHI micro pulverizer system technology

The ultrafine mill is designed to obtain ultrafine materials, mainly to obtain fine materials above 60 mesh, so it has certain requirements for the pulverized objects, such as material moisture content, particle size, mixing uniformity, etc.

In order to reduce the investment of the first phase, many aquaculture enterprises mostly use secondary mixing and ultra-fine grinding. The particle size of the materials entering the ultra-fine is different and the mixing is not uniform.

Such a process can only weaken Super Micro’s production capacity and increase energy consumption, and Super Micro’s production capacity has become the bottleneck of the entire production line. The crushing efficiency of the hammer mill is better than that of the micro pulverizer.

Therefore, in the aquatic feed pulverization system, we add a hammer mill before the ultrafine grinder for processing. Secondary mixing, if the coarse powder is used for secondary grinding, it is best to use a sieve below 2mm.

Wet materials and liquids should be added as much as possible in the secondary mixing to reduce the moisture content in the materials, which can improve the efficiency of the entire aquatic feed production line. The production capacity can also obtain high-quality granulation raw materials.

Aquafeed processors have a variety of raw material shredding technologies to choose from. The nutritional requirements of each fish feed must be analysed to determine the comminution parameters. The micro pulverizer can improve the conversion coefficient and particle quality of aquatic feed, control environmental pollution, bring convenience to processing operations and reduce the wear rate of twin screw extruder parts.

However, the pulverized particle size of the raw material is slightly reduced, and the processing cost will be significantly increased. Therefore, the economics of crushing must be considered, and excessive crushing is uneconomical.

Application of micro pulverizer

01 Micro pulverizer in the aquatic feed production

In the modern feed industry, almost all feed components are crushed to improve the mixing performance of the material and facilitate the compression of particles, and to improve the digestibility of the feed by animals. (Related product:fish food grinder)

For example, for aquatic pellet feed, the finer the crushing particle size of the raw material, the stronger the ability to absorb water in the steam before pelleting, which is beneficial to conditioning and pellet forming, so that the pellet has good water stability, which can improve feed returns and reduce water pollution.

In the production of aquatic feed, the crushing particle size of must also meet the requirements of granulation processing. The raw materials crushing particle size made by ultrafine powder pulverizer used for granulation or puffing must have 99% of the particles smaller than 1/3 of the diameter of the die hole to prevent the die hole.

For special aquatic feeds such as shrimp, eel, and soft-shelled turtle, the requirements for the pulverized particle size and particle size distribution of the raw materials are higher. For example, the feed for shrimp farming requires 95% of the raw materials to be crushed and the particle size is less than 250μm, and the ordinary eel feed requires that the raw material has a crushed particle size of 98% of the particles to be less than 180μm, while many larvae feeds require raw materials. Micro pulverizer can better meet this requirement. Ultra fine powder grinder technology is also widely used in the fine processing of various feed additives.

02 Micro pulverizer in deep processing of aquatic products

The application of fine powder grinding machine technology broadens the scope of deep processing of aquatic products and improves product quality. Aquatic products can be used as food industry raw materials after superfine grinding, and various functional foods can be developed, such as processing kelp, seaweed, spirulina, etc. into fine powder, which can be added to various foods.

Finely crushed by micro pulverizer can become nutritious food that is easily absorbed by the human body, such as the bones of aquatic products, which are rich in calcium. The bone meal made by ultra-fine crushing can reach more than 90% of the absorption rate of the human body.

The shell of shrimp, crab and other crustacean aquatic products is the raw material for the production of chitin and chitosan. Chitin and its derivatives can promote the metabolism of cells, repair damaged cells and wound healing, and enhance immune function to the human body.

In recent years, since livestock and poultry materials such as animal bones and egg shells often contain heavy metals and pesticide pollutants, people have turned their attention to selecting high-quality calcium sources to seafood.

For example, oyster shell powder obtained by a micro pulverizer can be widely used in liquid foods. Pearl is a natural nutritional product that contains more than 20 kinds of amino acids and trace elements and rare elements required by the human body, as well as protein, inorganic calcium, etc.

However, due to the hard concentric laminated structure of pearls, it is difficult to crush, and processing with traditional methods not only destroy some nutrients, and due to the coarse particle size of the product, the absorption rate of the human body is only less than 30%, and the particle size of the ultra-finely crushed pearl powder can reach below 2μm, which not only ensures the integrity and pure naturalness of the pearl ingredients. It is also beneficial to the human body’s absorption and can give full play to its effect.

Other aquatic products such as fish, shrimps, turtles, turtles, etc. are processed into fish meal, shrimp meal, turtle powder by micro pulverizer, which can be made into multi-functional health food. Shark cartilage can be made into a drug with better anti-cancer effect after ultra-fine crushing.

The application of the RICHI ultra fine powder grinder expands the deep processing technology of aquatic products, expands the deep processing scope of aquatic products, enables the development and utilization of aquatic product resources that could not be used before, and promotes the full utilization of aquatic product resources.

At the same time, the application of this pulverization machine technology simplifies the processing technology of aquatic products, improves the production technology of aquatic feed, not only reduces the production cost of products, but also improves the processing quality of products.

The RICHI pulverizer machine for powder is also conducive to the development of aquatic products into various functional and health-care foods, and is conducive to the development of multi-variety and high-quality aquatic feeds, and promotes the development of the aquaculture industry. Moreover, it is more convenient for product storage, transportation and use, and also lays the foundation for mechanized and large-scale production of subsequent processing.

Micro pulverizer technology is a new technology developed by RICHI MACHINERY rapidly, which will bring huge economic benefits to many enterprises.