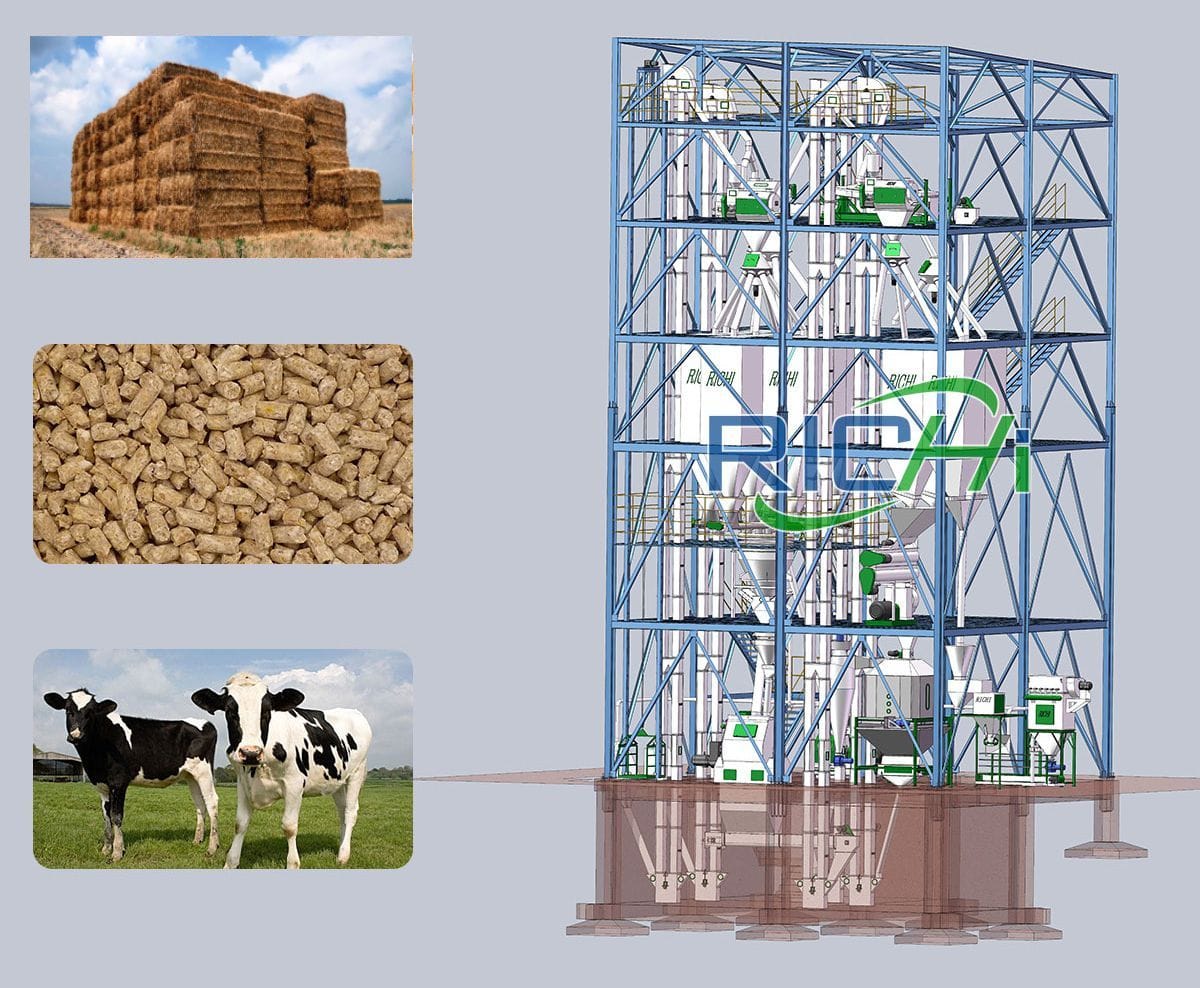

straw pellet production line for livestock cattle goat feed

The straw pellet production line is a technology that uses a pelleting system to process crop straw into livestock pellet feed. This technology is easy to operate, highly practical, has obvious feeding effects and has low investment. It is a practical feed production system worth promoting.

