rice husk pellet plant soultion

RICHI rice husk pellet plant is a biomass pellet processing system with rice husk as the main raw material, and it is also the simplest process in the biomass pellet system.

- Capacity: 0.6-90 T/H

- Cost: 30,000-1,500,000 USD

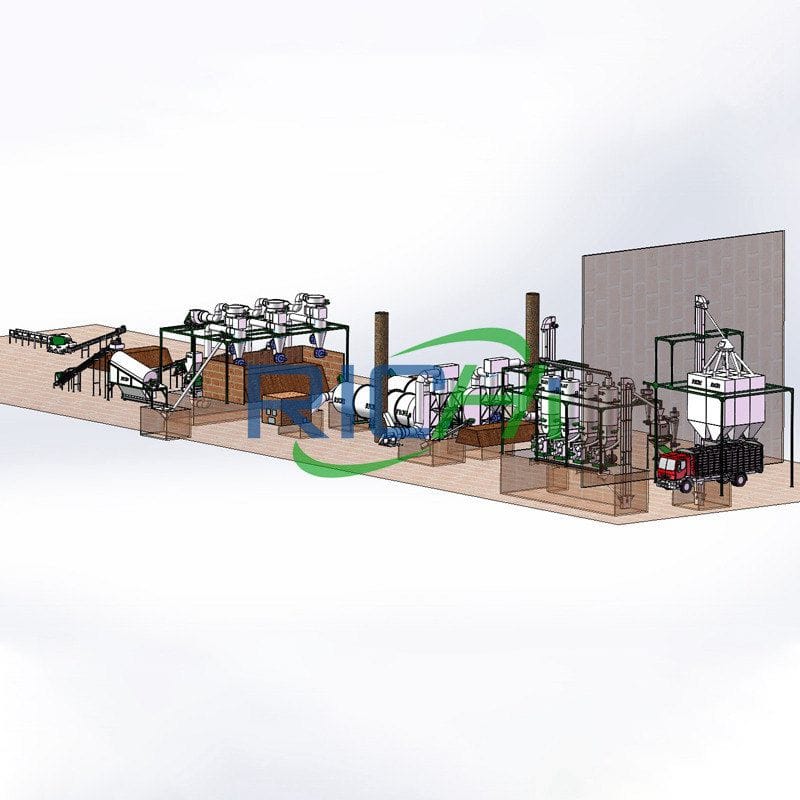

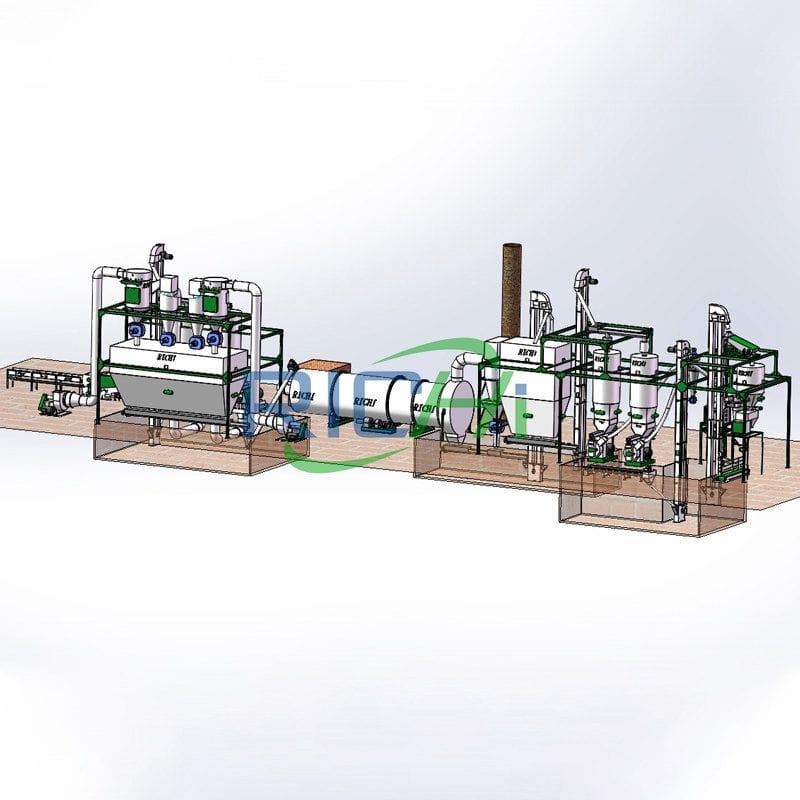

