Straw Pellet Machine For Sale

Straw pellet machine refers to the compression of crop straws and agricultural and forestry wastes with low energy density into pellet fuel with high energy density and hard texture for easy storage and transportation.

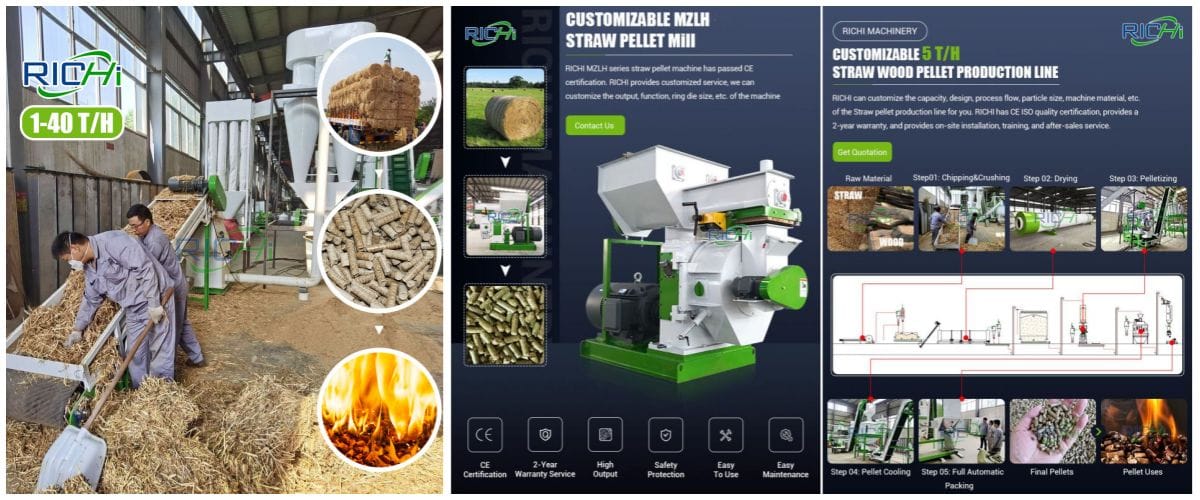

RICHI is mainly engaged in straw pellet machine for sale, Our ring die straw pellet making machine has good performance, can meet the needs of biomass raw material granulation, works stably, has a reasonable design, and is easy to maintain.

It has positive significance for the development and utilization of biomass resources and the protection of the ecological environment.

- Capacity: 1-10T/H

- straw pellet machine price: 10,000-100,000 USD

Richi Machinery has nearly 30 years of experience in the production of biomass equipment, and has been engaged in the renewable straw pellet machine for sale, and at the same time provides a complete set of straw pellet production line design.

Types of straw pellet machine

RICHI straw pellet maker machine is suitable for a variety of straw raw materials, such as: wheat straw, rice straw, corn straw, rapeseed straw, cotton straw, sugarcane straw, barley straw, yellow straw, etc.

According to the different types of straw pellets, the RICHI straw pellet machine has different names:

- corn stalk pellet machine

- rice straw pellet making machine

- wheat straw pellet machine

- flax straw pellets machine

- barley straw pellet mill

- sorghum stalk pellet machine

- soybean straw pellet machine

- beet straw pellet machine

- sugar cane straw pellet machine

- cotton stalk pellet machine

- …

Pelletized straw fuel has the characteristics of high calorific value, easy ignition, low ash content, high thermal efficiency, clean and hygienic combustion, etc. It is widely used in industrial, domestic boilers and civil fuels.

Richi Machinery specializes in straw pellet machine for sale. No matter what kind of straw raw material you are, we can provide suitable straw pellet equipment and pelletizing process solutions. (Related product: biomass pellet mill)

Features of Straw pellet machine

Straw pellets machine adopts the advanced ring die design structure, the product consumes less power, has stable performance and high productivity.

The actual measured ton of material and power consumption are less than the standard, the pellet density is greater than 1000 kg/m³, the pellet forming rate is greater than 95%, the pellet firmness is greater than 90%, the minimum productivity is greater than 800 kg/hour, and the maximum can reach 10 tons/hour.

