bird feed machine

Bird feed machine belongs to pet feed equipment and also poultry feed equipment. It is a complete set of equipment used to process bird feed pellets and extruded pellets.

These equipment are the core of the bird feed production line and usually include bird feed pellet machines, feed crushers, feed mixers, feed coolers, feed balers and other equipment.

The complete set of bird feed making machine is of great significance for feed maturation, increasing nutrition, improving absorption rate, killing pathogens, storage and transportation, reducing costs, saving resources, adapting to the chewing function of birds, and improving bird breeding efficiency.

- Capacity: 1-60 T/H

- Whole set bird feed machine Price: 10,000-3,000,000 USD

- Pellet size: 1-12mm

- Application: Used for processing pellet feed and powder feed

- Optional process types: pelletizing technology and extruding technology

- Business scope: Newly built bird feed factory, renovation and expansion of feed factory

As a professional bird food machine manufacturer, RICHI provides one-stop bird feed mill plant solutions from project design, process, installation and commissioning, and after-sales service.

We study every detail of the bird feed pelleting solution to ensure you get the best bird feed mill equipment, the best service and best plan.

Types of Bird Feed machine

- Wild bird food machine

- Parrot food machine

- Cockatiel food machine

- Lovebird food machine

- Conure feed machine

- Parakeet feed machine

- Cockatoo feed machine

- Macaw feed machine

- Pigeons and Dodos feed machine

- Kingfishers feed nachine

- Cuckoos feed nachine

- Sunbitterns feed nachine

- …

How to make bird feed pellets?

Bird feed processing machine has become an integral part of bird feed production. They not only improve production efficiency but also ensure feed quality and safety. The following will introduce in detail how the bird feed machine plant goes from raw materials to finished products.

The preparation methods of bird feed are generally divided into two types: wet method and dry method. The wet method mainly involves adding water to feed raw materials, mixing and stirring, and then drying or baking them to make dry feed.

The dry method mainly grinds and mixes the feed raw materials, and then presses or granulates them into granular feed. During the preparation process, attention needs to be paid to the reasonable combination of various raw materials to ensure the comprehensive nutrition of the feed.

- First, let’s take a look at the raw material receiving part of the bird feed processing plant. The main task at this stage is to receive various feed raw materials, such as corn, soybean meal, fish meal, etc., and inspect the raw materials to ensure their quality and safety. Only qualified raw materials can enter the next step of processing.

- Next comes the crushing part. In this process, the bird feed machine plant uses high-speed rotating blades to chop large pieces of raw materials into small particles suitable for further processing. This step can not only improve the utilization rate of raw materials, but also improve the taste and texture of the feed.

- Then comes the mixing section. At this stage, the bird feed making plant will mix the crushed raw materials and other additives (such as vitamins, minerals, enzymes, etc.) in a certain proportion to form feed that meets the nutritional needs of the animals. This step requires precise control of the proportions and addition time of various raw materials to ensure the nutritional balance of the feed.

- Next comes the pelleting and extrusion stages. In this process, the bird feed processing unit uses high temperature and high pressure to compress the mixed feed into pellets. This step can prevent the moisture in the feed from evaporating too quickly and maintain the freshness and nutritional content of the feed.

- The end is the packaging process. At this stage, the bird feed manufacturing unit will put the cooled and screened pellet feed into plastic bags and then seal them. This step not only protects the feed from the outside environment, but also facilitates transportation and storage.

In general, the bird food production process from raw materials to finished products is a rigorous and complex process, involving multiple links such as raw material reception, crushing, mixing, granulation, and packaging.

Every link requires precise operation and strict control to ensure product quality and safety. Through such a process, bird feed machine provides bird feed factories with high-quality, safe and reliable feed products.

Bird Feed machine list

Bird feed factories of different sizes often use different types of bird feed machines. However, some of the basic equipment used for bird feed manufacturing is the same.