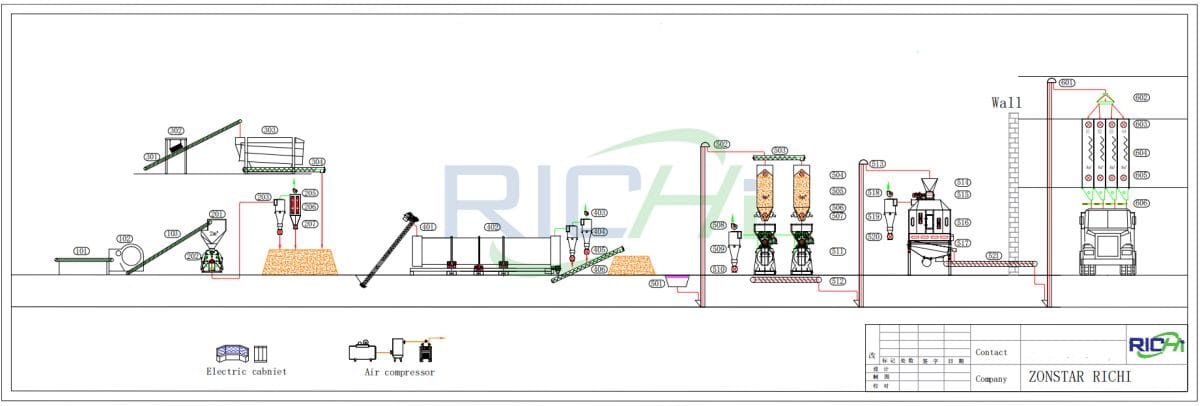

This rice husk pellet plant system mainly includes cleaning, granulation, cooling, screening, packaging and other sections.

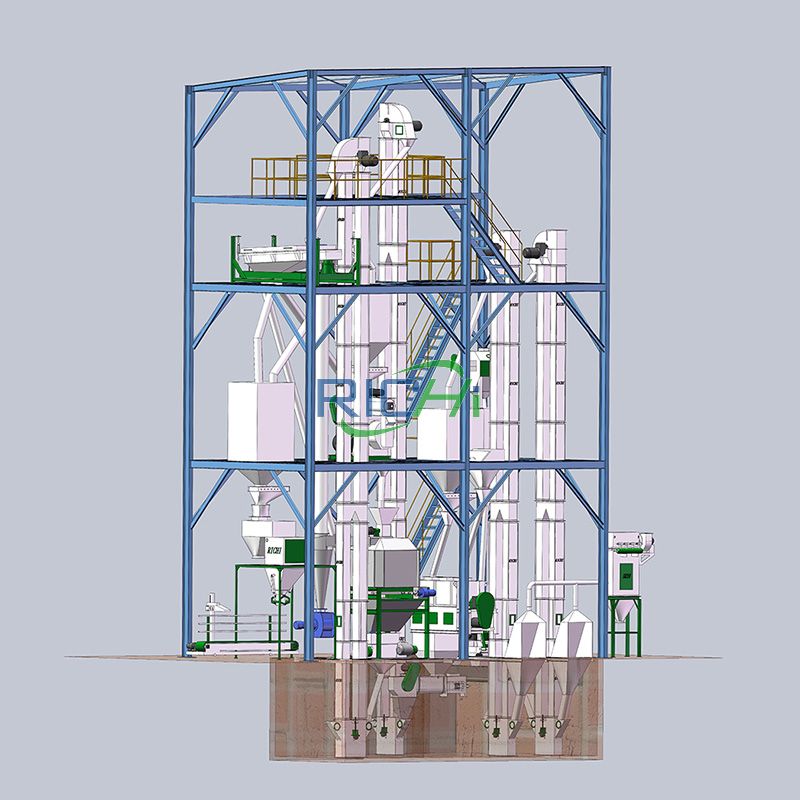

According to the customer’s raw materials and special process requirements, plant structure and height, the RICHI pellet production line can be customized and modularized.