Richi Machinery focuses on straw pellet machine for sale, our machine performance is stable, the maintenance is convenient, the reliability is high, and the product quality is at the domestic leading level.

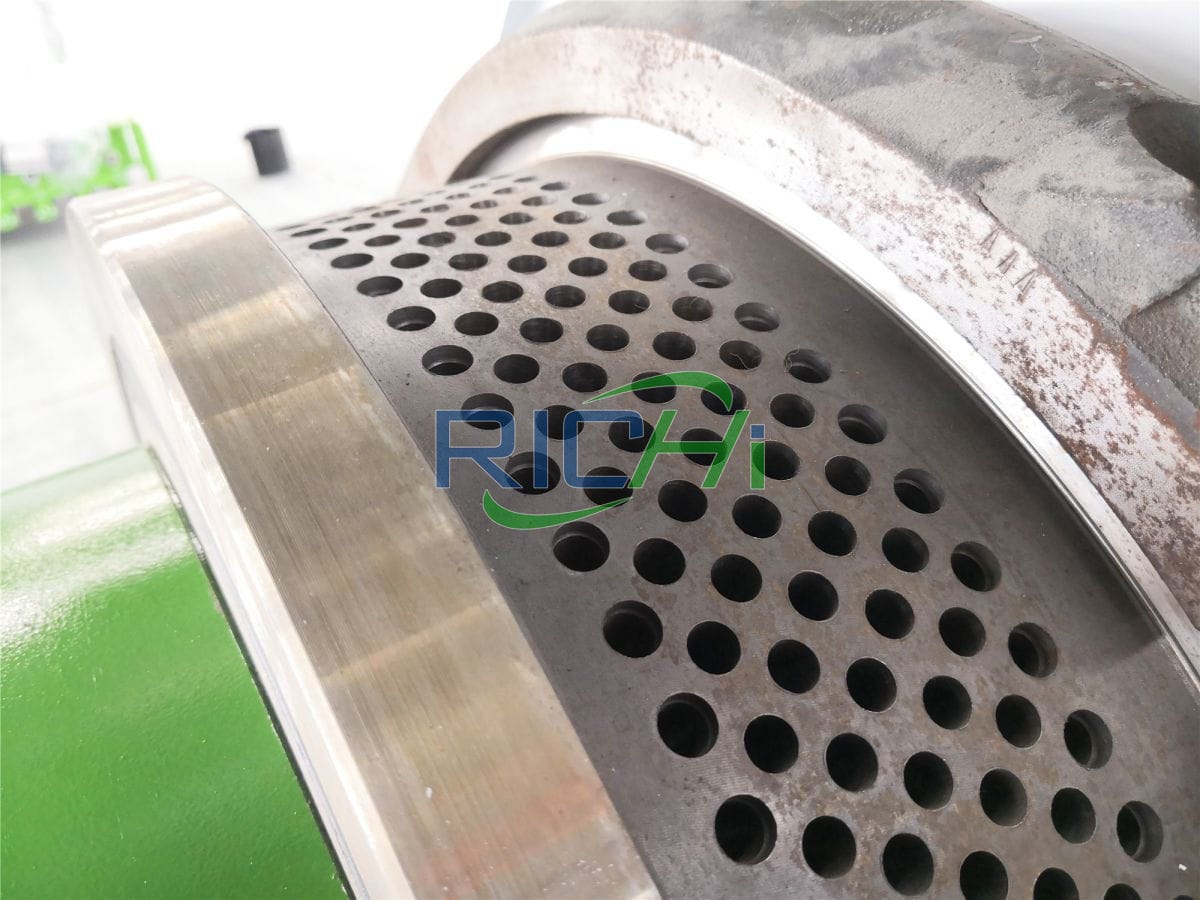

- RICHI machine adopts ring die structure, installs 2 pressure rollers, fixed on the pressure roller shaft, the pressure roller shaft is eccentric, the gap between the die rollers can be changed by turning the pressure roller shaft, and the gap adjustment is realized by turning the gap adjustment wheel of.

