1-160T/H Animal Feed Production Line Solution

RICHI animal feed production line provides the opportunity of processing feed for various livestock, such as pigs, poultry, cattle, goat, rabbit, horse, etc. No matter where in the world and no matter which requirements the client may have to the new plant, RICHI has a matching solution.

- Capacity: 1-160T/H

- Cost: 20,000-5,000,000 USD

- Area required: 300 – 20000m²

- Business scope: new construction, reconstruction and expansion of feed mills

Our animal feed production line technologies enable our customers to create their own unique recipes and combinations of ingredients – making sure that the animals are given the right amount of vitamins and protein.

Whether it is individual process machines, complete processing lines, or spare parts and services that youneed – RICHI will take you smoothly from raw material intake to finished feed bulk loading.

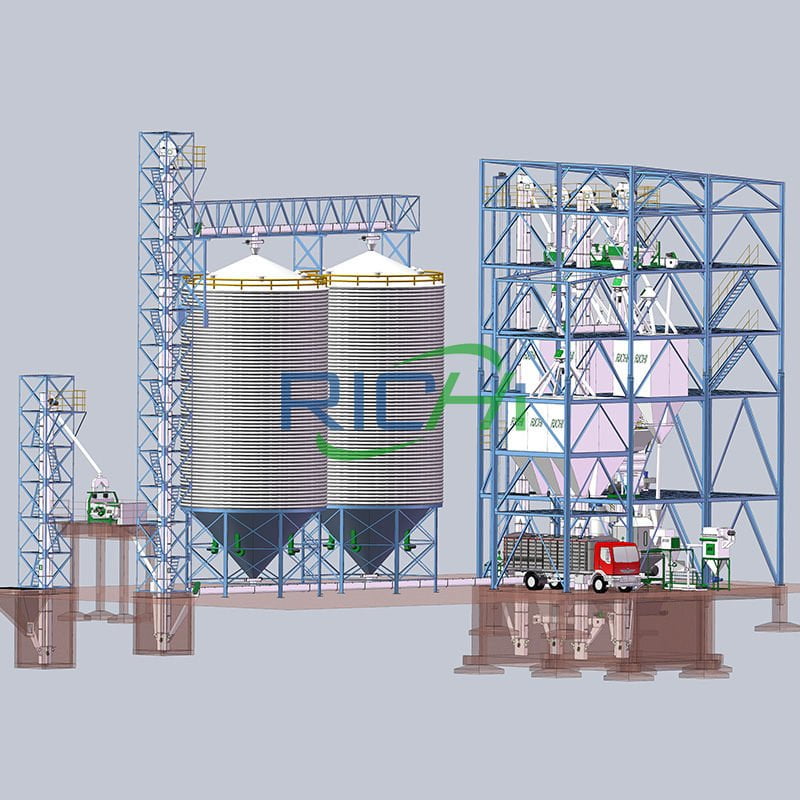

Complete animal feed production line process design

With years of experience in high-quality animal feed production line engineering in numerous countries around the world, RICHI is a reliable partner no matter the scale of the farm or medium large animal feed plant.

Different feed types, formulations, and raw materials correspond to different animal feed production processes. The following are the most common complete compound feed processing procedures:

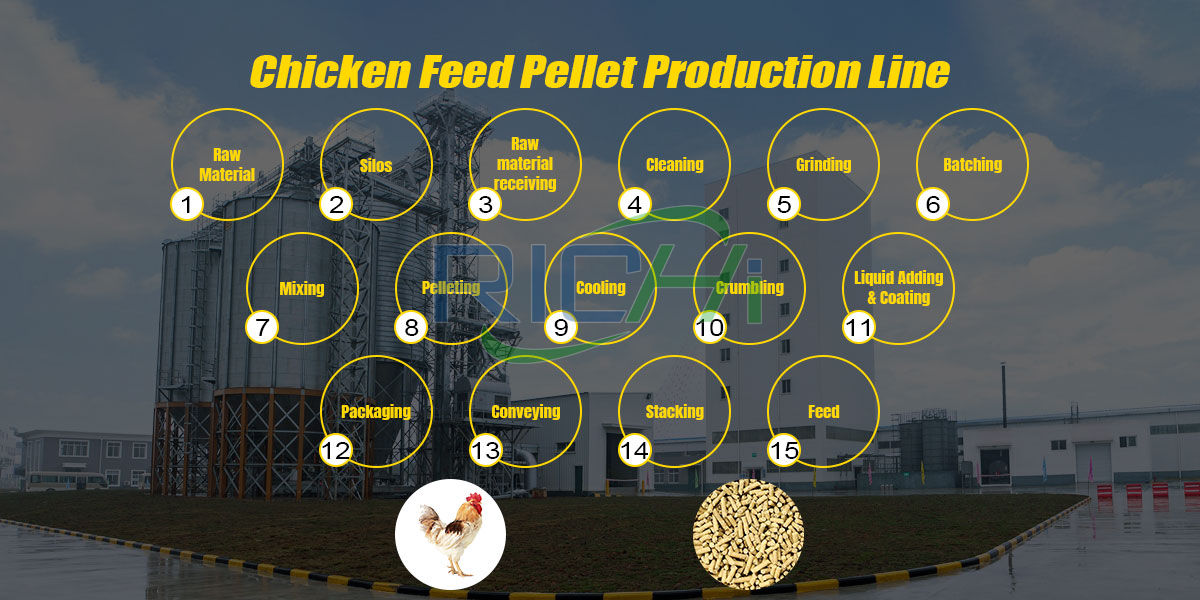

The processing steps of animal feed production line:

- Raw material intake

- Storage

- Conveying & dedusting systems

- Cleaning

- Dosing & weighing

- Grinding

- Mixing

- Conditioning & hygienization

- Pelleting

- Cooling

- screening

- Coating

- Bagging & bulk load out

1.Raw material receiving system

Receiving is the beginning of feed production. Receiving equipment is used for bulk storage of materials before silos or warehouses, including weighing systems, inspection instruments, unloading systems, cleaning systems, dust control equipment, receiving conveyors, distributors, spraying, etc.

2.steel silo system

To ensure continuous production, large quantities of raw materials such as corn, wheat and soybean meal need to be stored during feed processing. The steel silo adopts galvanized steel structure, which has the characteristics of low investment, convenient and quick installation, less maintenance, and long service life.

3.Conveying system

Conveying is the process of moving bulk raw materials or grain, processed raw materials and finished products horizontally with little or no inclination to their destination. In feed mills, horizontal conveyors and bucket elevators for lifting dry bulk materials are the most common conveying equipment.

4.Cleaning system

Bulk grain received from farms often includes grain by-products and impurities such as straw, stones, metal, paper, small animal carcasses and fines. This section remove these impurities through magnets, screeners, and dust collectors to ensure that the stored grain is of good quality and to protect the machinery.

5.Batching System

Proportioning and mixing are the most important steps in the feed production process and largely determine the capacity of the plant. Batch processing is a discontinuous batching operation. When the allocation order is issued, the batch processing operation will be carried out according to the specified quantity.

6.Mixing System

Mixing is a key link in the production of compound feed. Components with unique properties are blended together to formulate rations under the action of external forces to meet the nutritional needs of animals and add value to the blended product.

7.Pelleting System

The feed pelleting system converts the feed paste into shaped large pellets. Feed granulation is accomplished through a mechanical process using a combination of moisture, heat and pressure. Ring die feed pellet machine will used in this section.

8.Cooling System

During feed pelleting, cooling of the feed pellets is essential. When leaving the pellet mill, the feed pellets are very hot, soft and rich in moisture, the cooling process cools them down to 3°C-5°C slightly above room temperature and reduces their moisture content to a safe standard (≤12.5%), For easy transportation and storage.

9.Crumbling System

Crushing is the operation of reducing feed particle size and increasing its specific surface area, which can enhance animal digestion and improve feed utilization. It can also improve the processing quality and work efficiency of subsequent processes such as batching, mixing, and granulation.

10.Screening System

After cooling and drying, the whole pellets are sieved to remove fines and spills and bring the pellets to acceptable size.

11.Liquid addition and spraying system

Specific quality or nutritional requirements may require fat, molasses or other liquids to coat the surface of the feed pellets. When the cooled and screened feed pellets pass through the low-speed belt conveyor or coating machine, the liquid can be sprayed on the feed pellets to complete the spraying process.

12.Packaging System

The packing operation begins when the finished feed enters the supply box above the packer and ends when the bagged feed is put into storage. The procedure includes weighing each bag of feed, placing the weighed item in the bag, closing the mouth of the bag, applying a label to the bag, coding the bag, palletizing the bag, and moving the bag to a warehouse for storage.

The technology underlying our animal feed production line installations and the sound process expertise of our engineers will help you to produce animal feeds to the most rigorous hygiene requirements, while mitigating cross-contamination.

animal feed production line projects

RICHI has many years of experience with sales and designing of feed mills with capacities ranging from a 1 t/h to 160 t/h all over the world – from small farm plants to large industrial plants producing feed for poultry, livestock or ruminant.

