shrimp feed mill

Richi Machinery has been engaged in shrimp feed mill process design and aqua shrimp prawn feed mill equipment manufacturing, and has been continuously exploring the application of new technologies.

We will formulate multiple sets of process plans for comparative analysis according to the actual needs of customers, select a reasonable plan, and realize private customization.

- Capacity: 0.1-60 T/H

- shrimp feed plant Cost: 80,000- 4,000,000 USD

- technology: pelletizing or extrusion

Start A Shrimp Feed Mill

The shrimp feed making plant is a high-end aquatic feed processing system with the design concept of “high quality, high output, intensive, green environmental protection”. The shrimp feed production system can cover the processing of various shrimp pellet feeds and shrimp extruded feeds around the world.

No matter what your formula is, no matter what your shrimp feed processing plant structure is, no matter what your process requirements are, through RICHI customized shrimp feed production line for you process, you will be able to process high-quality shrimp feed and obtain higher economic benefits.

Our services run through all aspects of on-site topographical environment survey, shrimp feed production process design, raw material testing, cost requirement analysis, project investment budget, shrimp feed plant equipment installation and commissioning, etc.

Shrimp feed mill design

As an important part of the feed industry, aquafeed has been paid more and more attention by manufacturers and breeders. Due to the special feeding requirements of fish, shrimp and other aquatic products, the production technology and equipment of aquatic feed are constantly updated and developed.

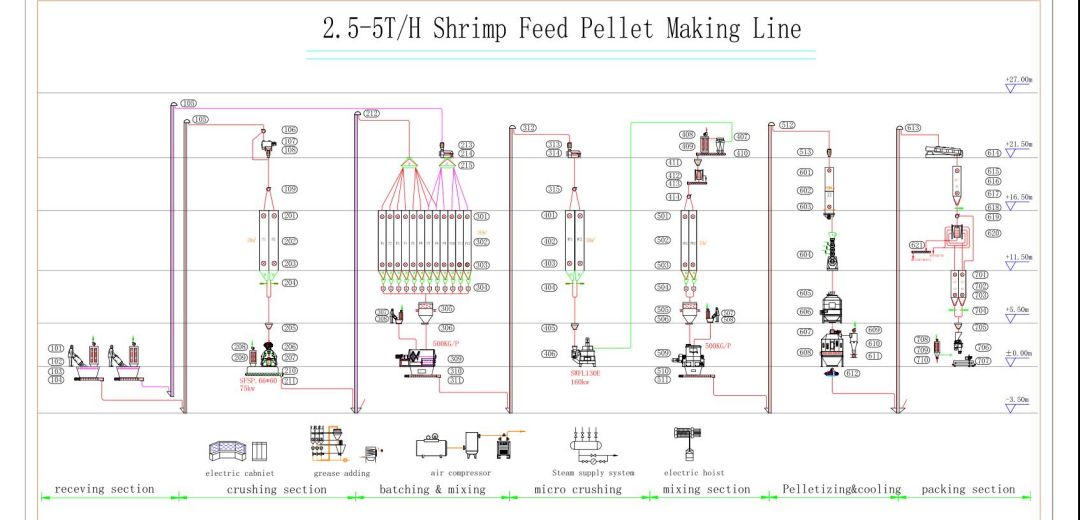

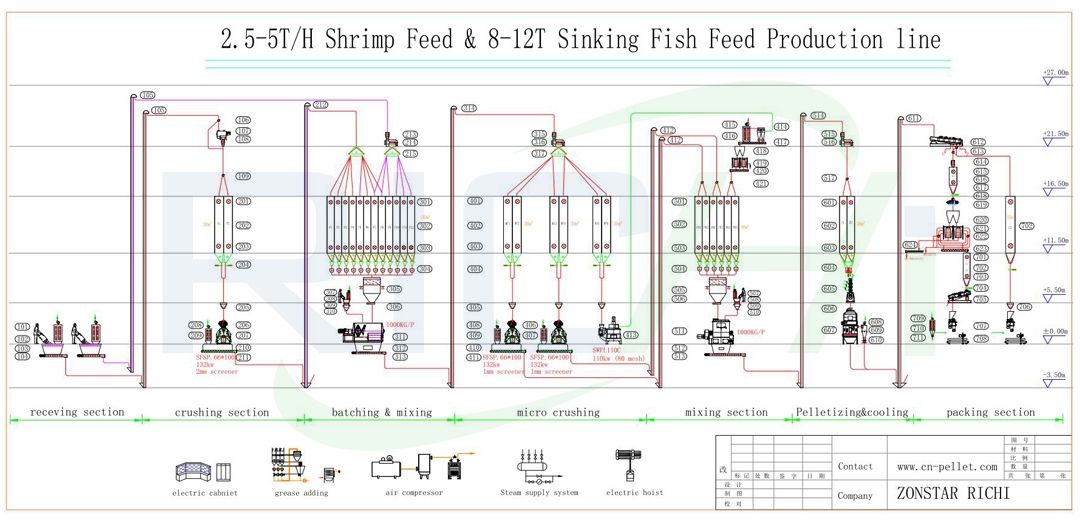

At present, shrimp feed making plant usually adopts two design, one is the ring die pressing method and the other is the puffing extrusion method.