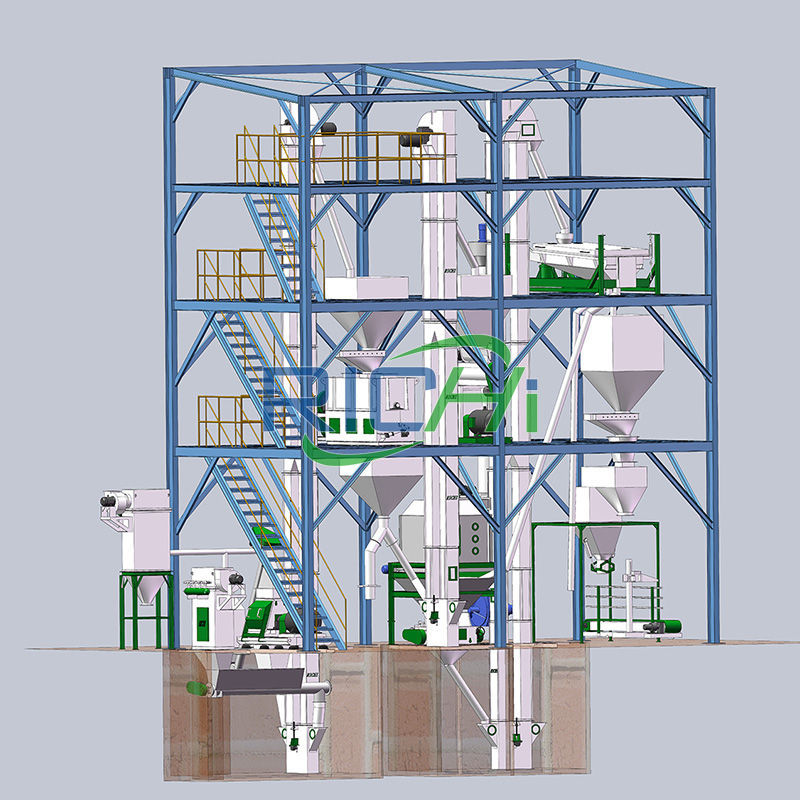

According to the bird feed production process flow, it generally includes raw material receiving and cleaning equipment, conveying equipment, crushing equipment, batching equipment, mixing equipment, pelletizing equipment, extruder equipment, liquid spray equipment, ventilation and dust removal equipment, packaging equipment and automatic control systems.

Bird feed grinding machine

Bird hammer mill feed grinder can be widely used to crush various granular materials, such as corn, sunflower seeds, sorghum, wheat, beans, etc. The working surface of the hammer is overlayed with hard material to extend its service life.

The motor and the pulverizer are installed on the same heavy-duty base, using a direct-coupled transmission with a fixed connecting shaft. The rotor has been dynamically balanced and can work in both forward and reverse directions.

- Capacity: 3-25 T/H

- Power: 30-160 KW

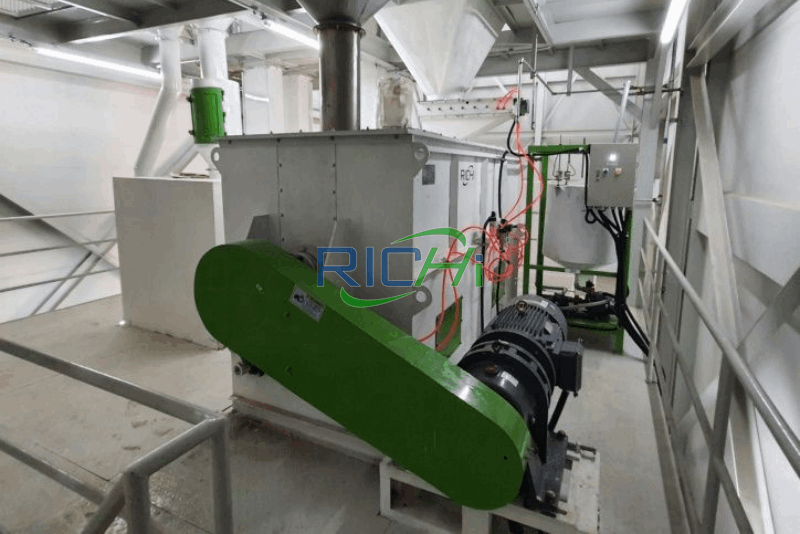

Bird feed mixing machine

The bird feed mixer machine adopts high uniformity and unique blade design to enhance material convection, shearing and mixing, with high mixing uniformity and CV≤5%.

The gap between the paddle and the casing is adjustable to ensure an extremely low residue rate and prevent cross-contamination of materials; the full-length discharge door allows the material to be emptied instantly without residue.

- Capacity: 250-3000 KG/P

- Power: 4-55 KW

Bird feed pellet making machine

Users can choose any one according to different needs to obtain the best technical and economic benefits.

This SZLH bird feed pellet mill model uses an advanced variable frequency motor for feeding, and is equipped with an overload protection device and an external discharge mechanism; this machine can be equipped with an extended single-layer, double-layer conditioner or double-shaft differential conditioner to produce bird feed of different qualities according to requirements.