Indonesia

3-5T/H animal feed production line in Indonesia

- Feed Type: cattle & poultry

- Date: April 9th, 2018

- The install period: 30 Days

- Workshop size(L*W*H): 10m*5m*12m

- animal feed line price: 110,000USD

Angola

3-4T/H animal feed production line in Angola

- feed Type: grass feed

- Date: Nov 1st, 2019

- The install period: 45 Days

- Workshop size(L*W*H): 60m*24m*12m

- animal feed line price: 150,000 USD

Saudi Arabia

15-16T/H animal feed production line in Saudi Arabia

- feed Type: broiler & cow

- Date: March 30th, 2018

- The install period: 60 Days

- Workshop size(L*W*H): 16m*8m*12m

- animal feed line price: 480,000 USD

United States

10-12 T/H animal feed production line in USA

- feed Type: ruminant cattle

- Date: May 2019

- Feed Pellet Size: 4-8 mm

- The install period: 40 Days

- animal feed production line price: 380,000 USD

Argentina

5 t/h animal feed production line in Argentina

- feed Type: alfalfa feed

- Date:2021.10.11

- Feed Pellet Size:6-8 mm

- The install period:50 Days

- animal feed production line cost:184,500 USD

El Salvador

5 T/H animal Feed line In El Salvador

- feed Type: premix

- Date:2020.11.19

- Control Mode:Full Automatic

- The install period:90 Days

- animal feed production line cost:450,000 USD

Uzbekistan

0.8-4T/H animal feed production line in Uzbekistan

- feed Type: broiler & layer

- Date:May 19, 2021

- Pellet Size:6-8mm

- MAIN POWER:283KW

- animal feed line price:85,000-95,000 USD

Brazil

20T/H animal feed production line in brazil

- feed Type: poultry

- Date:June 2019

- Feed Size:2-5mm pellets

- The install period: 10 months

- animal pellet feed line cost:1,800,000USD

Vietnam

30T/H animal feed production line in Vietnam

- feed Type: chicken & pig & fish

- Date:June 2020

- Pellet Size:2-6mm

- The install period:60 Days

- animal feed line Cost:800,000 USD

Algeria

6-10T/H animal feed production line In Algeria

- feed Type: poultry

- Date: Sep 31th, 2015

- Pellet Size:Power and 3.5mm pellet

- Workshop size(L*W*H):45m*29m*19m

- animal feed pellet line price:410,000 USD

Uzbekistan

10-15T/H animal feed line in Uzbekistan

- feed Type: poultry

- Date: July 1th, 2019

- Feed Size: Poultry mash feed and 2-5mm pellets

- Workshop size(L*W*H):35m*20m*25m

- animal feed pellet line cost:7,800,000USD

Malaysia

3-5T/H animal feed production line In Malaysia

- feed Type: broiler

- Date: October 29, 2021

- Pellet Size:2-4mm

- The install period:20 Days

- animal feed pellet production line project Cost:60000-65000 USD

Nigeria

1-2T/H animal feed production line in Nigeria

- feed Type: chicken

- Date: June 30, 2020

- Pellet Size:2-4mm

- The install period:20 Days

- animal feed production line price:25000-29000USD

Russia

5-7 t/h animal feed production line in Russia

- feed Type: cattle & pig & chicken

- Date: 2022.06.09

- Feed Size:2-6mm pellets

- The install period:25 days

- animal feed line cost:280,000USD

Thailand

10 t/h animal feed processing line in Thailand

- feed Type: animal premix

- Date:2021. 07. 22

- Feed Size:Powder

- The install period:45 Days

- animal feed production line Cost:120,000 USD

Need more information on our animal feed production line? Feel free to contact Richi Machinery?

Equipment for starting animal feed production line

feed mill pellet machine

Capacity:

1-48T/H

Main Power:

22-315KW

animal Feed Extruder

Capacity:

1-12T/H

Main Power:

0.75-355KW

Our animal feed processing technologies are available in various models and with optional accessories to offer the optimal animal feed production line solution for your specific production needs.

Types of animal feed production line

The animal feed production line solutions we can provide cover various types and forms of feed processing. The feed pellet production line we designed can process a single feed, or two or more kinds of feeds to meet the feed processing needs of different customers.

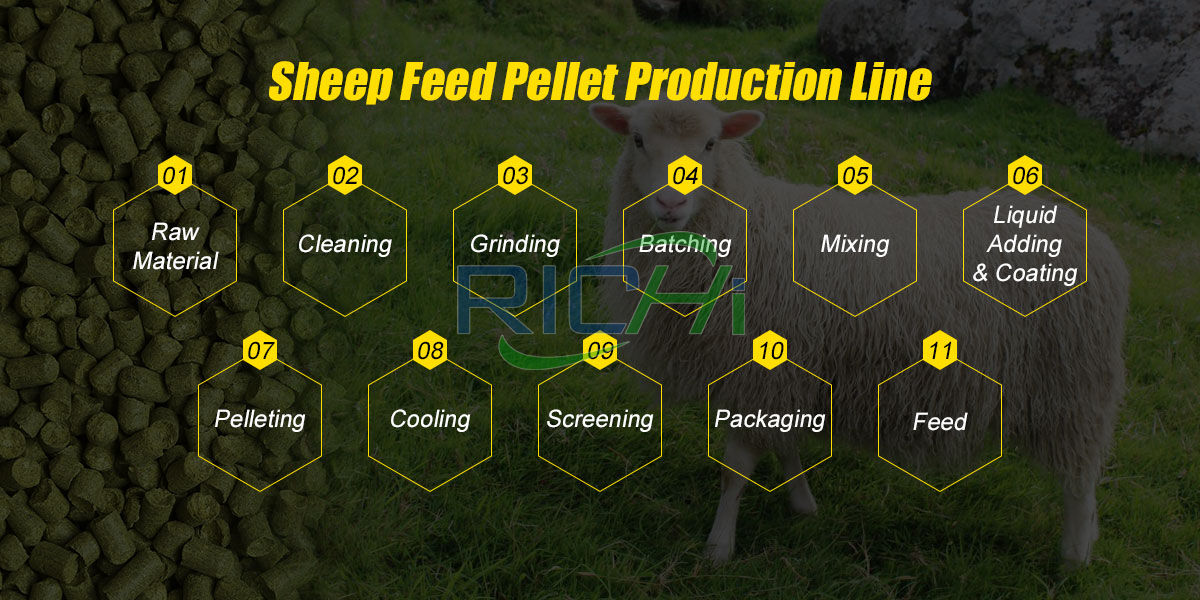

Sheep Feed Production Line

Rabbit Feed Production Line

ruminant feed production line

01

By product status

- Animal powder feed production line

- Animal mash feed production line

- animal feed pellet production line

- Crumbled feed production line

02

By product type

- Complete compound feed production line

- Premix production line

- Concentrated feed production line

- fermented feed production line

We offer animal feed production line process solutions and consulting to transform a wide range of feed ingredients to safe, healthy and nutritious animal feed in order to reach the highest animal welfare and feed conversion rate, be it in the form of pellets, crumbles or mash.