- First batching, then crushing, then mixing, granulating, post-curing, cooling, grading, grading after leaving the warehouse, packaging and leaving the factory;

- The ingredients are first mixed, then crushed, then finely crushed, mixed, puffed, dried, cooled, graded, graded out of the warehouse, and packaged for delivery.

Both of these two shrimp feed mill designs occupy a certain proportion in application, and both can meet the fineness required for the production of aquatic feed, the uniformity of the mixed material particles, and the quality of granulated or extruded products.

RICHI shrimp feed production technology can overcome a series of problems in the shrimp feed production process: High-protein materials are difficult to crush alone, and the ingredients warehouse is arched due to the crushing of the raw materials, etc.

There are advantages and disadvantages in the shrimp feed making plant by the ring die pressing method and the puff extrusion method.

Shrimp feed manufacturers and shrimp feed companies can choose according to their own characteristics and needs.

The ring die pressing method has been used for many years and is in a very mature stage, but it is still being optimized; and the extrusion method is also in a mature stage and still has great potential for development.

We are committed to providing customers with a good service experience. We can customize shrimp feed processing plant configuration solutions for customers according to their needs.

In addition, as long as you leave your email and requirements, our sales staff will get in touch with you as soon as possible to provide you with consulting services for various products.

Complete prawn shrimp feed mill equipment list

The whole set shrimp feed making machines needed in a shrimp feed plant project include:

High Square Screen

Capacity:

3-20T/H

Main Power:

1.5-5.5KW

Spraying Machine

Capacity:

3-15T/H

Main Power:

22KW

From the selection and design of the shrimp feed making process to the installation and commissioning of the shrimp feed equipment, RICHI has invested a lot of time and energy, and has also selected an excellent work team to ensure that the customer’s project is put into production as soon as possible, and this shrimp feed plant will fully meet the needs of customers and create value.

Shrimp feed mill projects

2T/H Turnkey Project shrimp feed mill in Indonesia

Based on the concept of “green intelligence”, RICHI has undertaken the turnkey project of the Indonesian shrimp feed production line.

The project adopts advanced automatic sampling of raw materials, automatic control of pellet mills, unattended guards and weighbridges and other production automation equipment. advantages are maximized.

2T/H shrimp feed processing plant in Ecuador

RICHI joined hands with Ecuador customer to actively respond to the “ecological and intelligent” development direction of the feed industry, and achieved strict feed safety indicators, excellent feed quality and production intelligence and environmental protection through one-stop overall solutions, creating a modern aquatic shrimp feed processing project.

5T/H shrimp feed mill project in Thailand

The client of this shrimp feed production plant project has two independently operating workshops for shrimp feed and fish feed. Among them, there are 4 shrimp and crab feed pellet lines, 4 high-grade aquatic product material pellet lines and 2 high-grade aquatic feed extrusion lines.

Among them, the two new shrimp feed production lines have adopted RICHI’s advanced process design scheme, forming an efficient and stable automatic feed production line based on RICHI equipment.

10T/H shrimp feed plant in India

In this 10tph shrimp feed mill plant project, RICHI has configured 4 advanced shrimp feed pellet production lines and shrimp feed extrusion production lines for customers.

The main products of the client company include shrimp feed, high-grade extruded fish feed, freshwater fish feed, crab feed and other products, which can provide 70,000 tons of high-grade aquatic feed every year.

15T/H shrimp feed production plant project in Vietnam

Constructed by Richi Machinery, the project has 5 shrimp feed production lines with an hourly output of 15 tons.

Reasonable process design and improving the utilization rate of raw materials and water and electricity in the processing process will surely drive the local aquafeed industry to develop to a higher level.

The production of quality shrimp feed depends on factors such as the raw materials and formulation, but superior equipment, designed to produce a pellet has all the right attributes, is truly the key.

RICHI provides global shrimp feed producers with the shrimp feed processing technology and services that allows for a competitive advantage.

Complete shrimp feed production process

The following is a detailed description of the shrimp feed pelleting process and puffing process technology. At the same time, you can also find the answer to “How to choose shrimp feed equipment” here! The followings are commer shrimp feed mill processes, we can also supply customized shrimp feed plant process design service.

01 Raw material receiving & Cleaning system

The raw material receiving system is the most important part of the shrimp feed manufacturing plant. Since the raw materials of aquatic feed are mostly fish meal and other cakes with high protein content, there are many lumps. Because the bags are mixed with hemp rope, plastic rope and plastic film, these sundries enter the initial cleaning sieve or powder cleaning.

It is difficult to handle after screening, which will cause blockage of screen mesh, chute or permanent magnet cylinder, resulting in production stoppage in the section, and even affect the entire shrimp feed production process.

For this reason, in the process design, we place the paddle screw conveyor in front of the feeding port of the primary cleaning sieve or powder cleaning sieve, so that the lumps in the raw materials can be broken, and the hemp ropes.

