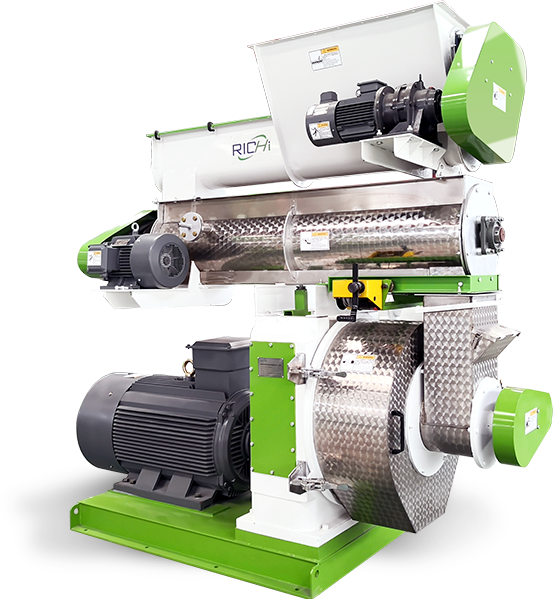

goat feed pellet making machine

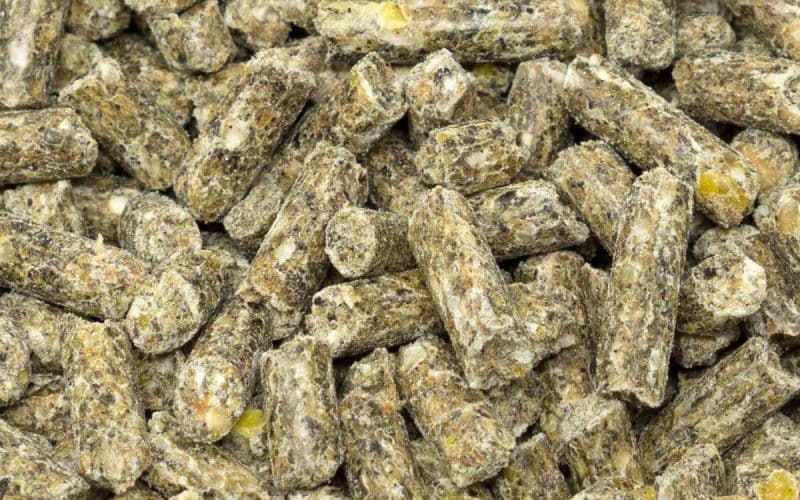

Goat feed pellet making machine, also called sheep feed pellet machine, is mainly used for the production of various types of sheep and goat feed pellets and flock feed. The feed materials suitable for this goat feed machine are very wide, including pasture, alfalfa, hay, teff grass, beet pulp, timothy, soy hull, etc.

- Capacity: 1-48 T/H

- Model: SZLH

- Power: 22-315 KW

- goat feed pellet machine Price: 10,000-100,000 USD

Types of goat feed pellet making machine

According to the application and raw materials of the sheep goat feed pellet mill, the equipment can be divided into the following commonly used types:

- hay pellets pellet machine for goats

- medicated goat feed feed pellet making machine

- grass pellets machine for goats

- milk pellets machine for goats

- timothy hay pellet machine for goats

- Fermented feed pellet machine for goats

- roughage pellet machine for goats

- Concentrate feed pellet machine for goats

- timothy grass pellet machine for goats

- alfalfa pellet machine for goats

- beet pellets machine for goats

- beet pulp pellets machine for goats

- best hay pellets making machine for goats

- goat grower pellets making machine

- organic goat pellets making machine

- soy hull pellets machine for goats

- teff grass pellets machine for goats

- flock feed making machine

Note: The main raw materials of sheep feed include roughage and concentrated feed. Roughage includes silage corn, forage, sorghum and other grass plants, as well as by-products such as soybean cake, bran, and peanut shells. Concentrated feed includes soybean meal, fish meal, bone meal, etc.

When selecting goat feed raw materials, attention needs to be paid to the quality of the raw materials and the nutritional balance of the feed formula. At the same time, the price and availability of raw materials must also be considered.

According to different sheep breeds and growth stages, the feed formula needs to be adjusted accordingly. In formula design, the nutritional needs and growth patterns of sheep need to be fully considered.