- Capacity: 1-42 T/H

- Power: 22-315 KW

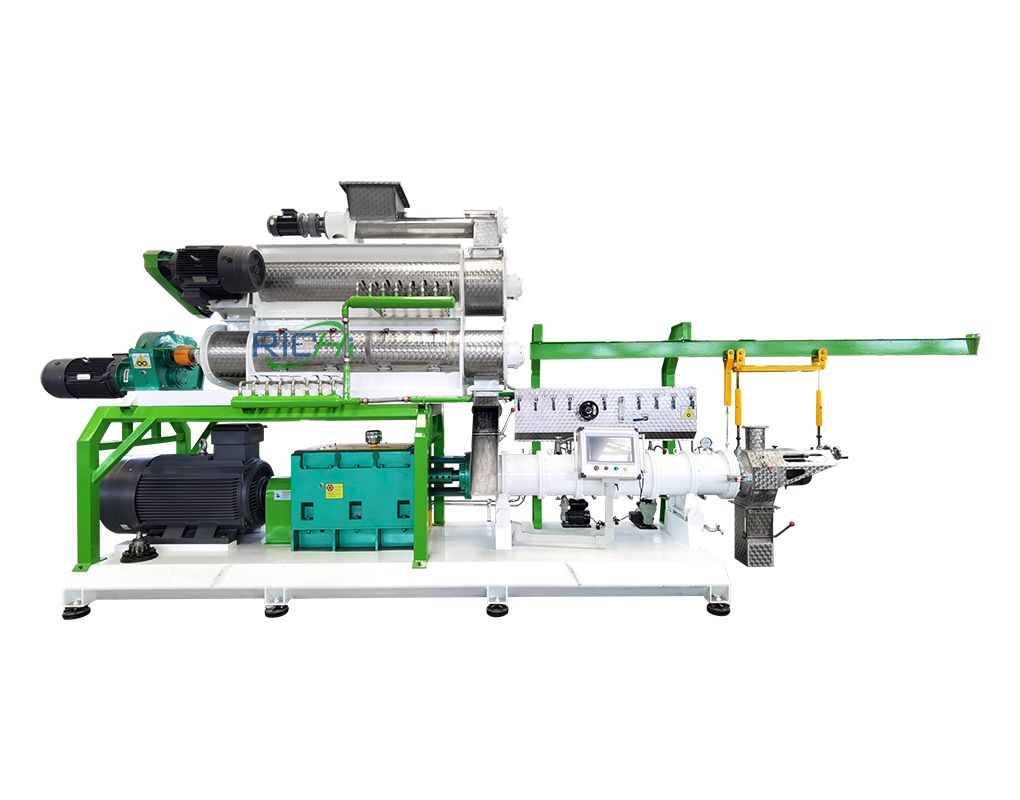

Bird food Extruder machine

Currently, more and more bird feeds use extrusion technology. The bird feed extruder adopts hydraulically controlled discharging device, which has high production capacity and low energy consumption.

The core purchased parts are all from international brands to ensure the safety and stability of equipment operation; the core parts screw adopts new processing technology to improve wear resistance, extend service life and effectively reduce production costs.

- Capacity: 1-12 T/H

- Main Power: 0.75-355 KW

Bird fed Pellet Crumbler machine

Pellet crumbler machine is mainly used after the pelletizing section. The material roller is driven by a variable frequency feeding motor, which makes the feeding more uniform and can realize automatic control.

Key parts are imported, with reliable performance and convenient operation and maintenance. According to the different crumbling pellet size requirements of users and bird feed at different growth stages, special toothed crushing rollers can be equipped.

- Capacity: 2-20 T/H

- Roller: 2-3

bird feed pellet Cooler machine

The bird pellet cooler machine can fully cool the prepared bird feed pellets and extend the storage time of the feed. There is an access door on the front of the equipment, and observation windows on the side and top cover to facilitate observation and maintenance of the equipment.

The cooling chamber with an octagonal cross-section reduces the cooling dead zone, which is beneficial to the uniform cooling of the material when the output is less than 6/h.

- Capacity: 1.5-18 T/H

- Power: 0.75-2.05 KW

Vibrating screening machine

RICHI’s vibrating screening machine adopts a special balancing method with low vibration, imported SKF bearings with low noise and smooth operation; it combines the characteristics of circular motion, elliptical motion and reciprocating linear motion, with large output, high screening efficiency and low power consumption.