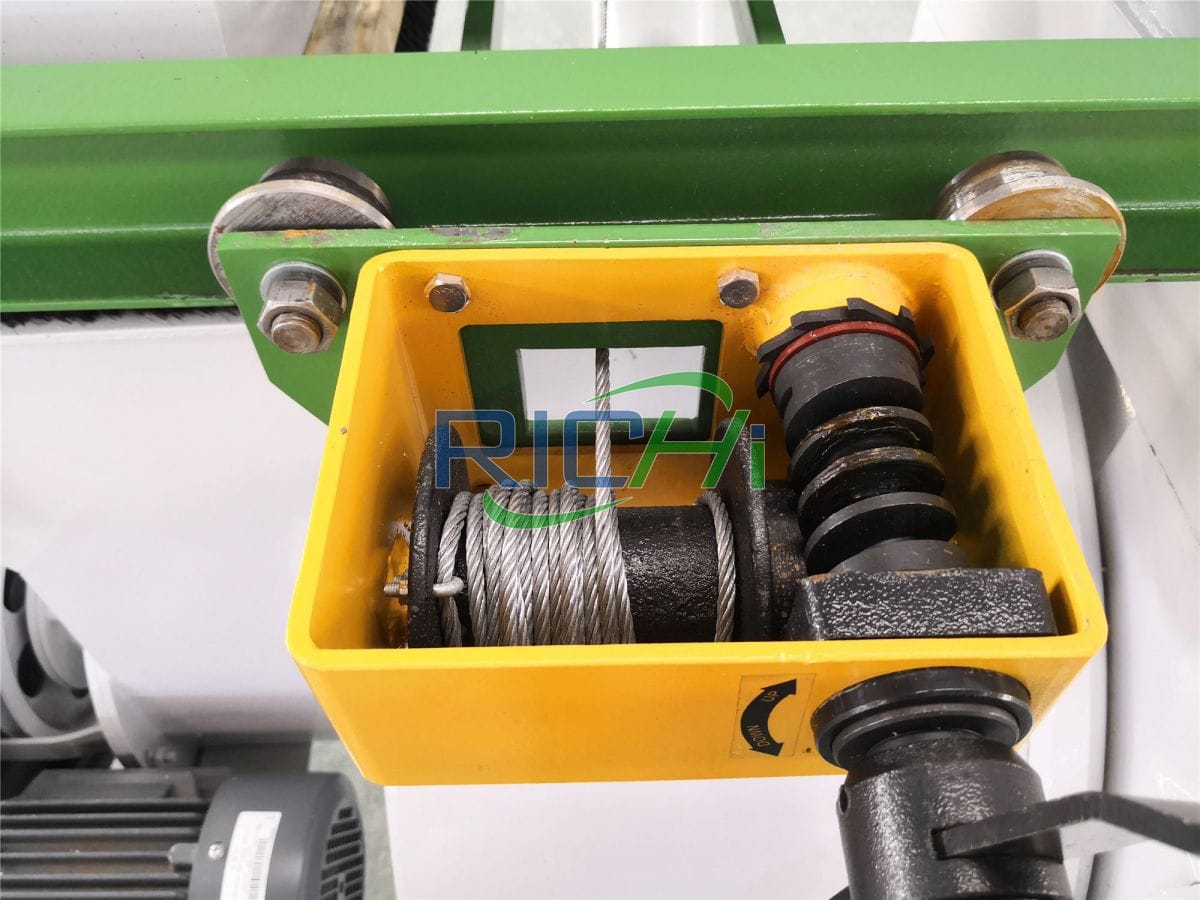

- Considering the complexity and diversity of biomass raw materials, a forced feeder was designed. Horizontal screw feeding is adopted at the front end of the feeder. At the rear end, an arc-shaped forced feeding shaft is used, and a forced scraper is welded on it.

