Cattle Feed Plant Project

200+ cattle feed plant projects, focusing on dairy and beef cattle feed processing in different growth stages, targeting cattle feed factories, cattle farms, and global cattle feed industry investors!

This page will summarize for you the cattle feed mill projects that RICHI has done, so that you can better understand RICHI’s professionalism and dedication to feed processing technology.

As one of the largest feed machinery manufacturers in Asia, RICHI Machinery has long been involved in international cattle feed machine business. Through years of market development, it has established complete external sales channels and network services in many countries and regions around the world, bringing the best standard cattle feed machinery and production technology in the world.

At present, our cattle feed machinery and cattle feed plant projects have been distributed in more than 80 countries and regions including Southeast Asia, the Middle East, Africa, Europe, Oceania, and South Africa, and are very popular among users.

- Business scope: New construction, expansion and reconstruction of cattle feed mills

- Cattle feed plant project cost: 10,000 -5,000,000 USD

Types of cattle feed plant project

The cattle feed mill plant projects we can supply are mainly divided into the following types:

- fully automatic cattle feed plant Project

- semi automatic cattle feed plant project

- Manual cattle feed plant project

- grass cattle feed plant Project

- cattle feed mash plant Project

- cattle feed pellet plant Project

- cattle feed mixing plant project

- maize cattle feed plant Project

- small cattle feed plant project

- cattle premix feed mill project

- poultry & cattle feed plant project

- Aqua & cattle feed plant Project

- sheep & cattle feed plant project

- Rabbit & cattle feed plant Project

- Horse & cattle feed plant Project

- livestock & cattle feed plant Project

- …

Features of cattle feed plant project

Looking at the current situation, ruminant cattle feed has great room for development in the future. At present, the breeding technology of most ruminant farmers is still at a relatively backward level, and there is a lack of professional technology in all aspects of breeding, reproduction, and feeding.

Only by solving the ration problem of ruminant animals from the source can we fundamentally promote Large-scale and specialized breeding of cattle and sheep to adapt to the increase in per capita consumption of beef, mutton and dairy products.

- Complete set of high-efficiency cattle feed production line, the overall process is advanced and flexible, and has a wide range of applications. The equipment can be matched one-to-one according to customer needs, perfectly realizing the production of multiple types of feed in one cattle feed manufacturing plant:

- Production of 100% pure alfalfa pellet crude fiber material and multi-effect forage mixture

- Pure concentrate formula cattle ruminant pellets

- Crude fiber + concentrated feed multi-proportion compound feed (production of powder and pellet feed)

- The process can also achieve perfect combination according to customers’ different raw material formulas and different crude fiber forage baling forms. Different processing techniques are customized for different raw material formulas to achieve differentiated value with high feed return rates.

- RICHI grass feed (whole diet) engineering, comprehensive nutrition, safe and environmentally friendly;

- Complete compound cattle feed patented process design, and equipped with a patented cattle feed pelletizer, which is suitable for processing both grass-containing and grass-free feeds;

- The grass powder, molasses and concentrate are fully mixed and then extruded. The pellet output of the same power model is increased by 40~50%.

- RICHI’s unique whole-diet processing technology can effectively reduce formula costs by 15-20%, increase feed utilization by 5-10%, and help feed manufacturers improve comprehensive benefits by more than 25%. It has served 65% of pasture cattle feed customers in the market It provides professional equipment, technology and technical support, and has been well received by customers.

RICHI has been committed to solving the pain points and difficult problems of the ruminant industry.

Driven by the introduction of international advanced cattle feed plant technology and combined with independent innovation, RICHI continuously upgrades ruminant cattle feed technology and equipment, helping major cattle feed manufacturers win in the increasingly competitive ruminant sheep cattle feed market.

Featured cattle feed plant project

cattle feed plant project In indonesia

- Output: 4-6T/H

- Feed type: Cattle Sheep Feed

- Workshop size: 12m*10m*23m

- Main equipment of the project: Cattle feed hammer mill*110KW; 2.Cattle feed mixer*1000kg/batch; 3.batching scale*1000kg/batch; 4. cattle feed pelletizer machine*110kw; 5.cooling machine*SKLH20*20; 6. grass crusher machine; 7.screen machine, etc.

