broiler feed mill

The broiler feed mill is a kind of chicken feed system for processing broiler feed at different growth stages. It uses various broiler feed making machine and broiler chicken feed manufacturing technologies to make various types of broiler feed from various feed ingredients in certain proportions.

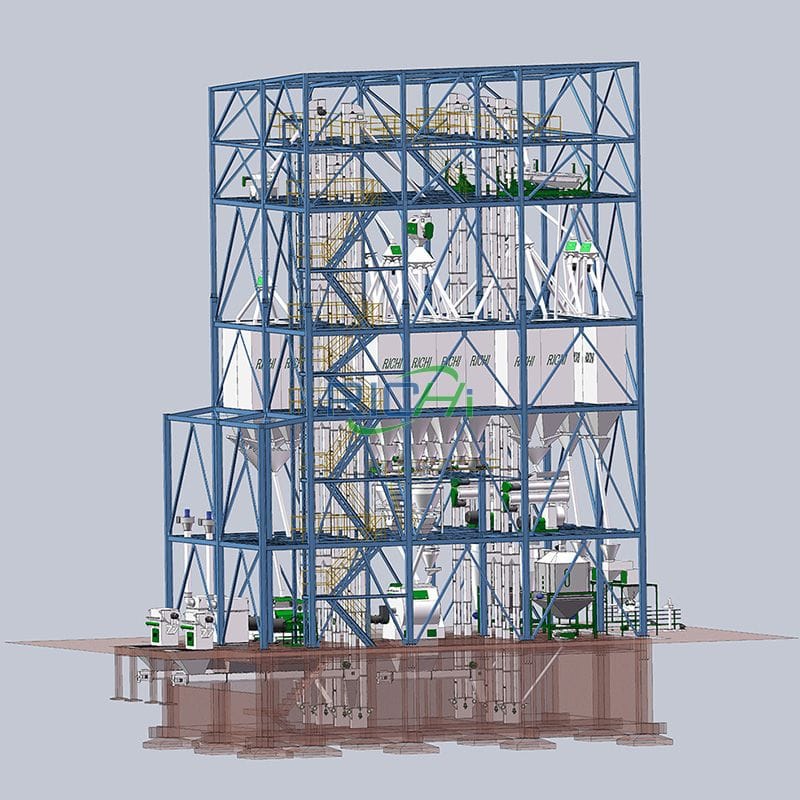

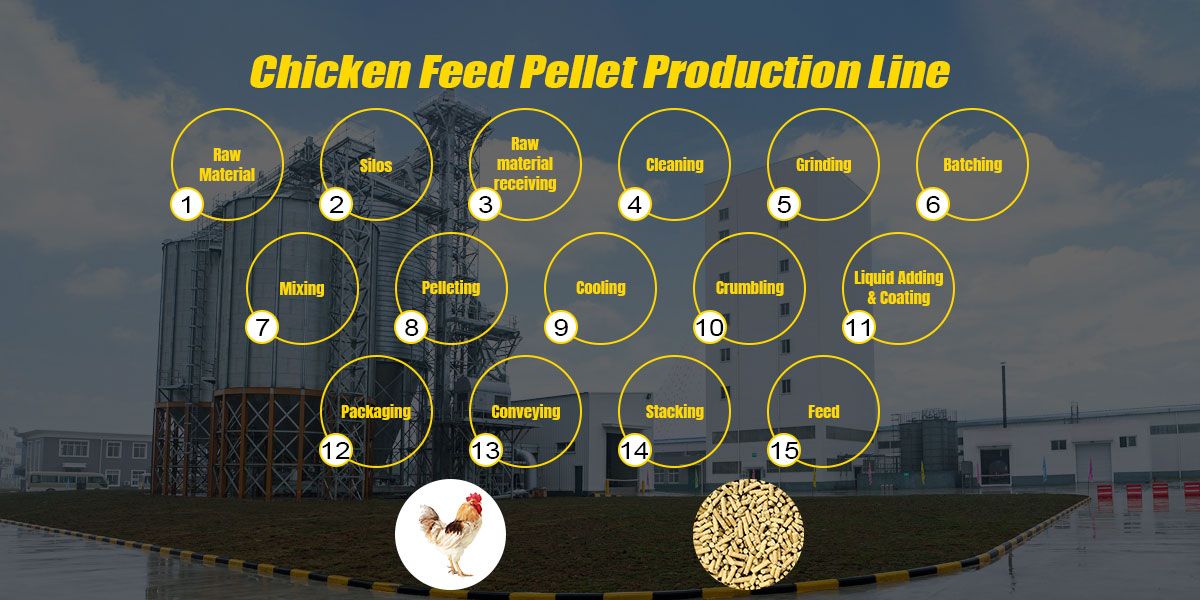

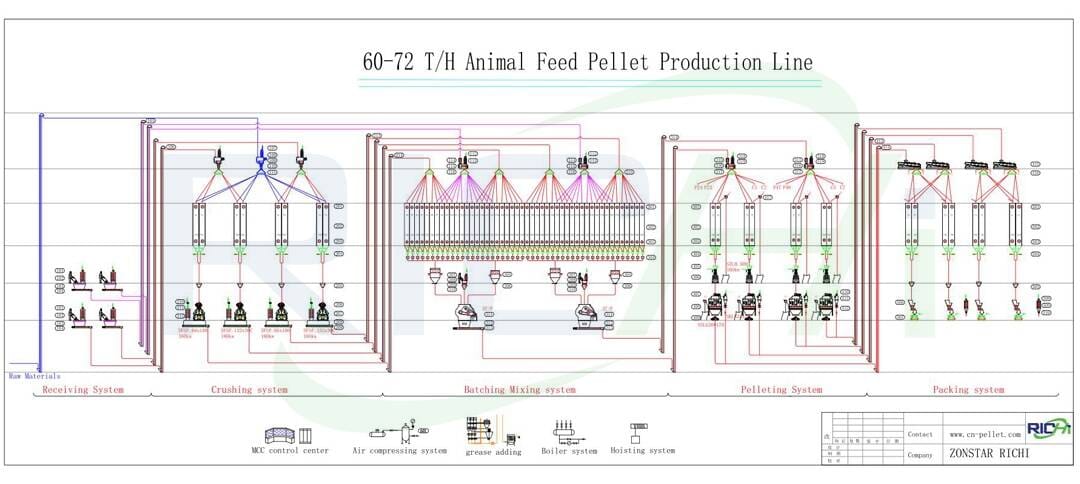

The broiler feed mill mainly includes six major sections including raw material receiving and cleaning, crushing, batching, mixing, granulation and finished product packaging. It also includes auxiliary systems such as air compression, microcomputer electronic control and dust removal.