The plastic rope and plastic film are wrapped around the shaft and paddle of the screw conveyor, which can effectively prevent such debris from entering the next cleaning equipment, and can also save the height of the floor of the workshop building, thereby reducing the construction cost of the shrimp feed factory production workshop.

02 Batching and crushing system

The batching and crushing system is the most important part of the shrimp feed mill plant production process. Using the production process of first batching, then crushing and then mixing, the initial mixing of raw materials is very important. If the raw materials cannot be preliminarily mixed, after entering the pulverizer, the difficulty of pulverizing the raw materials of aquatic feed will increase due to the particularity of the raw materials.

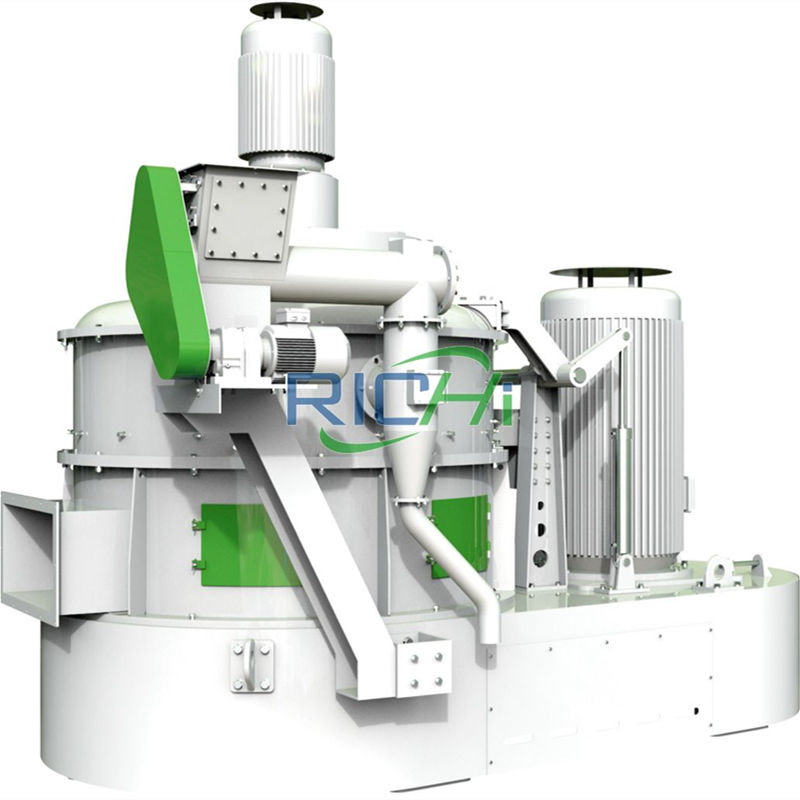

At present, when producing high-grade aquatic feed, the requirements for the crushing fineness of the material are very high, and it is generally believed that it needs to reach 80-120 mesh or finer. In order to meet the fineness requirements, an ultrafine grinding mill is generally used for ultra-fine pulverization, and a vertical shaftless sieve-type ultra fine powder grinder is generally used.

Shrimp live in an aqueous medium environment, the digestive tract is simple and short, and the digestive enzymes are not highly active due to low body temperature. Such special physiological characteristics and ecological environment determine that they need easy-to-digest bait. The crushing particle size of the feed has a great correlation with the digestibility of the bait.

The smaller the particle size of the bait, the larger the surface area in contact with the digestive juice, and the better the digestibility. At the same time, it is also conducive to the conditioning of the material and stimulates the natural bonding components in the material.

When the particle size is 11-13 mesh, the digestibility is 11%; when the particle size is 30-50 mesh, the digestibility is 51%; when the particle size is >50 mesh, the digestibility is 71%. Such a requirement can be achieved with an ultrafine pulverizer.

(According to our experience with the twin screw extruder machine: the crushing fineness of the material only needs to reach 60 ~ 80 mesh, so use a water drop hammer mill feed griner with vibration discharge in the machine, Φ0.6 ~ 0.8 mm sieve plate or Φ0.8 ~1.0 mm fish scale sieve plate can be achieved. Its power equipment and power consumption are significantly reduced (power: 200 kW; output: 3-5 t/h). This configuration can change people’s perception that “when producing high-end extruded feed, the concept of a micro pulverizer must be used.)

03 Mixing and micro-addition system

The mixing section and selection of shrimp feed mixer is very important for the production of aquatic shrimp feed. Since the shrimp feed raw materials to be mixed are relatively fine and the bulk density difference between the components is large, a mixer with better performance and high mixing uniformity should be selected. We generally choose a double-shaft paddle mixer with short mixing time and high performance.

The micro-addition system adopts a manual feeding system with a vibrating screen, a weighing scale device and a high-pressure pulse dust collector, which can not only clean up the sundries and agglomerates in the material, but also record the weight of the input material.

And through the comparison with the quantity set in the program, it will issue an instruction to remind the feeder to complete the task on time and accurately.

04 Pellet granulation & post-curing system

The pelleting production process of shrimp feed is different from the shrimp feed mill production process. When the raw materials are mostly high protein, higher temperature (increase the amount of steam) should be used to achieve protein denaturation and better maturation of materials, to meet the needs of aquaculture.