How to build an animal feed production line?

Nowadays, what elements are needed to build a high-quality animal feed mill plant? Based on years of experience in the construction of complete sets of projects, RICHI summarizes the following points for you:

- Reasonable factory environment planning

- Detailed quality standards for process equipment

- Control of engineering construction

- International standard quality control system

- Continuous innovation of smart factories

- Stable and reliable animal feed equipment

We are your ideal partner in producing safe and healthy feeds thanks to our broad technological knowledge, process know-how, global experience of building feed plants and state-of-art automation solutions as well as equipment supply along the entire animal feed production value chain.

Our solutions:

- Superior quality through state-of-the-art, tailored solutions

- Feed safety concepts for safe feed

- Professional project management and project execution

- Manual, semi-automatic and fully automatic solutions are optional – We work closely with you and share our technology know-how in training, support and advisory services

- One stop shop – full animal feed mill solution provider

- Your reliable partner for the lifetime of your plant

Below, RICHI will share some examples of animal feed production lines that he has done. I hope you can learn more about the construction of animal feeds production lines.

10-12 t/h animal feed production line

—— RICHI MACHINERY ——

- Project type: annual output of 50,000 tons of feed (45,000 t/a compound feed, 5,000 t/a extruded corn)

- Total land area: 3564m²

- Working system: There are 15 employees, annual production time is 300 days and 4800 hours.

- Annual water consumption: 6180m3/a, power: 500,000 kW·h/a, gas: 455,000 m³/a

- Consumption of main raw materials: 30,000 t/a of corn, 10,000 t/a of soybean meal, 5,000 t/a of corn germ meal, 5,000 t/a of DDJS, 500 t/a of calcium hydrogen phosphate, 100 m3/a of soybean oil, 5 t/a of methionine, Stone powder 200t/a, salt 10 t/a

- Main equipment: corn grinder, puffed corn grinder, full-price feed raw material grinder, full-price feed raw material grinder, animal feed pellet processing machine, baler, extruder, air compressor, small material mixer, mixer, sieve machines, palletizers, oil storage tanks, corn storage bins, forklifts, fans, natural gas steam boilers, soft water preparation systems, etc.

Complete 10-12 t/h animal feed production line process

- Feeding: Raw materials such as soybean meal, crushed corn, corn germ meal, and DDJS are fed through the feeding port, conveyed by a screw conveyor, and then lifted by a bucket elevator to enter the next step. After the small material is put in through the powder feeding port, it is transported by the screw conveyor and lifted by the bucket elevator to enter the next process. Soybean oil, etc. are directly transported from the storage tank to the batching process;

- Crushing: The granular material in the crushing bin enters the pulverizer through the impeller feeder, and the crushed granular material is conveyed by the screw conveyor and lifted to the batching bin by the bucket elevator.

- Ingredients and mixing: According to the scientific formula, the materials are accurately configured by the computer and weighed and then enter the mixer. After a reasonable and scientific mixing time, the computer controls the discharge and enters the granulation bin through the buffer bucket, scraper, bucket elevator, and distributor.

- Pelleting: Before entering the feed pelletizer, it needs to be conditioned. The conditioned material should be fed with steam to directly contact and mix with the material and wet the material. After uniform conditioning, it will fall to the feed pelleting machine for granulation by extrusion. Steam is provided by a natural gas fired boiler.

- Cooling: The pellets are cooled and used wind cold.

- Screening: The finished pellet feed is transported to the grading sieve through the elevator, and the grading sieve is a two-layer sieve.

- Packaging: The finished product is transported to the finished product temporary storage warehouse, and then packed and measured and packaged.

8-10 t/h animal feed production line project design

—— RICHI MACHINERY ——

- Annual production capacity: 20,000 tons (3,000 t/a concentrated pig feed production line, 17,000 t/a chicken concentrate supplementary feed)

- Project area: 3000 square meters

- Working system: The project has 14 employees. The project implements a one-shift system, each shift works 8 hours, and the annual working days are 300 days.

- Natural gas consumption: 1000m³, Power consumption: 500,000 kwh, Water consumption: 600t

- Concentrate feed (chicken) raw material consumption: corn 12000t/a, soybean meal 4100t/a, fine rice bran 500t, corn germ meal 2000t/a, rapeseed meal 1400t/a,

- Raw material consumption: soybean meal 2500t/a, fish meal 450t/a, feed additive 50t/a

- Production equipment: pulse dust collector, bucket elevator, granular coarse cleaning screen, permanent magnet cylinder, powder coarse cleaning screen, pulverizer, rotary distributor, screw feeder, twin-shaft paddle mixer, automatic sewing bag systems, refrigeration dryers, etc.