- Installation time: 30 Days

- cattle feed plant project cost: FOB $280,000

cattle feed plant project In USA

- Output: 10-12T/H

- Feed type: cow & poultry feed

- Workshop size: 16m*7m*7.5m

- Main equipment of the project: 1.feed hammer mill*90KW; 2. feed mixer*1000kg/batch; 3. feed pellet machine*160kw; 4. cooling machine; 5. crumbler machine; 6. screen machine; 7. automatic packing machine, etc.

- Installation time: 40 Days

- cattle feed plant project cost: FOB $550,000

cattle feed plant project In south africa

- Output: 3-4T/H

- Feed type: Ruminant cattle goat feed

- Workshop size: 60m*24m*12m

- Main equipment of the project: 1. Hammer mill * 110 kw; 2. Mixer * 1000kg/batch; 3. Pellet machine * 110 kw; 4. Cooling machine* 0.93 kw; 5. screen machine*0.25kw, It’s full automatic control system.

- Installation time: 90 Days

- cattle feed plant project cost: FOB $320,000

cattle feed plant project in Argentina

- Output: 5T/H

- Feed Type: Ruminant Alfalfa Feed

- Project area: 320m2

- Main equipment of the project: bale breaking machine, alfalfa crusher machine, ring die alfalfa pellet machine for cattle, scraper conveyor, belt packaging scale, molasses adding machine, gas boiler, screener, etc.

- Installation time: 40 days

- cattle feed plant project cost: 350,000 USD

cattle feed plant project in Uzbekistan

- Output: 0.8-1.2T/H

- Feed type: cattle and goat feed

- Workshop size: 6m*5m*5.5m

- Main equipment of the project: Cattle feed crusher machine, single-shaft ribbon mixer for cattle feed, SZLH-250 1-2T/H double-layer conditioner cattle goat feed pellet making machine, cooling belt, etc.

- Installation time: 30 Days

- cattle feed plant project cost: FOB $57,000

cattle feed plant project in U.K.

- Output: 12T/H

- Feed type: Ruminant premix Feed

- Workshop size: 3500 m2

- Main equipment of the project: Hopper and fence, Pulse dust collector, Twin shaft mixer, Bucket elevator, Finished product warehouse, automatic packing scale, etc.

- Installation time: 135 Days

- cattle feed factory project cost: FOB $650,000

cattle feed plant project in india

- Output: 16-20T/H

- Feed type: cattle & poultry sheep feed

- Project area: 4193m2

- Main equipment of the project: Pulse dust collector, Permanent cylinder magnet, cattle feed pellet machine, Counter flow cooler, Bucket elevator, Permanent magnet cylinder, Pulse dust collector, Rotary distributor, Rotary grading screen, Electronic packing scale, Weighing grease adding machine, Steam line , Air compressor, silo sytems, etc.

- Installation time: 130 days

- cattle feed plant project cost: 670,000 USD

cattle feed plant project In Russia

- Output: 60T/H

- Feed type: Cattle horse goat rabbit feed

- Project area: 5650m2

- Main equipment of the project: Scraper conveyor, Bucket elevator, Initial cleaning and screening of materials, Permanent magnet cylinder, Grinder, Single shaft mixer, cattle livestock feed pellet machine, stock pellet cooler, screening machine, extruder, Double bucket belt packing scale, Sewing conveyor , Boiler, etc.

- Installation time: 300 days

- cattle feed plant project cost: 2,700,000 USD (Including silos)

cattle feed plant project in Vietnam

- Output: 40-50T/H

- Feed type: cattle & fish feed

- Project area: 4574m2

- Main equipment of the project: Dust removal fan, Scraper conveyor, Bucket elevator, Auger conveyor, Spiral distributor, Rotary grading screen, Impeller feeder, Powder sieve, Animal feed granulator, Twin screw extruder, Feed grinder, Ultrafine grinder, Twin-shaft paddle mixer, Counter flow cooler, dryer machine, bagging machine, etc.

- Installation time: 270 days

- cattle feed plant project cost: US$1.8 million (Including silos)

cattle feed plant project in brazil

- Output: 20-30T/H

- Feed type: Dairy Cow Feed

- Project area: 1996.3m2

- Main equipment of the project: Cow feed crusher, Rotary distributor, cow feed mixer, Cow feed pellet making machine, Scraper conveyor, Belt packaging scale, Molasses adding machine, Electric hoist, Gas steam generator, Silo system, etc.