Prior to pelleting an intense, high temperature and long conditioning time ensures complete adsorption of added liquids and activation of available starch vital for required water stability of finished product. Dies for shrimp feed applications are carefully selected and this will lead to excellent pellet durability and consequently long and good water stability and full sink ability.

Pellet shrimp feed requires good water resistance and non-collapse in water. Initially, binders or stabilizers were added during the shrimp feed production process. In fact, aquatic animals have low digestibility and absorption rate of such feed, and increase the cost of feed.

Later, post-curing equipment was used in the shrimp feed mill process design to coagulate and denature the protein and carbohydrates in the material. The pellets not only have good water resistance and non-collapse, but also are more easily digested and absorbed.

However, the disadvantage is that the moisture of the granulation raw material should not be too high, the ring die and the cutter of the shrimp feed pellet machine are easy to wear, and the surface of the material is not smooth after the granules are post-cured, which affects the appearance quality of the product.

We use a combination of post-curing and drying equipment, which not only achieves the effect of material aging, but also because of the drying equipment, a certain amount of water or other liquid materials can be added during the granulation process to ensure the outer surface of the granules.

The smoothness of the pellet mill reduces the wear of the ring die and cutter of the pellet mill. But its disadvantage is that the equipment investment and floor space are large, the energy consumption is also high, and the production cost is high.

Therefore, in the production of ordinary aquatic fish feed, post-curing process should be adopted. When producing high-grade aquatic shrimp and crab feed, it is advisable to use a post-cooker and drying process.

05 Extruded shrimp feed system

Due to the unique production technology and equipment of the extruded pellet feed, the extruded pellet feed can not only fully float, fully sink and slowly sink in the water, but also meet the feeding needs of different types of aquatic animals and greatly enrich the variety of feed products, so it has become a high-end product for production.

The selection of aquafeed hotspots. At present, the feed extruder machine used by RICHI to produce shrimp feed is a twin-screw extruder. Most of them are mainly based on the production of full-floating feed, and some equipment can produce full-sinking and slow-sinking feed.

The density control system of the RICHI twin screw extruder machine is one of the most reliable systems for controlling the degree of expansion/density of finished products in the world.

It can use pressure to control the boiling point of water; use the boiling point to control the degree of expansion (flash); use the degree of expansion to control the density of the product, to ensure 100% sinking property of the sinking feed and the slow sinking property of the slow sinking feed, and can also increase the output of the sinking feed.

The puffed shrimp feed are usually distributed directly into the distributor, dried by a horizontal dryer, and then lifted, graded, grease sprayed, and cooled.

This kind of design is convenient to place the large-volume horizontal dryer on the bottom layer, and the installation and maintenance are more convenient. It is the process design form adopted by most shrimp feed production mills at present. This is more practical for floor-type shrimp feed plants. However, for the design of the warehouse-type shrimp feed factory, the extruded material should be transported by air to the horizontal dryer for drying, and then air-lifted for subsequent classification, grease spraying, and cooling.

This process can also be used for floor-type shrimp feed mill factories. However, when producing extruded feeds of different varieties (sinkability and floatability) and different particle sizes, the parameters of wind transportation cannot be adjusted greatly, so the effect will be greatly affected.

06 Cooling system

In the feed pelleting process, the cooling of feed pellets is essential. When leaving the pellet mill, the feed pellets are very hot, soft and rich in moisture, the cooling process cools them down to 3℃- 5℃ slightly above room temperature and reduces their moisture content to a safe standard (≤12.5%), for easy transportation and storage.

Through the cooling of pellets and extruded feed, the moisture and temperature of pellets and extruded feed can meet the requirements of safe storage and transportation. However, the treatment of condensed water in this system is more difficult. Therefore, most manufacturers place the cyclone discharger next to the shrimp feed pellet cooling machine.

07 Screening system——shrimp feed mill process

The granular feed is classified after cooling. The purpose is to separate the fine parts that meet the requirements of the finished product, return the fine part to the machine for re-granulation, and return the coarse part to the crusher for crushing or return to the warehouse for re-granulation.

In this system, whether to use a rotary grading screen or a vibrating screen can be determined according to the specific conditions of the product. For example, to produce high-grade aquatic pellet feed, we use a rotary grading screen, which has a significant screening effect, obvious product grading, and relatively simple operation.

If ordinary pellet feed is produced, a vibrating screen can be used, but its screening effect is average, the product classification is acceptable, the operation and maintenance are relatively simple, the replacement of the screen grid is more convenient, and the mutual wear between the particles and the screen surface is also low.

The grading of extruded feed is mostly completed by single or double square sieves. Due to the diversity of extruded products, the use of square sieves can achieve the purpose of multi-variety discharge by changing the sieve grid.

The powder content of the finished pellets and the powder coating rate of the outer layer of the pellets will directly affect the appearance quality and sales of the products. Therefore, the finished pellets are classified by a vibrating screen before being packaged to ensure the quality of the finished product, which is a process system that must be perfected for the current feed.