- Capacity: 3-20 T/H

- Power: 1.5-5.5 KW

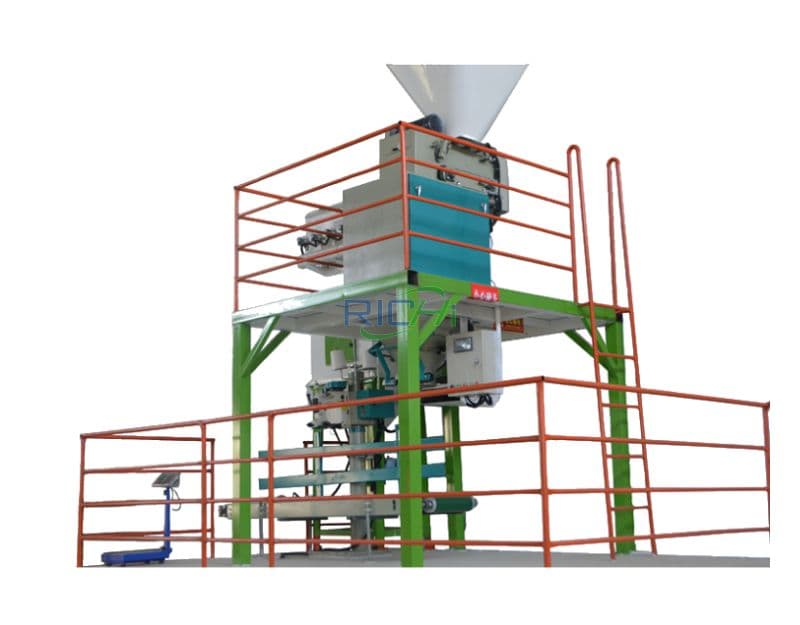

Bird feed Packaging scale

The bird feed quantitative packaging scale is a kind of automatic bagging machine, specially designed for quantitative packaging of feed. It uses a long-distance auger to feed the material. The feed enters the buffer silo through a pneumatic butterfly valve and is sent to the bag through a spiral transmission.

The feeding amount is controlled by controlling the speed of the belt. Once the bag is full, the bag clamp is opened through the control system, and the bag is sent away through the conveyor belt and sealed manually.

- Speed: 6-12 Bags/Min

- Power: 1.1-5 KW

At Unique Enterprises, we are Manufacturing and Exporting the most advanced bird feed machines, Ribbon Blender, Drum Mixer, Commercial Feed Grinder Machine, Feed Pellet Machine, Pellet Cooler Machine and Packing Machinery and much more, which are provided without any compromise in quality.

Our vast range stands high in terms of cost-efficient prices, quality, durability and their sturdy design.

Bird feed machine projects

1-2T/H bird feed machine in England

- Date: Sep 13th, 2015

- feed type: bird pellet

- technology type: extrusion

- bird feed machine cost: 40,000 USD

3-5T/H bird feed machine in united states

- Date: July 10th, 2019

- feed type: bird & chicken feed

- technology type: Pelleting

- bird feed machine cost: 80,000 USD

5T/H bird feed machine In german

- Date: February 2021

- feed type: bird & broiler pellet

- technology type: Pelleting

- bird feed machine cost: 100,000 USD

8T/H bird feed machine In australia

- Date: October 29, 2021

- feed type: bird & poultry pellet

- technology type: Pelleting

- bird feed machine cost: 150,000 USD

Bird feed machine cost

The prices of the main bird feed equipment for bird feed production are as follows:

- Bird feed grinder: 5300-35000 USD

- Bird feed Mixer: 2800-36500 USD

- Bird feed Granulator: 7000-100000 USD

- Bird feed pellet Cooler: 4000-20000 USD

- Bird feed Vibrating screen: 2000-10000 USD

- Bird feed Packing scale: 5000-10000 USD

Usually, bird feed processing lines select bird feed machines based on production scale, production variety, and production technology. Generally speaking, the higher the output of the bird feed processing machine, the higher the price.

Of course, this is under the condition that the quality and materials are the same. The quotation for a complete set of equipment for a 1-60t/h bird food factory is usually between 10,000-1,500,000 USD.

Generally speaking, the price of bird feed equipment is affected by the following factors:

- Bird feed processing scale, that is, daily production capacity

- Automation level of feed processing machines

- Bird feed manufacturing process flow design

Advantages of bird feed machine

RICHI bird feed making machine has the following advantages:

- Low operating costs:

The overall automation of the bird feed equipment is high, and the functional configuration is relatively complete. It is relatively convenient and worry-free to operate, and can reduce labor expenses, so the operating costs are low. - Low investment cost:

The complete set of bird feed processing equipment not only has high production efficiency, but also has large output and short investment recovery period. - Big profits:

The process design of bird feed mill equipment is relatively complete, and the quality of the processed products is relatively high, which can bring better reputation to users and obtain higher value. Help users obtain higher profits. - Program design:

RICHI complete sets of bird feed machinery are generally complete animal feed production lines that can be formed in one go. We plan a scientific and reasonable bird feed production line process design for our customers based on the environment, geology, and climate. We can also flexibly change it according to the needs of users. We process a wide variety of finished products and realize pre-sales service, in-sales service, and after-sales service promise.

Complete bird feed machine configuration for different scale

01 1-2 t/h bird feed machine system

- Main bird feed equipment: Screw conveyor*TLSS16, Hammer mill*15-200, Mixing machine*SLHY0.5A, Storage bin*1m³, Feeder*WLQ16, Stainless steel condtioner*TZQ22180, bird feed Pellet machine*SKLH-250, Cooling belt*WLSS50 , etc.

- bird feed machine Price: 15,000-20,000 USD

02 3-4 t/h bird feed machine system

- Main bird feed equipment: Screw conveyor*TLSS20n Iron removing device*Z-Type, Hammer mill*SFSP.5640, Mixing machine*SLHY.1, Feeder*WLQ22, Stainless Steel Conditioner*TZQ32X200, bird feed Pellet machine*SZLH.320, Cooling Machine *SKLN14x14, Vibrating screener*TDZS80, Cooling draft fan*4-72-4A, Cyclone*SK600, etc.