The broiler feed production line has a wide range of applications. It is not only used for broiler feed processing, but also for the processing of poultry feed such as laying hens, meat ducks, laying ducks, and geese. A complete broiler feed mill plant can pellet a variety of raw materials, which is economical and practical.

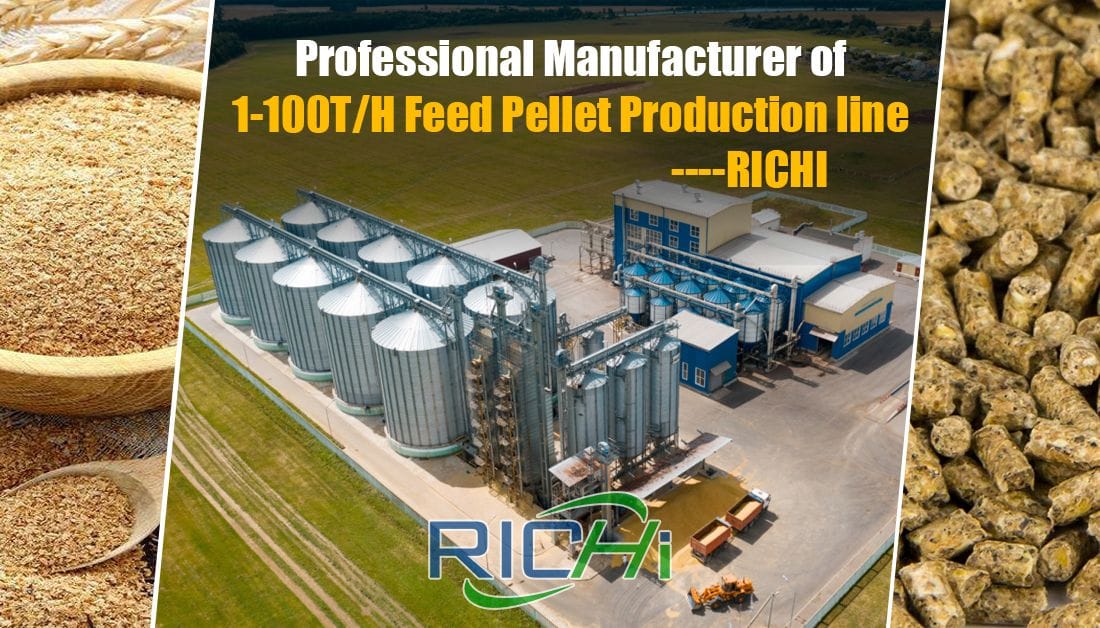

- Capacity: 1-160T/H

- Price: 10,000-5,000,000 USD

- Feed Type: broiler pellet feed, broiler mash feed, broiler premix feed

- Feed Size: 2-6mm pellets & powder

- Suitable broiler type: broiler chickens in brooding, growing and fattening periods

- Applicable customers: broiler feed manufacturers, broiler feed industry investors, broiler farms

broiler feed mill types

According to the different nutrients contained in the broiler feed, it can be divided into energy feed, protein feed, mineral feed, green feed, roughage, vitamin feed and feed additives. By nutritional content, the types of broiler chicken feed mill plants we can provide are:

broiler compound feed mill

It can produce compound broiler feed composed of protein feed, energy feed, roughage and additives in a certain proportion. Compound feed can meet the various nutritional needs and has high economic benefits. It is most used in chicken breeding, includes pellet feed, mash feed, crumbles feed.

broiler Premix feed mill

Used to manufacture broiler premix feed. The premix is mixed with various nutritional and non-nutritional additive carriers and can be used to produce concentrated feed and complete feed. The general addition amount is 0.5% to 5%. you can check our premix feed mill solution directly.

broiler Concentrated feed mill

Concentrated feed is made of protein feed, mineral feed and additive premix in accordance with specified requirements. Generally, it contains more than 30% protein, accounting for 30% to 40% of the complete compound feed. This feed cannot be fed directly to chickens.

Advantages of broiler feed mill

After several years of development and research, RICHI has designed a complete broiler feed plant by matching the advanced ring-die broiler feed pellet machine with other series of products.

- The production speed of RCIHI broiler feed processing plant is relatively fast, the production efficiency is very high, and it can quickly provide a large amount of products to the market.

- Integrating a complete set of broiler feed production processes, a variety of processes and systems can be arranged on the feed mill to meet production needs.

- RICHI broiler feed mill can make feed production more coherent, parallel and balanced.

- High scalability, broiler feed plants can be designed to meet the production needs of feed products according to customer needs.

- Save factory production costs, save the number of production workers, and achieve a certain degree of automated production. The initial investment for medium and small-volume feed mills is small and the return rate is high.

- The broiler feed making plant uses professional feed technology and broiler feed machine to achieve mechanized operation, which can greatly improve production efficiency, shorten the feed production cycle, speed up product output, thereby speeding up the broiler feed company’s capital flow and reducing the broiler feed company’s costs.

If you are interested in broiler chicken feed manufacturing, feed free to contact Richi Machinery for more information: feed mill cost, equipment list, process design, broiler starter feed ingredients, broiler feed formulation, etc.

how to make broiler feed? ——broiler feed mill process

The following takes the most commonly used broiler feed pellet process as an example to briefly describe “how to make chicken feed for broilers”.