08 Spraying system

Post-spraying plays a vital role in ensuring the high nutrition and added value of aquatic feeds. The key to the system is the use of post-spraying equipment with uniform spraying and accurate metering.

At present, oil spraying mostly adopts roller type, and a few manufacturers use vacuum spraying equipment system for puffed material. For the enzyme preparation, the imported enzyme preparation spraying system is used.

09 Packaging of finished pellets

The packaging of granular finished products mostly adopts the belt feeding type, which is also the most recognized and the best way in actual production. It can pack both granular and powdered products. Both large and small packages are available. Moreover, the precision and packing speed of the existing belt-feeding packing scale are also reasonable.

10 Automatic control system

The automatic control system of the feed factory is the soul of the production of the shrimp feed factory, especially the first batching, then crushing, then mixing, granulating, post-curing, cooling, grading, oil or enzyme preparation spraying, grading after leaving the warehouse, packaging and leaving the shrimp feed factory.

The shrimp feed pellet production process has higher requirements on the automatic control system.

Because the interlocking and inter-controlling control systems are used between the various sections, if there is no good automatic control system, the entire production system may be paralyzed. For this reason, it is necessary to be more perfect and reliable in terms of the increase of control points and control components in equipment manufacturing, or in terms of electrical control principles and control systems.

The above-mentioned shrimp feed mill technology and shrimp feed making machine all reflect the design principles of people-oriented, energy saving and environmental protection.

And they are implemented in the production of aquatic shrimp prawn feed, which can reduce production costs, energy consumption and investment scale under the premise of fully guaranteeing product quality, economic and social benefits have been greatly improved.

With full shrimp feed mills accounting for half the world’s production of shrimp feed alone, we continuously support leading producers in achieving the highest levels in safety, quality, and control from feed stock to final product.

If you have any needs or questions, please You leave a message, we will reply to you as soon as possible after receiving it! You can also contact us directly via WhatsApp (+86 138 3838 9622)!

Are you wondering:

- How to choose high-quality, low-cost shrimp feed production technology solutions for high-grade shrimp, crab and special aquatic products?

- How to choose micro-grinding and ultra-fine grinding equipment, and reasonably control the grinding fineness, which is suitable for the needs of aquatic animals without wasting energy consumption?

- How to make the conditioner better control the degree of maturation of the feed and improve the degree of maturation and digestion and absorption?

- How to use anoxic sterilization and conditioning after granulation to effectively kill various bacteria and improve the quality of feed, but have a good effect on the effective retention of vitamins?

- How to control the sinking and floating characteristics of the extruded material more accurately?

- How to choose the post-spraying process such as vacuum spraying grease equipment to improve the nutritional quality of feed?

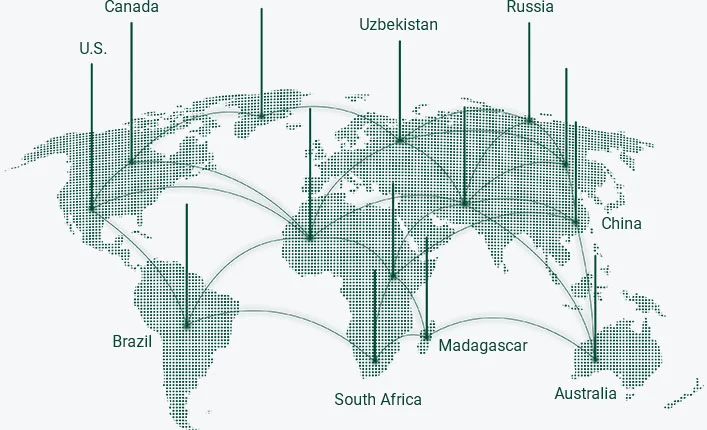

In the past 30 years, we have accumulated rich practical experience, and have reached cooperative relations with more than 10,000 customers in more than 130 countries and regions, providing them with complete solutions and services covering the entire product life cycle.

If you need to know the detailed shrimp feed processing and shrimp feed production line construction, you can consult immediately, or you can leave your contact information, our engineers will contact you in time! (Hot product: Sinking Fish Feed Machine)

Customized Shrimp Feed Plant Project Report

In the past 30 years, we have accumulated rich practical experience, customized reasonable and practical shrimp feed making plant configuration for thousands of customers, and provided a full set of services throughout the pre-sale, in-sale and after-sale.

Our services run through all aspects of on-site topographical environment survey, shrimp feed production line process design, raw material testing, cost requirement analysis, project investment budget, equipment installation and commissioning, etc.

Next, I will share with you two detailed shrimp feed making plant cases, hoping to help you!

How to start a 4T/H shrimp feed plant?

Here is a 4 tons per hour high -end prawn shrimp feed pellet processing plant project report.

The client of the 4 tons per hour shrimp feed mill project is a modern agricultural and animal husbandry technology enterprise integrating import and export trade of feed additives and feed raw materials, feed R&D and production and aquaculture.

The planned total area of shrimp prawn feed mill is 21893m2², the total construction area is 8765.5m², the plot ratio is 0.68%, the greening rate is 19.2%, and the total construction area is 14949.1m², including:

- the finished product workshop 2607.8m²,

- the main production workshop 2441m²,

- the auxiliary production workshop 134.7m²,

- the raw material workshop 4383.6m²,

- comprehensive office building 2921m²,

- doorman weighing room 61m².