As a professional straw feed pelletizing system manufacturer, we provide a full set of straw pellet line construction services from consultation, design, manufacturing to installation, commissioning, and maintenance.

Cost: 30,000-500,000USD

- Raw material: The straw pellet production line is suitable for pressing various crop straws feed pellets such as wheat straw, rice straw, corn straw, rape straw, cotton straw, etc. It is also suitable for making baggase feed pellets, sunflower husk feed pellets, peanut shell feed pellets, rice husk feed pellets, grass feed pellets, alfalfa feed pellets, hemp feed pellets, hay feed pellets, timothy pellets, etc.

- Applicable customers: Agricultural resource companies, animal feed mill plants, fully automatic cattle feed plant, livestock feed factory, rabbit feed factory, sheep feed factory, fermented feed factory, etc.

The conversion of straw into feed is an area of concern for many customers. Feeding straw directly will cause waste. If it is processed into straw pellet feed, it is easy to store and transport, which can improve economic benefits and facilitate commercialization.

Types of straw pellet production line Solution

According to different animal types, different raw material properties, and different pellet processes, straw biomass pellet production lines are divided into the following common types:

- Complete compound straw pellet feed production line

- Straw concentrate feed pellet feed production line

- Straw coarse pellet feed production line

- Fermented straw pellet feed production line

- Dry straw feed pellet production line

- Wet straw feed pellet production line

- Cattle straw feed pellet production line

- Sheep straw feed pellet production line

- Horse feed straw pellet production line

- Rabbit straw pellet production line

- . . .