Its purpose is to ensure that the material moves vertically downward after the horizontal movement, and at the same time prevent the accumulation, winding and reverse material of the material. - The arrangement of the forced scrapers is symmetrically arranged like a double helix. During the working process, the left and right symmetrical forced scrapers convey the material downward at the same time, ensuring that the force on the arc-shaped forced feeding shaft is even, and the material will not be pushed to one side.

- RICHI straw pellet machine has high production efficiency and low energy consumption. Large and medium-sized ring die compression equipment can produce more than 10 tons of finished pellets per hour, and the energy consumption is 56% to 33% of the energy consumption of heating and compacting;

- The raw material pretreatment requirements are low, and the moisture content is 10% to 18% and can be formed;

- RICHI pellet machine ring die wear is small, because it is formed at room temperature, the strength and wear resistance of the ring die will not be reduced, and the service life of the ring die is longer;

- The calorific value of the straw fuel basically does not change. The normal temperature molding of the biomass straw raw material does not destroy the molecular structure of the raw material, and there is no chemical reaction and any thermal cracking and decomposition.

- Therefore, the straw pellet fuel has almost no heat loss and can maintain the stable calorific value of the raw material.

Biomass pellet fuel manufacturing technology is developing in the direction of high-efficiency, energy-saving, and low-cost ring die compression molding.

When you are choosing a straw pellet equipment or a manufacturer who focus on straw pellet machine for sale, you should purchase the corresponding supporting equipment and determine the model and quantity of the supporting equipment.

Technical Parameters of straw pellet machine

| Model | Main Power(kw) | Anti-caking Feeder(kw) | Capacity | Final Pellet(mm) |

|---|---|---|---|---|

| MZLH320 | 37 | 1.5 | 600-800kg/h | 2-12 |

| MZLH350 | 55 | 1.5 | 800-1000kg/h | 2-12 |

| MZLH420 | 90 | 1.5 | 1.5-2t/h | 2-12 |

| MZLH520 | 132 | 2.2 | 3-4t/h | 2-12 |

| MZLH768 | 250 | 3 | 5-7t/h | 2-12 |

| MZLH858 | 280 | 3 | 8-10t/h | 2-12 |

Straw pellet machine price

RICHI straw pellet machine price: 10000-100000USD.

From preliminary selection of straw pellet making machine→pelletizing system design→equipment manufacturing and delivery→on-site installation→operation guidance→maintenance”, the whole process can be arranged by us. Customers can rest assured that we will fully guarantee the user’s profit , so that you can benefit more at ease!

Richi Machinery is mainly engaged in straw pellet machine for sale, The straw pellet fuel processed by RICHI straw pelletizer overcomes the shortcomings of large volume, low energy density and difficult transportation of biomass. It also maintains the advantages of high volatility of biomass, easy combustion, less ash content, low emission, and no environmental pollution.

At the same time, the ashes after burning biomass fuels are high-grade high-quality organic potassium fertilizers, which can be recycled for profit. Therefore, biomass straw pellet fuel has broad development prospects in every country.

Straw pellet machine for sale the world

The service territory under our feet is slowly expanding. We have exported straw pellet machine for sale Canada, United States, Indonesia, Chile, Poland, Thailand, Germany, South Africa, etc.

straw pellet mill in United States

straw pellet machine for sale Poland

straw pelletizer machine in Indonesia

straw pellets machine for sale Canada

straw pellet mill for sale Chile

straw pelleting machine in Congo

In the communication and contact with tens of millions of customers, we have received sincere suggestions and sincere praise… Let you see the real case scene, gain a deep understanding of our products and service fields, and realize the multiplication and sharing of value.

working principle of straw pellet machine

In the process of producing pellet fuel, it must be applied to the key equipment of straw pelleting machine. The raw material is extruded by pressing rollers and ring dies and made into pellet fuel.

- First, the material is conveyed to the working area by the forced feeder;

- With the rotation of the mold and the roller, the material in front of the pressing roller is squeezed into the compression zone for extrusion;

- And the gap between the material and the material will be rapidly reduced.

- As the internal pressure and density of the material continue to increase, elastic deformation no longer exists, and plastic deformation begins to take effect.

- As the density increases, the material will be pressed into the grinding holes for pressure retention, and finally extruded to form straw fuel pellets.