The 4t/h high grade shrimp feed processing plant project has an annual output of 15,000 tons, an annual working time of 320 days, a total operating time of 12 hours a day, and a two-shift system.

The shrimp feed mill plant project is to produce the main workshop equipment for two SZLH420 shrimp feed pellet mill machine.

The main shrimp feed machine adopts RICHI high-quality shrimp prawn feed mill equipment, the shrimp pulverizer is a fine powder grinding machine, which is professionally used for fine pulverization.

The shrimp feed mixer is SSHJ4b, the mixing time is 60-120s, and the mixing uniformity cv can reach 2.5.

Adjustable blade structure increases blade service life, reduces residue, and prevents cross-contamination. Reasonable arrangement of air ducts and access doors for easy maintenance and cleaning. Reliable spraying system to ensure trouble-free spraying, and can add water, oil and other liquids.

The shrimp feed pellet machine is SLZH420D, the main drive adopts high-precision gear drive, the prawn feed pellet machine ring die adopts quick-release hoop type.

The output of ring die shrimp feed pelletizer is 20% higher than that of the belt drive type, the all-stainless steel three-layer lengthened conditioner, the feeding adopts frequency conversion speed regulation control, ensure high quality pellet feed.

This 4t/h shrimp feed production plant breaks the conventional production process and adopts the first batching and then crushing system. This system is selected by most shrimp feed factories in Europe. Compared with the first crushing and then batching system, it can adapt to the change of material varieties, and the number of required silos is reduced. Save capital investment.

Raw Materials of 4 t/h shrimp feed mill

Shrimp feed production process of 4T/H Shrimp feed plant

01 Raw material receiving and initial cleaning:

Raw materials such as soybean meal are sent to the bucket elevator through the scraper conveyor, lifted to the cleaning screen to remove the sundries, and then the ferromagnetic sundries are removed by the permanent magnet cylinder, and distributed to the corresponding ingredients by the distributor warehouse.

This shrimp feed mill process will generate dust, waste grass rope, sand and gravel, etc. A pulse dust collector is arranged at the feeding port to collect dust, and the dust is reused as raw material.

02 Primary batching, mixing, primary crushing, secondary crushing:

All kinds of raw materials are weighed and batched by computer control and then entered into a dual-shaft high-efficiency feed mixer machine for primary mixing. The mixing equipment used in this 4t/h high-end shrimp feed project is high-efficiency sealing equipment.

The mixed materials It is sent to the bucket elevator through the scraper conveyor, and after being lifted to the silo to be pulverized, the material is fed into the ultrafine mill for two pulverization.

The pulverized material is pneumatically conveyed to the dust removal device (Cyclone), and the powder is further collected by the pulse dust collector and then enters the high-end screen for screening.

After the screening and leakage materials are collected, they are reused to the feeding stage, and the screened and qualified crushed materials are sent down to the auger, and then sent to the batching bin by the conveyor. This process is all closed and automated, which will generate dust and noise.

03 Secondary batching and mixing:

After the secondary crushed qualified material is weighed and batched by computer control, it enters the mixer together with the primary premix for secondary mixing. The mixing process is completely airtight, and this shrimp feed palnt process will generate noise.

04 Granulation

The mixed material enters the shrimp feed pellet granulator, and the product is steamed by high temperature steam (80~90℃). According to the different particle size of the product, the required granulation time is different.

The three shrimp feed pellet machines in this 4t/h shrimp feed processing mill project run at the same time, the granulation capacity per unit time is 5~6t/h, and the production time is calculated as 3000h, which can meet the production demand. The maturation process produces a foul odor.

05 Drying and cooling & screening:

The feed passes through the dryer/cooler to reduce the moisture content of the material. This shrimp feed mill process produces foul odors. Part of the cooled particles is directly lifted by the elevator to the grading sieve, and the qualified ones enter the packaging process; the remaining part is crushed and processed, and products of different specifications are obtained after being screened by the grading sieve.

06 Packing and warehousing:

The finished products are automatically stacked by robots and palletizers and transported to the warehouse for storage. The packaging process will generate dust, and a pulse dust collector is equipped to collect the dust.