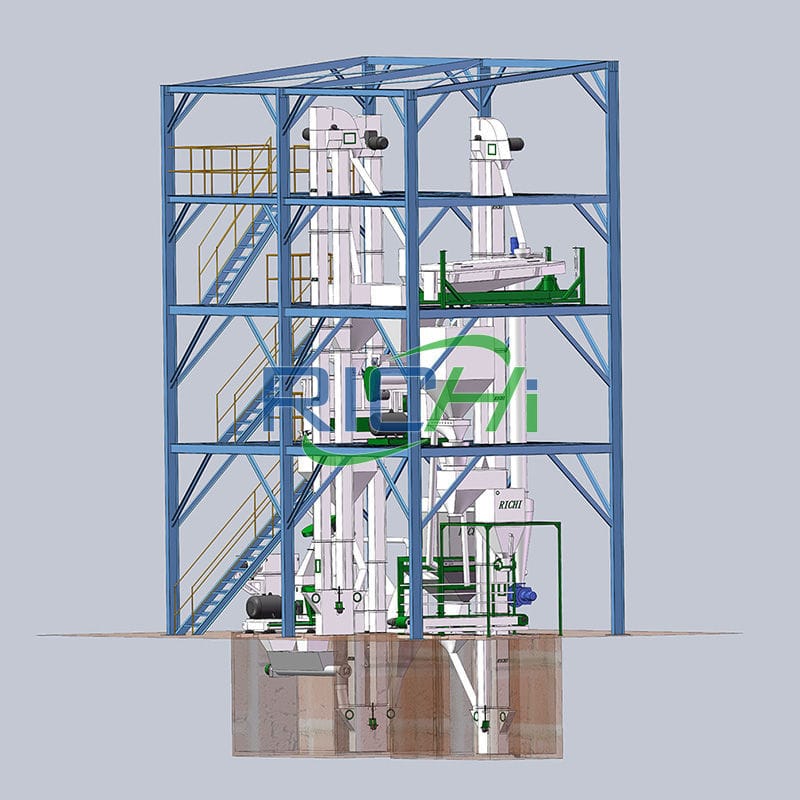

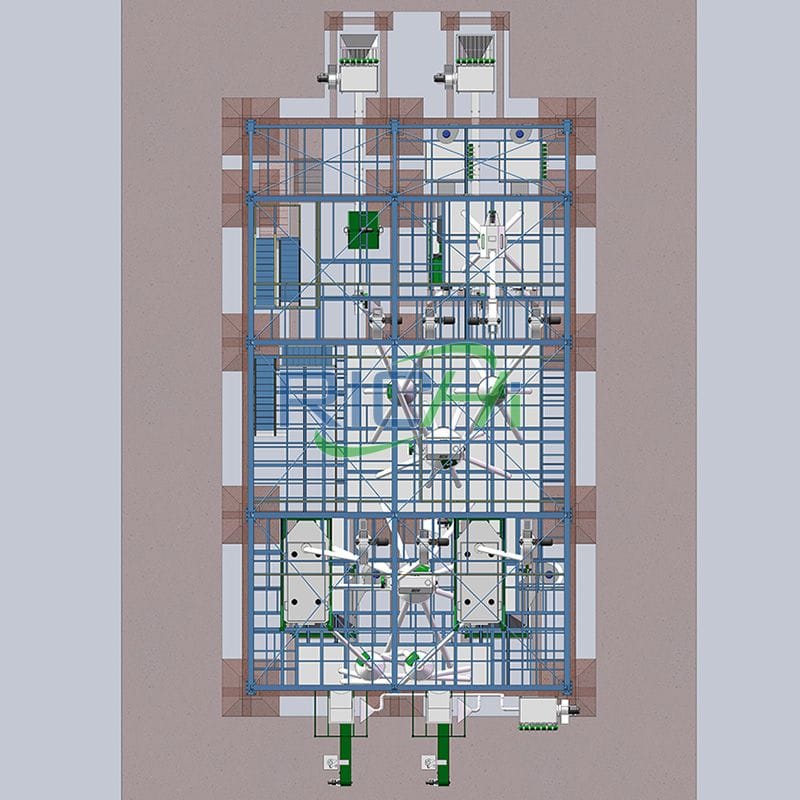

straw pellet production line process design

The straw pellet production line technology is a technology that kneads and crushes the straw into powder, and then uses pelleting equipment to press the straw into granular feed. The entire process includes coarse crushing, fine crushing, mixing, granulation, packaging and auxiliary systems.

- If feed pellets containing only straw are processed, only one raw material is needed and no ingredients are required.

- During the processing of straw pellets, concentrates and other nutrients are often added to form a full-price feed, which not only improves the pelleting performance, but also complements nutrients and gives full play to the nutritional value of the feed.

- Usually, hot water is sprayed or steam is introduced to moisten the grass powder during granulation. The amount of water is generally controlled at 3-6% of the feed amount, so that the grass powder reaches a suitable moisture content for granulation of 14-16%.

- The grass powder should be crushed finer, or about 5% of oil or molasses can be added to the grass powder raw materials. The particle diameter is generally between 10-30mm.

- It can be determined according to the objects to be raised. The smaller the livestock and poultry, the smaller the required particles will be.

- The pellet density is preferably 1.2-1.3 g/cm³, and the pellet bulk density is between 550-600 kg/m³.

Straw pellets have the advantages of good palatability, large feed intake for livestock, short feeding time, and less waste. However, different equipment costs and final project operating expenses will also be different. Below, RICHI will tell you how to build a straw pellet production line.

equipment for starting straw pellet production line

Bale breaker

Capacity:

1-15T/H

Main Power:

30-150KW

straw crusher Machine

Capacity:

0.3-3 T/H

Main Power:

22-93 KW

Hammer Mill crusher

Capacity:

3-25T/H

Main Power:

30-160KW

From the selection of equipment, we must choose high-quality, guaranteed equipment. If we want to build an efficient straw pellet production line, purchasing suitable production equipment is the key. Efficient straw pellet production equipment can help us improve production efficiency, product quality and safety, while reducing production costs and promoting the sustainable development of the breeding industry.

When purchasing straw pellet production line equipment, you need to choose the appropriate equipment brand and model based on your own production scale and needs, and pay attention to the performance and technical indicators of the equipment, as well as the manufacturer’s after-sales service and support.

Featured straw pellet production line design

Here, RICHI will give you a list of several featured straw pellets production line processes and equipment configurations.

01 how to make straw pellets 0.8-1.2 ton per hour?