Features of goat feed pellet making machine

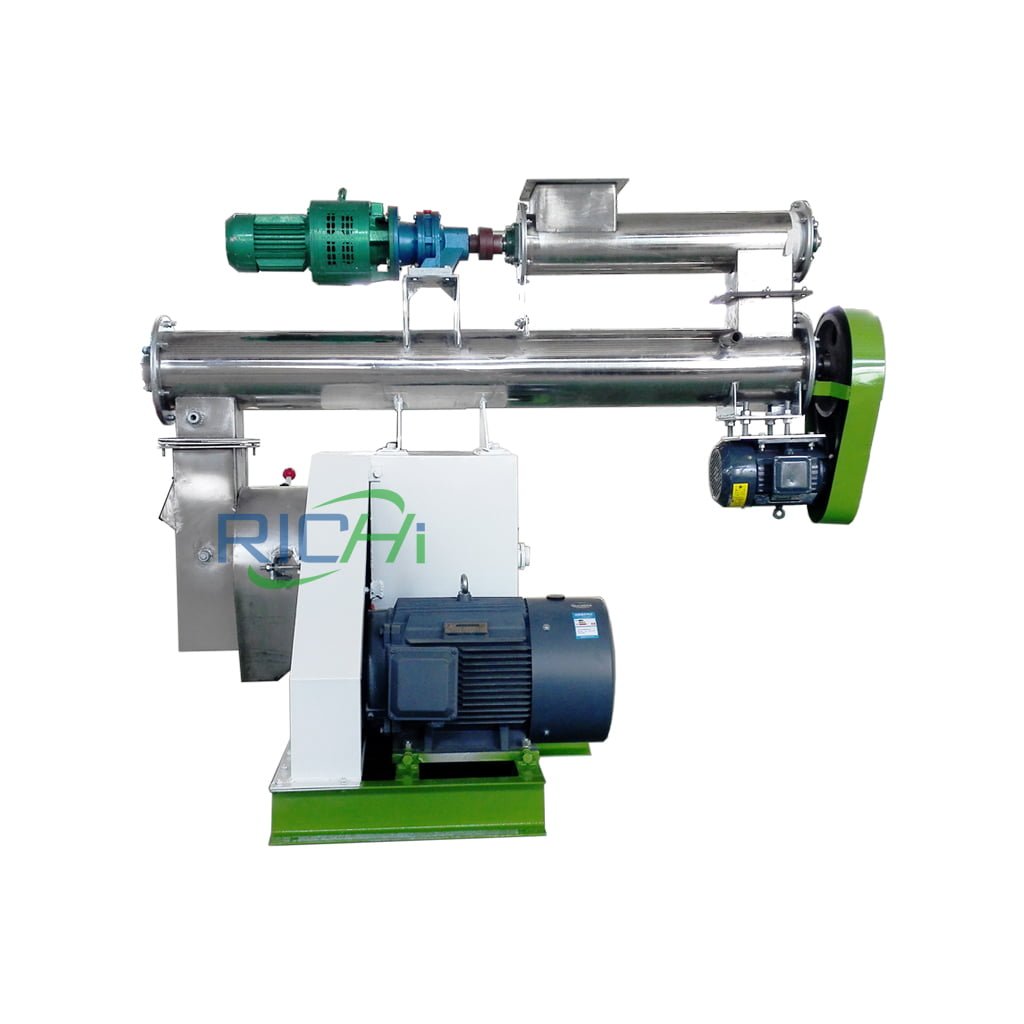

RICHI goat feed pellet machine is suitable for processing all types of sheep feed pellets, and can also be customized according to the type of sheep feed processed by the customer.

- High-precision gear transmission, its output is about 15-20% higher than that of the belt transmission type.

- The large gears and pinion shafts adopt hard tooth surface and gear grinding technology, with high precision and a service life of up to 15 years.

- The feeder adopts an “O-shaped” cylinder, which not only improves the uniformity of feeding, but also effectively prevents steam from escaping upward.

- The conditioner is increased by 15% based on the CPM model to improve the maturation degree of the material.

- The goat pellet mill adopts synchronous toothed belt direct transmission mode, which has large driving torque, stable rotation, high output, low noise, and no need for lubrication. It is equipped with synchronous belt cooling technology to reduce operating costs.

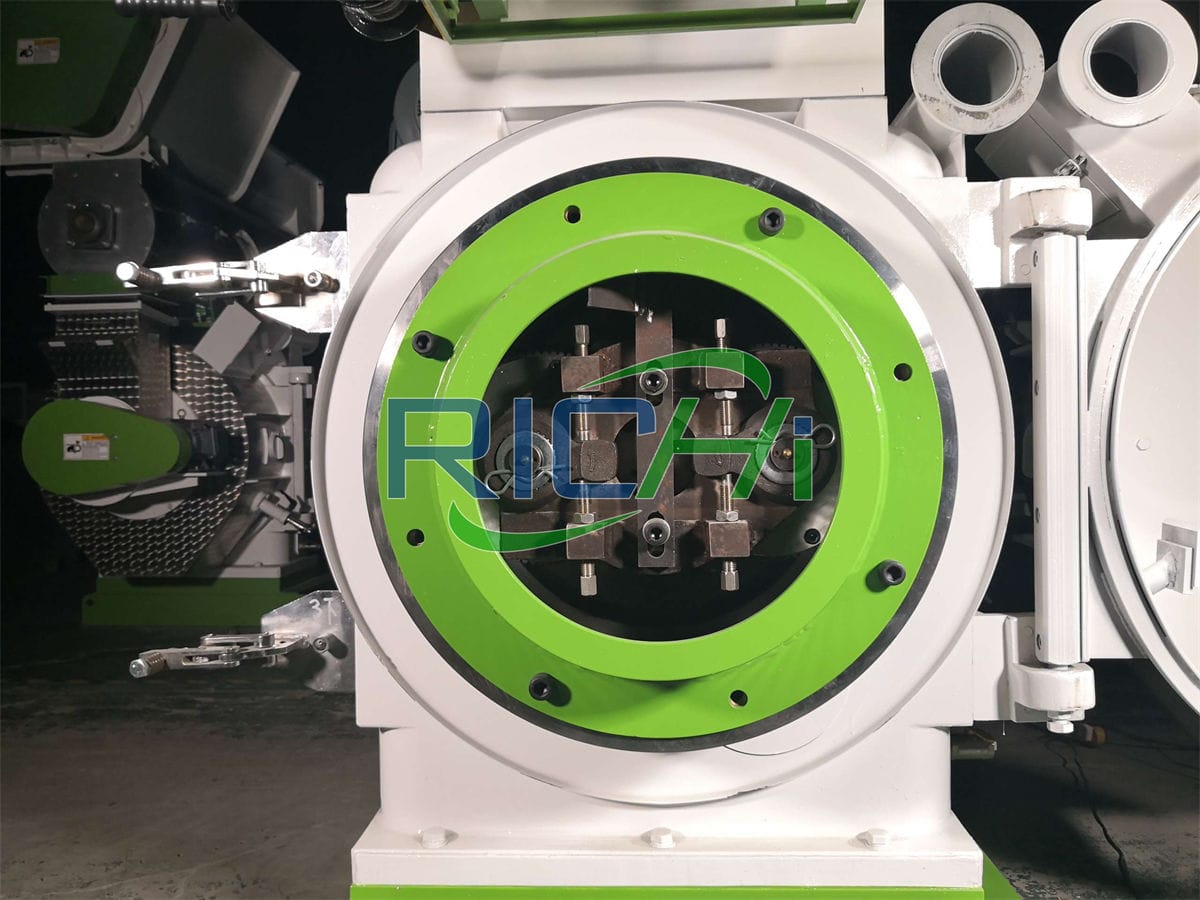

- The ring die opening area of this equipment is increased by 25% to achieve the best area to power ratio; the cutter angle is adjustable, and the production of small-diameter particles can achieve greater output.

- This equipment uses advanced variable frequency motor for feeding, which is easy to operate and maintain, stable and controllable.

- The goat feed equipment is equipped with an overload protection device and an external discharging mechanism to automatically ensure stable and safe operation of the equipment.

- According to customer needs, different types of conditioners and feeders can be selected.

- Automatically adjusts the load, reducing the requirements for operating level; precise temperature control, reducing the probability of slipping; supports a variety of formulas.