01 Receiving of raw materials

- Receiving of bulk raw materials: If transported by bulk trucks or trains, the raw materials should be weighed by a dump truck and then unloaded to the unloading pit.

- Receiving of packaging raw materials: divided into two types: manual handling and mechanical receiving.

- Receiving of liquid raw materials: Bottled and bottled materials can be directly transported into the warehouse manually.

02 Cleaning raw materials

Impurities in feed raw materials not only affect the quality of feed products but are also directly related to broiler feed machines and personal safety. In severe cases, the entire equipment may be damaged and affect the smooth progress of broiler feed production, so they should be removed in time.

The cleaning equipment of the broiler feed mill is mainly screening and magnetic separation equipment. The screening equipment removes large and long impurities such as stones, mud blocks, and sacks in the raw materials, and the magnetic separation equipment mainly removes iron impurities.

03 Crushing raw materials

The process flow of feed crushing is determined according to the required particle size, type of feed and other conditions. According to the number of times of raw material crushing, it can be divided into primary crushing process, circulating crushing process or secondary crushing process.

According to the combination form with the batching process, it can be divided into batching first and then crushing process and first crushing and then batching process.

04 Ingredients process

Currently commonly used technological processes include manual addition of ingredients, volumetric ingredients, ingredients with one warehouse and one scale, ingredients with multiple warehouses and several scales, ingredients with multiple warehouses and one scale, etc.

05 Mixing process

Batch mixing is to mix various mixing components together according to the proportion of the formula, and send them to the “batch mixer” that works periodically for mixing in batches. This mixing method is more convenient to change the broiler chicken feed recipe. There is less mixing between them, and it is a commonly used mixing process at present. The opening and closing operations are relatively frequent, so most of them adopt automatic program control.

The continuous mixing process is to continuously measure various feed components separately and at the same time, and mix them into a stream containing various components in proportion. When this stream enters the continuous mixer, it is continuously mixed to form a uniform stream. Material flow, the advantage of this process is that it can be carried out continuously.

06 Conditioning process

Conditioning and tempering is the most important step in the granulation process. The quality of conditioning directly determines the quality of broiler pellet feed. The purpose of conditioning is to condition the mixed dry powder into powdered feed with a certain moisture and humidity that is conducive to pelleting.

Currently, most broiler feed mills complete the conditioning process by adding steam.

07 Granulation process

The uniformly tempered material first passes through the security magnet to remove impurities, and then is evenly distributed between the pressure mixer and the die.

In this way, the material enters the pelleting area from the compression area of the feed area, and is continuously squeezed out by the pressure roller clamp into the die hole. The feed is divided into columnar shapes, and as the die rotates, it is cut into pellets by a cutter fixed outside the die.

08 Cooling process

During the broiler feed pelleting process, due to the introduction of high-temperature, high-humidity steam and the extrusion of the material, a large amount of heat is generated.

As a result, when the pellet feed just comes out of the broiler chicken feed pellet machine, the moisture content reaches 16%-18% and the temperature reaches as high as 75 ℃ -85 ℃, under these conditions, the pellet feed is easily deformed and broken, and will also cause sticking and mildew during storage.

The moisture must be reduced to less than 14%, and the temperature must be reduced to less than 8 ℃ higher than the air temperature, which requires cooling.

09 Crumbling process

In the production process of the pellet machine, in order to save electricity, increase output, and improve quality, the finished pellets are often first made into small pellets of a certain size, and then crumbled into qualified products by a pellet crumbler according to the particle size for broiler feeding.

10 Screening process

After the pellet feed is crumbled, some powder clumps and other unqualified pellets will be produced. Therefore, the crumbled pellet feed needs to be screened into products with neat pellets and uniform size.

11 Packaging process

The finished product section is the last section of the broiler feed making process, which completes the storage, packaging, and transportation of finished feed. The traditional finished product section consists of a cache warehouse, packaging scales, dust removal air nets, etc., and mainly packages, preserves and sells finished feed in bags.

If you want to process other types of broiler feed, please contact us directly online to get the corresponding animal feed mill plant solutions and full broiler feed mill quotation!

broiler feed mill Equipment

The broiler feed making machine used in the broiler feed line has high performance and incorporates advanced technology. It can configure a variety of production plans according to different production needs, and its functions and performance can meet the needs of users.

broiler Feed Grinder machine

Capacity:

3-25 T/H

Main Power:

30-160 KW

broiler Feed Mixer machine

Capacity:

250-2000 KG

Main Power:

4-55 KW

broiler Feed Extruder

Capacity:

1-12 T/H

Main Power:

0.75-355 KW

broiler feed mill projects

1-2T/H broiler feed mill in Nigeria

- Date: June 30, 2020

- Feed type: broiler & layer feed

- Project cost: 25,000-29,000 USD

15-20T/H broiler feed mill in Vietnam

- Date: December 2020

- Feed type: broiler & pig feed

- Project cost: 500,000 USD

5-7 t/h broiler feed mill in Zimbabwe

- date: 2022.06.09

- Feed type: broiler pellet feed

- Project cost: 97160 USD

10T/H broiler feed mill in the Philippines

- Project date: 2018.09.13

- Feed type: pig & broiler feed

- Project price: 460,000 USD

10-15T/H broiler feed mill in Uzbekistan

- Date: July 6th, 2019

- Feed type: broiler & hen feed

- broiler feed mill cost: 150,000-400,000 USD

6-10T/H broiler feed mill in Algeria

- Date: Sep 21th, 2015

- Feed type: broiler & hen feed

- broiler feed mill cost:80,000-400,000 USD

3-5T/H broiler feed mill In Malaysia

- Date: October 29, 2021

- Feed type: broiler feed

- broiler feed mill cost: 60,000-65,000 USD

5T/H broiler feed mill In Peru

- Date: February 2021

- Feed type: broiler pellet & mash feed

- broiler feed mill cost: 220,000-250,000 USD

5 T/H broiler feed production line In El Salvador

- date: 2022. 09.13

- Feed type: broiler premix

- cost: 480,000 USD

10 T/H broiler feed production line In Thailand

- date: 2021. 07. 22

- Feed type: broiler premix

- cost: 120,000 USD

50T/H broiler feed production line in russia

- Date: June 2019

- Feed type: broiler & ruminant feed

- cost: 960,000USD

30T/H broiler feed production line in Kazakhstan

- Date: December 2018

- Feed type: broiler & stock feed

- cost: 1,250,000 USD

5 t/h broiler feed plant in Argentina

- Project date: 2021.10.11

- Feed type: broiler & cow feed

- broiler feed mill cost: 184500USD

5-10 t/h broiler feed plant in Ethiopia

- Project date: 2022.10.14

- Feed type: broiler & goat feed

- broiler feed mill cost: 131820 USD

15 T/H broiler feed plant In Egypt

- Project date: 2022.06.30

- Feed type: broiler & fish feed

- broiler feed mill cost: 159070 USD

20T/H broiler feed plant in USA

- Project date: 2019.05.10

- Feed type: broiler & cattle pellet feed

- broiler feed mill cost: 550000 USD

broiler feed mill Videos

broiler feed mill price

How much does a broiler feed mill cost? Here are the price ranges available to you:

- 1-2 t/h broiler feed mill cost: 10000-50000 USD

- 3-4 t/h broiler feed mill cost: 50000-120000 USD

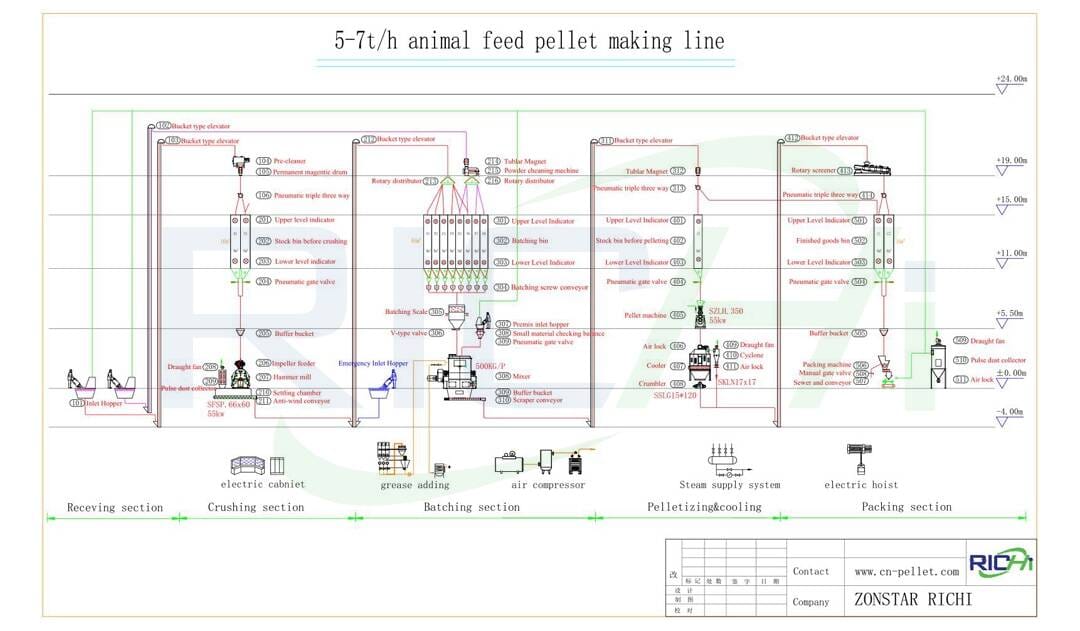

- 5-7 t/h broiler feed mill cost: 70000-250000 USD

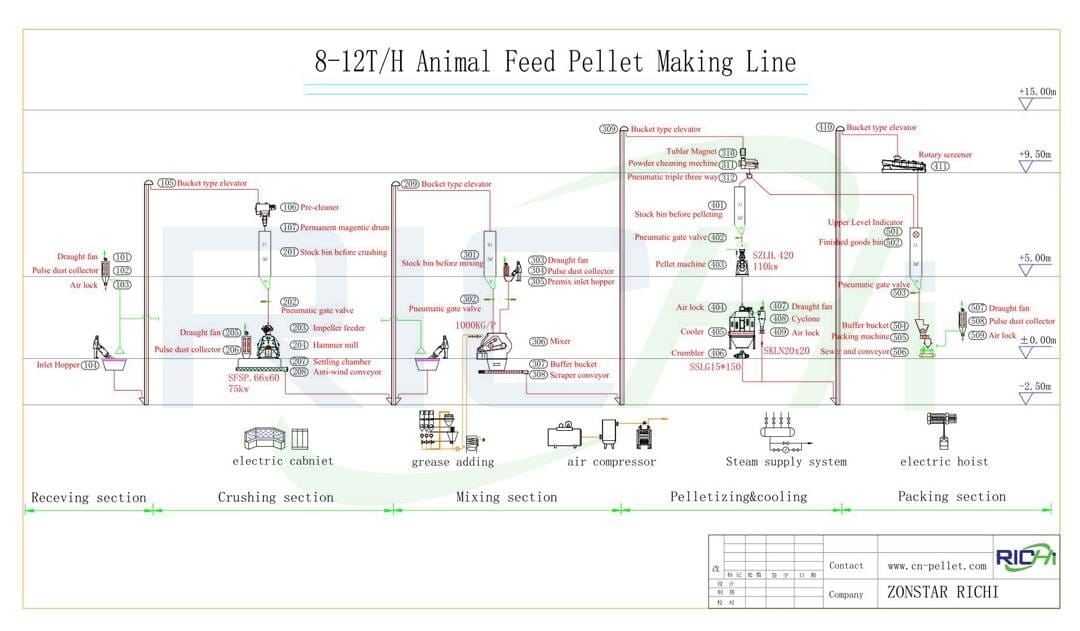

- 8-10 t/h broiler feed mill cost: 150000-300000 USD

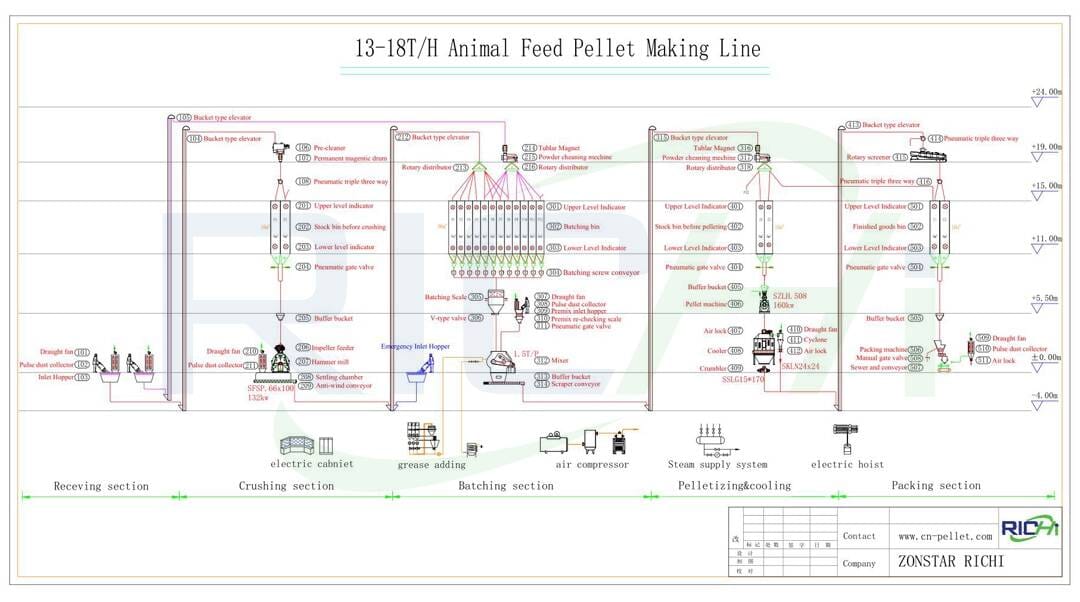

- 12-20 t/h broiler feed mill cost: 250000-580000 USD

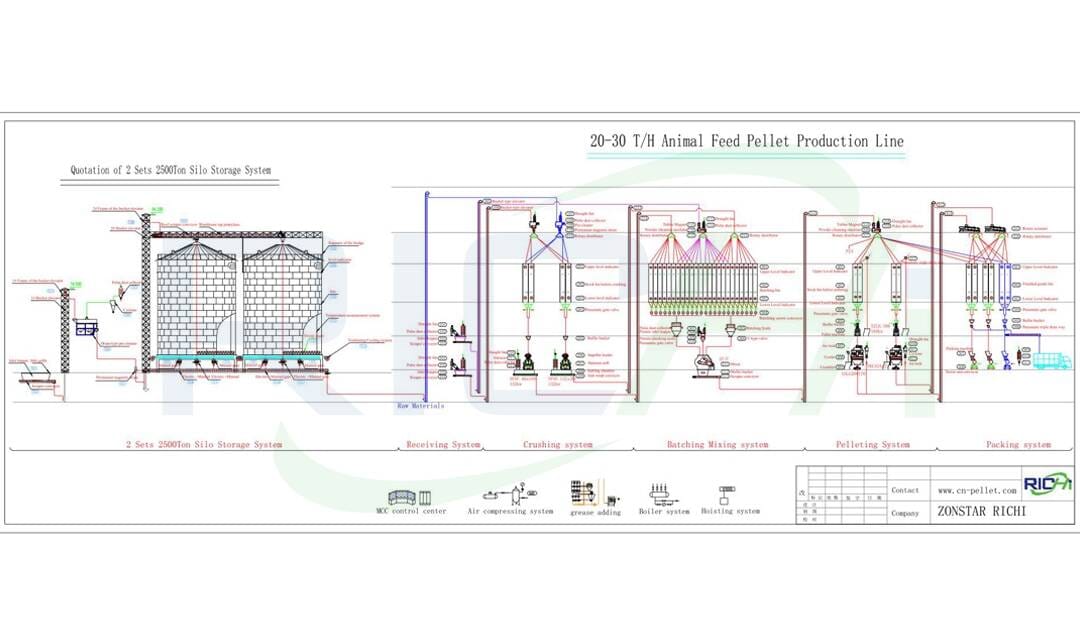

- 25-40 t/h broiler feed mill cost: 450000-850000 USD

- 50-60 t/h broiler feed mill cost: 900000-1400000 USD

- 60-80 t/h broiler feed mill cost: 1450000-1800000 USD

- 80-100 t/h broiler feed mill cost: 2000000-2800000 USD

The above are just the prices of broiler feed mill machines.

If you want to open a broiler feed plant, you need to consider more factors, including equipment, space, raw materials, labor, etc. Therefore, the investment costs of feed mills will vary by region and size.

- Equipment is the main factor in the cost of feed processing plants. You need to purchase equipment such as crushers, mixers, and packaging machines.

- Cinderella placement is also an important factor in cost. You need a site large enough to store equipment and ingredients, and enough space to operate the equipment. The rental or purchase price of a venue varies by region.

- You also need to purchase raw materials, such as corn, soybean meal, fish meal, etc. The prices of these raw materials also vary based on market fluctuations.

- You also need to consider labor costs. You need to hire workers to operate equipment, move ingredients, package products, etc.

In summary, the cost of starting a broiler feed mill depends on your region and the size of your broiler animal feed production line. Before making a decision, it is recommended that you conduct detailed research and planning to determine the best cost budget and profit model.

Custom broiler feed mill design with different scale

RICHI poultry feed production line is mainly determined based on raw materials and formulas, and customer requirements for products. According to different production site conditions, we can provide customers with detailed process plans and technical support, and can also design according to the customer’s actual installation conditions. Non-standard supporting parts, etc.