As an emerging raw material of biomass pellets, rice husk has the characteristics of easy collection, low price, small particle size and good molding effect. The mass of rice husk is about 1/5 of the total mass of rice, and the resource reserves are abundant, and the application prospect is very broad.

Rice husk pellet plant types

The rice husk pellet production line is mainly divided into pure rice husk fuel production line, rice husk and other agricultural and forestry waste mixed pellet production line, rice husk feed production line, and rice husk organic fertilizer production line.

At present, since the main application of the rice husk pellet production line is to process fuel pellets, our solution is mainly for fuel rice husk pellets. If your application is different, welcome to consult us directly, and our technical consultant will send you the corresponding solution.

Rice husk pelleting plants we can supply:

Pure rice husk fuel pellet plant

rice husk and other biomass Pellet Combined Line

Rice husk organic fertilizer production line

Rice husk feed production line

Processing technology of rice husk pellet plant

In the process of producing rice husk pellet fuel products, process conditions directly affect the production efficiency and quality of pellet products. Therefore, it is necessary to determine a reasonable rice husk pellet production process for customers.

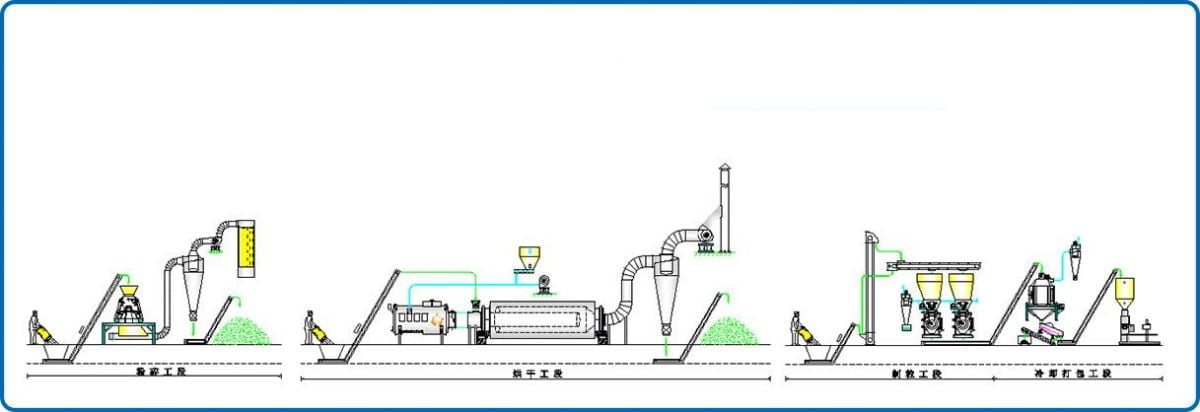

Generally speaking, the technological process of the rice husk biomass pellet production line is relatively simple, mainly including:

- Screening: remove impurities in the rice husk, such as rocks, iron, etc. (If the raw material is clean rice husk or biomass raw material, this section is not required)

- Pelleting: transport the cleaned rice husk to the silo, and then transport it to the rice husk pellet machine through the silo for granulation.

- Cooling: After granulation, the temperature of rice husk pellets is very high, and it needs to enter the pellet cooling machine to cool down.

- Screening: Screen out the unqualified pellets, and the qualified pellets enter the packaging section or enter the finished product warehouse for storage.

- Packing: If you sell the rice husk pellets, you need a packing machine to pack the rice husk pellets.

Equipment needed to start rice husk pellet plant

Screening Machine

Capacity:

3-20T/H

Main Power:

1.5-5.5KW

When using two or more types of agricultural and forestry wastes, such as rice husk & sawdust, rice husk & straw, rice husk & planks, rice husk & straw & efb & bamboo, etc., we need to customize the rice husk pellet plant process according to your raw material size, moisture. If you have any questions, you can consult us directly!

Why use rice husk as Raw materials?