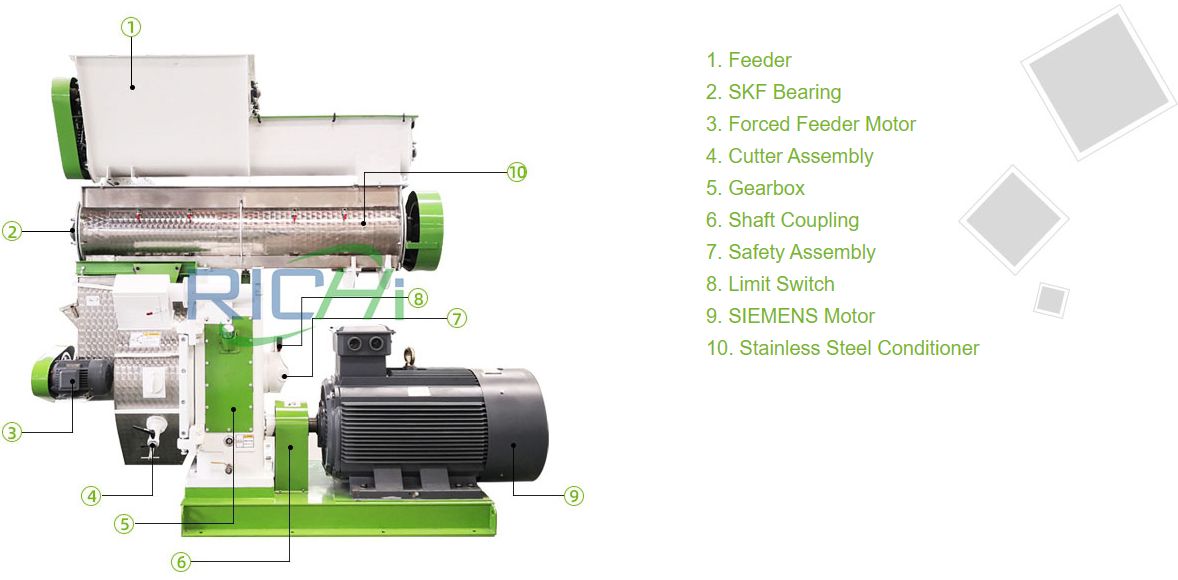

Structural design of goat feed pellet making machine

The structure of the goat feed pellet making machine mainly includes the following parts:

- Main structure: This is the support part of the goat pellet making machine, usually composed of a frame to carry the work of other components.

- Power system: including motors, speed-adjustable motors (if necessary), reducers, etc. These components are responsible for providing the necessary mechanical movement and working energy.

- Feeding mechanism: The feeder is used to receive raw feed and process it through the conditioner to make it suitable for the subsequent pelleting process.

- Conditioner: This is an important part. It can soften and gelatinize the raw feed through heating and stirring, so that it can better enter the next stage of the pelleting process.

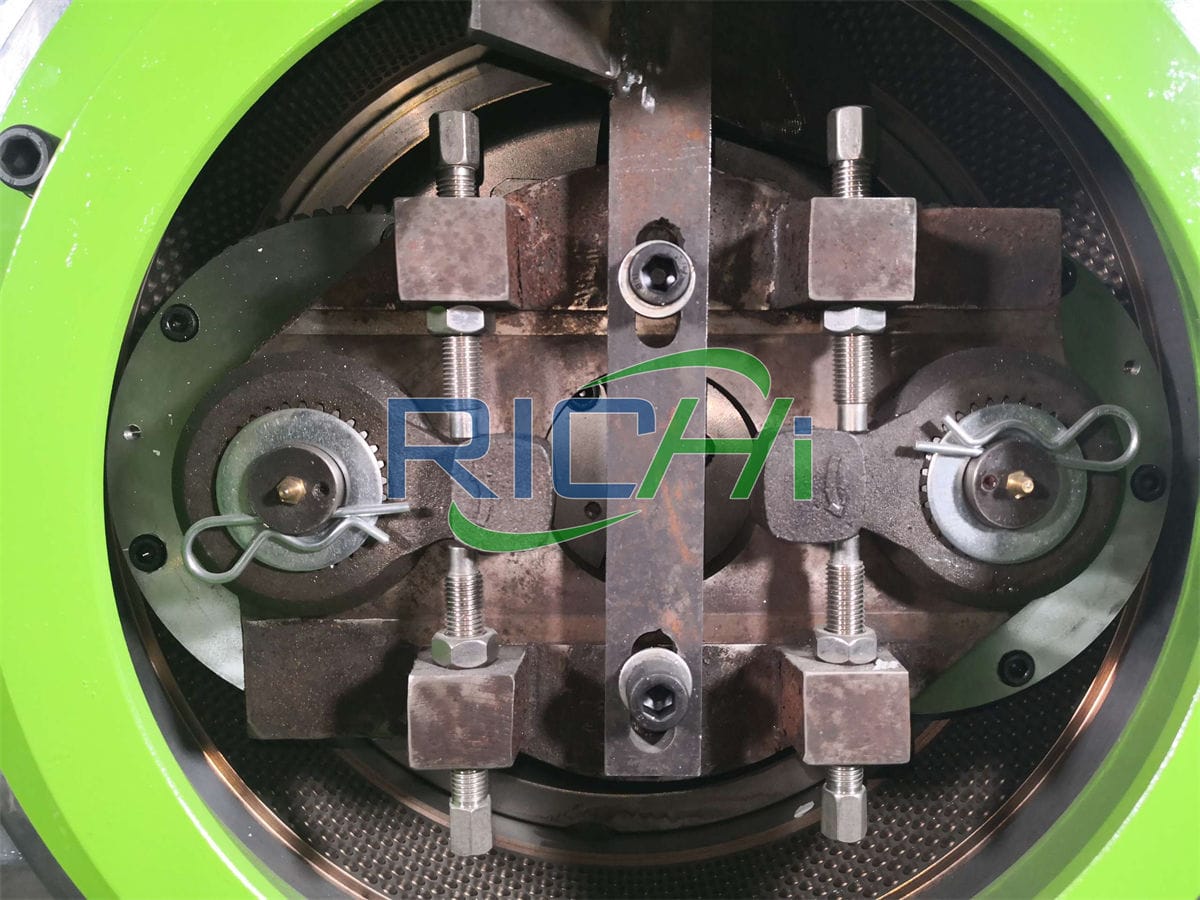

- Pressure roller structure: The pressure roller is the core component to achieve granulation. They are squeezed in the ring die to form granules.

- Ring die: The ring die is a key component in pellet molding. It is composed of a template and a die hole. The size and shape of the die hole have a great impact on the quality of the goat pellets.

