Horse feed mill

The horse feed mill is an integrated horse feed processing system, which can also be called a horse feed production line or horse feed plant, horse feed factory.

It can be used to process pellet horse feed, grass pellets for horses, foal creep pellets, alfalfa pellets for horses, fiber pellets for horses, soy pellets for horses, sugar beet pellets for horses, teff hay pellets for horses, timothy pellets for horses, balancer pellets for horses, rice bran pellets for horses, etc.

RICHI focuses on the research, design, manufacturing and installation services of various types of horse feed mill projects, tailor-made for horse breeding and horse feed production enterprises, integrating raw material reception, automatic cleaning, rapid crushing, precise batching, uniform mixing, efficient granulation, and cooling screening.

- Capacity: 1-100T/H

- price: 10,000-3,000,000 USD

- Feed size from feed mill: 2-12mm pellet feed

- Optional Technology: pelletizing and extrusion technology

- Business scope: New horse feed factory, horse feed factory renovation

- Available horse feed ingredients: alfalfa, teff, timothy, beet pulp, hay, whole oats, corn, rice bran, wheat bran, clover, ryegrass, orchard, oat, wheat, kikuyugrass, mitchell grass, kangaroo grasses, etc.

RICHI complete horse feed production line can integrates separation, automatic packaging and palletizing, and strives to create a horse feed plant project of “safe feed and safe food”.

Types of horse feed mill

According to the type of feed, it can be divided into:

- Complete compound Horse Feed mill

- Concentrate Horse Feed mill

- Ration Balancing Horse Feed mill

- Forage & Hay Horse Feed mill

- fermented feed mill

- …

According to Horse Life Stage, it can be divided into:

- Foal Horse Feed mill

- Growing Horse Feed mill

- Breeding Horse Feed mill

- Maintenance Horse Feed mill

- Adult –Performance Horse Feed mill

- Senior Horse Feed mill

- Weanling/Yearling Horse Feed mill

- …

According to different Special Diet, it can be divided into:

- Alfalfa Diets Horse Feed mill

- Flax-Free Horse Feed mill

- Grain-Free Horse Feed mill

- High Fat Horse Feed mill

- High Fiber Horse Feed mill

- High-Protein Horse Feed mill

- Limited Ingredient Diet Horse Feed mill

- Low Fat Horse Feed mill

- Low Glycemic Horse Feed mill

- Low Starch Horse Feed mill

- Low-Protein Horse Feed mill

- Molasses-Free Horse Feed mill

- No Corn No Wheat No Soy Horse Feed mill

- Organic Horse Feed mill

- …

how to making horse feed pellets? horse feed mill process design

No matter what your horse feed raw materials and formula are, generally speaking, the complete production process of horse feed pellets is as shown below:

01 Raw material receiving section

According to actual production needs, scientific raw material receiving technology is adopted to reduce energy consumption and production costs, reduce personnel labor intensity, and improve production efficiency.

02 Raw material cleaning section

The granular material feeding and cleaning and the powder material feeding and cleaning are independently separated, with high impurity removal efficiency. Appropriate sieve holes can be selected according to the material properties to achieve the required separation effect.

03 Crushing section

Match the special multi-chamber crusher according to the horse feed crushing particle size to improve the crushing efficiency. At the same time, multiple chambers to be crushed are designed to meet the needs of crushing different raw materials and greatly improve the production efficiency.

Depending on the horse feed ingredients and mix, it may be necessary to configure both a grain grinder and a grass grinder.

04 Ingredients section

The batching program control independently developed by RICHI achieves precise feeding, fast batching speed and high precision; the batching scale hopper is enlarged, and the unloading sequence controlled by the batching program is optimized.

05 Mixing section

According to the proportion of forage and the characteristics of light weight, a scientific and reasonable selection and customization of a large-volume, low-speed, high-uniformity feed mixer machine adopts a humanized structure and is easy to operate and maintain. The specially designed full-length door-opening discharge structure has been patented.

06 Granulation section

We will scientifically select equipment such as horse feed pellet machine, conditioners, and quality-maintaining aging systems based on the needs of customers and horse feed.

We will combine the characteristics of horse feed technology with directional design to save investment costs. Multiple granulation bins can be configured to facilitate switching when changing varieties to achieve efficient granulation.