The birth of rice husk pellet plant is mainly based on the advantages of rice husk itself. Compared with other types of biomass pellet products, rice husk pellets have wider sources of raw materials, lower prices, better molding effects, simpler production processes, and good economic, ecological, and social benefits.

01 rice husk uses

Biomass rice husk pellet fuel can replace coal, and its sulfur dioxide emission value is about 1.3 g/kg, which is more than 90% lower than that of coal. It can be used for urban heating, steam generation by biomass boilers and power generation, etc., and is widely used. The burned rice husk ash can be used as fertilizer.

02 calorific value

The calorific value of pellet fuel made from rice husk is 3700-4200 kCal/kg. Rice husks are flakes, small in particle size, and generally less than 15% moisture.

Compared with wood product waste, orange stalks and other materials with large particle size and high moisture content, the rice husk pellet plant process does not require crushing and drying sections.

It has the characteristics of short processing route and low cost. It is the ideal raw material for making pellet biomass fuel.

03 Economic advantages

Taking one of our Asian customers as an example, the processing cost of making biomass fuel from rice husk is about 17.5 US dollars/ton. The price of rice husk around this area is 45 US dollars/ton, and the sales price of pellet biomass fuel in the market is 102-160 US dollars/ton.

Based on the minimum sales price of USD 102/ton, the value of rice husk can be increased by USD 40 per ton. For a rice processing plant with a daily processing capacity of 100 tons, the daily profit can reach 730 US dollars, and at the same time, it solves the problems of warehouse capacity and rice husk crushing.

The investment in building a rice husk biomass pellet manufacturing plant with a daily processing capacity of 30-40 t of rice husks is about US$87,706, covering an area of 300 m2, and the full cost can be recovered within one year.

Case study of rice husk pellet plant

[CASE 1] 2.5T/H rice husk pellets production plant

—— Origin of project——

The client of this project is a grain intensive processing enterprise.

In order to utilize the rice husk solid waste generated by the rice production line, an investment of 93,000 US dollars was invested in the expansion of four rice husk pellet production lines in the original factory area, with an annual output of 5,000 tons.

After the project is completed and put into production, it will solve the problem of inconvenient transportation of chaff, increase jobs, promote local economic development, and have good economic and social benefits.

- Site area: 1230m²

- Total project investment: 120,000USD.

- Working system: 240 days of annual production, 8 hours a day, no production at night

- Number of employees: 5

- Raw material size: about 1-7mm, moisture content about 8-12%

- Pellet size: about 8mm in diameter and about 8cm in length

- Existing engineering construction: mainly including warehouse of 5297.7m², production workshop of 3775m², total storage capacity of 20,000 tons; a nutritional rice processing production line with an annual output of 120,000 tons.

Main construction scale and content

This biomass pellet making plant project uses the existing vacant workshop to build a new rice husk pellet production plant, which mainly includes production workshops and finished product warehouses.

The customer purchased a set of pelletizing production equipment, which has a production capacity of 2.5 tons of biomass pellets per hour. These include granulators, feeders, fans, coolers, etc.

| Engineering category | Construction content and scale |

|---|---|

| production workshop | One floor, with a construction area of about 600m2 (30m×10m×2), a height of about 9m, four production lines, and a production scale of 5,000 tons per year |

| General Office | is located on the southeast side of the factory area, mainly including restrooms, toilets, and offices |

| Material warehouse | Consists of 4 hoppers, each with an outlet |

| Finished Bucket | 18 finished buckets |

| finished product library | The area is about 630m2 (30×21m), the height is about 9m, and it is used for stacking finished products in bags |

Product solutions

The supporting drying workshop of this 2.5t/h rice husk pelleting plant project has a processing capacity of 32t/batch (each batch takes 75-95 minutes).

| Product name | Designed production capacity (tons/year) | Wrapping method |

|---|---|---|

| Rice husk pellets | 5000 | bagged |

Raw material consumption

| Name | Quantity (t/a) | source |

|---|---|---|

| Rice husk | 5500 | The husks produced by the rice production line are purchased when they are not enough |

2.5T/H rice husk pellet plant process flow

- Raw materials: Raw materials are taken from the rice production line and transported to the granulator through a closed air duct. The raw material hopper is installed on the top of the production workshop.