- Lubrication system: This system is responsible for lubricating the contact area between the pressure roller shaft and the ring die to reduce friction.

- Adjusting mechanism: This may include electronic metering devices, automatic unloading devices, etc., which can adjust the size and shape of pellets for goats according to different needs.

- Cutting mechanism: The cutting mechanism is responsible for cutting the produced goat food pellets to ensure that the length of the finished pelleted goat feed is consistent.

- Transmission and lubrication system: This part ensures the normal operation and coordinated action of all components.

The goat feed pellet making machine is a complex mechanical equipment integrating multiple structures and functions, designed to efficiently convert raw feed into pellet feed that meets specifications.

How does the goat feed pellet making machine work?

Working principle of sheep feed pellet machine:

- The powdery raw materials are passed through a magnetic separation device to remove iron, and are sent to the stirring and conditioning system through a continuously variable speed screw feeder.

- They are stirred and mixed with the steam added at the same time (sometimes molasses and fat are added) to make the protein in the feed. The starch is diluted by water under the action of heat and become a highly plastic material, and the crude fibers are heated and softened.

- At this time, the feed moisture reaches 15% ~ 17%, and the temperature is 65 ℃ ~ 85 ℃. The quenched and tempered materials are sent between the operating ring die and the working surface of the pressure roller.

- The rotating die drives the pressure roller to rotate through friction with the material. Under strong extrusion, the material overcomes the resistance of the hole wall and is continuously extruded from the die hole in strips.

- During pelletizing, the cutter installed outside the die is cut into goat food pellets of appropriate length. The position of the cutter can be adjusted to control the length of the goat pellets.

Model And Parameters of goat feed pellet making machine

SZLH250 goat Feed Pellets Machine

| Capacity(T/H) | 1.5-2.5 |

| Main Motor Power(kw) | 22 |

| Feeder Motor Power(kw) | 0.75 |

| Conditioner Power(kw) | 1.5 |

| Dia.of Ring Die(mm) | 250 |

| Transmission form | Belt drive |

SZLH320 goat Feed Pellets Machine

| Capacity(T/H) | 4-5 |

| Main Motor Power(kw) | 37 |

| Feeder Motor Power(kw) | 1.5 |

| Conditioner Power(kw) | 2.2 |

| Dia.of Ring Die(mm) | 320 |

| Transmission form | Gear drive |

SZLH350 goat Pellet feed Machine

| Capacity(T/H) | 6-8 |

| Main Motor Power(kw) | 55 |

| Feeder Motor Power(kw) | 1.5 |

| Conditioner Power(kw) | 3 |

| Dia.of Ring Die(mm) | 350 |

| Transmission form | Gear drive |

SZLH420 goat Feed Making Machine

| Capacity(T/H) | 10-13 |

| Main Motor Power(kw) | 110 |

| Feeder Motor Power(kw) | 1.5 |

| Conditioner Power(kw) | 7.5 |

| Dia.of Ring Die(mm) | 420 |

| Transmission form | Gear drive |

SZLH508 goat feed making machine

| Capacity(T/H) | 12-18 |

| Main Motor Power(kw) | 160 |

| Feeder Motor Power(kw) | 2.2 |

| Conditioner Power(kw) | 11 |

| Dia.of Ring Die(mm) | 508 |

| Transmission form | Gear drive |

SZLH558 goat feed making machine

| Capacity(T/H) | 22-28 |

| Main Motor Power(kw) | 180/20 |

| Feeder Motor Power(kw) | 2.2 |

| Conditioner Power(kw) | 11 |

| Dia.of Ring Die(mm) | 558 |

| Transmission form | Gear driveve |

SZLH678 sheep feed pellet machine

| Capacity(T/H) | 28-32 |

| Main Motor Power(kw) | 220/250 |

| Feeder Motor Power(kw) | 2.2 |

| Conditioner Power(kw) | 11 |

| Dia.of Ring Die(mm) | 678 |

| Transmission form | Gear drive |

SZLH768 sheep feed pellet machine

| Capacity(T/H) | 32-38 |

| Main Motor Power(kw) | 280/315 |

| Feeder Motor Power(kw) | 2.2 |

| Conditioner Power(kw) | 11 |

| Dia.of Ring Die(mm) | 768 |

| Transmission form | Gear drive |

SZLH858 sheep feed pellet machine

| Capacity(T/H) | 42-48 |

| Main Motor Power(kw) | 280/315 |

| Feeder Motor Power(kw) | 2.2 |

| Conditioner Power(kw) | 15 |

| Dia.of Ring Die(mm) | 858 |

| Transmission form | Gear drive |

Customizable Design:

Richi Machinery can customize the goat animal feed pellet making machine according to the actual needs of customers, including voltage, electrical components, door opening method, product color matching, and can also customize different conditioners, conditioner layers according to customer cattle feed formulas and sheep goat feed making process, etc.

| Conditioner layers | one or two layers |

| Ring Die Compression Ratio | 1:6:1:9 |

| Requirements Before Entering Pellet Machine(mm) | 3.0-5.0 |

| Number of pressing rollers | 2 |

| Final Pellet(mm) | 6~12 |

| Pellet Length(mm) | 12-18 |

Featured goat feed pellet making & feed mill plant project

At present, our goat feed pellet making machine and complete goat feed making plant equipment has been exported to the United States, Morocco, Australia, Saudi Arabia, Kazakhstan, Argentina, South Africa, Russia, Uzbekistan, Indonesia, India and other countries.

If you are planning to buy goat feed pellet making machine or start a commercial goat animal feed mill plant, you can take the following project for reference. It is designed with a ring die feed pellet machine and automatic batching system, so that to ensure high efficiency and low production cost.