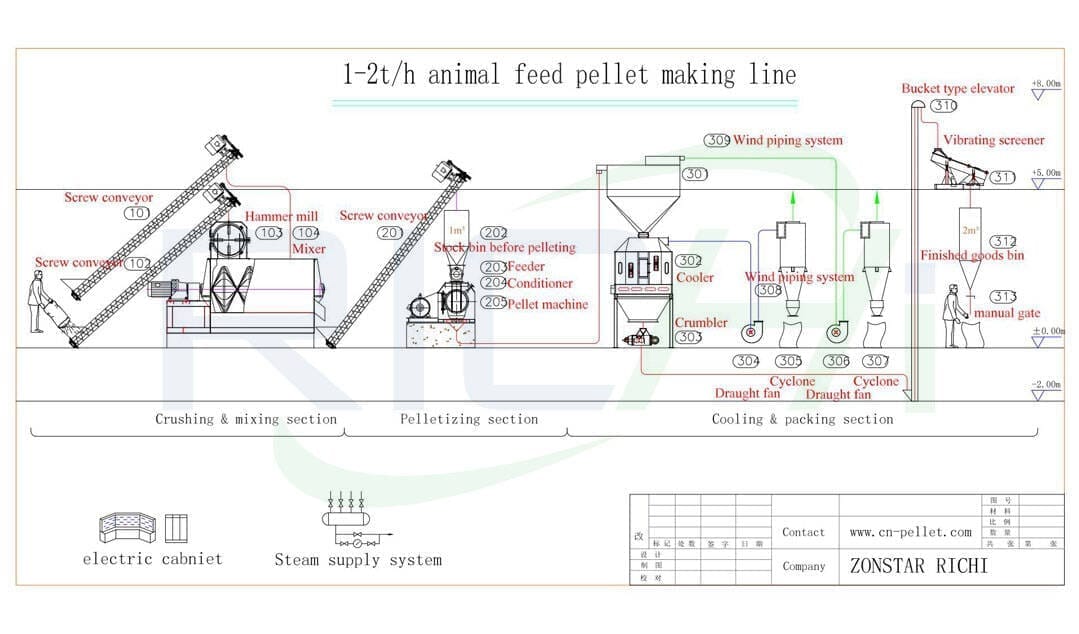

1-2 t/h broiler feed mill plant design

This 1-2 t/h broiler feed pellet line is suitable for processing various animal feed pellets, such as poultry feed, ruminant feed, livestock feed, pig feed, cattle feed, sheep feed, goat feed, fish feed, shrimp feed, crab feed , aquatic feed, etc. The main equipment of this broiler feed line is a hammer mill crusher, a poultry feed pellet making machine, feed mixer, etc.

5T/H broiler feed mill Plant Design

The 5t/h broiler feed processing line plays for feed industry to produce pellet or powder feed for aqua, livestock and poultry. Apply to small feed factory and large farms. Can make pellets for kinds of poultry animals. the final pellets is 2-4mm.

10 t/h broiler feed mill Plant Design

The 10t/h broiler feed plant can help you produce top quality feed and to make economical use of your raw materials and energy. As a technology partner with long-lasting experience in the industry, RICHI support you in every aspect of the production of reliable broiler feed.

15 t/h broiler feed mill Plant Design

Our 15t/h broiler feed making plants are available in various models and with optional accessories to offer the optimum solution for your specific production needs. RICHI designs and manufactures all key broiler poultry feed mill equipment and offers complete solutions to the global broiler industry.

30 t/h broiler feed mill Plant Design

Our chicken feed mill plants are of modular design and are designed based on different feed requirements and customer needs. Due to innovative machinery and deep process knowledge, our animal feed mill equipment are the best choice for broiler feed millers to produce high quality, safe feed to their client maximum efficiency.

60T/h broiler feed mill Plant Design

The technology underlying our poultry feed plants meeting the most rigorous hygiene requirements, and mitigating cross-contamination at the same time. We contract to design and build complete broiler feed processing plant 1-120t/h for a wide range of poultry broiler animal species.

Richi Machinery can provide the broiler feed mill project design, flow chart, feed-making machine, the project installation and commission, your staff training, after-sales service, etc. Also, our professional install team will serve you if you need it.

Broiler feed production quality control

During the operation of broiler poultry feed production line, there are some quality control points:

01 Batching system

The procedures that affect the accuracy of ingredients include: loading, adding small ingredients, adding grease, adding liquid, packaging, labeling, etc.

02 Particle quality

The physical quality of pellets is important in optimizing feed intake and growth in modern broiler chickens. If the feed is too small or too large (length and diameter) or too hard, spitting can occur. The general diameter is 3mm, with crushed materials used in the early stage, and the length in the middle and later stages is 4 mm.

Large grain pellets are good for intestinal health but bad for pelleting quality. Pelleting temperatures above 85°C will destroy nutrients. Good pelleting is important for pellet quality but will dissolve non-starch polysaccharides.

03 Quality of small ingredients (premix)

Adequate amounts of vitamins and minerals are critical for broiler chicken growth. The quality of vitamins (activity, stability, expiration date), minerals (activity, contaminants), and organic minerals are best purchased from professional premix manufacturers to ensure that they are added correctly (one batch to One batch, password confirmation).

How to build a new broiler feed mill?

01 Determine the processing scale of the broiler feed mill

Based on the ingredient mixing system:

Single shift production: The mixing volume of each batch of the mixer (tons/batch) × batch number/hour × 8 hours × 250 days = annual shift production

02 Determine the feed processing technology and select related equipment

- Product variety, quality, and output requirements;

- Broiler feed formulations;

- Broiler feed production processes and broiler feed equipment;

- Equipment performance and quality;

- Equipment cleaning and maintenance;

- Production costs and usage costs;

- Standardization, serialization, and parts universalization;

- Broiler feed mill project construction space;

- Environmental protection, fire protection and other national mandatory requirements;

- …

03 Selection of control mode

The size of the chicken feed mill production capacity, the complexity of the process, and the number of product varieties.

04 Selection of factory structure form

Full concrete structure, semi-steel structure, full steel structure, sliding form structure.