- Pelletizing: The material in the raw material hopper is transported to the feed port of the granulator due to the center of gravity. Under the condition of high temperature and high pressure, moisture is discharged to the atmosphere in the form of water vapor. The raw materials are pressed into rice husk pellets, which are transported to the next process by belt conveyor. The granulation process adopts electric heating, and the granulation temperature is about 80°C-120°C.

- Conveyor belt transportation: After being processed by the rice husk pellet making machine, the rice husk pellets fall from the discharge port to the belt conveyor, and transported to the finished product bucket by the belt conveyor.

- Cooling: When the rice husk pellet granulator is discharged, the temperature of the pellets is as high as 80-90°C, and they must be cooled to room temperature before being put into storage. This rice husk pellet plant project uses air cooling, because the biomass pellets have been compressed and dense.

- Finished product bagging and storage: the bottom of the finished product warehouse is a funnel-shaped discharge port, which is pneumatically unloaded. finished product transported by the conveyor belt to drop into the packaging bag, and transported to the finished product warehouse with a forklift.

Note:

(1) Dry exhaust gas

In the drying process, dust will be generated. The annual drying of rice husk is 1000t/a, and the amount of dust generated in this process is 0.1‰ of the drying amount, which is about 0.1t/a.

After being exhausted through the closed exhaust pipe and treated by the matching bag dust removal facilities, the tail gas is discharged into the ash storage (the ash storage is closed). The treatment efficiency is 99.9%, and the unorganized waste gas emission is 0.001t/a (0.0125kg/h).

(2) Water vapor

Water vapor is the evaporation of water in the raw materials due to high temperature and high pressure in the granulation process and is discharged to the external environment. There is no harmful substance in the water vapor.

The moisture content of raw materials for this rice husk pellet making plant project does not exceed 12%, and the moisture content of finished products is less than 5%. The water vapor generated by this project is about 489t/a.

Equipment for 2.5 t/h rice husk pellet plant

| Device name | QTY |

|---|---|

| Rice husk pellet machine | 4 |

| Feeder Φ273 | 4 |

| Rotating steel frame XZJ-80 | 4 |

| Finished Bucket | 18 |

| Conveyor belt | 10 |

| Pellet cooler | 4 |

| Fan 9-26 | 4 |

| CycloneΦ120 | 4 |

| Simple sieve | 4 |

| Forklift | 1 |

| Electric control cabinet | 1 |

| Hot stove | 1 |

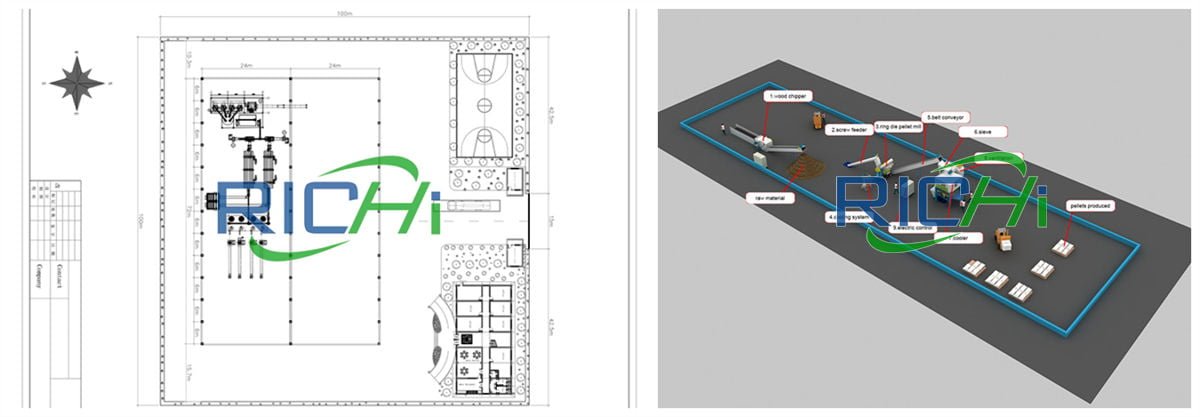

General layout

This biomass pellet line project is located in the original factory building, the site is roughly rectangular, and the office and living areas are based on the original project.