Indonesia

3-5 T/H goat feed pellet making machine system in Indonesia

- Date: April 9th, 2018

- The install period: 30 Days

- Workshop size(L*W*H): 10m*5m*12m

- goat feed plant price: 160,000 USD

Australia

3-4 T/H goat feed pellet making machine system in australia

- Date: Nov 1st, 2019

- The install period: 45 Days

- Workshop size(L*W*H): 60m*24m*12m

- goat feed plant price: 250,000 USD

Saudi Arabia

15-16 T/H goat feed pellet making machine system in Saudi Arabia

- Date: March 30th, 2018

- The install period: 60 Days

- Workshop size(L*W*H): 16m*8m*12m

- goat feed plant price: 480,000 USD

United States

10-12 T/H Goat Feed Pellet mill Plant in United States

- Date: May 2019

- Feed Pellet Size: 4-8 mm

- The install period: 40 Days

- goat feed machine plant price: 380,000 USD

Argentina

5 t/h Goat Feed Pellet mill Plant in Argentina

- Date:2021.10.11

- Feed Pellet Size:6-8 mm

- The install period:50 Days

- goat feed machine plant cost:184,500 USD

El Salvador

5 T/H Goat Feed Pellet mill Plant In El Salvador

- Date:2020.11.19

- Control Mode:Full Automatic

- The install period:90 Days

- goat feed machine plant price:450,000 USD

Uzbekistan

0.8-4T/H Goat Feed Pellet Machine Plant in Uzbekistan

- Date:May 19, 2021

- Pellet Size:6-8 mm

- MAIN POWER:283 KW

- goat feed machine price:85000-95000 USD

China

40-42T/H goat feed pellet machine plant in china

- Date:June 2019

- Feed Size:2-5 mm pellets

- The install period:10 months

- goat feed machine cost:1,800,000 USD

China

25T/H Goat Feed Pellet Machine Plant in china

- Date:June 2020

- Pellet Size:2-6 mm

- The install period:60 Days

- goat feed machine Cost:800,000 USD

All our goat feed making machine projects are designed according to our clients’ specific needs and requirements, so just feel free to contact us and get a tailor-made feed processing business plan and sheep goat livestock feed production line price and construction cost.

goat feed pellet making machine price

For different goat feed making machine manufacturers, there is no fixed market price due to large differences in models, production capacity, configuration, brand, region and other factors.

Generally speaking, the price of a small (1-2t/h) goat feed pellet mill is between 7,000-10,000 USD, while the price of a large, high-capacity, high-configuration feed pellet machine may reach 100,000 USD. And some customers will customize the equipment additionally.

Depending on the customized design, some additional costs will be incurred. Therefore, when purchasing, it is recommended to directly consult the relevant equipment manufacturers or dealers to obtain detailed equipment configuration plans and corresponding goat feed machine price quotations based on your actual needs.

How to choose goat feed pellet making machine?

What factors should be considered when purchasing sheep feed pellet mill equipment?

Sheep feed pellet machine is one of the commonly used equipment in sheep feed production. It is used to press sheep compound feed pellets, roughage pellets, concentrated feed pellets, etc. When purchasing a goat feed pelleting machine, you need to consider the following factors:

- Types of goat feed pellet making machine:

There are many types of sheep feed pellet mills, including goat feed machines with forced feeders, goat feed machines without forced feeders, single-layer conditioning goat feed pelletizer, double-layer conditioner sheep feed pellet machine, etc. Different types of sheep feed pellet machines are suitable for different feed ingredients. When purchasing, you need to choose a suitable type of goat feed pellet making machine according to the needs of sheep feed production. - The output of goat feed pellet making machine:

The output of the sheep feed pellet machine directly affects the production efficiency. When purchasing, you need to select the processing capacity of the crusher based on the expected production volume of the sheep feed mill to meet production needs. - The feed particle size and discharge particle size:

The feed particle size of the sheep feed pellet machine refers to the particle size of the material when it enters the sheep feed pelletizer, and the discharge particle size refers to the particle size after preparation. The range of feed particle size and discharge particle size has a direct impact on the processing of raw materials and subsequent processes. When purchasing, you need to consider the characteristics of raw materials and sheep and goat pellets products and the requirements of subsequent processes, and select the appropriate feed particle size and discharge particle size range. - Energy consumption:

The energy consumption of goat feed pellet making machine refers to the energy consumed by the sheep feed pellet machine per unit time. The amount of energy consumption directly affects production costs. When purchasing, you need to consider the energy consumption level of the sheep feed pellet machine and choose equipment with lower energy consumption to improve production efficiency. - Reliability and maintainability:

The reliability and maintainability of the crusher are very important factors in sheep feed production. Reliability refers to the failure rate and operational stability of the equipment, and maintainability refers to the maintenance difficulty and maintenance cycle of the equipment. When purchasing, you need to choose a goat feed pellet mill with high reliability and good maintainability to ensure continuity and stability of production. - Price of goat feed pellet making machine:

The price of sheep feed pellet machine is one of the important factors to consider when purchasing. The price is not only related to the quality and performance of the goat feed pellet mill, but also to market supply and demand and brand influence. When purchasing, you need to choose equipment with reasonable prices based on the above factors. - Supporting equipment:

During the production process, the goat feed pellet making machine needs to cooperate with other equipment, such as crushers, mixers, screening machines, conveyors, etc. When purchasing a sheep feed pellet machine, you need to consider the type, model and specifications of the supporting equipment to ensure the coordinated operation of the entire sheep feed production line. - The manufacturer and after-sales service:

The manufacturer and after-sales service of the sheep feed pellet machine are also one of the important factors to consider when purchasing. Well-known goat feed machine manufacturers usually have high technical strength and production experience, and can provide better product performance and high-quality after-sales service. When purchasing, you need to choose a manufacturer with a good reputation and good service attitude to obtain a better purchasing experience and usage experience. - Safety and environmental protection:

Safety and environmental protection issues in mining production have received more and more attention. When purchasing a goat feed pellet machine, you need to consider the safety and environmental performance of the equipment, choose equipment that meets national and industry standards, and meet safety and environmental requirements during the production process. - Technological innovation and development trends:

The goat feed pellet machine industry is in the development stage of technological innovation, and new sheep feed pellet machines and pelletizing technologies are constantly emerging. When purchasing, you need to pay attention to the technological innovation and development trends of sheep feed pellet mills, and choose equipment with the latest technology to improve production efficiency and keep up with the trend of industry development.

Richi Machinery recommends that you consider multiple factors when purchasing a livestock sheep feed pellet mill, including the type of sheep feed pellet granulator, processing capacity, feed particle size and discharge particle size, energy consumption, reliability and maintainability, price, supporting equipment, manufacturers and after-sales service, safety and environmental protection, as well as technological innovation and development trends, etc.

When purchasing, you need to comprehensively weigh the above factors and choose a sheep feed pellet mill that suits your production needs to improve production efficiency and reduce production costs.

how to make goat feed pellets? complete goat feed pellet machine line process

How to make pellets for goats? Sheep and goat pellets production technology refers to the process of making various raw materials into feed suitable for animal feeding through a series of technological operations and processing.