4T/H high-grade shrimp feed Making machines

| Device Name | QTY |

|---|---|

| Feeding section | |

| Pulse Dust Collector | 2 |

| Scraper conveyor | 3 |

| Bucket elevator | 2 |

| Clean Screen | 2 |

| Permanent Magnetic Cartridge | 2 |

| Distributor | 2 |

| The first batching section | |

| Ingredient Warehouse | 20 |

| Feed Auger | 1 |

| Hammer Mill Feed Grinder | 1 |

| Ingredient Auger | 20 |

| Ingredient Scale | 3 |

| Feed Mixer | 2 |

| Scraper Conveyor | 2 |

| Bucket Elevator | 2 |

| Permanent Magnetic Cartridge | 1 |

| First Crushing Section | |

| Silo To Be Crushed | 2 |

| Feed Auger | 1 |

| Water Drop Pulverizer | 1 |

| Closed Wind Auger | 1 |

| Bucket Elevator | 1 |

| Permanent Magnetic Cartridge | 1 |

| Second Crushing Section | |

| Silo To Be Crushed | 3 |

| Feed Auger | 3 |

| Superfine Pulverizer | 3 |

| Cyclone | 3 |

| Pulse Dust Collector | 3 |

| High Pressure Fan | 3 |

| Air Shutoff | 3 |

| Scraper Conveyor | 3 |

| High Square Sieve | 3 |

| The 2nd Batching Section | |

| Ingredient Warehouse | 4 |

| Ingredient Auger | 4 |

| Ingredient Scale | 2 |

| Mixer | 2 |

| Scraper conveyor | 2 |

| Bucket elevator | 2 |

| Permanent Magnetic Cartridge | 2 |

| Clean Screen | 2 |

| Pelletizing And Cooling Section | |

| Silo To Be Granulated | 3 |

| Feeders | 3 |

| Feeders | 3 |

| Preservation | 6 |

| Shrimp Feed Pelletizer | 3 |

| Air Shutoff | 3 |

| Horizontal Dryer | 1 |

| Cooler | 3 |

| Cooling fan | 4 |

| Bucket elevator | 6 |

| Classifier | 3 |

| Scraper conveyor | 1 |

| Pellet Crumbler | 2 |

| High Square Sieve | 2 |

| Packaging section | |

| Finished Product Warehouse | 8 |

| Classifier | 3 |

| High Square Sieve | 2 |

How to start a large scale 12T/H prawn shrimp feed mill plant?

Here is an example of 12 tons per hour large capacity prawn shrimp feed manufacturing plant project report.

This is a compound feed factory expansion project. In order to meet the market demand, the client of this 12t/h shrimp feed production project invested nearly 3,000,000 USD to build a new shrimp feed production plant and its ancillary facilities in the existing compound feed mill area, with a total construction area of about 14,000 square meters.

There are 42 sets of main 12t/h shrimp feed production equipment such as paddle-type high-efficiency shrimp feed mixers.

After the expansion project is completed and put into production, it can form an additional annual production capacity of 190,000 tons of shrimp, crab, lobster and other compound feed.

- Project nature: expansion;

- Labor capacity: The 12t/h shrimp feed factory expansion project needs to add 20 employees; the expansion project is produced in three shifts, 8 hours per shift, 312 days of work per year, and 7488 hours of operation per year.

- The 12t/h shrimp feed factory project covers an area of 14,000 square meters.

Main Product Plan

| No. | Product Name | Product Specifications (mm) | Current project production capacity (t/a) | Design production capacity of the expansion project (t/a) | Production capacity of the whole 12t/h shrimp feed project (t/a) |

|---|---|---|---|---|---|

| 1 | More than 300 kinds of feeds in five categories including livestock and poultry, general water, special water, premix and additives | / | 20000 | / | 20000 |

| 2 | Ecological Nutrition Special Aquatic Feed | / | 60000 | / | 60000 |

| 3 | Shrimp Feed | 1.0-1.2 | / | 90000 | 90000 |

| 4 | Crab Feed | 0.1, 0.3, 0.5 | / | 50000 | 50000 |

| 5 | Specialty Aquatic Feed | 1.0-4.0 | / | 50000 | 50000 |

Shrimp feed production process

01 Pellet feed production:

Manual feeding: The soybean meal, rapeseed meal and peanut meal are manually fed into the pipeline according to the proportion. The feeding port is under negative pressure. The raw materials are in flake and powder form, and the particle size is large, so a small amount of dust is generated in the feeding.

Crushing: The raw materials of the project are soybean meal, rapeseed meal and peanut meal are crushed by a closed drop-type hammer mill feed grinder.

Mixing: According to the requirements of the formula, the flour, imported fish meal, domestic fish meal and chicken meal are sequentially weighed into the mixer and mixed evenly in the double-shaft paddle-type high-efficiency mixer. The effective mixing time for each batch is 90 seconds. This shrimp feed mill process is completely airtight.

Ultrafine pulverization: The mixed raw materials are pulverized by an ultrafine grinder. The pulverizing chamber of the ultra fine powder grinder adopts a fixed knife structure as a secondary impact pulverization technology, which can increase the output by more than 30%, and can change the hammer on the rotor.

Secondary mixing: The ultra-finely pulverized material is transported to the batching bin, and the material enters the computer-controlled secondary batching scale through the bin discharging machine, and is automatically weighed according to the formula requirements and then enters the mixer. Liquid raw materials are added during the mixing process. (Grease) and 5% water, effective mix time 4 minutes per batch. Part of the mixed raw materials go through the granulation process, and part of the mixed product goes into the shrimp feed mill puffing process.

Granulation: The mixed raw materials are put into the shrimp feed pellet mill, the temperature of the material is adjusted to 80-85°C by steam, and the moisture content of the material is about 15%, and then the granules of the specified particle size are formed by the shrimp feed pellet making machine.