07 Cooling section

The temperature of the cooled horse feed pellets can be monitored in real time, and the optimally designed cooling air network ensures the predetermined cooling effect. The efficient and reliable screening system enables the finished product to meet the needs of customers and the market.

08 Packing section

According to different finished materials, automatic packaging scales for large or small packages can be selected for precise measurement, fast and efficient, and can also be configured with a mechanical palletizing system, which greatly improves the degree of automation and saves costs for customers.

Principles of horse feed mills process design

- Use advanced, mature, and reliable new processes, new technologies, and new horse feed mill equipment to make the production process as continuous and mechanized as possible.

- Adopt advanced and feasible process indicators. On the premise that the process indicators can be achieved, the process flow lines should be shortened and the transportation equipment should be reduced as much as possible.

- Make full use of raw materials and try to achieve comprehensive utilization while obtaining high product yields and ensuring excellent product quality.

- Consider the possibility of processing different raw materials and producing different products.

- The permissibility of production scheduling should be considered, and possible failures in production should be estimated so that production can proceed normally.

- To ensure safe production, the horse feed mill process must be equipped with relatively complete control instruments and safety facilities.

RICHI Machinery has been committed to providing customers with a comprehensive plan for horse feed pellet production. We provide full consulting services to help our clients realize their vision of rapid development.

Our services include: project evaluation, technical consultation, horse feed mill plant design, equipment manufacturing, installation and commissioning, worker training and other after-sales services. (Find RICHI on YouTube)

Equipment needed to start a Horse feed mill

Proper selection of core horse feed mill equipment can achieve twice the result with half the effort for a continuous production horse feed factory, effectively reduce equipment maintenance time and improve horse feed production efficiency. The followings are main equipment needed in a horse feed mill:

Horse feed Hammer Mill

This grain feed hammer mill crusher machine is used for reducing the particle size of different ingredients in feed. It consists of a rotor on which swinging hammers.

Capacity:

3-25 T/H

Main Power:

30-160 KW

Grass crusher machine

It is especially suitable for large-scale coarse crushing of bales of alfalfa, licorice, ryegrass, straw and other pasture grasses. It has high crushing efficiency and low production cost.

Capacity:

0.3-3 T/H

Main Power:

22-93 KW

Horse feed Mixer

RICHI engineer team of highly qualified & experienced workforce helps us in manufacturing and supplying horse feed mixing machine for various livestock feeds in feed mills.

Capacity:

250-2000 KG

Main Power:

4-55 KW

Horse feed Pellet machine

Pelleting is a process in which mixed horse feed in powder form is converted into pellets by mechanical compression in combination with moisture and heat.

Capacity:

1-48 T/H

Main Power:

22-315 KW

Pellet Cooler Machine

Used to cool the horse pellets after pressed by the pellet mill, since the horse feed pellets are hot and contain much vapor when just get out of the horse feed pellet mill.

Capacity:

3-25 T/H

Main Power:

30-160 KW

Horse feed Screening machine

Used for screening and classifying powdery materials or pellet feeds in horse feed mills, and can also be used for preliminary cleaning of raw materials in animal feed mill plants.

Capacity:

3-20 T/h

Main Power:

1.5-5.5 KW

Automatic Bagging Machine

Suitable for quantitative packaging of horse feed pellets of various sizes and is widely used in feed, chemical industry, grain and oil, new energy pellet and other industries.

Capacity:

6-12 Bags/Min

Main Power:

1.1-5 KW

horse feed mill Conveyor

An elevator, screw conveyor or scraper conveyor is transport vehicle that efficiently moves people or goods between floors of a building.

Capacity:

1-12 T/H

Main Power:

0.75-355 KW

In addition to the three core equipment of feed crusher, mixer and horse feed pellet mill, the horse feed factory also has some supporting equipment, such as scraper conveyor, bucket elevator, feeding auger, rotary vibrating screen, distributor, etc.

It has little impact on the quality of finished horse feed products, and most of them are general-purpose equipment, so they will not be introduced in detail here. If you are interested in our complete equipment for horse feed mills, contact us to get a quote for the complete feed mill equipment!