Production process of 8-10 t/h animal feed production line

- Crushing section: Raw materials that pass the inspection are fed according to the production plan, and then lifted into the crushing bin by the elevator, and crushed by a crushing machine with a diameter of 3 mm sieve. The project uses a high-frequency speed-adjustable pulverizer (hammer pulverizer and vertical shaft type screenless micro pulverizer), both of which have the characteristics of good sealing, good stability and low noise.

- Batching workshop: According to the formula, the various raw materials are input into the computer, and the computer automatically weighs the ingredients according to the program.

- Mixing section: The prepared material is automatically put into the mixer and mixed for 180 seconds (twin-shaft paddle type high-efficiency mixer). The mixed feed is graded, measured, packaged and put into storage.

22-25 t/h animal feed production line project design

—— RICHI MACHINERY ——

- Annual output: 180,000 tons (construct 3 production lines, including 2 high-grade livestock and poultry feed production lines, high-grade ruminant feed production line 1)

- Total area: 20003.43m²

- Annual water consumption: 17490 m³/a, power consumption: 5.4 million kw h

- Working system: 50 people, with 330 working days per year, three-shift system

- Raw materials: corn 75160t/a, flour 54t/a, soybean meal 63932t/a, cotton meal 7990t/a, rapeseed meal 2710t/a, secondary meal 18264t/a, fish meal 3560t/a, auxiliary raw materials (soybean meal, beer meal , meat and bone meal mixed oil, hydrogen powder, stone powder, etc.) 8740t/a.

- Main production equipment: micro pulverizer, high-pressure fan, self-cleaning bucket elevator, paddle high-efficiency mixer, SZLH series animal feed pelletizer, cooling fan, stainless steel cyclone dust collector, quantitative packaging scale, sewing bag conveyor, circular pulse dust collector, grease adding machine, grease scale, air compressor, air freeze dryer, etc.

process flow of 22-25 t/h animal feed production line

- Feeding port: The material is put into the feeding port, and after being lifted by the bucket elevator, it goes to the primary cleaning screen to screen out large and small sundries. The granular raw materials are screened and enter the crushing bin, and the powdery raw materials are screened and directly enter the batching bin group.

- Crushing: After the granular material enters the crushing bin, it is controlled by the pneumatic gate and enters the impeller feeder to feed evenly into the crushing chamber. The crushed fines are sent to the elevator, and after being lifted, they are guided by the specified distributor and then enter the specified batching bin.

- Mixing of ingredients: After the raw materials reaching the specified fineness enter the batching bin with the set bin number through a special distributor, the personnel in the central control room input the formula data into the computer strictly according to the formula requirements, and realizes automatic batching.

- Granulation and cooling: The material enters the silo to be granulated, and is granulated by two feed granulators with saturated steam to produce different types of feed. Different pellet feed, respectively enter the counterflow cooler for cooling through the closed fan. The finished products after the granules are classified to meet the specified requirements enter the finished product warehouse.

- Quantitative packaging: The whole pellet finished material is automatically measured and packaged by two electronic units, and then automatically sewed by two flat belt conveyors before being transported to the finished product warehouse.

40-42 t/h livestock and poultry animal feed production line project

—— RICHI MACHINERY ——

- Annual output: 200,000 tons (195,000 tons/year of granular material, 5,000 tons/year of powder material)

- Land area: The project covers an area of 53085m², with a total construction area of 48509.96m²

- Operating system: 50 employees, 300 days of work per year, 16 hours a day

- Main raw materials: corn, soybean meal, wheat, wheat bran, corn gluten powder, calcium hydrogen phosphate, stone powder, DDGS, imported steam fish meal, glutamic acid residue

- Main energy consumption: natural gas*1.152 million m³/a, electricity*500,000 Kwh/a, water*22636.3m³/a

- Main equipment: feeding hopper, fan, fan, buried scraper conveyor, bucket elevator, cylinder initial cleaning screen, screw conveyor, permanent magnet cylinder, pulse dust collector, pulverizer, double-shaft paddle mixer, Preservatives, animal feed pellet machines, coolers, cooling fans, rotary grading screens, finished product bins, packing scales, air compressors, air storage tanks, etc.

Process flow of 40-42 t/h animal feed production line:

- Raw material receiving and cleaning system: corn, soybean meal, wheat, wheat bran and other raw materials need to be dried and crushed, and the project adopts a set of feeding system for feeding. After being screened by the primary cleaner and magnetically separated by the permanent magnet cylinder, the pellets enter the bin to be crushed.

- Crushing system: This process is mainly carried out for corn, soybean meal and other granular materials that need to be crushed. The crushed raw materials are lifted by the hoist and then enter the batching bin.

- Mixing system: According to the formula quantity and batching sequence set by the system, the raw materials are conveyed by the batching auger and enter the computer automatic batching scale for cumulative measurement. The small material is added through the small material inlet, and the premixed material is put into the mixer through the premixed silo for mixing.

- Granulation system: The project products include powder and granular forms. The powdered product (raw feed) can be obtained after the ingredients are mixed, and the powdered product directly enters the finished product packaging system.

- Finished product packaging system: The pellet finished product enters the grading screen, completes the three-stage sieving, and the qualified finished product enters the finished product warehouse for packing. The packaging adopts automatic quantitative and vacuum packaging.

55-60 t/h animal feed production line design

—— RICHI MACHINERY ——

- Annual output: 240,000 tons of feed) compound feed 9.6 t/a, concentrated feed 14.4 t/a)

- The total area is 23083m², and the construction area is 17160m².