The production workshop is located on the east side of the site. The finished product conveyor belt, finished product hopper, cooler, conveyor belt,rice husk granulator, feed air duct and feed hopper are arranged in sequence from north to south in the workshop.

To the west of the workshop is the finished product warehouse. A gate is set on the west side of the finished product warehouse for vehicles to enter and exit.

[CASE 2] 10T/H rice husk pellet plant project

—— Origin of project——

This project is to make use of waste resources and process waste resources (wood chips, chaff, reed residue, etc.) issues, increase jobs, and protect the environment.

The main raw material of this project is mainly chaff. The combustible content of chaff is more than 70%, and the calorific value of chaff is 12560-15070kJ/kg, which is about half of standard coal.

It is a convenient and cheap energy source. Especially in rice mills, where energy is obtained and rice husks are processed at the same time.

There are more than 100 large and small rice mills around the project, and the main by-products of rice mills are chaff, which provides raw materials for this project.

- Project investment: 430,000 USD

- Number of employees: 10 people,

- Working system: the number of working days per year is 300 days

- This project uses the new factory building that has been built, and only needs to install and debug the equipment. The construction period is relatively short, about 15 days.

Scale of rice husk pellet plant

- Production workshop: a one-story building with a construction area of about 1000m² (20m×50m), a total of 3 rice husk production lines, and a production scale of 30,000 tons per year.

- Office and living area: a two-story building with a floor area of about 100m² and a construction area of about 200m². The first floor is a canteen and lounge, and the second floor is an office.

- Warehouse: a one-story building, with a building area of about 1000m² for the raw material warehouse, which is used to stack the collected raw materials, and a building area of about 500m² for the finished product warehouse, which is used for stacking finished products.

Main raw and auxiliary materials and products

The raw material is mainly chaff, with a diameter of about 8mm, a length of 2~3cm, ash content ≦ 8.0%, density ≧ 1.1t/m3, and a low calorific value of 3200kg/calorie.

The moisture content of the finished product is less than 2%. The annual raw material consumption of the 10t/h rice husk pellet plant project is about 33,000 tons.

| Name | Consumption | Remarks |

|---|---|---|

| Rice Husk | About 20,000 tons/a | Outsourcing from the market, surrounding rice factories |

| Sawdust | About 10,000 tons/a | Market outsourcing, furniture factory |

| Reed residue | About 3,000 tons/a | Market outsourcing |

| Electricity | 125,000 kW·h/a | / |

| Water | 240 t/a | / |

10T/H rice husk pellet plant process flow design

In this biomass pelletizing plant project, the production process we designed for the customer has strict requirements on the moisture content of the raw materials. The moisture content of raw materials purchased by customers is lower than 12%, and the moisture content of finished products is not higher than 2%.

①Crushing

Raw materials pass through the conveyor belt of the belt conveyor and enter the feed port of the biomass pulverizer for pulverization. Crushing is the process of turning large solid raw materials into smaller particles.

Due to the large size of the purchased raw materials, they need to be crushed so as not to affect the normal operation of the subsequent granulation process.

② Granulation

The crushed raw materials are fed from the feed port. Under high temperature and high pressure conditions, moisture is discharged to the atmosphere in the form of water vapor through the roof exhaust fan. The raw materials are pressed into rice husk pellets and transported to the next process by a belt conveyor. The granulation process adopts electric heating.

③Packaging

The rice husk pellets are transported to the elevator through the conveyor belt, and the position is lifted, and then cooled by the induced air of the cooler, and packed into bags.

The entire production process of the 10t/h rice husk pellet plant project is completed on a closed assembly line, only raw material transportation, granulation feed transportation, and finished product transportation are open.

The process of closed operation is equipped with bag filter for dust control, and the process of open operation is equipped with cleaning and vacuum cleaner for dust control.