Horse feed mill projects

20T/H horse feed mill in united states

- Project date: 2019.05.10

- project cost: 550000 USD

- horse feed mill equipment: Bale breaker, grass crusher, feed mixer, hemp pellet mill, cooling machine, screener, baling scale, oil adding system, etc.

5 t/h horse feed mill plant in Russia

- Project date: 2021.10.11

- project cost: 184500USD

- horse feed mill equipment: Alfalfa grinder, feed mixer, batching scale, alfalfa granulator, cooler, screening machine, baling scale, silo system, etc.

8-10 t/h horse feed mill in France

- Project date: 2022.10.14

- project cost: 131820 USD

- horse feed mill equipment: grass crusher, corn crusher, feed mixer, grass granulator, livestock feed granulator, cooler, screening machine, packaging scale, etc.

10 T/H horse feed mill factory In Italy

- Project date: 2022.06.30

- project cost: 159070 USD

- horse feed mill equipment: Feed grinder, ultra-fine grinder, feed mixer, feed granulator, horse feed extruder, cooler, screening machine, packaging scale, etc.

5T/H horse feed mill in Australia

- Date: Sep 21th, 2015

- project cost: 80,000-400,000 USD

- horse feed plant equipment: Feed crusher, mixer, granulator, cooler, horse feed granulator, baling scale, screening machine, silo system, etc.

7 T/H horse feed mill in Germany

- Date: July 6th, 2019

- project cost: 150,000-400,000 USD

- horse feed plant equipment: Feed grinder, grass grinder, mixer, grass pellet machine, cooler, baling scale, pellet screener, silo system, boiler, etc.

5T/H horse feed mill In Chad

- Date: February 2021

- project cost: 220,000-250,000 USD

- horse feed plant equipment: horse feed grinder, pulser, distributor, horse feed mixer, horse feed granulator, horse feed pellet cooler, packing scale, screening machine, boiler, etc.

3-5T/H horse feed mill In Ireland

- Date: October 29, 2021

- project cost: 60,000-65,000 USD

- horse feed plant equipment: animal Feed grinder, mixer, alfalfa pellet machine, cooler, pellet crumbler, baling scale, screening machine, etc.

Horse feed mill cost

Based on our past customized plans and quotations for customers, the price of horse feed can be summarized into the following ranges:

- 1-2 t/h horse feed mill cost: 10000-50000 USD

- 3-4 t/h horse feed mill cost: 50000-120000 USD

- 5-7 t/h horse feed mill cost: 70000-250000 USD

- 8-10 t/h horse feed line cost: 150000-300000 USD

- 12-20 t/h horse feed mill cost: 250000-580000 USD

- 25-40 t/h horse feed plant price: 450000-850000 USD

- 50-60 t/h horse feed mill cost: 900000-1400000 USD

- 60-80 t/h horse feed plant cost:: 1450000-1800000 USD

- 80-100 t/h horse feed mill price: 2000000-2800000 USD

- …

If you have plan to make feed pellets for your horse, just contact Richi Machinery directly! Our customized plan for horse feed pellet production definitely can help you reduce the investment cost and ensure the horse feed mill production efficiency !

Characteristics of horse feed

The physiological characteristics of horses are a fermentation zone in the hindgut and a large number of fiber-decomposing bacterial flora in the cecum and colon.

A horse’s diet can be a combination of grass, hay, concentrate or well-sealed high-quality grain crop silage. High-quality green hay with less fiber and green pasture in summer and autumn are the best feed for horses. Crop straw with good palatability and good quality can also be used as roughage for horses.

The tender upper part of corn straw has good palatability, and the straw should be crushed before feeding. Sweet corn and waxy corn stalks left over from processing fresh and tender ears are good forage for horses, and their digestibility is higher than that of cereals.

Cooked soybean meal, oats, and bran are safe feeds for horses and should account for a certain proportion in the diet.

Faqs of setting up Horse feed mill

How to prepare to build a horse feed mill?

Enterprises preparing to establish horse feed mills are generally divided into feed companies built by feed groups to develop new markets, feed supporting projects for agricultural industrialization enterprises, and some transformation of old equipment. Different types have different preparation methods.

- Horse Feed mill employees.

First of all, horse feed mills are an industrial chain of agricultural industrialization enterprises.- Many of them are government projects, and of course some are created for enterprise development needs. When it is determined that the construction of a horse feed mill is needed, the first issue is to solve the “people” problem.