- straw pellet production process: Crushing and Mixing System – Pelletizing System – Cooling& Screening and Packing System – Electrical Control section

- straw pellet production line cost: 30,000-50,000 USD

- pellet size from this line: 6.0-8.0 mM

- The proportion of straw in the formula: With 50% straw in recipe

- Machinery for 0.8-1.2 t/h straw pellet plant:

| Name | Model | QTY |

| straw Hammer mill | 9F56*40 | 1 |

| Mixing machine | SLHY1.0A | 1 |

| Stainless steel condtioner | TZQ22*180 | 1 |

| straw Pellet machine | SZLH250 | 1 |

| Conterflow cooling machine | SKLN1.0*1.0 | 1 |

| Vibrating sifter | ZDS60*1 | 1 |

| Winnowing cyclone | SK60 | 1 |

02 how to making straw pellets 2- 3 t/h?

- straw pellet production process: Crushing system – Pelletizing and cooling system – Packing system

- straw pellet production line cost: 140,000-160,000 USD

- pellet size from this line: 6.0-12.0 mM

- The proportion of straw in the formula: With 100% straw in recipe

- Machine list:

| Name | Model | QTY |

| Bale breaker | MPKJ170*225 | 1 |

| Straw/Grass crusher | 9FQ50-100 | 1 |

| Bucket elevator | TDTG40/23 | 2 |

| U-Screw conveyor | TLSSU30 | 1 |

| straw pellet mill | MZLH-420 | 1 |

| Cooling machine | SKLN11*11 | 1 |

| Vibrating screener | TDZS80 | 1 |

| Packing machine | DCS-50 | 1 |

03 how to processing straw pellets 4-6 t/h?

- straw pellet production process: Crushing System – drying system – Pelletizing System – Cooling& Screening and Packing System

- straw pellet production line cost: 350,000-450,000 USD

- pellet size from this line: 6.0-12.0 mM

- The proportion of straw in the formula: 100% Wet Bale Straw

- Machine list:

| Name | Model | QTY |

| Bale breaker | MPKJ170*225 | 1 |

| Straw crusher | 9FQ50-120 | 2 |

| Drum dryer | ф2400*100000 *3 Layer | 1 |

| straw pellet press | MZLH 520 | 2 |

| Cooling machine | SKLN17*17 | 1 |

| Vibrating screener | TDZS80 | 1 |

| Packing machine | DCS-50 | 1 |

04 how to make straw feed pellets 10-12 t/h?

- straw pellet production process: Crushing system – Drying system – Second Crushing system – Mixing system – Pelletizing and cooling system – Packing system

- straw pellet production line cost: 500,000-700,000 USD

- pellet size from this line: 6.0-12.0 mM

- The proportion of straw in the formula: With 60% -80% Straw in recipe

- Machine list:

| Name | Model | QTY |

| Straw crusher | 9FQ50-120 | 2 |

| Drum dryer | ф2400*100000 *3 Layer | 2 |

| Straw/Grass crusher | 9FQ50-120 | 2 |

| Single shaft double ribbon mixer | SLHY5.0L | 2 |

| straw pellet making machine | SZLH.508 | 3 |

| Cooling Machine | SKLN20*20 | 1 |

| Rotary screener | SFJH125*2C | 1 |

| Packing machine | DCS-50 | 1 |

The above plan is only a project plan we have already done, and it simply lists some equipment conditions. Each customer’s raw material and process requirements are different. Contact us at any time to customize your straw pellet production line plan! (Find RICHI on YouTube)