Straw fuel pellets have broad market prospects and can be widely used in industrial production and residential life.

At present, many countries subsidize the use of biomass energy by power companies, and the use of straw pellet fuel by power companies is becoming a reality. The development of biomass straw pellets is bound to become a trend.

RICHI specializes in straw pellet machine for sale, next let us give you some advice of “Prerequisites for the molding of straw raw materials”.

Prerequisites for the molding of straw raw material

The higher the unit density of crushed raw materials, the better

The greater the unit density of crushed raw materials, the better the self-flowing property and the higher the granulation output.

After being processed by chaff cutter and kneading machine, it is best to use a straw pulverizer to crush crop straw into granules; the pulverized raw material produced by kneading machine has more filaments, poor feeding performance, and low granulation output.

The moisture content of the material should be appropriate

- If the moisture content of the material is too high or too low, it will affect the yield and quality of granulation.

- If the moisture content of the material is too high, when it exceeds 20%, it will be difficult to temper, and it will easily cause the material to slip between the inner wall of the ring die and the pressure roller, resulting in blockage of the ring die hole, unable to press out the pellets, and reducing the output.

- It is also easy to cause the pellets to become fat, low density, poor finish, and reduced quality. If the water content is lower than 14%, the friction between the material and the machine will be severe, powder will be produced, and the granulation output will be reduced.

- It is generally required that the moisture content of the material before quenching and tempering should be 15% to 18%.

So, find a professional straw pellets machine manufacturer who can tell you this,and specializes in straw pellet machine for sale.

How to start a straw pellet machine plant?

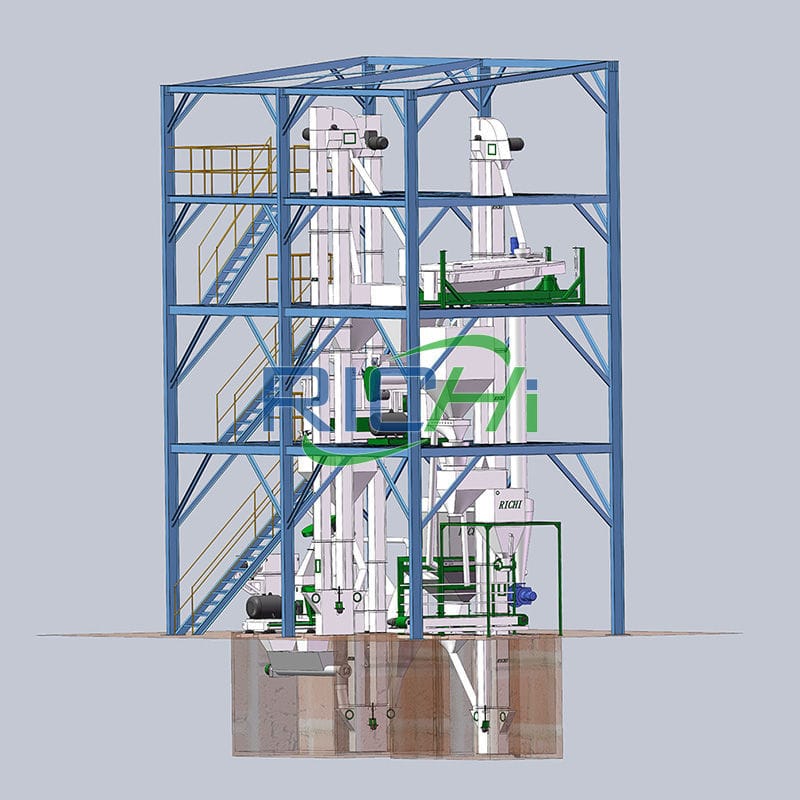

It is obviously not enough to process straw pellets with a single straw pellet machine, and it is usually necessary to establish a complete pellet processing system.