- Many companies only consider this issue after the preparation of the feed mill is completed.

- In fact, it is a bit late. This “person” can be the future production department manager or the future general manager. It is better to have an experienced construction consultant, so that your feed mill can better adapt to the development of the industry.

- Horse Feed mill land.

With people, it is possible to carry out the preparation work of the hardware part. The next thing to consider is to determine the land suitable for building your own horse feed mill factory. Generally, 30-50 acres is appropriate.- The location of the horse feed mill is very important. It is necessary to choose a place with no pollution sources, and the perennial wind direction of the area must also be considered.

- More importantly, the logistics are convenient, the cost is low, and it is close to the dock and train station.

- The convenient transportation can provide a good foundation for future work. Brings great convenience. Of course, there are too many places where the choice of location is limited. Sometimes companies think more about the operability of the company.

- Planning the land.

After selecting the land, you need to go through the relevant procedures, leasing, buying and selling of the land. Then there is the planning of the land (factories, auxiliary buildings, office buildings, gates, weighing rooms, etc.). Of course, RICHI can directly help you consider these issues, but you still need to communicate with us based on your own ideas. In terms of specific matters, there are two points that need to be noted:- 1. The smaller the distance between the boiler room and the workshop, the better;2. It is better to design the power distribution room under the central control room.

- Horse feed mill equipment.

After planning, you begin to face the choice of horse feed mill equipment.- The choice of equipment and process flow depends on the specific circumstances of each company. Some feed mills are located in companies with large breeding plants and professional bulk batching systems.

- When designing the process, bulk batching needs to be added. System, premix production should be based on stainless steel equipment.

- It is better to use a single horse feed production line for fish feed, shrimp and crab feed, and do not put them on the same production line as livestock and poultry feed.

- The size of the horse feed mill equipment must match the company’s long-term plan, and it must be clarified that it is mainly for self-use, not sales. You can first reserve a line in the design, so as to reduce the fixed investment when installing the equipment again.

- However, if the reserved line is not available for a long time, it will also cause a series of problems such as excessive early equipment.

- Therefore, before buying equipment, you must fully understand a series of issues such as business development ideas and market factors, and do not blindly determine equipment.

- Find horse feed mill machine manufacturers.

After determining the type of horse livestock feed mill equipment, you can communicate with horse feed equipment processing manufacturers. Different equipment manufacturers will give you some references for process processes and equipment.- At this time, the equipment and process flow must be checked according to the specific conditions of the company. It is necessary to determine the model, quality and equipped motor and reducer (box) of the single machine in case there is no reliable basis during installation.

- The quotations of each equipment manufacturer will vary greatly, but you must learn to compare from all aspects and finally determine For the equipment you need, after determining the horse feed mill equipment manufacturer, you need to sign a contract.

- During the contract signing process, you need to pay attention to some details, such as transportation costs, oxygen and acetylene costs, and the food issues for the installation workers during purchase and installation, as well as the price of the electric hoist. Issues such as installation, invoices, payment methods, etc., it is best to write down all the details that can be thought of in the contract.

- If the construction project is fully covered by the horse feed mill equipment manufacturer, many problems should be solved by the equipment manufacturer itself (the crane is arranged by the feed factory and paid for by itself) As appropriate.

- Horse feed mill design and drawings.

After the equipment is ordered, go to the local drawing review department to issue a blueprint based on the drawings issued by the equipment manufacturer, and then conduct bidding or direct contracting for the construction of workshops, auxiliary rooms, warehouses and other buildings based on the drawings. The entire construction generally takes 4-6 months. , during the construction process, three issues should be paid attention to:- 1. The basement of the workshop must be watered and compacted; 2. The size and location of the reserved holes must be accurate; 3. The location of the floor scale must be compacted, and there must be a sewage outlet under it to enter the sewer. Generally, workshops are made of concrete structures, and warehouses are mainly made of steel structures. During this period, project personnel need to participate in the management and supervision of the entire project. Strong companies can invite supervision companies to participate.

- Equipment installation.

When the horse factory building is capped and the warehouse construction is completed, the equipment manufacturer can be notified and the equipment can be installed in the factory.- Before installation, the road connections, electric connections, and internal decoration must be completed (except for the parts specified in the contract).