- bird feed machine Price: 48,000-55,000 USD

03 5-7 t/h bird feed machine system

- Main bird feed machines: Drum type precleaner*SCY63, Permanent magnetic sleeve*TCXT20, Hammer mill*SFSP6660, Rotary distributor*TFPX6, Powder precleaner*SCQZ6050100, Rotary distributor*TFPX4, Batching scale*PLC0.5A, Small material checking balance*PLC0.1B, Single-shaft mixer*SLHJ1A, Feeder*WLQ25, 1-Layer Conditioner*TZ35244, bird feed Pellet machine*SZLH350, Cooling Machine*SKLN17x17, Crumbler*SSLG15100, Rotary screener*SFJZ1002C, Automatic Packing machine*DCS-50, Sewing machine+conveyor, etc.

- bird feed machine Price: 70,000-250,000 USD

04 8-10 t/h bird feed machine system

- Main equipment: Drum type precleaner*SCY63, Permanent magnetic sleeve*TCXT20, Hammer mill*SFSP6660, Double Ribbon Mixer*SLHY2.5L, Bucket Elevator*TDTG36/18, bird feed Pellet machine*SZLH420, Stainless steel conditioner*TZ38300, Feeder*WLQ25, Cooling Machine*SKLN20×20, Crumbler*SSLG15X150, Rotary screener*SFJH1252C, Automatic Packing machine*DSC-50, Sewing machine and belt conveyor, etc.

- bird feed machine Price: 150,000-300,000 USD

A complete set of bird feed production machine includes but is not limited to the above configurations. The surrounding environment, physical and chemical properties of raw materials, discharging requirements, etc. will affect the selection of bird animal feed mill equipment.

If you also want to configure a bird feed manufacturing plant that suits your needs, contact us to customize a bird feed factory plan and get a detailed product quotation!

What should you consider when purchasing bird feed machine?

1. Production scale and output

The primary consideration when purchasing bird feed machine is production scale and output. The larger the production scale, the larger the processing capacity and production capacity of the purchased equipment are, and more investment is required in the maintenance of the equipment.

2. Product quality requirements

The selection of bird feed machine should also consider product quality requirements. If the product quality requirements are high, the automation and accuracy requirements of the equipment will also increase accordingly, such as the need for higher-precision testing equipment.

3. Factory area and layout

Factory area and bird animal feed mill plant layout are also important factors in purchasing production equipment. Bird feed enterprises with small plant areas and compact layout need to choose equipment with small floor space. At the same time, they must follow the principles of safe production and choose bird feed machine with low stacking height and slow movement speed.

4. Equipment safety

Equipment safety is an important consideration when purchasing bird feed machine. Enterprises must choose equipment that meets the requirements of national safety standards. For example, the equipment should have anti-interference capabilities and prevent electromagnetic field interference and static interference.

5. Equipment maintenance

Equipment maintenance is also an important factor to consider when purchasing bird feed machine. The maintenance cycle of the equipment needs to be adapted to the production cycle of the enterprise. At the same time, the wearing parts of the equipment need to be replaced in time to prevent the occurrence of failures.

6. Cost investment

When companies purchase bird feed machine, they also need to consider financial factors such as investment costs and production costs. If a company considers cost input when purchasing equipment, it will have an important impact on the company’s economic benefits.

Bird food enterprises can better improve production efficiency and reduce production costs by choosing bird feed machine that meets their own production scale, output, product quality requirements, factory area, equipment maintenance and other factors.

How to choose bird feed machine?

Below, RICHI will provide a detailed explanation of the selection of some bird feed machine so that customers can refer to it when purchasing bird feed making machine!

What is the function of bird feed grinder? How to choose a bird feed grinder?

Crushing is an operation method that uses mechanical methods to overcome the cohesion of solid materials to break them. It is one of the most important processes in the bird feed machine system and is an important factor affecting feed quality, output, power consumption and processing costs.

The function of bird feed grinder:

- a. Increasing the surface area and particle size of feed is beneficial to the digestion and absorption of animals.

Animal nutrition tests have proven that reducing particle size improves the digestion and absorption of dry matter protein and energy, and reduces the feed-to-meat ratio; - b. Improve and enhance the processing performance of bird feed.

Through crushing, the particle size of the material can be basically consistent, and the material classification after uniform mixing can be reduced; for trace elements and some small component materials, only when they are crushed to a certain extent to ensure that they have sufficient particle numbers, can the mixing uniformity requirements be met; - c.The pulverized feed particle size can significantly improve the feed conversion rate, reduce the amount of animal feces excretion, improve the animal’s utilization of bird feed, and improve the efficiency and quality of subsequent bird feed mixing, conditioning, granulation, puffing and other processing.