Straw pellet fuel making process refers to the method and technology of processing biomass raw materials such as straw into pellet fuel, including the entire pellet production line technology and equipment. (If you want to product straw pellet feed, visit : straw pellet production line )

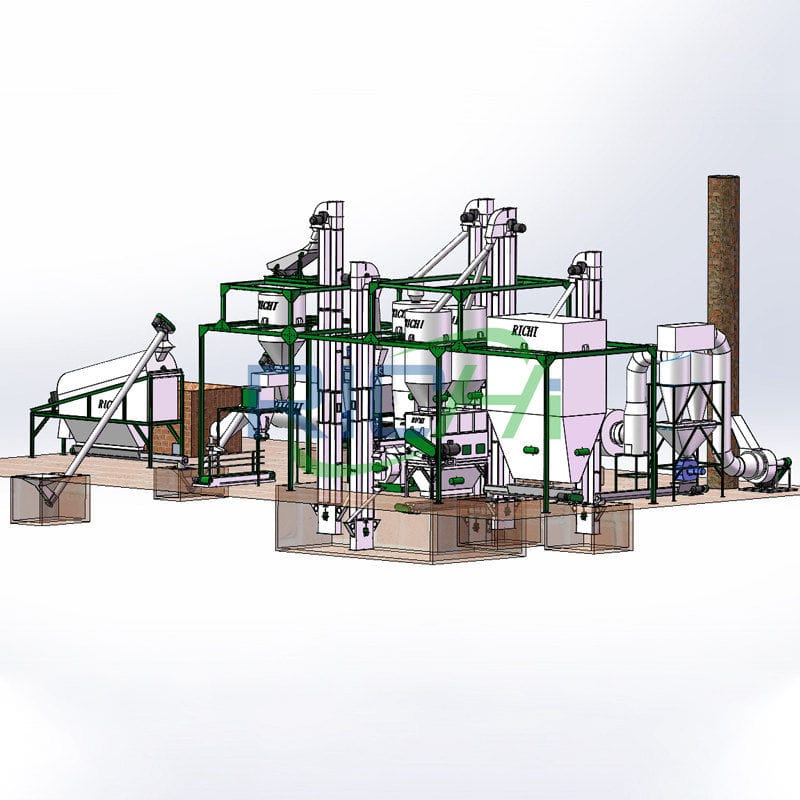

Straw fuel pellet plant solution

straw feed pellet plant solution

01 According to the continuity of production, it can be divided into continuous production process and stand-alone production process

It has processes such as raw material crushing, drying, conveying, mixing, feeding, forming, cutting, cooling, measuring and packaging, and the production process that can automatically and continuously stabilize the production line is continuous production.

Stand-alone production mainly relies on manual intermittent feeding, which is non-continuous production.

02 According to the degree of automation, it can be divided into automatic production process and non-automatic production process

The main product or the process route and the labor ratio of the process of the straw biomass pellet plant of each production process determine that a production line has the necessary machinery and equipment to complete the processing tasks of certain products, the arrangement of the machinery and equipment and the layout of the work place wait.

The process route of each production process adjusts the process parameters to meet the production needs of the product, and adopts the best straw pellet production process to obtain good economic benefits.

According to the specific requirements of customers, we can tailor-made straw pellet machine for sale and supporting overall design. Through the optimized combination of various types of equipment, different wood pellet mill plant process requirements can be met.

supporting Equipment for straw pellet machine plant

No matter those biomass straw raw materials, our straw pellet machine is ideal for fuel processing.

The equipment required for a complete set of straw pellets production process includes: straw cutters, straw pulverizers, conveyor belts, straw pellet press machines, straw dryers, straw pellet coolers, straw pellet packaging machines, pulse dust collectors, etc., and is formed with other facilities and equipment including a feeding system, forming system, discharging system, power distribution system, etc.

Bale breaker

Capacity:

1-15T/H

Main Power:

30-150KW

straw crusher Machine

Capacity:

0.3-3 T/H

Main Power:

22-93 KW

Hammer Mill crusher

Capacity:

3-25T/H

Main Power:

30-160KW

Richi Machinery not only provides a single straw pellet machine for sale, but also a complete set of straw pelleting plant equipment.