- Working system: 30 project employees, 260 days of annual production, 8 hours a day.

- The total water consumption: 6238t/a, electricity consumption is 500,000 KW•h.

- Consumption of raw and auxiliary materials: 36,000 t/a of corn, 12,000 t/a of barley, 112,500 t/a of soybean meal, 19,300 t/a of DDGS, 19,200 t/a of puffed corn, 4,900 t/a of stone powder, bran 19,600 t/a of leather, 15,200 t/a of rice bran powder, 2,100 t/a of additives

- Main equipment: scraper conveyor, bucket elevator, rotary distributor, batching bin, pulverizer, double-shaft paddle mixer, granulator, crusher, plane rotary grading screen, finished product bin, quantitative packaging scale , batching scale hopper, microcomputer batching system, weighing liquid adding system, natural gas boiler, initial cleaning screen, cylinder initial cleaning screen, counter flow cooler, etc.

Production Process of 55-60 t/h animal feed production line:

- Material cleaning and crushing section: raw materials such as corn and barley need to be crushed, and other powders do not need to be crushed. The project adopts 2 sets of feeding systems to feed materials separately. Granular materials such as corn and barley are put into the feed inlet and are lifted by the bucket type fast elevator into the cylinder for primary cleaning and screening. After being screened through the high level difference, they directly enter the crushing bin for crushing. The powder that does not need to be crushed directly enters the batching bin through the powder feeding port.

- Batching and mixing section: input various raw materials into the computer according to the formula, and the computer automatically weighs the ingredients according to the program. The prepared materials are automatically put into the mixer for mixing. The project products include concentrated feed and compound feed. The concentrated feed product is obtained after the ingredients are mixed, and the concentrated feed product is directly packaged into the finished product warehouse; the compound feed needs to be further processed through the pelleting process.

- Granulation section: The project uses hot granulation to granulate, and the granulation process uses steam modulation. After the material is pressed, it is ventilated and cooled.

- Classification and packaging section: the cooled compound feed is screened out by a sieving machine to obtain qualified products, and then packed into the finished product warehouse. The powder under the sieve enters the animal feed pellet machine again for granulation.

35-40 t/h animal feed production line construction project design

—— RICHI MACHINERY ——

- Project area: 39163m², with a construction area of about 31458 m²

- Main raw material consumption: 106,016.77 tons of corn, 30,000 tons of soybean meal, 2,500 tons of wheat, 6,000 tons of corn protein meal, 3,000 tons of oil, 15,000 tons of wheat flour, 500 tons of sodium chloride, etc.

- Working system: 60 people are required to work, board and lodging in the factory, two shifts a day, 8 hours per shift, working hours 8:00~24:00, 300 days a year.

- Main equipment: silo, temperature and humidity measurement system, silo bottom fan, back-turning hydraulic flap, conveying scraper machine, bucket elevator, cylinder initial cleaning screen, grease storage tank, water drop mill, batching bin group, double-layer high-efficiency mixer, pellet machine for animal feed, cyclone Dust collector, vibrating grading screen, double scale hopper belt feeding packing scale, belt conveying sewing machine, finished product bulk warehouse, liquid adding system, gas storage tank, biomass boiler, etc.

35-40 t/h animal feed production line Process Description:

- Raw material receiving section: Corn, meal and other raw materials are manually fed into the cleaning grid, and the bucket elevator transports the material to the primary cleaning screen of the cylinder, and the large impurities in the material and the permanent magnet iron remover are screened out through the primary cleaning screen, and enter the silo for temporary storage.

- Crushing section: The material entering the crushing chamber is evenly fed into the crushing machine through the stone removal impeller feeder.

- Batching section: The materials entering the batching bin. After the batching is completed, the material is put into the mixer; the small material (core material) is batched manually or by a micro-batching device, and after batching, it is ordered to enter the mixer. After the small material is put in, the mixing time is 60-90 seconds, and the mixing uniformity requirement is reached. The mixed finished powder enters the granulation section.

- Granulation section: The material entering the granulation bin is fed to the conditioner after opening the feeding auger. The material is in the conditioner, and then enters the animal feed granulator for granulation after being fed with steam.

- Cooling & packing section: The pellets enter the cooler after passing through the air locker, and are cooled by air cooling. The material cooled by the cooler needs to be granulated according to the particle size requirements of the chicken feed, and the granulated pellets with large pellet size are crumbled into small pellets, and then enter the rotary classifying sieve through the bucket elevator. The materials that meet the requirements after being screened by the rotary grading screen enter the bin to be packed and wait for packing.

2-3 t/h pet animal feed production line project

—— RICHI MACHINERY ——

- Annual output: 20,000 tons

- Project nature: newly built

- Raw materials: 10,000 tons of corn, 4,000 tons of wheat flour, 2,000 tons of wheat bran, 2,000 tons of chicken powder, 2,000 tons of beef bone meal, 100 tons of chicken liver (for meat pulp production), 300 tons of chicken oil.

- Working system: The labor quota of this project is 30 people, two shifts are implemented, each shift works 12 hours, and the annual working time is 300 days.

- Production equipment: pet food extruder, feed crusher, drying box, oil mixing-mixing tank, mixing mixer, vibrating screen, etc.