05 Plan the general layout of the factory area

Factors to consider: Logistics distance, safety regulations, avoidance of mutual interference, factory center of gravity, visual effects.

The overall layout of the broiler feed pellet plant varies according to the production nature, scale and process flow of the broiler pellet feed plant. Buildings should account for 30-35% of the total factory area; factory roads account for 13% of the total area; greening area should be no less than 10-15% of the entire factory area.

Why invest in broiler feed production business?

The poultry broiler sector is one of the significantly growing meat sectors.

Due to strong economic growth, factors such as population growth, disposal income growth, increasing broiler chicken feed, and changes in consumer dietary preferences are influencing global per capita consumption of poultry meat. These factors are expected to fuel the poultry broiler feed market growth during the forecast period.

Global Broilers Feed Market size was valued at USD 117.78 billion in 2021 and is poised to grow from USD 125.2 billion in 2022 to USD 204.11 billion by 2030, growing at a CAGR of 6.30% in the forecast period (2023-2030).

RICHI service

RICHI supplies broiler feed making machines and complete broiler feed mill factories for the sustainable production of compound feed and premixes to broiler feed mills. We offer you the certainty of an investment that provides maximum added value.

- Based on thorough process knowledge and our extensive experience, we define with you the optimal solution.

- Together with you we reach concrete agreements on performance of broiler feed mill machines and installations with process control.

- We guarantee excellent quality and reliable broiler feed mill machines with a long lifetime and high performance by combining full expertise in all disciplines under one roof.

- A careful approach and cooperation with you are important for us. We coordinate the entire project, from concept to completion – with our own people.

- We find knowledge sharing and continuous innovation of great importance in order to realize maximum performance and even better solutions, now and in the future.

FAQs of broiler feed mill

How to choose broiler feed mill equipment that suits you?

Broiler feed mill equipment is an important way for broiler feed mills to enter the poultry feed processing industry. However, how to choose a suitable broiler feed production line is a problem faced by many entrepreneurs.

1. Consider your actual situation

Before choosing broiler feed mill equipment, you need to consider your actual situation, including investment capital, production scale, market demand, etc. According to your actual situation, choose the broiler feed line that suits you.

2. Consider the quality and performance of the equipment

When choosing broiler feed mill equipment that suits you, you need to consider the quality and performance of the equipment. The quality of equipment is an important guarantee for ensuring production quality, and the performance of equipment is directly related to production efficiency and cost.

Therefore, when selecting broiler feed making equipment, you must carefully check the equipment parameters, quality certificates and other relevant certificates to understand the equipment’s production efficiency, performance, stability and ease of maintenance.

3. Consider the feed mill manufacturer’s reputation and after-sales service

When choosing broiler feed mill equipment, the manufacturer’s reputation and after-sales service are also important factors to consider. The reputation of a manufacturer can be examined from its historical experience, product quality, customer reviews, etc.

After-sales service refers to whether you can get timely and effective technical support and solutions when there is a problem with the equipment. Therefore, when choosing a manufacturer, you must consider the manufacturer’s service capabilities and after-sales guarantee.

4. Consider the production process and formula

Broiler feed mill equipment need to formulate different feed formulas according to different types of broiler poultry. Therefore, when selecting a broiler feed making line, you need to consider the feed production process and formula.

Choose a broiler feed production line that can meet your own production needs, and adjust the formula according to your own needs, so as to better adapt to market demand.

5. Consider the degree of automation of the production process

With the development of science and technology, broiler feed mills are constantly developing towards digitalization, intelligence and automation. Choosing a broiler feed mill solution with a certain degree of automation can improve production efficiency, reduce production costs, and improve product quality, thereby better adapting to market demand.

6. Consider equipment quality and after-sales service

When choosing broiler feed mill equipment, you need to pay attention to the quality and after-sales service of the equipment. High-quality equipment can improve production efficiency, reduce production costs, improve product quality, and also reduce equipment failure rates and maintenance costs.

When choosing an equipment supplier, you need to understand the quality of its after-sales service and whether it can respond and solve equipment failures in a timely manner.

7. Consider the price and cost-effectiveness of the feed equipment

The prices of broiler feed mill equipment vary greatly, and you need to choose the equipment that suits you according to your own economic strength. At the same time, it is also necessary to consider the cost-effectiveness of the equipment, that is, the ratio of equipment price to performance.

Choosing cost-effective equipment can improve the efficiency of the equipment and better adapt to market demand.

8. Consider equipment scalability and adaptability

When selecting broiler feed mill equipment, you also need to consider the scalability and adaptability of the equipment. That is, whether the equipment can meet its future production needs and adapt to changes in market demand. Choosing equipment with good scalability and adaptability can reduce the cost and risk of future equipment updates and upgrades.

9. Consider the energy saving and environmental protection of equipment

The energy saving and environmental protection of broiler feed mill equipment are also factors that need to be considered when selecting equipment. Choosing energy-saving equipment can reduce production costs while reducing energy consumption and environmental pollution.

Choosing environmentally friendly equipment can avoid negative impacts on the environment and improve the social image and reputation of your company.

10. Consider the reliability and safety of equipment

Finally, when choosing broiler feed mill equipment, you need to consider the reliability and safety of the equipment. Choosing equipment with good reliability and safety can reduce the risk of production accidents and the probability of equipment failure, while ensuring the safety and stability of the broiler feed production process.

How long does it take to build a broiler feed mill?

The time required to build a broiler feed mill varies depending on the specific situation and mainly depends on the following factors:

1. Factory construction scale and purpose:

The larger the feed factory construction scale, the longer the construction time will be. However, reducing the scale of construction will not necessarily shorten the construction time, because the size of the plant is related to the installation of its equipment and is closely related to the engineer’s construction plan. The purpose of the factory building is also a factor that affects the construction time.

2. Design of architectural and civil structures:

The design and preparation of architectural and civil structures takes a lot of time. Therefore, the construction time of a broiler feed mill project is usually calculated based on site selection and preparation of the site. During this time, the design of the building and civil works was factored into discussions of many issues, including local government regulations and special requirements required for the project.