How to make straw pellets with straw pellet machine & pellet plant

The preparation process of straw fuel pellets includes straw cutting, cleaning, straw crushing, drying, separation, pelleting, pellet cooling, screening, packaging and other processes:

- Crushing: The straw is crushed to a suitable material size by chaff cutters, pulverizers and other equipment, and transported to a high-power screening machine by an auger conveyor.

In the production process of using straw to produce biomass pellet fuel, fine powder should be carried out after straw coarse powder to make the particle size of straw powder smaller and make the particle size distribution more uniform, which can improve the molding quality of straw pellet fuel. - Drying: The preparation of fuel pellets from straw has strict requirements on the water content of the crushed material, and the screened crushed material must be transported to the drum straw dryer through the auger conveyor for hot air drying.

- Cyclone separation: There is still a lot of moisture in the dried pulverized material, which must be removed through the cyclone separator, and then transported to the straw pelletizing machine for granulation.

- Crushed material transportation: Straw crushed material is carried out by screw conveyor, auger conveyor and hoist.

- Pelletizing: The preparation of straw fuel pellets is a key part of the process, and a straw pellet making machine suitable for different crushed materials such as sawdust, corn stalks, soybean straw, cotton straw and peanut shells is used.

- Cooling: When the straw-shaped pellets are discharged, the temperature is as high as 80-90°C, and the structure is relatively loose and easy to break. They must be cooled to normal temperature through a counter-flow cooling system before they can be bagged and stored or sent by belt conveyors and elevators. into the silo.

- Screening: In order to ensure the quality of straw fuel pellets, the cooled fuel pellets need to be screened out by vibrating sieves for finely divided fuel pellets that do not meet the standards for re-granulation.

- Bagging and storage: After the selected fuel pellets that meet the standards are sent to the finished product warehouse through the elevator, the packaging conveyor is used for metering and bagging, and then sent to the finished product warehouse.

Richi Machinery focuses on straw pellet plant and straw pellet machine for sale, and can provide customers with one-stop, complete set of professional biomass pellet production line solutions to solve the problems of customers.

Why process straw pellet fuel?

Biomass energy is abundant as a renewable energy source, and many countries are actively developing and utilizing it.

Among them, there is a huge amount of crop straw resources, but due to the relatively scattered, high collection, storage, and transportation costs restrict the effective use of such resources.

The straw pellets machine provides a good way to use biomass energy. This method is to crush, dry, modulate and process the waste generated in the processing of corn, rice, cotton, wood chips and other agricultural crop straws and forestry products. .

Through the molding process of the pellet machine, the dispersed pellets are pressed into fuel pellets with a higher density and a certain shape. This pellet is convenient for storage and transportation, and its calorific value is equivalent to medium coal.

Characteristics of straw pellet fuel

- Using wastes in the process of agricultural and forestry production (crop straw, rice husk, peanut shell, corn cob, sawdust, branches, leaves, wood scraps, etc.) as raw materials, environmental protection, energy saving, good safety, and good for fire prevention.

- High density and long burning time. The straw is crushed and processed into a compact shape, and the volume of the pellet fuel is reduced by 4 to 6 times, which greatly prolongs the burning time of the straw.

- Easy to burn, store and transport.

- The diameter of the fuel is generally 4mm, 6mm, 8mm, the length is 10-20mm, the ash content is not more than 10%, the density is not less than 1100kg/m3, the ash content is not more than 0.9%, and the calorific value is not less than 14.6505 million J.

As a manufacturer focusing on the straw pellet machine for sale, Richi Machinery firmly believes: If straw waste can be widely used, it can greatly improve the phenomenon of illegal open-air burning of orange stalks, improve air quality and save coal resources.

Why Choose Richi Machinery

Richi Machinery is a powerful overall solution provider for pellet equipment. It has successively served tens of thousands of customers in more than 130 countries and regions, and all equipment has passed ISO international quality system certification, EU CE certification and customs union CU-TR certification.

As a manufacturer focusing on the straw pellet machine for sale, , we not only provide customers with pellet equipment and services from a single unit to a complete system, but also our expertise covers the entire process chain of pellet processing.