- At this time, technical personnel in future production should also enter the factory at the same time, including production managers, electricians, mechanics, central control workers, and horse feed pellet making machines.

- During the installation process, pay close attention to the progress and quality of the installation. Generally, manufacturers sign a start-up contract as the basis for the start-up time and strive to do corresponding auxiliary work for the installation, such as assisting in the purchase of oxygen, acetylene, etc.

- At this time, electricians and repairmen have to follow and do some basic work in order to learn more horse feed equipment knowledge.

- Construction of auxiliary areas.

While installing horse feed mill equipment, it can handle the construction of auxiliary rooms and office areas, the construction of laboratories and boiler rooms, the installation of boilers, the connection of steam pipes, the installation and debugging of transformers and electrical cabinets, and the installation and debugging of floor scales.- Equipment installation generally takes 45-180 days (annual output of 120,000 tons). In the later stage of equipment installation, some software work needs to be prepared, such as environmental impact assessment certification report, preparation and filing of corporate standards, working capital gradually in place, construction of procurement channels, personnel recruitment and so on.

- Generally, in the second half of the installation, in addition to the completion of the project, management personnel will gradually arrive on duty, and boilers, transformers, and electrical cabinets will be commissioned and accepted. Formula design, production tools, laboratory equipment and other things required for trial production also need to be on duty.

- Training.

When all trial production items, raw materials, production tools, laboratory equipment, and coal enter the factory, all employees must also be recruited into the factory. Prior to entering the factory, personnel must undergo intensive training, including corporate culture and production discipline, general knowledge of feed production and quality control in the production process and a series of issues. - Trial production.

General trial production includes three parts: stand-alone debugging, clearance and linkage. As an increasingly mature horse feed machinery technology, trial production will not cause problems.

Preparing to build a horse feed mill is a complex and long-term systematic project. It is difficult to explain clearly, thoroughly and completely in a few paragraphs. Here RICHI will only briefly communicate with you on the preparation process. If you are interested in building a horse feed mill, contact us to get detailed horse animal feed production line construction processes and plans.

How to choose horse feed mill equipment?

When selecting horse feed mill equipment, there are several key factors to consider:

1. Product structure

First, you need to understand the structure of the product, as well as the equipment and processes required during assembly. This includes understanding the composition of the product, the number and type of parts, the assembly process, etc. This information will help determine the type and quantity of horse feed making equipment needed.

2. Product selection

When selecting horse feed mill equipment, factors such as equipment performance, accuracy, reliability, and efficiency need to be considered. At the same time, the suitability of the equipment also needs to be considered. Depending on the product, different types of equipment may be required, such as assembly machines, inspection machines, packaging machines, etc.

In addition, you also need to consider the sustainability of the equipment and choose equipment that is upgradeable and maintainable.

3. Product advantages

When choosing horse feed mill equipment, you need to understand the product’s advantages. Some equipment may have higher production efficiency, and some equipment may be more suitable for specific products. Therefore, it is necessary to select the most suitable equipment based on the characteristics and needs of the product.

4. Usage scenarios

Finally, the usage scenario needs to be considered, including production volume, production cycle, operating environment and other factors. For example, for large-scale production, equipment with higher production efficiency may be needed; for small-scale production, more flexible equipment may be needed.

In addition, the operation and maintenance requirements of the horse feed mill machine need to be considered to ensure that it is suitable for the specific environment.

In short, when choosing to purchase horse animal feed mill equipment, you need to comprehensively consider factors such as the structure of the product, the performance of the required equipment, and usage scenarios to ensure that the selected equipment can meet production needs and improve production efficiency and product quality.

How to design the horse feed mill process?

The process design of the horse feed mill includes the following:

(1) Design of horse feed plant process flow chart

Generally speaking, RICHI process design takes the horse feed mixing machine as the core of the design.

The model and specifications of the mixer are first determined, and then the production capacity of the processes before and after the mixing process is calculated. In order to ensure that there is no capacity bottleneck in the horse feed production process, the design should consider that the production capacity of the subsequent equipment is larger than that of the previous equipment, usually 15% to 20% larger.