Sheep are ruminant feed, and ruminant feed refers to the feed used by ruminant animals such as cattle, sheep, rabbits, camels, and deer. Its characteristics are different from general monogastric animal feed. It needs to contain necessary cellulose and microorganisms to achieve the purpose of efficiently utilizing feed and promoting animal growth.

The sheep feed production process generally includes raw material procurement, cleaning and grinding, batching and mixing, granulation, drying and cooling, packaging and storage.

- Raw material procurement: Select appropriate feed raw materials, including grains, soybean meal, fish meal, protein powder, etc., to ensure that the quality and nutritional content of the raw materials meet the needs of the goat and sheep.

- Cleaning and grinding: Clean, screen and grind the raw materials to remove impurities and indigestible substances, making the raw materials easier to digest and absorb.

- Batching and mixing: According to the needs of animal feeding, various raw materials are batched according to a certain proportion, and the raw materials are fully mixed evenly through the mixing equipment to ensure the balance of various nutrients in the feed.

- Granulation: Add the mixed feed into the goat feed pellet making machine, and use mechanical force and heat to compress it into sheep and goat pellets to increase the density and stability of the feed and improve the utilization rate of the feed.

- Cooling: The pelleted goat feed pellets are then cooled through cooling equipment to bring it to room temperature for easy packaging and storage.

- Packaging and storage: When packaging feed, plastic bags, woven bags and other packaging materials are generally used to ensure the sealing and moisture resistance of the feed. Then store the packaged feed in a dry, ventilated, and dark warehouse to prevent the feed from getting damp and moldy.

The above are the main process steps of a complete goat feed pellet making machine plant system. Different types of goat feed may have different specific processes.

RICHI provides customized animal feed production line services according to customer needs. Optimization and improvement of goat feed production technology can improve goat feed quality and yield, reduce energy consumption and environmental pollution, and improve animal feeding efficiency.

Complete goat feed making machine list

The main processing equipment for sheep feed includes mowers, grass grinders, grain grinders, mixers, grass dryers, goat feed pellet making machine, coolers, screening machines, packaging scales, etc.

goat Feed Grinder machine

Hammer crusher is mainly suitable for crushing pasture, cereals, corn, sorghum, wheat, and crushed cake materials. Equipped with a high-precision dynamic balance detection rotor, the equipment has small vibration and low noise.

Capacity:

3-25 T/H

Main Power:

30-160 KW

goat Feed Mixer machine

RICHI sheep feed mixing machine has a patented double-layer rotor design, with a mixing uniformity of up to 97.7% and a short mixing time. Equipped with a large-section return air duct to reduce dust and prevent material segregation.

Capacity:

250-2000 KG

Main Power:

4-55 KW

Bale breaker

Many customers’ sheep feed ingredients contain grass, and the grass is in bales. This requires the use of a bale breaker to break up the bales of grass in order to enter the next stage: grass crushing.

Capacity:

1-20 T/H

Main Power:

30-90 KW

grass hay crusher

This is a crusher specially designed for crushing grass, straw, hay. With more and more customers processing cattle, sheep, horses and rabbit feed, the application of this equipment is becoming more and more widespread.

Capacity:

0.3-3 T/H

Main Power:

22-93 KW

Rotary distributor

This equipment is mainly used to introduce materials into different channels, and is widely used in goat feed processing plants, oil plants, and starch plants to distribute powdery and granular materials.

Capacity:

1-48 T/H

Main Power:

22-315 KW

Pellet Cooler Machine

It can be applied to the cooling of lumps, blocks and powders, as well as the cooling of pellets, extruded feed and fragile feed. This can ensure the quality of pellet feeds during packaging, transportation and storage.

Capacity:

3-25 T/H

Main Power:

30-160 KW

vibrating screening machine

Suitable for screening and classifying powdery feed or pellet feeds. It can also be used for primary cleaning of raw materials in sheep feed mills and grading of intermediate products after secondary crushing in goat feed mills.

Capacity:

3-20 T/h

Main Power:

1.5-5.5 KW

Automatic Bagging Machine

Quantitative packaging scales are suitable for quantitative packaging of granular and powdery feed. The key components are all imported with original packaging, with long service life and strong anti-interference ability.

Capacity:

6-12 Bags/Min

Main Power:

1.1-5 KW

Prospects for investing in goat feed pellet processing business

With the continuous development of the global economy, people are increasingly paying attention to quality of life and health issues, and the prospects of the mutton market have always been promising. Likewise, the outlook for the sheep goat feed market is also very positive.

- On the one hand, feed is an essential input in the sheep goat breeding process, which directly affects the breeding effect and output. Therefore, the demand for sheep feed market is closely related to the scale and quantity of breeding. With the rapid development of the cattle and sheep breeding industry, the demand for sheep feed market is also increasing.

- On the other hand, the raw materials for the production of sheep goat feed come from a wide range of sources, such as corn, soybeans, wheat, pasture, oats and other crops and natural herbs, which can be used as raw materials for the production of sheep feed. The diversification of raw material sources makes sheep feed production more resistant to risks and has a more stable market prospect.

- In addition, with the continuous development of science and technology, the sheep goat feed market will usher in more innovation and development opportunities. For example, innovations in using gene editing technology to improve the nutritional content of plant-based feeds and improve sheep production efficiency and product quality will become important directions for the future development of the sheep goat feed market.

The sheep goat feed market has a very broad prospect, with stable demand growth and diversified sources of raw materials, as well as innovative opportunities for technological development. In the future, as consumer demand for beef and mutton meat continues to increase, the sheep goat feed market will continue to maintain steady growth.

video of goat feed pellet making machine

FAQs of goat feed pellet making machine

Why process goat food pellets with goat feed pellet making machine? are goat pellets good for goats?

Using a goat feed pellet making machine to process pellets must be very valuable, which is why more and more sheep feed processors are paying attention to goat feed pellet mill machines.

The goat feed pellet making machine is one of the indispensable equipment in the breeding industry and has important functions and prospects. The following are its important roles and prospects in several aspects of the breeding industry.

(1) Save forage

The biggest problem in raising sheep is the lack of forage. Even if a large amount of forage is planted, the large size and heavy weight of the forage will cause great difficulties in transportation and storage. Moreover, both pasture and crop straw grow on ravine slopes. In particular, sheep are very picky about forage and are accustomed to eating a variety of forages.

At the same time, sheep have a cleanliness habit, and if the forage grass is slightly stepped on, contaminated, or dropped on the ground, even if the sheep are very hungry, they will not want to eat it. In this way, if the sheep are fed with original grass or even short, crushed and processed forage , will also lead to a large amount of waste of forage, making the utilization rate of hard-won forage very low.