3. Equipment manufacturing and installation:

During the construction of the broiler feed mill, a large number of broiler feed mill equipment needs to be manufactured and installed, such as crushers, conveyors, mixers, etc., which require time and professional manufacturing skills. Therefore, equipment manufacturing and installation can take several months.

4. Local government approval:

In some areas, the construction of broiler feed mills requires local government approval. Approval may take several months or longer. To sum up, taking the above factors into consideration, it usually takes 6 months to a year to build a standard size broiler feed mill.

Crushing first and then batching vs. batching first and then crushing, which one is better for broiler feed mill?

Compound broiler feed is a mixture composed of a variety of raw materials (including additives) evenly mixed according to animal feeding standards and the nutritional characteristics of the raw materials.

Internationally, the production technology of broiler feed mill is generally divided into two categories: one is the process of crushing first and then batching; the other is the process of batching first and then crushing.

(1) Crushing first and then batching processing technology

The first crushing and then batching processing technology is to crush the raw materials to be crushed into powder one by one through the crushing equipment, and then enter their respective intermediate batching bins according to the proportion of the feed formula.

After measuring these powdery raw materials one by one, they enter the mixing equipment for mixing. After thorough mixing, the powdered compound feed will be formed. If it needs to be formed, it will enter the granulation system and be processed into granules.

The characteristics of the process are: this process adopts computer-controlled production, and the ingredients, mixing process and pre-mixing process need to be carried out according to the formula and production procedures; it is mostly used for large-scale broiler feed mill production, high proportion requirements and mixing uniformity, and many types of raw materials.

(2) Processing technology of batching first and then crushing

The first mixing and then crushing processing technology first mixes various raw materials (excluding vitamins and trace elements) together according to the ratio of the pet food formula using a metering method, and then crushes them.

The crushed powder enters the mixing equipment for batch processing. Mix continuously, and add diluted vitamins, trace elements and other additives at the beginning of mixing. After mixing evenly, it will be powdered pet food.

If the powdered compound feed needs to be pressed into pellet feed, the powdered feed will be conditioned with steam, heated to soften, and then entered into a broiler pelletizer for granulation, and then cooled and pelletized to become broiler feed.

The characteristics of the process are: the raw material warehouse is also an ingredient warehouse, reducing investment; no more warehouses are needed, and it can adapt to changes in material types; the working condition of the feed crusher will directly affect the work of the entire plant.

Advantages and disadvantages of the two processes

1. Crushing first and then batching process

- Advantages: When crushing a single type of feed, the crusher can give full play to its crushing efficiency, reduce power consumption, increase output, and reduce production costs according to the physical characteristics of pet food. The screen or air volume of the crusher can also be adjusted according to different particle size requirements. Selection and replacement can achieve the best particle size quality of powdered compound feed.

- Disadvantages: It requires more batching bins, inlet and outlet control valves, arch breaking and other vibration devices, so the production process is complex and the broiler feed mill construction investment is large; when more than three types of feed need to be crushed, multiple crushers must be used, otherwise will cause the crusher to frequently change varieties, operate frequently, have large load changes, low production efficiency, and high power consumption.

2. First batching and then crushing process

- Advantages: simple process flow, compact structure, low investment, and energy saving. The raw material warehouse is the batching warehouse, thus eliminating the need for intermediate batching warehouses and intermediate control equipment.

- Disadvantages: Part of the crushed feed needs to be crushed, resulting in too fine particles, which affects the output of the crusher and wastes electricity.

Generally speaking, both methods are used by broiler feed mill factories, and ultimately it depends on your needs, raw materials, formula, and whether there is a special process. (Find RICHI on YouTube)

What should you pay attention to when installing complete sets broiler feed mill equipment?

The installation process of broiler feed mill equipment is crucial to the normal operation of the equipment. The following are things to note when installing:

- Site selection: Choose a flat, well-ventilated site that is convenient for broiler feed equipment installation and maintenance. Make sure the installation location has enough space and complies with relevant safety regulations.

- Equipment placement: According to the actual layout requirements of the equipment, place each equipment reasonably to ensure ventilation and maintenance space between the equipment, and pay attention to the convenient connection between the equipment.

- Accurate measurement: Carry out precise measurements and markings to determine the location, connection points and layout of the broiler feed making equipment to ensure that the location of the equipment is accurate and meets the design requirements.

- Equipment fixation: Fix the equipment as required to ensure that the broiler feed plant equipment does not cause shaking or instability during operation, thereby affecting the normal operation of the equipment.

- Electrical layout: Carry out electrical wiring according to the electrical layout diagram of the equipment to ensure safety and reliability, while complying with relevant electrical specifications and safe operating procedures.

- Equipment balance: During the installation process, special attention should be paid to the balance of the equipment, including the level and verticality of the machine and equipment, to avoid unnecessary vibration and noise during operation.

In short, the installation process of complete set feed mill equipment needs to be carried out in strict accordance with relevant specifications and requirements to ensure that the equipment is put into use safely and effectively. During the broiler feed project installation process, special attention must be paid to safety, precision and reliability.

Is the broiler feed market suitable for investment?

With the rapid development of the breeding industry and the improvement of environmental protection requirements, the demand for complete sets of broiler feed mill equipment is increasing, and the market size is also expanding.

At the same time, with the advancement of technology, automation, intelligence and environmental protection performance are receiving more and more attention, which also provides investors with more opportunities and potential.

In addition, market competition is becoming increasingly fierce. Investors need to carefully analyze market trends, competitors, their own strengths and weaknesses and other factors to formulate reasonable investment strategies.

The broiler feed mill production scale, technical level, product quality, after-sales service, etc. are all important factors that investors need to consider.

Therefore, for those who are willing to invest, the feed production complete equipment market is still a market worthy of attention and exploration, but it is necessary to carefully evaluate risks and opportunities and formulate reasonable investment strategies.

At the same time, investors also need to pay attention to industry dynamics and market changes, and adjust investment strategies in a timely manner to respond to market changes and challenges.