Equipment for 10t/h rice husk pellet plant

| Device Name | Quantity |

|---|---|

| Rice husk grinder | 1 |

| Rice husk pellet mill | 3 |

| Pellet cooler | 1 |

| Bucket elevator | 1 |

| Automatic sewing machine | 1 |

| Cyclone | 3 |

| Bag filter | 1 |

| Belt Conveyor | 4 |

| Forklift | 3 |

| Transformers | 1 |

| Weighbridge | 1 |

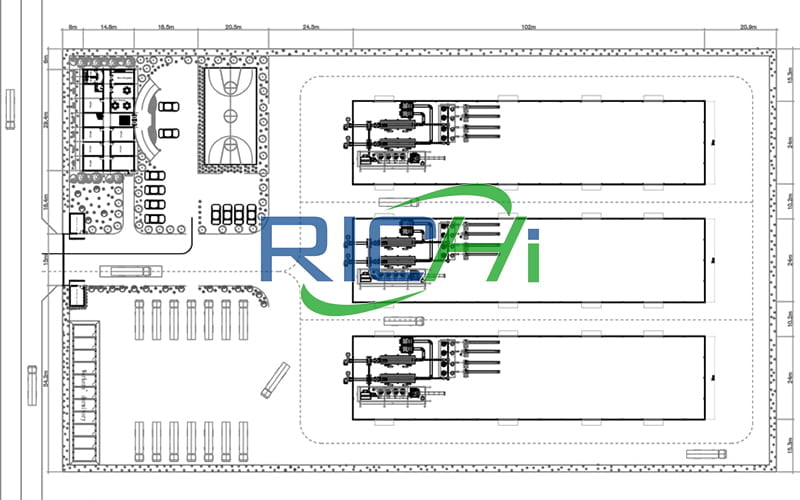

Rationality Analysis of Plane Layout

The 10 tons per hour rice husk pellet manufacturing plant project site is roughly rectangular. The gate is located on the west side of the project, close to the highway, which is convenient for the transportation of raw materials and the output of finished products.

The factory area consists of production workshops, warehouses, and office and living areas. From north to south, the order is: warehouses, production workshops, and office and living areas.

The production workshop is located in the middle of the project, the finished product warehouse is located on the west side of the production workshop. The crushing area is located on the northeast side of the production workshop, the granulation area is located on the west side of the crushing area, and the packaging area is located on the south side of the production workshop.

Due to the barrier and distance attenuation of the wall, the impact of noise and dust on the surrounding environment is reduced, and the weighbridge is located on the west side of the warehouse.

The layout of the rice husk pellet plant project is reasonable, the logistics is smooth, the production line is arranged in accordance with the sequence of the technological process, and the layout meets the requirements of environmental protection.

The noise sources are relatively concentrated, and noise control measures such as shock absorption and sound insulation can effectively ensure that the noise at the factory boundary meets the standard.

[CASE 3] 8T/H rice husk pellets production line production project

—— Project Overview——

The client is an investor. There are many rice processing enterprises in the client’s local area, which generate a large amount of chaff waste, which has good resource recycling value. In this context, the customer invested 146,000 yuan to build a construction project with an annual output of 20,000 tons of rice husk pellets.

- Construction nature: newly built

- Construction scale: total construction area 1200m²

- Labor quota: 6 people

- Working system: The production shift system is one shift, each shift is 8 hours, and the annual working time is 300 days

Construction scale

The total construction area of this 8 ton rice husk pellet plant project is 1200m². The main project of the project includes production workshops, raw material warehouses, finished product warehouses, office buildings, etc.

Among them, the raw material warehouse is 30m×15m×15m (length, width and height), and the production workshop is 30m×25m×20m (length, width and height). A total of 4 rice husk pellet mills are used for granulation in this project, and 4 sets of bag dust collectors are used for dust removal.

- Production workshop: One floor, steel frame structure, construction area of about 1200m² (30m×25m), one side height is 20m, one side height is 15m, 4 production lines are set up, and the production scale is 20,000 tons/year.

- Office: One floor, steel frame structure, construction area is about 100m².

- Weighbridge: Equipped with an electronic weighbridge, which is located on the southwest side of the workshop and is used for production management.

- Power distribution room: on the first floor, the construction area of the power distribution room is about 20m², and it is located in the southeast direction of the factory building.

- Raw material warehouse: The building area of the raw material storage yard is about 450m² (15m×30m), and the height is 15m. The raw material storage yard is used to store the collected raw materials.