- Installation time: 120 days

- cattle feed mill project cost: 1,640,000 USD

cattle feed plant project in Thailand

- Output: 3-5T/H

- Feed type: Cattle mash feed

- Workshop size: 8m*7m*6.5m

- Main equipment of the project: 1.cattle feed hammer mill*37KW; 2.cattle feed mixer*500kg/batch; 4.cattle powder feed packing machine and other auxiliary equipment, etc.

- Installation time: 15 Days

- cattle feed mill project cost: FOB $140,000

cattle feed plant project In New Zealand

- Output: 1-2T/H

- Feed type: maize cattle feed

- Workshop size: 6m*3m*7m

- Main equipment of the project: 1.feed hammer mill*11KW; 2.feed mixer*250kg/batch; 3.feed pellet machine*22kw; 4.cooling machine; 5. screen machine; 6. packing machine and other equipment.

- Installation time: 50 Days

- cattle feed plant project cost: FOB $90,000

We have successfully helped our clients understand, plan, and execute their goals with our expertise in cattle feed manufacturing industry. We are proud to showcase our work and the success our clients obtain through our initiatives.

Cattle feed plant project report

Below is some project report for cattle feed plants project that we hope will be helpful to you if you want to invest in a cattle feed processing business.

4-5T/H project report cattle feed manufacturing in U.K.

—— RICHI MACHINERY ——

- Annual output: 40,000 t/a

- Building area: 680m2

- Cattle feed manufacturing plant cost: 290,000 USD

- Ingredients type: corn, straw hay, corn

- Customer type: Large beef cattle farms.

- Construction content: Mainly constructing standard cattle sheds, silage pits, grass and material warehouses, forage processing workshops, anaerobic fermentation tanks, etc.

- Working system: 30 people, three shifts, 8 hours per shift, 365 working days per year.

- Main raw material consumption: Dry materials (corn, hay), silage corn stover, concentrated feed (corn, cake meal, bran, stone powder, salt, calcium hydrogen phosphate, mineral trace element additives, vitamin additives , calcium hydrogen phosphate, whey powder), etc. Corn straw*7920, corn/hay*3960, etc.

- Main production equipment: ration mixer, straw grabber, lawn mower, baler, corn crusher, straw crusher, conveyor, etc.

cattle feed plant project Process flow:

- Silage is mainly made from fresh corn straw, soybean straw, leguminous grass, etc., which are chopped into pieces, packed in silage pits, compacted, covered with soil, and stored for 45 days;

- Hay is mainly purchased and packaged wheat straw, bean straw and peanut straw. Among them, silage corn straw is purchased from surrounding areas;

- During the harvest season, the silage corn straw is transported to the site by vehicle, and the silage corn straw is unloaded into the silage cellar by the loader (covered with tarpaulin) and compacted before storage;

- Dry feed is packed in bags, and is transported to the site by car after purchase, and is stored in the feed processing workshop; all concentrated feed is packaged in bags, and is transported to the site by car after purchase and stored in the feed processing workshop.

Various feeds need to be mixed during feeding, that is, a nutritionally balanced diet obtained by fully mixing chopped roughage and various mineral and vitamin additives in the feed feeding vehicle according to the nutritional formula of the beef cattle. Add concentrate, silage, and hay to a mixer to make mixed feed. Add an appropriate amount of water during the mixing process to make the feed moisture content 45%-50%.

30 T/H Dairy cattle feed project report in russia

—— RICHI MACHINERY ——

- Annual output: 150,000 tons of dairy feed

- Cattle feed plant project cost: 1,200,000 USD

- Area: 6196.3m2

- Raw and auxiliary materials (t/a): corn*88950, rapeseed meal*13950, soybean meal*36000, premix*1800, salt*1200, stone powder*1800, baking soda*2700, demycin*450, magnesium oxide*900, fat pink*2250

- Annual water consumption: 674t/a

- Annual power consumption: 960,000 kwh/a

- Main equipment: pulse dust collector, scraper conveyor, bucket elevator, rotary distributor, pulse dust collector, ultra-fine grinder, double-shaft high-efficiency mixer, cattle feed granulator, counterflow cooler, permanent magnet cylinder, belt Packaging scale, seam conveyor combination machine, packaging dust collector, air dryer, molasses adding machine, etc.

cattle feed plant project Process flow:

- First, the purchased feed raw materials such as corn, rapeseed meal, soybean meal, etc. are manually put into the feeding hopper, and then lifted to the feeding port through the conveyor, and then screened by the primary cleaning screen, and then sent to the warehouse to be crushed.