straw pellet production line Projects

6-10T/H straw pellet production line in Australia

- Date: Sep 21th, 2015

10T/H straw pellet production line in Uzbekistan

- Date: July 1th, 2019

5T/H straw pellet production line In Argentina

- Date: February 2021

3-5T/H straw pellet production line In Malaysia

- Date: October 29, 2021

5 t/h straw pellet production line in Netherlands

- Project date: 2021.10.19

5-10 t/h straw pellet line in New Zealand

- Project date: 2022.10.14

15 t/h straw pellet production line in India

- Project date: 2022.06.30

10-12T/H straw pellet production line in USA

- Project date: 2019.05.10

1-2T/H straw pellet making line in Canada

- Date: June 30, 2020

16T/H straw pellets line South Africa

- Date: December 2020

5-7 t/h straw pellet processing line in Russia

- date: 2022.06.09

10T/H straw pellet production line in Indonesia

- Project date: 2018.09.13

5 T/H straw pellet production line In Brazil

- date: 2022. 09.13

10 t/h straw pellet production line in Thailand

- date: 2021. 07. 22

20T/H straw pellet production line in China

- Date: June 2019

15 T/H straw pellet production line in China

- Date: December 2018

How to build a 1-160 t/h straw pellet production line?

The design of the straw biomass pellet plant is a very detailed and serious work. The quality of the design not only affects the cost of capital construction investment, but also directly affects the quality of the product and various technical and economic indicators after it is put into production.

01 Land planning and site selection:

- Save land. Whether it is a new straw pellet production line or the renovation of an old straw pellet production line, land resources are a major investment.

- While trying to adopt new processes, new technologies, and new equipment, consider adding automated control systems, which will provide more resource preparation for the production, management, and later Internet marketing of the straw pellet production line.

- Environmental protection issues must be fully considered, and dust, odor, noise, earthquake resistance, logistics, lightning protection, fire protection, etc. in the straw pellet production line workshop must comply with relevant regulations and specifications. Therefore, when choosing a site, consider living areas away from people.

- Process design and equipment selection should cooperate with each other. Process design is an overall design closely related to civil engineering, power, water supply and drainage, etc. Different types of straw pellet production lines have different process designs. It is the selection of equipment. The principles of process design and equipment selection are: reducing the waste of personnel walking back and forth, reducing the waste of moving materials back and forth, reducing the waste of waiting, and reducing the waste of unqualified products. Make solid preparations for later lean production management.

- Straw pellet production line construction projects are usually proposed based on the long-term development plan of the industry or enterprise. Before making preparations for the straw pellet production line, the customer team must fully discuss but not limited to: the site selection, product line composition, production process, raw material description, equipment description, etc. of the new straw pellet production line.

- Policy orientation should also be one of the factors that customers consider, especially for complete compound straw pellet production lines. As the breeding area moves inward, forward-looking site selection needs to be considered in advance.

- After site selection, unified consideration should be given to whether a single-story factory building can be built, building density, green space ratio, building height, motor vehicle parking space configuration, non-motor vehicle parking space configuration, etc.

- Full consideration and discussion in advance will have a certain guiding role in the later graphic layout design and process design, and will avoid many detours.

02 technological design

The process design of the straw pellet production line is a relatively complex task. A good process design not only guarantees product quality, but also reduces investment and use costs. At the same time, the process design of the straw pellet production line also needs to be quite flexible and adaptable to meet the needs of producing various products.

- Use the product line description and raw material description in the early preparation stage to select process specifications and determine the process.

- Use the description of the straw pellet production process to calculate process parameters and select process equipment.

- Determine a good straw pellet production process, determine the power required for the process, and determine the dust removal, odor removal and noise reduction plan.

- Establish process operation procedures and determine program control methods with reference to ergonomics.

- Design and determination of information network.

If it is your first time to set foot in the construction of straw pellet production line, you must have many questions. If you are interested in our equipment, please feel free to contact Richi Machinery. Our technical consultants will explain the detailed technical solutions to you and send our project site videos and pictures.

service for straw pellet production line

Stocking and transportation

In terms of equipment packaging, we use professional packaging and modular solutions to ensure safe and undamaged delivery of equipment.

installation and commissioning

According to customer needs, installation engineers will guide the construction of site infrastructure, equipment installation and commissioning, and trial operation of the entire straw pellet production line throughout the process.

training

We provide comprehensive and systematic training for users’ technical personnel to better serve straw pellet production line project needs and ensure stable operation of customer projects.

Accessories

As long as the customer makes a call, we can transfer the goods from the warehouse in time, reducing the waiting time for customers and reducing the risk of equipment downtime.