Therefore, raising sheep must save forage to the greatest extent, that is, we must adopt the path of grass-saving sheep raising. When raising sheep with pellet feed, the forage grass and other concentrated feeds are mixed together to form pellets. The forage grass and the concentrated feed are mixed to make the palatability better. When the sheep eat the concentrated feed, they will also swallow the forage grass together.

This will not cause a waste of forage. Even if poor suitability, rough and hard forage, weeds, and crop roots are mixed in, the sheep will eat them all. According to production practice, feeding sheep with pellet feed can save about 30% of forage compared with feeding sheep with prototype grass.

(2) Sheep like to eat pellet feed

Sheep especially like to eat granular food, which is made by goat feed pellet making machine, so if the food is made into granular form, the sheep’s feed intake will be significantly increased. At the same time, feeding sheep with granular feed will greatly improve the digestion and utilization rate of the feed.

Because sheep need to chew the pelleted feed for a long time before swallowing it, food that has been chewed many times can be easily digested and absorbed in the stomach. Especially when lambs start eating, the best effect is to use pellet feed, and lambs also like to eat pellet food the most.

(3) Able to achieve nutritional balance

The pellet feed made by goat feed pellet making machine is reasonably formulated according to the nutritional needs of the sheep and the nutritional components of various forage feeds. The formulas are different according to the different growth stages of the sheep and different production types, so that the sheep’s diet will be comprehensive.

If it is all controlled by humans, the growth and development of sheep will become very fast, and the feed rewards will be very high. This cannot be achieved by any form of feeding method. Even if the grazing sheep freely eat the original forage in nature, the effect of comprehensive nutritional balance cannot be achieved because the grazing sheep have phenomena such as pica.

(4) Able to utilize the research results of modern sheep farming

Many new additives, new formulas and different varieties, different growth properties and different nutritional supplements developed by modern scientific research are difficult to use by relying on other feeding methods and grazing methods using advanced technology. They can only be used freely by feeding sheep with feed pellets.

(5) Expanded forage feed resources

Pellet feed made by goat feed pellet making machine is a combination of concentrated feed and roughage to make food for sheep to eat. Therefore, the roots, stems, stalks, shells, skins, etc. of various plants with poor palatability are mixed into the concentrated feed with good palatability, and its palatability will also become better, the sheep also eat it together and cannot pick out the poor palatability.

This increases the available forage resources and greatly increases the types of forage that can be fed to the sheep. For example, thick and hard stems that cannot be used for a long time can be made into sheep and goat feed pellets.

(6) Low production cost

The method of making sheep pellet feed is simple, not only for sheep feed factories, but also for general sheep farmers. Especially the advent and promotion of the current goat feed pellet making machine has provided a basis for the application of pellet feed, and at the same time, the production of pellet materials The cost increase is not significant and practice has proven to be very appropriate.

(7) Improve feed utilization

The goat feed pellet making machine can process bulk feed into pelletized feed, which increases the density of the feed, reduces the scattering and waste of feed, and improves the feed utilization rate. Pelleted feed can also reduce feed selection behavior, promote the healthy growth of livestock and poultry, and improve breeding efficiency.

(8) Improve sheep quality

The pelleted feed made by goat feed pellet making machine can make the feed ingredients better integrated, and the nutrition is balanced and difficult to lose. Therefore, the sheep can better absorb and utilize the nutrients in the feed, and improve the growth rate and meat quality of livestock and poultry.

(9) Reduce breeding costs

The goat feed pellet making machine can mix feeds of different types and particle sizes into pellet feed. It can also add a variety of nutrients to make full use of by-products, reduce feed costs, and improve breeding efficiency.

(10) Environmentally friendly feed processing methods

Pelleted feed is more environmentally friendly than bulk feed, and can effectively reduce dust and exhaust gas pollution generated during feed processing, thus avoiding environmental impact.

(11) Broad market prospects

As people’s demand for food safety and health increases, the demand for high-quality, nutritious livestock and poultry products is also increasing. Feed pellet machines have broad market prospects in producing high-quality feed.

(12) Improve production efficiency

The goat feed pellet making machine can realize automated production and greatly improve production efficiency. Moreover, pellet feed also has the advantages of being easy to store and transport, which can reduce labor and time costs.

(13)Optimize the proportion of feed ingredients

The goat feed pellet making machine can accurately control the proportion of feed ingredients according to the needs of different sheep. At the same time, different types of feed can also be mixed and processed to produce feed suitable for various farmed animals.

(14) Improve animal health

Pelleted feed can improve the digestion and absorption capacity of animals, avoid problems such as indigestion and insufficient nutrient absorption caused by too large or too small particles, thereby improving the health of animals.

(15) Promote the development of breeding industry

The use of goat feed pellet making machines can promote the development of the breeding industry, improve the output and quality of livestock and poultry products, increase farmers’ income, promote the development of agricultural modernization, and is of great significance to promoting rural economic development.

(16) Sustainable development

The waste generated during the manufacturing process of pellet feed can be used as fertilizer, used for soil improvement and crop growth, achieving recycling, and has the advantage of sustainable development.

The goat feed pellet making machine plays an indispensable role in the breeding industry and plays an important role in improving breeding efficiency and promoting the sustainable development of the breeding industry. With the continuous advancement of science and technology and the increasing market demand, the prospects of goat feed machines will become increasingly broad.

How to prepare goat feed formula?

The proportioning method of goat feed needs to be prepared according to different seasons, different breeds, different genders, different ages and different uses. Generally speaking, goat feed needs to include ingredients such as roughage, concentrate, minerals and vitamins.

1. The proportioning method of roughage:

- (1) Straw feed: corn straw, double-cropping rice straw, oat straw, etc.

- (2) Grass feed: silage corn, silage beans, etc.

- (3) Hay feed: alfalfa hay, cardamom hay, alfalfa hay, etc.

- (4) Highly nutritious forage: rapeseed meal, soybean meal, corn tortillas, etc.

2. The proportioning method of concentrated feed:

- (1) Cereal feed: oats, corn, wheat, barley, rice, etc.

- (2) Oil feed: rapeseed oil, soybean oil, peanut oil, etc.

- (3) Protein feed: soybean meal, bean cake, rapeseed cake, cotton cake, etc.

- (4) Sugar feed: sugar beet, sweet corn, etc.