- After being crushed by the pulverizer, the crushed raw materials are transported to the batching bin through the bucket elevator.

- Then prepare the prepared powdery materials (such as salt, baking soda, premixes, additives, etc.). In this process, the materials are first conditioned by the conditioner, and then the air supply system (steam generator) Appropriate steam is introduced into it to soften the raw materials.

- Then, these added materials will be added according to the preset requirements of the dairy cow feed formula, using a specific ingredient metering system to feed and weigh different types of raw materials. The prepared materials will be sent to the mixing equipment for mixing and mixing, and then enter the dairy cow feed. The pelleting machine produces pelleted dairy cattle feed that meets qualified product standards.

- The pelletized cow feed pellet product is cooled by the cooler and then sent to the finished product warehouse.

- The products that pass the inspection are poured into woven bags through the packaging system, and then sent to the sewing machine for sealing, and then sent to the finished product warehouse for sale.

25 T/D cattle feed manufacturing project report in Ghana

—— RICHI MACHINERY ——

- Annual output: 7300 tons

- Feed type: fermented feed pellets

- Customer type: Large dairy farms

- Technology type: silage, ammoniation, pelleting

- Cattle feed plant project cost: 230,000 USD

- Construction period: 1 year

- Power consumption: 219000 kw·h

- Water consumption: 9855 cubic meters

- Main raw materials: corn straw*60000, liquid ammonia*491000, urea*80140

- Main equipment: straw silage ammoniation equipment, hay mower, straw pellet machine, baling scale and other equipment

cattle feed plant project Process flow

The principle of cattle straw pellet feed processing is mainly to use industrial chemical treatment and physical treatment methods to use low-value roughage such as corn straw, rice straw, wheat straw, sunflower straw, sorghum straw and other crop straws, add a conversion agent, and then compress and utilize the temperature and pressure generated during compression ammoniatize, alkalize and mature the straw, completely denature the straw lignin, improve its nutritional content, and produce granular feed with consistent quality, which becomes the basic food for ruminants.

- Straw ammoniation parameters. After ammonia treatment of straw, the crude protein content increases by 1 to 1.5 times, and the digestibility increases by more than 20%.

- Straw silage parameters. The moisture content of green corn straw is 65% to 70%, and the pH value is 3.4 to 4.2.

- Straw pelleting (briquetting) parameters. The density of straw pellet is 0.6-1 g/cubic centimeter, and the stacking capacity is 0.4-0.6 tons/cubic meter.

Construction plan: Build 10 silage ammoniation tanks, each with a capacity of 6,000 cubic meters, totaling 60,000 cubic meters. Each silage ammonia tank has an annual output of 4,000 tons of corn straw feed, and the 13 silage ammonia tanks have an annual output of 52,000 tons of corn straw feed, of which 12,000 tons are consumed by the client company’s high-breed dairy breeding farm.

25 T/H cattle feed business project report in australia

—— RICHI MACHINERY ——

- Annual output: 60,000 tons/year

- Cattle feed plant project cost: 780,000 USD

- Project construction content: The project designs and constructs 10 production lines to achieve an annual production capacity of 150,000 tons of cattle straw feed pellets. Among them, 4 production lines in the first phase can achieve an annual production capacity of 60,000 tons of straw feed pellets; 6 production lines in the second phase can achieve an annual production capacity of 90,000 tons of straw feed pellets.

- Annual electricity consumption: 1 million kW·h;

- Annual water consumption: 360t.

- Work system: 40 people, 300 days of work per year, single shift system, 8 hours of day shift work every day.

- Main raw materials: straw*40000, corn*10000, bran*5000, protein raw materials*5000

- Main equipment: silo to be pelletized, loading position machine, lowering position machine, feeder, stainless steel modulator, straw feed pelletizer, closed belt conveyor, closed air feeder, counterflow cooler, silencer, etc.

cattle feed plant project Process flow:

- Conveying: The straw, corn, bran, and protein raw materials purchased by the project are all crushed powder materials. There is no need for further crushing and processing after entering the site. The purchased fine materials are transported to the granulator using an elevator for granulation.