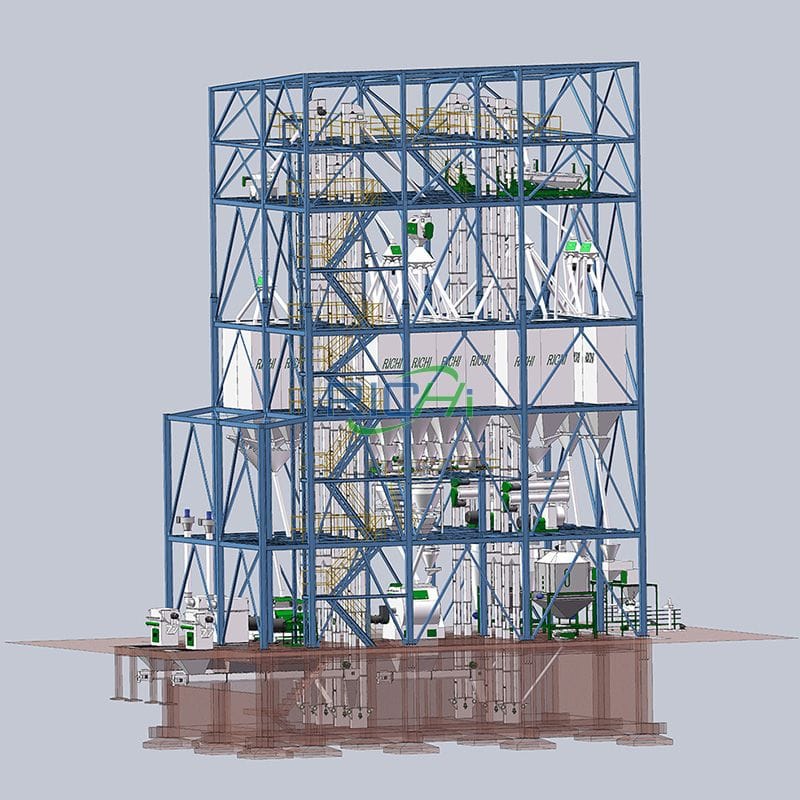

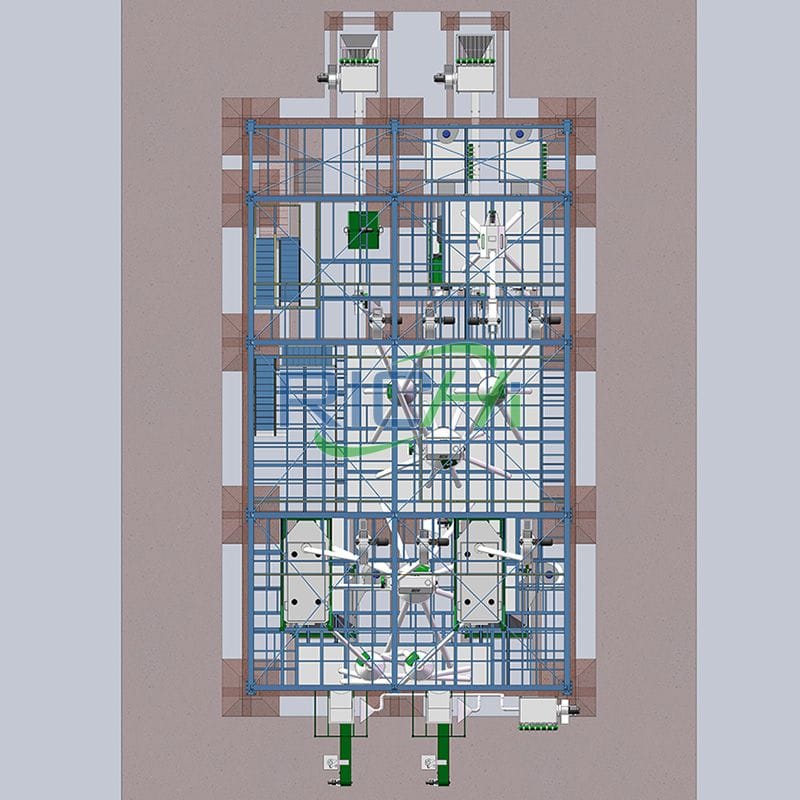

(2) Workshop equipment layout

Generally, the batching barrel is the core of the design. Its location is determined first, and then other processing equipment and conveying equipment are arranged. If possible, you can use software to make a 3D layout drawing first, so that the team can participate in the discussion more deeply.