- Raw material hopper: It consists of 2 hoppers and a prismatic steel frame structure, each hopper can branch out to 4 outlets, and the maximum storage capacity is about 200t.

- Product hopper: It is composed of 2 hoppers and 1 prismatic steel frame structure, with a maximum storage capacity of about 200t.

Main raw materials and products

The annual raw material consumption of the 8 ton per hour rice husk pellet plant project is about 23,000 tons. The raw and auxiliary materials of the project are detailed in the table below:

| Name | Consumption | Remarks |

|---|---|---|

| Rice husk | About 23,000 tons/a | Outsourcing from the market, surrounding rice factories |

| Electricity | About 125,000 kW h/a | Local grid |

| Water | 110 t/a | Municipal pipe network |

Note:

- Raw material moisture content≦12%

- Products: The raw materials are mainly rice husks. The formed biomass granules have a diameter of about 8mm, a length of about 8cm, an ash content of ≦8.0%, a density of ≧1.1t/m³, and a low calorific value of 3200kg/calorie. The moisture content of the finished product is less than 5%.

8T/H rice husk pelleting plant Process flow

The process of this 8 ton hr rice husk pellet plant project has strict requirements on the moisture content of raw materials. The moisture content of raw materials purchased in this project is lower than 12%, and the moisture content of finished products is not higher than 5%.

①Raw material

The raw materials are stored in the raw material warehouse, and the raw materials are transported through the airtight duct.

②Conveying

The materials transported through the air duct are lifted by the bucket elevator to the next process.

③ Dust removal by dust collector

The material lifted by the bucket elevator is transported to the raw material hopper after being dedusted by the dust collector.

④ Pelleting

The material in the raw material hopper is transported to the feed port of the rice husk pelletizing machine due to the effect of the center of gravity. The raw materials are pressed into rice husk pellets, which are transported to the next process by belt conveyors. The granulation process adopts electric heating.

⑤Conveyor belt conveying

After being processed by the rice husk pellet press, the formed rice husk pellets fall from the outlet to the belt conveyor, and are transported to the bucket elevator by the belt conveyor.

⑥ Cooling

The bucket elevator lifts the rice husk pellets to the raw material hopper, and uses wind cooling during the transportation process. The front cooling process is closed and uses electric energy.

⑦ Finished product bagging and storage

The rice husk pelelts after cooling are temporarily stored in the finished product hopper, and some finished products are stored in the finished product warehouse after being bagged and sealed.

Equipment needed in 8t/h rice husk pellet plant

| Device name | QTY |

|---|---|

| Rice husk pellet making machine | 4 |

| Bag filter | 4 |

| Fan | 1 |

| Belt conveyor | 3 |

| Forklift | 2 |

| Bucket elevator | 3 |

| Transformer | 2 |

| Weighbridge | 1 |

General layout

The raw materials of this 8t/h rice husk pellet plant project are stored in the raw material warehouse and the hopper of the raw material area, and the raw material warehouse is set inside the factory building; the finished products are stored in the finished product hopper and the finished product warehouse, and the finished product warehouse is set inside the factory building. The workshop is a closed structure.

The project site is roughly rectangular. There is an entrance and exit on the south side of the project to facilitate the import of raw materials and the export of finished products. The factory area is composed of raw material warehouse, raw material hopper, finished product warehouse, finished product hopper, granulation area and so on.

The granulation area is located in the middle of the north side of the factory area. The east side of the granulation area is the raw material warehouse and the finished product warehouse. The upper part of the rice husk granulator is the raw material hopper. The upper part of the rice husk pelletizer machine is equipped with a raw material hopper branch.

Due to the barrier and distance attenuation of the wall, the impact of noise and dust on the surrounding environment is reduced. The weighbridge is located at the entrance on the south side of the factory area, which is convenient for weighing raw materials and finished products.

Rice husk, as a kind of biomass pellet energy with great potential, can almost replace part of fossil energy in the process of solidification and molding. It is green, clean, convenient and affordable, and is of great significance to solve the problem of global environmental pollution. If you want to build your rice husk pellet plant, welcome to contact Richi Machinery for details! (Find RICHI on YouTube)