- Granulation: Straw pellet feed granulator are key equipment of the production line. According to customer needs, the cattle straw pellet granulator is adjusted and used. The raw material contains a certain amount of lignin and cellulose. The lignin is the structural monomer in the material. polymer compounds. It has the function of strengthening cell walls and binding cellulose. When the temperature reaches a certain value, the lignin softens and the bonding force increases. Under a certain pressure, the cellulose molecular groups are dislocated, deformed, and extended. The adjacent biomass particles inside are toothed to each other, reassembled, and pressed into shape. The temperature during the granulation process should be controlled at 80~100 degrees Celsius.

- The produced granules have increased palatability. At the same time, the granules can be soaked in warm water for 2 to 3 hours without breaking. Therefore, they are particularly suitable for cattle rumination needs. The diameter of pellets for sheep is 4~6mm, and the diameter of pellets for cattle is 6~8 mm. The size of the particles depends on the size of the mold holes. Select the mold according to your needs, start the machine, and add the material into the feed hopper to produce pellet feed.

- Packaging and finished product storage: After the product is packaged, it is stored in storage for sale.

50 T/H cattle feed industry project report in Kazakhstan

—— RICHI MACHINERY ——

- Annual output: 120,000 tons

- Feed type: ruminant cattle and sheep feed

- Cattle feed plant project cost: 1,800,000 USD

- Power supply load: 150KV

- Production costs: mainly include direct material costs, direct wages, depreciation, repair costs, etc.

- Raw material consumption: soybean meal*24000, rapeseed meal*12000, cotton meal*36000, corn*24000, trace elements*3600, vitamins*1800, grass meal*5400, stone powder*4800, salt*2400, etc.

- The equipment unit includes: corn receiving system, corn silo system, auxiliary material receiving system, crushing system, ingredient mixing system, granulating system, and finished product packaging system.

cattle feed plant project Design Features:

- The cattle feed production line of the project adopts the process of cleaning, crushing, electronic scale ingredient measurement, and batch mixing. The entire production process is controlled by a microcomputer and is a complete feed production line.

- Dig a T-shaped basement with a depth of 7m on the ground, and place the crusher, mixer, and preliminary cleaning equipment for granular and powder raw materials in the basement. This can reduce the noise of the crusher, mixer, and preliminary cleaning screen, and facilitate Workers operate to reduce the height of the frame and reduce the cost;

- The use of point ventilation and dust removal can improve equipment utilization and save energy consumption. The design, manufacturing, installation and commissioning of this production line equipment are undertaken by Richi Machinery.

Civil engineering:

- Covering an area of 316 square meters, a five-story production machine room with a height of 34 meters;

- A raw material warehouse covering an area of 5040 square meters;

- Finished product warehouse covering an area of 2520 square meters;

- A weighbridge and weighbridge room covering an area of 44 square meters;

- Three-story office building; boiler room, power distribution room;

- Garages, parking lots, dormitory canteens, concierges and other ancillary service facilities.

35 T/H cattle feed manufacturing plant project report in united states

—— RICHI MACHINERY ——

- Annual output: 300,000 tons

- Cattle feed plant project cost: 1,420,000 USD

- Product type: ruminant premixed feed and ruminant cattle and sheep pellet feed

- Main construction content: new office building, raw material warehouse, finished product warehouse, auxiliary warehouse, boiler room, etc.

- Energy consumption: Steam*3t/h gas boiler, water *9000m3/a, electricity *200,000 kWh/a

- Work system: 360 days a year, with 3 shifts of 8 hours each.

- Main raw materials (t/a): corn 150,000, cotton meal 60,000, dried distiller’s grains 60,000, soybean meal & sunflower meal & salt, etc. 30,000, stone powder calcium powder 8,000, calcium hydrogen phosphate 4,000, soda, rice husk powder 10,000, vitamins 5,000, trace elements complex 5000, etc.