3. The ratio of minerals and vitamins:

- (1) Minerals: Calcium, phosphorus and other minerals can be supplemented by adding mineral feed.

- (2) Vitamins: It can be supplemented by adding vitamin feed or adding feed additives.

The above proportioning methods are only basic proportioning methods. In fact, specific proportioning needs to be carried out according to different situations. To ensure that goats receive comprehensive nutrition, they should be guided by professionals.

How to install and debug goat feed making machine?

- Before installation, check whether the dimensions of each installation foundation meet the requirements of the drawings according to the equipment plan and foundation diagram. If there are any discrepancies, they should be repaired until the dimensions are correct before installation.

- The installation personnel should first be familiar with the installation requirements of each sheep feed machine and carry out construction according to the technical requirements.

- Equipment may be deformed, damaged or lost during transportation. Before installation, check and accept the goat feed making machine detailed list, and take corresponding measures to ensure that each equipment is in good condition before installation. Each equipment should be numbered before entering the installation site, and the installation process flow card and schedule should be drawn up.

- According to the requirements of the installation process sequence, the goat feed machines should be transferred to the site one by one for installation. The installation sequence is from top to bottom. After the host equipment and rack are in place, the connecting pipes and electrical equipment are installed.

- The tools, equipment and materials required for installation must be available. After installation, each rotating part of the goat feed making machine must rotate flexibly without jamming, bumping or impacting sounds. Each connecting part must be firm and sealed, and there must be no powder leakage, air leakage, oil leakage, etc.

- The installation of electrical equipment should comply with relevant national regulations. The lines should be clearly routed and there should be no power leakage or leakage. Wires and cables should have protective shells.

- After the installation is completed, each single goat feed machine should be put into empty test operation. Only when the operation is normal can it be put into load test operation.

- Before load test, the electronic batching scale and packaging scale must be calibrated to meet the specified accuracy. After 8 hours of load operation and no faults, it can be handed over to the goat feed factory for production use.

How to operate and use goat feed making machine?

In order to ensure the normal operation of the complete set of goat feed machine, extend its service life, reduce failures, and improve economic benefits, attention should be paid to its correct use.

Before driving, the goat feed mill equipment will be inspected by the personnel on duty at each position.

- Whether there are any foreign objects falling into the equipment;

- Whether the rotating parts are flexible, whether they are stuck or bumped;

- Whether the connecting parts are firm; whether there are powder leaks, air leaks, oil leaks, etc. If there is a fault, it should be eliminated in time.

- Whether there is lubricating oil in each gear; whether the tension of the transmission belt is appropriate;

- Whether the pulverizer hammer, goat feed pellet making machine die and pressure roller need to be replaced;

- Whether the screen specifications meet the requirements.

The personnel on duty in the control room should know the daily production schedule and the storage volume of main and auxiliary materials in order to schedule production.

- The operation sequence is to first turn on the main power switch, and then place each system switch to the working position.

- Turn on the audio signal switch to notify all staff to enter their work stations.

- After completing all preparations, the person on duty in the control room determines the entry number of each material, assigns each three-way valve to the corresponding position, starts the dust removal fan first, and then turns on the switches according to the processing process sequence.

The starting sequence of the raw material system is dust removal fan → crushing elevator → horizontal conveyor → raw material crusher → cleaning screen → raw material elevator. If the raw material system is shut down, the reverse process of starting it should be followed. The stop and start of the auxiliary material system is roughly the same as that of the raw grain system.

The batching and mixing system has two control modes: manual and automatic. In the manual mode, manual batching can be carried out according to the predetermined formula and mixing time. In the automatic mode, a computer can be used to control automatic weighing, batching and mixing time. The goat feed pellet making machine system is operated and started by a special control cabinet.

The personnel on duty in the control room should always pay attention to the various signal lights on the simulation screen. If the batching warehouse sends out an empty or full signal, the relevant loading personnel should be notified in time and operate the warehouse gate. Staff should follow production arrangements, call out and enter the required material formulas, and operate computers and their auxiliary devices correctly.

When operating the feeding device of the goat feed pulverizer and goat feed pellet making machine, ensure that the main motor operates at rated current and does not cause blockage. Various trace elements, vitamins, etc. are put in proportionally from the additive inlet of the mixer. The goat feed mixer mixes one batch of materials and feeds once. The input time is given by the control room when each batch of materials just starts to be mixed.

How to maintain and repair goat feed making machine?

- Carry out maintenance and upkeep according to the requirements of each equipment instruction manual. If there are no special requirements, ZG-3 calcium-based lubricating oil is used for the bearings, and HJ-60 mechanical oil is used for the reducer lubricating oil. In winter, if the room temperature is lower than -10℃, HJ-20 mechanical oil is used.

- The goat sheep feed making machine should undergo minor repairs once within half a year and major repairs once within a year. During minor repairs, the lubricating oil should be replaced, the bearings should be cleaned, damaged parts should be replaced, and the belt tightness should be adjusted in a timely manner. When the machine is running, the belt must not have serious slippage.

- Consumable parts such as the hammer and screen of the pulverizer, the die and roller of the goat feed pellet making machine system should be repaired, adjusted and replaced in a timely manner. The time for replacement, maintenance and adjustment depends on the productivity or product quality of the feed processing products.

- Generally, when the productivity drops significantly and the pellet forming rate and surface quality fail to meet the requirements, timely adjustments or replacements should be made.

- After the hammer blades of the pulverizer are worn, they must be reversed or turned around. When turning around, the original arrangement of the hammer blades must be maintained.

- When all four corners are worn and new hammers need to be replaced, each set of new hammers must be weighed. The weight difference of each set of hammers must not exceed 5 grams.

- During installation, the hammers must be assembled according to the hammer arrangement diagram to avoid crushing the crusher. After half a year of use, the accuracy of the electronic scale needs to be checked and calibrated.

- After each shift, bean cake powder should be used to flush out the residue in the die holes in the pellet machine cavity. The computer control room is always kept clean and quiet.

How to choose best goat feed pellet making machine? How to make goat feed pellets? How to make pellets for goats? are timothy pellets good for goats? What are goat pellets made of? what pellets are best for goats? What equipment is needed to process sheep fermented feed pellets? What type of feed pellet machine does a 3-ton sheep feed factory need? ..Maybe you have more questions.

Whether you need a single goat sheep feed pellet machine or a complete set goat feed making machine, contact Richi Machinery to get a complete sheep and goat feed production line process plan, goat feed pellet making machine prices and other auxiliary equipment quotations!