Process flow of 2-3 t/h pet animal feed production line

Main process: feeding-stirring-crushing-expansion-drying-cooling-oil mixing-cooling-stirring-screening-packaging finished product.

- First, the purchased raw materials such as corn, wheat secondary material, wheat bran, etc. are put into the mixer according to a certain proportion and stirred, and then enter the pulverizer for pulverization.

- The pulverized material is added with water and enters the puffing process. The material is suddenly decompressed under the condition of heating and pressurization (using electricity), and the moisture in the material vaporizes and expands, resulting in many small holes and becoming brittle, forming an extruded feed.

- After the material is extruded by a pet feed extruder, it is dried by an electric oven to remove most of the moisture in the material. After drying, the granules enter the cooler for cooling, and then enter the mixing tank to add chicken oil and meat slurry for stirring.

- The oil-mixed material enters the cooler for cooling to normal temperature, stirs in the mixer to disperse the material, and then screens out the qualified product through a vibrating screen. Products are packaged and stored for sale (the conveying process is all pressure conveying).

25 t/h animal feed production line project design

—— RICHI MACHINERY ——

- Annual output: 60,000 tons (40,000 tons of chicken feed, 20,000 tons of pig feed)

- Total construction area: 4300 m²

- Annual water consumption: 900t/a, power: 180,000 Kwh, gas: 150,000 Nm³

- Production shift system: The project labor quota is 30 people, the annual working days are 300 days, one shift system, and each shift works 8 hours.

- Main production equipment: high-efficiency mixer, pulverizer, bucket elevator, batching scale, feed pellet machine, dust collector, processing air volume 4500-6450m3/h, filter area 25m2, initial cleaning screen, natural gas boiler

- Auxiliary material consumption: corn 27000t/a, soybean meal 18000t/a, wheat 7200t/a, rapeseed meal 3000t/a, soybean oil 3000t/a, calcium hydrogen phosphate 1200t/a, liquid methionine 600t/a

Brief description of 25 t/h animal feed production line process flow:

This project is mainly engaged in the production of feed, and the production process mainly includes primary screening, crushing, batching, mixing, granulating, cooling, and finished products, etc., which are briefly described as follows:

- Pre-cleaning and screening: The purchased raw materials are pre-cleaned and screened, if there are stones, mud and other sundries.

- Crushing: Crushing is an operation that mechanically overcomes the cohesive force of solid materials and breaks them.

- Batching: the process of measuring raw materials in a certain proportion. The batching and metering process of this project is automatically controlled by the computer, and the crushed raw materials are distributed according to the ratio set by the system;

- Mixing: the process of fully mixing the raw materials. The mixing process of this project is operated in a closed manner in the mixer;

- Granulation: Granulation means using heat, moisture, and pressure to make powder into pellet feed of a certain shape and size.

- Cooling: use blower to blow air to cool;

- Finished product: Put the finished product into the packaging bag and pack it into the warehouse.

30 t/h animal feed production line project

—— RICHI MACHINERY ——

- Site area: 3333m2

- Work system: 20 workers, 310 working days a year, one shift, 10 hours per shift.

- Consumption of main raw materials: corn 30000t/a, wheat 2000t/a, bran 1000t/a

- Water (ton/year): 3000, Electricity (kWh/year): 800,000, Steam (ton/year): 3000

- Main equipment: pulse dust collector, buried scraper conveyor, bucket elevator, cylinder initial cleaning screen, rotary distributor, permanent magnet cylinder, impeller feeder, superfine pulverizer, high-pressure fan, mixer, feed pellet mill, muffler, settling chamber, vibrating grading screen, electronic packing scale, belt conveyor sewing machine, dust removal fan, quantitative scale, etc.

- Storage and transportation system: The inventory of this project is kept for 40 days, and the total inventory of various raw materials is about 4,500 tons. The corn is stored in the steel silo, and the rest of the raw materials are stored in the raw material warehouse; the feed inventory is used for 2-3 days, stored in the finished product warehouse and the finished product warehouse. , the total amount is about 400 tons.

30 t/h animal feed production line process flow:

- Crushed into the warehouse: the corn, soybean meal, wheat, and bran in the feed tank are transported to the first floor of the production workshop through the buried scraper conveyor, and the impurity is removed through the cylinder initial cleaning (removing small particles mixed in the raw materials) Granular gravel, soil particles and other debris, etc.), and then re-screened through the granular material hopper and fence, and finally the crushed granular material is put into the warehouse through the material-sealed screw conveyor.

- Ingredients: The crushed corn, soybean meal, wheat and bran in the storage bin are transported to the 5th floor of the production workshop through the bucket elevator, and enter the buffer hopper from the upper material level device, and the unloading material from the buffer hopper From the positioner to the impeller feeder on the 2nd floor of the production workshop, the ingredients are mixed according to the ratio of 30:8:2:1 (corn: soybean meal: wheat: bran), and then pulverized again by the super micronizer.

- Mixing: The crushed materials are transported to the settling chamber on the 6th floor of the production workshop through the fighter elevator, and then transported to the Muyang rotary distributor on the 3rd floor of the production workshop to rotate and mix the materials in the settling chamber.

- Pelleting: transport the mixed pellets to the mixer on the 6th floor of the production workshop through the bucket elevator, put steam into the mixer, and start pelleting, and the pelleted broiler breeders are transported with pellet feed to the packaging line.