The power equipment of the crusher generally accounts for about 1/3 of the total power equipment of the bird feed factory. How to reasonably select advanced crushing equipment, design the best process route, and use the crushing equipment correctly is crucial for bird feed production companies.

Choose a feed grinder for bird feed machine system:

Purchasing a centrifugal fan for a crusher can get twice the result with half the effort to improve crushing efficiency. After the material passes through the friction between the hammer and the screen, it should be discharged from the crushing cavity immediately to avoid clogging the machine, causing the temperature in the crushing cavity to rise, or even causing a dust explosion.

How is the crushed material quickly discharged from the crushing chamber? After the centrifugal fan is started, a continuous negative pressure environment will be formed in the crushing chamber and settling chamber. Qualified materials will quickly pass through the screen under the action of negative pressure to complete the crushing of the materials.

The centrifugal fan can absorb the moisture of the finished product, reduce the humidity in the finished product, facilitate storage, increase the crushing efficiency by 10% to 15%, and reduce the dust in the crushing chamber. Therefore, choosing a centrifugal fan with suitable wind pressure is very important to improve the crushing efficiency. .

How to choose a bird feed mixer machine?

There are many types of bird feed mixer machines on the market and can be used in bird feed machine system: in terms of shape, they are divided into horizontal bird feed mixers, and drum feed mixers. From the perspective of mixing raw materials: there are dry powder feed mixers, vitamin feed mixers, bird feed mixers that can add liquid, etc.

So which feed mixer is suitable for you? Specific reference can be made from the following points:

(1) Choose the feed mixer that suits you according to your output

Each bird feed mixer machine has its own hourly output, and the hourly output will vary depending on the model. For example, a vertical feed mixer takes about 15 minutes to mix a batch of materials.

If the hourly output of this model is 500kg/h, then it will take more than 2 hours to mix 5 tons of feed. Of course, this refers to the time of simply mixing feed. If it is a pellet unit, then the time for crushing and granulating needs to be added.

(2) Choose the feed mixer that suits you according to the bird feed raw materials you need to mix.

As mentioned before, there are different types of bird feed mixers based on different raw materials. Generally speaking, vertical feed mixers and horizontal ribbon mixers are used to mix dry powders.

Because it uses twisted blades inside, even if it is thickened, it still has a certain resistance to the liquid mixture. If there is resistance, it may cause hinge wear. Twin-shaft paddle feed mixers can be used to mix and add liquid mixtures. Therefore, according to different raw materials, you can choose a suitable feed mixer.

(3) Choose a bird feed mixer that suits you according to the required mixing coefficient

Generally, the mixing uniformity of vertical bird feed mixers and horizontal ribbon mixers is sufficient for small and medium-sized farms. But if the requirements for bird feed are relatively high or it is a bird feed machine plant, then the requirements for the mixing uniformity of the feed will also be relatively high.

The mixing uniformity of the twin-shaft paddle bird feed mixer machine is also relatively high, but at the same time, its cost will be higher.

How to choose a bird feed pellet machine?

After the mixed powdered feed is granulated, the nutrition and eating quality of the bird feed can be improved to varying degrees. Due to the different varieties and components of bird feed raw materials and the different scales of finished products, there are also different requirements for the performance and structural parameters of the bird feed pelleting equipment.

There are two types of bird feed pellet mills used in bird feed mills: ring dies and flat dies. The flat die is more suitable for pelleting roughage, so only the ring die bird feed pelletizer is explained.

Since the working principles of ring die bird feed granulators are basically the same, the evaluation of their performance when selecting models is mainly based on the rationality of structural design, ease of operation, selection of structural parameters, processing methods, manufacturing level, parts selection, purchase channels and control functions and other aspects should be considered comprehensively. (Find RICHI on YouTube)

How to choose a bird feed pellet cooler?

Cooling is to maintain better storage performance of the product after granulation, and is an indispensable procedure after bird feed granulation. For a long time, cross-flow cooling has been used for cooling after bird feed granulation. Although it can meet the usage requirements and the cooling granule temperature is less than 7°C, it is easy to fail to meet the standard if you are not careful during operation.

Therefore, the counterflow cooler that has appeared recently is a model with a more reasonable cooling principle. Because the convection heat exchange system is the most complete and reasonable, the cooling effect is 3°C lower than room temperature, and the cooling effect is extremely ideal.

When selecting this bird feed machine, since the models produced by each bird feed mill factory are similar, you should pay attention to the manufacturing quality, materials and accessories, such as: how effective is the automatic control of the incoming and outgoing material linkage mechanism, and whether the main part is made of stainless steel.

In addition, for output selection, not only large-sized models can be used, but also two machines can be superimposed to increase output.