We focus on the needs of customers in different fields, and the product processing range covers 2-12mm biomass pellets, 0.5-12mm feed pellets, 2-12mm organic fertilizer pellets and the processing of various powdery materials.

Whether it is in the field of energy, feed processing or circular economy, energy saving and emission reduction, environmental protection and other fields, Richi Machinery has a presence; whether it is in biomass, wood chips, aquatic feed, livestock and poultry feed, or in organic fertilizer, cat litter and other fields, Richi Machinery is an ideal choice.

Our service pursues refinement and standardization. From pre-sales technical consultation to after-sales maintenance, we always put the interests of customers first and provide customers with meticulous and considerate services.

01 Tailored/Solution

Design reasonable and economical supporting schemes according to the actual situation, assist in drafting/construction plans.

02 Guide installation/and commissioning

Provide door-to-door installation services, professional technical teams come to install and debug equipment, guide and train operators to ensure stable operation of the machine.

03 Regular inspection/visit

Provide regular return visit services to help users optimize and maintain equipment, and analyze and solve equipment problems reported by customers in a timely manner.

As a manufacturer focusing on the straw pellet machine for sale,the turnkey straw biomass pellet making plant solution is the answer submitted by Richi Machinery under the new situation of the biomass straw fuel pellet processing industry, and it also coincides with the future development trend of the industry.

faqs of straw pellet machine for sale

The molded biomass pellet fuel also has good combustion performance similar to coal briquettes, and compared with coal, it has the advantages of less sulfur content, less ash content, and less environmental pollution. Compared with firewood, biomass straw pellet fuel has lower moisture content, higher specific gravity and higher calorific value, which is conducive to improving the thermal efficiency of biomass pellet fuel stoves.

Therefore, biomass pellet fuel is widely used in biomass straw power plants, boilers of enterprises and institutions, biomass straw gasification stations, cooking and heating of household special stoves, European-style heating fireplaces, etc., and then replaces coal burning to solve environmental pollution problems.

No, multiple wastes can be granulated together. Our straw pellet machines are suitable for processing various crop pellets for fuel and livestock feed.

This MZLH series straw pellet mill is used to process straw fuel pellets. We can provide special straw feed pellet machines, and have established projects such as a straw pellet feed production line in South Africa.

Yes, Richi Machinery has lots of projects straw pellet machine for sale Asian countries, includes Indonesia, Thailand, Malaysia, Japan, Korea, etc.

Yes. If you want to process straw feed pellets or straw organic fertilizer pellets, please contact us to customize the pellet processing plan that suits you best.

Richi Machinery is a pellet machine factory, a professional manufacturer, not a middleman.

The company has a complete accessories system, and in order to ensure the continuous operation of the equipment, there are many types and high quality accessories. It can be shipped quickly, reducing customer waiting time, reducing the risk of equipment downtime, and enjoying a one-year warranty.

We will tailor the solution according to your actual needs, configure the appropriate equipment model and processing technology, and as a direct sales manufacturer, the price is relatively favorable.

The delivery cycle of our stand-alone and complete production line equipment is generally 7-60 days. If it is a stand-alone device, the delivery will be faster.

Yes, our technical team can go to the site for installation and commissioning, and provide technical training on operation and maintenance. Richi Machinery has always provided a full set of services. From customer consultation to project completion, pre-sales, sales, and after-sales services are all guaranteed, and customers can rest assured.

Richi Machinery started in 1995. nearly 30 years.

According to our actual statistics, our equipment has been exported to more than 130 countries around the world.

You can make an appointment online at any time, and a dedicated technical consultant will take you to visit our equipment processing workshop and learn more about the equipment.

Yes, we provide inspection services of the actual project site.

All our straw pellets machines adopt horizontal ring die structure. The vertical structure has only emerged in recent years. None of the well-known pellet machine manufacturers will follow suit to manufacture vertical ring die pellet mills, because the comprehensive advantages of horizontal ring die pellet mills are incomparable. If you want to know more information of straw pellet machine for sale, welcome to contact Richi Machinery directly online!