60-65 t/h large scale animal feed production line project design

—— RICHI MACHINERY ——

- Annual output: 300,000 tons of feed (130,000 tons/year of pig compound feed, 40,000 tons/year of chicken compound feed, 40,000 tons/year of duck compound feed, 70,000 tons/year of aquatic puffed fish compound feed, layer chicken compound feed Feed 20,000 tons/year)

- Energy consuption: Water consumption: 4320m³/a, Power consumption: 50,000 kW·h/a, Steam consumption: 4800t/a

- Work system: 80 people, working 300 days a year, 2 shifts per day, 8 hours per shift.

- Consumption of raw materials: 100,000 tons/year of corn, 80,000 tons/year of soybean meal, 10,000 tons/year of wheat hulls, 10,000 tons/year of secondary flour, 21,000 tons/year of rapeseed meal, 5,000 tons/year of flour, 45,000 tons/year of auxiliary materials, 30,000 tons/year of vegetable oil

- Main equipment: pulse dust collector, scraper conveyor, bucket elevator, cylinder silo, bulk material cylinder silo, screw conveyor, twin-shaft paddle mixer, superfine pulverizer, poultry livestock feed pellet mill, countercurrent type cooler, feed extruder, drying box, electronic packaging scale, palletizing robot.

Production process of 60-65 t/h animal feed production line:

- Raw material receiving and cleaning: Bulk raw materials are transported into the factory by vehicles, and raw materials enter the powder cleaning screen through the scraper conveyor and bucket elevator to remove large impurities, then enter the permanent magnet cylinder to remove iron impurities, and then directly enter the batching bin.

- Crushing: The materials to be crushed (corn, soybean meal, rapeseed meal) are fed from the top inlet through the feeder, and enter the crushing chamber from the left or right through the feeding guide plate, and the materials are gradually crushed.

- Batching and mixing: The materials enter the mixing system after automatic batching, and the various materials are fully mixed, and the mixing uniformity exceeds 93%. The mixed ultrafine powder feed enters the subsequent puffing and granulation process.

- Granulation: After the mixture enters the feed granulator to mature and granulate, the granulated compound feed with nutritional components and mixing uniformity meeting the qualified product standard is produced.

- Packaging: The cooled granules enter the finished product warehouse, and are packed and put into storage by automatic measurement.

- Secondary crushing and secondary mixing: After the pellets are cooled, they are crushed, measured according to the formula requirements, and then mixed.

- Expansion: The crushed and mixed powder is extruded by an extruder. After puffing, the volume of the raw material becomes larger.

- Drying & spraying: The extruded feed is further dried in a feed drying machine.Grease spraying is carried out on the surface of the pelleted feed after puffing.

- Cooling & Packing: A counter-current cooler is used to make the product both cool and dry, reaching the level of safe use. The cooled granules enter the finished product warehouse, and are packed into the warehouse by automatic measurement.

Need more information on our animal feed production line? Feel free to contact Richi Machinery? (Find us on YouTube)

Video of animal feed production line

TURNKEY SERVICE

consult

Richi Machinery has been committed to the solution of complete sets of agricultural and animal feed mill equipment. The group has a professional customer service consulting team to provide customers with full life cycle consulting services to help enterprises quickly realize their development vision. The group’s customer service center has nearly 50 people, providing 24-hour consulting services, and answering customers’ various questions and problems according to their actual needs.

design

RICHI has mature process design experience, experienced technical engineers participate in the whole animal feed production line process, design your exclusive plan according to the actual needs of customers, and guide the selection of equipment. The group currently has a product research and development center, and has carried out scientific research cooperation projects with many universities to cultivate professional technical research and development teams. It now has more than 60 product patents.

civil works

RICHI currently supports the provision of overall development plans, complete plant planning and the construction of steel structure workshops, and can also provide steel structure general drawings according to customer needs. The steel structure workshop built by RICHI has comprehensive advantages such as light weight, high strength, short construction period and strong seismic performance, which can shorten the construction period, reduce costs and improve the comprehensive benefits of the animal feed production line project.

manufacturing

Richi Machinery has an independent modern CNC machining production center, which adopts international advanced professional production equipment to ensure the refined production of products. At the same time, the motors of our key equipment adopt high-quality brand accessories at home and abroad, aiming to provide customers with sophisticated and durable animal feed production line equipment. It has a new product experiment base, and all new products have been overloaded to ensure that the product quality is qualified before leaving the factory.

Install

Install relevant animal feed mill equipment according to the actual situation of the customer, do a good job in debugging, follow up the service throughout the process, and ensure zero errors in the installation stage. The professional and excellent installation team brings peace of mind to customers. Since its establishment, the company has successfully built more than a thousand feed projects of various types around the world and successfully delivered them to customers. We will strive to create a turnkey animal feed making line project that satisfies customers with a short installation period.

training

In order to ensure the safe and reliable operation of the entire production system, the company provides training to customers in three stages of equipment manufacturing, installation and commissioning, aiming to help customers complete the daily management, operation, maintenance and basic troubleshooting of equipment, reducing economic losses that may result from machine failure problems. Customized training and a comprehensive training system truly allow customers to quickly and independently control the animal feed production line production process.