The selection and use of fans and separators has a great effect. The air suction duct should be made of stainless steel sheets, otherwise the service life will be greatly affected by the presence of water vapor, so attention should be paid to it, otherwise it is impossible to obtain the most ideal use effect.

How to choose bird feed pellet machine?

Crushed grains can save energy consumption and improve the digestion and absorption rate of birds.

At present, almost all bird feed pellet machines use roller-type bird feed granulators, and their performance is mainly evaluated by the structural rationality, structural parameters, process parameters, and processing level of the machine. The large roller diameter and high pressure make it easy to break.

There are two types of pressure roller tooth shapes:

- One type is crossed helical teeth, and it is better to have front-to-front teeth. The number of teeth should not be too many, which will reduce the powder extraction rate;

- The second type is a combination of straight teeth and helical teeth. This combination The disposal rate is also low, but these two types of tooth arrangement can meet the usage requirements, and the powder extraction rate should be controlled within 3%.

However, from the perspective of actual use, it is very important to adjust the distance between the two rollers. Otherwise, if the distance between the two rollers is unequal, the product will be uneven.

A scale can be provided at the adjustment handwheel to facilitate operation. In addition, when selecting the model, attention must be paid to the inlet size of the bird feed pellet making machine, which must completely match the outlet of the cooler, otherwise the powder extraction rate will be increased.

How to choose bird feed grading screen?

The crumbled bird feed pellets are classified and the powder part is removed to ensure that the feed has pure small particles and achieve the best feeding effect.

The existing classification screens mainly include vibrating classification screens and rotary vibrating screens, both of which can achieve better results. The vibration grading screen should adjust the amplitude of the screen body according to the properties and flow rate of the material to achieve the best effect.

Due to the long distance between the screen surfaces, the vibrating screen has better classification effect and is also one of the commonly used bird feed machine. In short, both types of machines can meet the usage requirements, and the grading efficiency can reach over 98% to 99%.

How to choose a bird feed curing post-curing machine?

In the individually customized bird pellet feed process, some customers will specifically add a post-curing process. Aging is a process set up to increase the gelatinization degree of the feed and improve the water resistance of the pellet feed. It can also improve the pelleting performance and eating quality. The aging process is still in its infancy.

At present, the post-curing process uses a curing stabilizer with a steam addition system and a jacket insulation device to maintain the material temperature at 80°C to 90°C.

The bird pellets can be kept in the bird feed machine for 20 to 40 minutes (adjustable), so that the temperature in the pellets can be maintained. Starch is gelatinized or can form a network structure, which can meet the requirement of water resistance of more than 6 minutes.

How to choose a bird feed extruder (expansion) or extruder?

The working principle of the extrusion expander is very similar to that of the bird food extruder.

The main structural parameters and process parameters are quite different, such as:

- The screw compression ratio, 1.05~1.2:1;

- The extrusion chamber is stable at 120℃~130℃;

- The extrusion chamber work pressure is 9.8×10-5~4.9×10-6Pa;

- The destruction rate of harmful factors is above 80% to 90%;

- The gelatinization degree of the starch part is 85% to 90%.

In addition, whether the material of the screw and sleeve is alloy steel, whether the processing methods are reasonable and advanced, and what the performance is after heat treatment. These parameters are directly related to the use effect and cannot be ignored and must be understood.

Through the above detailed introduction to the necessary bird feed machine for bird feed production, we can find that for bird feed manufacturers, choosing appropriate bird feed equipment requires not only paying attention to its actual efficacy, but also needing to coordinate various conditions well.

Only in this way can the quality of bird feed production be continuously improved and the development of the bird feed processing industry be promoted.

what is bird feed made of?

Alfalfa, organic hulled millet, organic barley, organic rice, organic sunflower seed hulled, organic sesame seeds unhulled, organic quinoa whole, organic pumpkin, organic buckwheat hulled, organic dandelion leaf powder, organic carrot powder, organic spinach leaf powder, organic purple dulse, organic kelp, organic rose hips powder, organic rose hips crushed, organic orange peel powder, organic lemon peel powder, organic rosemary whole leaf, organic cayenne ground, organic crushed red chili peppers, organic nettle leaf, organic cinnamon.

Different birds use different ingredients in the food they eat. Birds with different feeding habits also require different feed preparations during daily feeding.

- Generally, hard-eating birds need to eat pellets, and the protein content in the pellets can account for about 50-70%, so as to satisfy the growth of the birds.

- Soft-eating birds eat meal feeds, which can be divided into plant-based protein feeds, such as soybean meal, pea meal, mung bean meal, broad bean meal, etc.; plant-based energy feeds such as corn meal; animal protein feeds such as fish meal, silkworm chrysalis or eggs, etc.