Curing and cooling: The hot granulated shrimp feed from the shrimp feed pelletizing machine enters the stabilizer evenly, and the temperature of the pellets is built into a stable container heated by a spacer for a certain period of time, so that the shrimp feed is further cooked, increase the stability of the feed water and improve the digestibility of the feed. The cooling is air cooling, using air as a heat exchange medium for heat exchange, and the heat is taken away by the air. Part of the cooled feed enters the screening process, and part enters the crushing process for finished powder.

Screening: The feed is removed by the vibrating screen to remove the broken pellets that do not meet the requirements. The pellets of 1.0-1.2 mm are qualified, and the unqualified products are re-entered into the shrimp feed mill granulation process.

Packaging of finished products: The finished products are packaged into the warehouse and stored for sale.

02 Powder feed production:

Crushing: The cooled material passes through the crusher to make the particle size of the material finer.

Screening: The material is removed by the vibrating screen to remove the broken particles that do not meet the requirements. The powders of 0.1mm, 0.3mm and 0.5mm are qualified, and the unqualified products are re-entered into the granulation process.

Packaging of finished products: The finished products are packaged into the warehouse and stored for sale.

03 Extruded feed production:

Expansion: The material from the secondary mixing section is added with 25% water, and heated to 85°C by high-temperature steam for gelatinization.

Drying: The moisture content of the puffed pellets is higher than the moisture content specified in the product specification, so it needs to be dried in a drying oven, the drying temperature is controlled at 100℃, and the time is controlled at 30 minutes.

Cooling: The prepared puffed pellets enter the pellet cooler for cooling, the feed temperature is lowered from 50-60°C to normal temperature, and the cooling is air-cooled, using air as the heat exchange medium for heat exchange, and the heat is taken away by the air.

Vacuum spraying: After the feed is weighed, it enters the vacuum spraying mixer.

Screening: The extruded feed are removed by the vibrating screen to remove the particles that do not meet the requirements. The extruded pellets of 1.0mm-4.0mm are qualified, and the unqualified products re-enter the shrimp feed mill crushing process.

Packaging of finished products: The finished shrimp feed pellets products are packaged into the warehouse and stored for sale.

Main Equipment Needed in 12T/H shrimp feed project

main raw and auxiliary materials

Public measures of of 12T/H shrimp feed project

- Water supply system:

The fresh water consumption of the 12t/h shrimp feed factory expansion project is 60744.66t/a. The fresh water of the expansion project is mainly used for the domestic water, product water and production water of the new employees. The water supply system relies on the existing compound feed mill project.

At present, the water supply pipe diameter of the feed enterprise is ¢200mm, and the water supply pressure is 0.2MPa, there is enough water supply to meet the needs of the 12t/h shrimp feed plant expansion project. - Drainage system:

The “rainwater and sewage diversion” system is implemented in the 12t/h shrimp feed milling plant. Rainwater is collected by the rainwater pipe network and then discharged into nearby rivers.

The wastewater produced by the 12t/h shrimp feed production project is treated by the sewage treatment station in the 12t/h shrimp feed factory. After treatment, the water is recycled and discharged about 30% every day. - Power supply system:

The new electricity consumption of the 12t/h shrimp feed company expansion project is 8.25 million kWh/year, which comes from the local municipal power grid.

At present, the 12t/h shrimp feed making plant has built a substation and is equipped with 4 transformers. The power supply of the expansion project is directly connected to the existing one. - Air supply:

The natural gas of the 12t/h shrimp feed company expansion project will be transported to the location of the expansion project through the gas supply pipeline of the park.

In order to meet the water quality requirements of gas-fired steam boilers, each boiler is equipped with a set of automatic softened water treatment device, the system design output is 8m³/h.

Richi Machinery can accurately control cost accounting, scientifically calculate expected profits, reduce costs and increase efficiency, and profits can be expected.

The operating profit ratio of thousands of customers is clear and testable, and they jointly test the entire service system from the aqua fish shrimp feed mill plant design and development team to the installation and maintenance team, and witness the realization of the investment value of the entire aqua fish prawn shrimp feed mill plant project.

Richi Machinery is always based on market trends and customer needs, constantly seeking changes and improving, timely innovation, and relying on standard shrimp feed manufacturing solutions, flexible and reasonable configuration of shrimp feed production line equipment, to achieve stable performance and mature customized design.

If you have any needs or questions about the construction of shrimp feed mill, please leave a message and we will reply to you as soon as possible after receiving it! You can also contact us directly via WhatsApp (+86 138 3838 9622)!

2,000+ /PROJECTS

In the past 30 years, as shrimp feed machine plant manufacturer, we have accumulated rich experience. We has exported shrimp feed equipment for sale the world, and has reached cooperative relations with more than 2,000 customers in more than 130 countries and regions, providing them with complete solutions and services covering the entire product life cycle.

130+ /COUNTRIES

Customer experience is the touchstone. Richi Machinery has benefited a lot from winning the market with connotative products and high-quality services. Richi Machinery specialize in shrimp feed processing equipment for sale, our shrimp feed mill machines are carefully designed for customers according to the actual feed production requirements.