(3) Design of logistics and people flow within the factory

The logistics method in the horse feed factory is mainly mechanical transportation or pneumatic transportation. It is necessary to determine the delivery location of raw materials and the location of unloading. At the same time, the route of personnel walking needs to be considered, and the intersection of logistics and human flow should be avoided as much as possible.

(4) Pipe network design

The pipe network design mainly includes dust removal pipe network, pneumatic conveying pipe network, steam system pipe network, compressed air pipe network and material flow pipe network. The space required for maintenance and cleaning should be considered during the design.

(5) Power supply design

The design of strong and weak current requires separate bridges. Considering the design of some BUS buses in the automation control process, separate pipelines should be used to avoid signal interference.

How to design the equipment layout of a horse feed mill?

How are horse feed equipment arranged in a horse feed factory? Various equipment are reasonably arranged according to the specific conditions of the factory structure and are arranged in a compact manner, which is not only convenient for operation, maintenance and management, but also saves area, is practical and beautiful. Reserve the production line and the equipment of the first phase in the same workshop and reserve interfaces.

If it is fully capable of producing high-quality various feeds, you can consider sharing some equipment with the first phase to ensure that the process and horse feed mill equipment layout are complete, and to facilitate the construction design in one step. .

- Main production equipment, such as crushers, batchers, mixers and horse feed pellet machines, are placed close to windows to facilitate lighting and operation. Bag filters, ventilators, cyclone separators and other equipment can be placed in poor lighting conditions. Location.

- Equipment with heavy weight and large vibration (such as crushers) should be placed on the ground floor or basement of the workshop and isolated to facilitate sound insulation and fire prevention.

- The picker and dust removal equipment for pneumatically conveying materials are placed on the highest floor of the factory building.

- Arrange the same machines on the same floor to facilitate unified operation and reduce the number of material lifting times.

- The batching bin is set up on the upper floor of the batching equipment, and the mixing equipment is placed on the lower floor of the batching equipment, leaving a wide operating distance to facilitate the addition of trace ingredients, sampling inspection, and cleaning of internal residues.

- The horse feed pellet press is arranged on the upper layer of the cooler, and the hot and humid particles directly enter the horse feed pellet cooler.

How to determine the product solution of horse feed mill ?

When using one raw material to produce products of multiple specifications, in order to facilitate mechanized production, efforts should be made to streamline the process.

However, in order to maximize the utilization rate and use value of raw materials, or to meet consumer demand, it is often necessary to produce one raw material into several specifications of products. The amount of various products can be determined according to the raw material conditions.

The feed product plan is expressed in the form of a table, which includes the product name, annual output, shift output, and production schedule from January to December, expressed in the form of lines or numbers.

- Comparison of product solutions

- Comparison of annual output value of major products;

- Comparison of the number of production workers required per day;

- Comparison of labor productivity (annual output t/total number of workers)

- Comparison of the difference between the number of raw materials and products per day (month)

- Comparison of average annual output value per person (yuan/person·year);

- Comparison of equipment balance conditions;

- Comparison of water, electricity and gas consumption;

- Comparison of difficult and easy situations in organizing production;

- Comparison of infrastructure investment;

- Comparison of social benefits;

- Economic benefits (profit and tax yuan/year);

- Conclusion.

Why Choose Us?

Tell us about your great team. A few lines of enthusiastic self-introduction can quickly shorten the distance between you and visitors.

Advancing Technology

Create and develop advanced technologies and provide outstanding horse feed mill solution and services that fulfill the needs of customers worldwide.

Excellent Relationship

Develop customer relationships which provide services tailored to specific customer needs

24/7 Supports

Utilize Continuous Process Improvement strategies to ensure the highest quality products and services.

RICHI was founded in 1995. As a high-tech enterprise, RICHI remains true to its original aspiration and is committed to the research and development of livestock feed processes for horses, cattle, sheep and other livestock, and provides high-standard and high-quality forage pellet processing for livestock feed production companies and livestock smart breeding companies, and high-efficiency all-dairy horse feed engineering system solutions, continue to innovate independently, upgrade horse livestock feed production line technology, technology and equipment, and achieve green economic and sustainable development of the livestock industry.