- At the same time, both soft-feeding birds and raw-feeding birds must eat animal feed. It is a high-protein supplementary feed for all birds and is also the main feed for soft-feeding birds and raw-feeding birds. Common animal feeds mainly include skinworms, locusts, mealworms, silkworm pupae, corn borers, fly maggots, oil gourds, grasshoppers, crickets, earthworms, etc.

What are the requirements for raw materials when using bird feed machine to process feed?

The raw materials for caged bird feed must be full-grained, free of mildew, and free of impurities (such as grass mustard, fruit shells, iron filings, etc.).

Do not use grains with thorns to feed birds, and feed them according to the type, feeding habits, and The physiological conditions as well as the physical properties and nutritional value of the raw materials should be scientifically selected and processed appropriately to determine the proportion of various raw materials in the feed.

The raw materials used in pellet feed for caged birds are screened to remove impurities, washed clean, dried, and mixed in proportion before use directly.

However, some birds do not remove the shells of granular feeds and should be fed after manually removing the shells. If these caged birds reluctantly eat shelled feeds, they will cause indigestion and eventually become emaciated and die.

About bird feed recipes

- Pigeons are common poultry, and many people raise pigeons. Pigeon feed mainly consists of five parts: cereals, beans, oils, fish meal and minerals. Cereals include wheat, corn, glutinous rice, etc., beans include mung beans, soybeans, etc., oils include peanuts, rapeseed, etc., fish meal is an important source of protein, and minerals include salt, limestone, etc.

- Parrots are popular pet birds and raising them requires special feed formulations. Parrot feed mainly consists of cereals, beans, nuts, fruits and vegetables. You can choose wheat, corn, glutinous rice, etc. for cereals, mung beans, soybeans, etc. for beans, almonds, walnuts, etc. for nuts, apples, grapes, etc. for fruits, and carrots, spinach, etc. for vegetables.

Bird feed recipes vary slightly between species, but all contain grains, legumes, protein sources, fats and minerals. According to the characteristics and needs of birds, a variety of raw materials can be reasonably combined to formulate feed formulas suitable for different birds.

During the feeding process of birds, attention should be paid to the freshness and cleanliness of the feed, as well as reasonable feeding amount and time to ensure the health and growth of the birds.

Richi Machinery ——Bird feed machine manufacturer

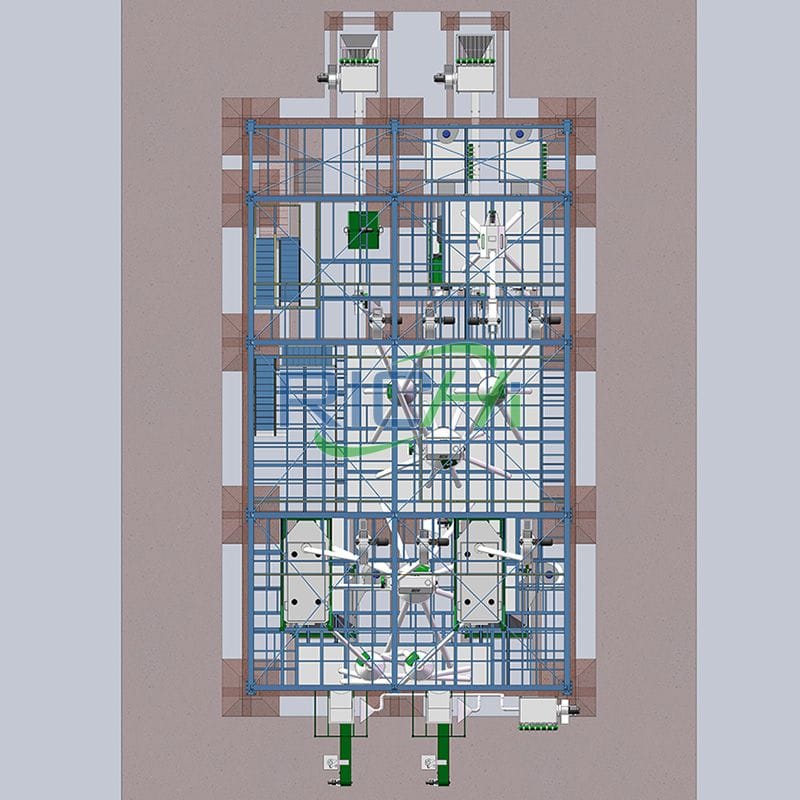

RICHI Machinery can design bird feed machine plant project planning plans and provide 3D renderings according to customers’ different needs; design solutions according to customers’ different requirements, different raw materials, and different sites; the company has a team of design, manufacturing and installation professionals with 25 years of practical experience. Technical team provides door-to-door installation services.

Whether in terms of pre-sales or after-sales technical support, we provide customer-satisfactory services at any time, and receive customers’ technical inquiries 24 hours a day, on-site services, equipment maintenance, production failures, service complaints and a series of other issues. In terms of service quality control, we insist on bird feed machine lifelong service; RICHI Machinery is trustworthy.