- Main equipment: scraper conveyor, permanent magnet drum, bucket elevator, silo, batching bin, mixer, granulator, control and steam pipeline system, counterflow cooling, rotary grading screen, distributor, finished product bin 55m³, belt packing scale, sewing conveyor, computer control system, etc.

cattle feed plant project technological design:

- After being transported to the factory by truck, the corn is stored in four 1500t silos, and other raw materials are stored in the raw material warehouse. The raw materials in the raw material warehouse are manually cut and fed into the packaging bags, and then go through the cylinder preliminary cleaning screen, the permanent magnet cylinder to remove sand in the materials, the packaging bag line, etc.

- The cleaned raw materials are crushed by the crusher; the crushed materials are measured by the batching scale and enter the batching bin according to a certain proportion, and are mixed by the mixer; the mixed materials enter the granulation bin and are processed by the granulator. grain.

- The granular feed produced in the cattle feed granulator is cooled by the counter-flow cooler; the powdered feed and pellet feed are weighed by the packaging scale, and sewn and transported by the sewing conveyor to the finished product warehouse for temporary storage for sale.

How to build a Cattle feed plant project?

Building a cattle cow feed plant project and running it well is a very complicated matter, but if you find the right cattle feed plant manufacturers, the process of building a feed plant will be smooth. If you want to start a cattle feed mill project, the following content is some reference provided by RICHI for you.

01 Cattle feed plant scale, product types and specifications

- Factory scale

- Product type and specifications

02 Factory location

- Factory site selection

- Address conditions

03 Cattle feed plant design

- Cattle feed mill layout planning

- Feed mill buildings and facilities

- General plan of feed factory

- Design principles and features

- Civil engineering design

- Feed mill process design

- Main workshop design

- Warehouse design

- Laboratory design

- Process specifications and technical requirements

- Cattle feed equipment configuration and selection

- Automated control

04 Organization and supply of production raw materials

- Types and nutritional characteristics of raw materials for cattle feed production

- Demand for various raw materials in cattle feed mills

- Procurement and acceptance of feed raw materials

05 Demand and sales of cattle feed products

- Cattle feed product varieties and types

- Cattle feed formula design

- Cattle feed product standards

- Sales of feed products

06 Environmental protection and production safety

- Environmental protection

- Fire safety

07 Cattle feed plant project investment and economic benefit analysis

- Investment budget

- Total project investment estimate

- Project investment budget estimate

- Cattle feed plant cost and profit

- Market prospects and risk analysis

08 Organization structure and labor quota

- Organizational structure

- Labor quota

09 Factory construction period and implementation progress

10 Personnel training

- Training objects

- Training content

- Training time

11 Management system

- Cattle feed production process specifications

- Cattle feed equipment operating procedures

- Job responsibilities

- Labor discipline and personnel management system

- Safety production system

- Total quality management system

- Financial system

If you want to start a cattle feed plant project, feel free to contact us to customize your cattle feed processing plan!

Process design of different Cattle feed plant projects

For the processing technology of cattle, sheep and ruminant feed, different raw materials and product types will make the processing technology very different. Whether you want to process complete compound feed, concentrate feed, grass feed, premix or fermented feed, you are welcome to contact Richi Machinery to customize your cattle feed factory process and obtain the corresponding equipment quotation!

Production lines and processes designed for cattle feed plant projects in different countries:

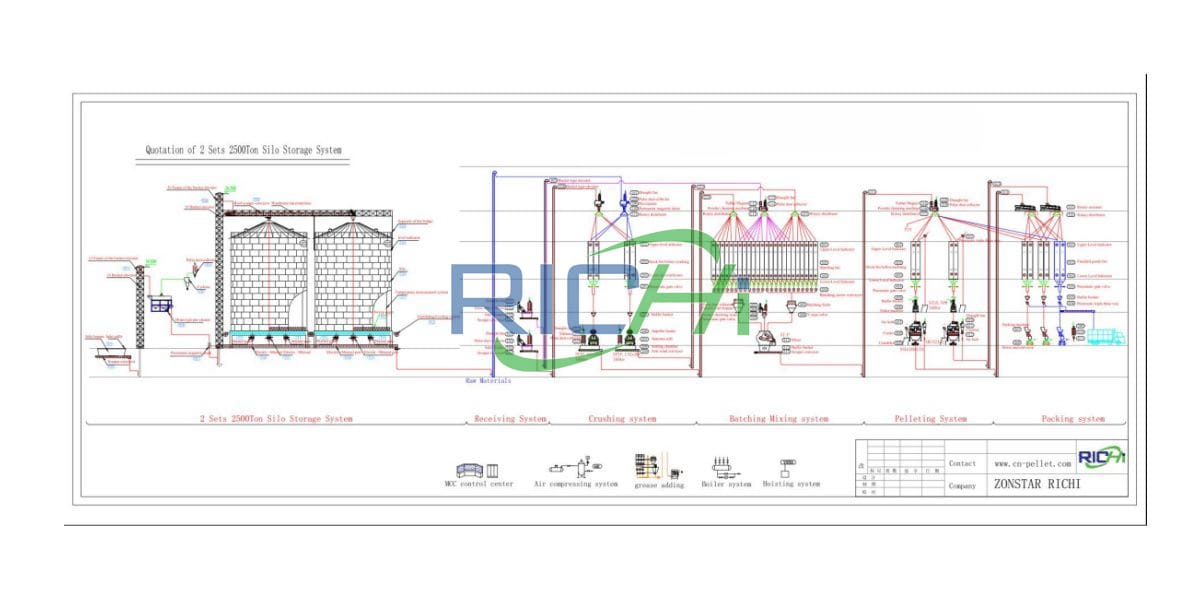

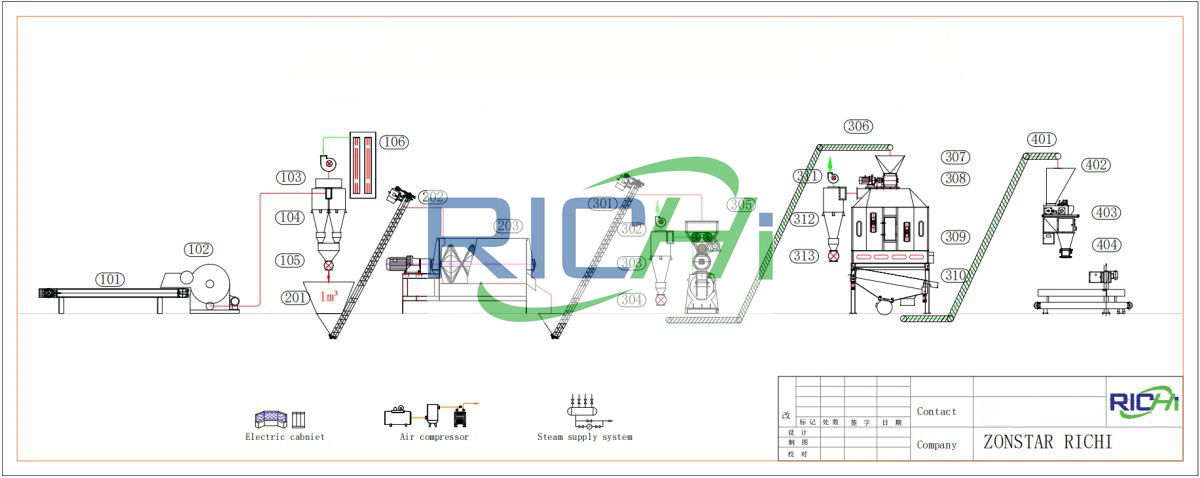

40-50 T/H cattle feed mill project design

- Type: combined feed plant

- feed product: chicken and cattle pellets

- Applicable to large feed company

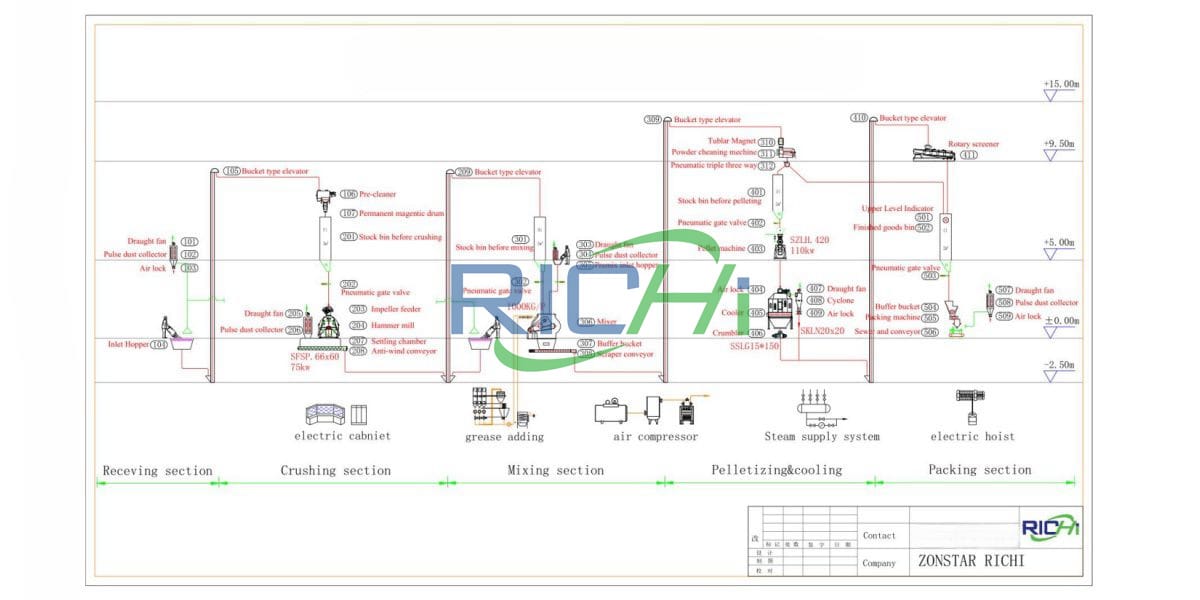

10 T/H cattle feed mill project design

- Type: combined feed plant

- feed product: cattle feed pellets

- Applicable to Medium-sized feed mills and medium- and large-scale breeding farms

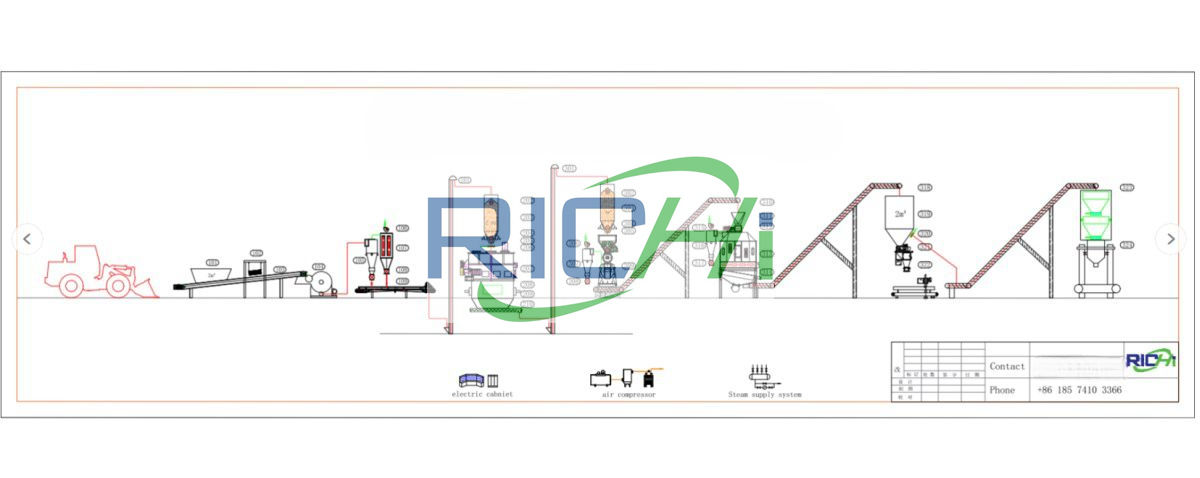

3-12 T/H grass feed line for cattle feed (from grass alfalfa hay)

- Type: grass feed plant

- feed product: ruminant cattle pellets

- Suitable for small and medium-sized farms and feed mills

0.8-4 T/H cattle feed processing design (From corn straw & rice straw)

- Type: straw feed plant

- feed product: ruminant cattle pellets

- Suitable for small sized farms and cattle feed mills

If you have any needs or questions for cattle animal feed production line project process design, contact Richi Machinery for professional technical support!

Equipment needed to start cattle feed plant project

Generally speaking, cattle feed mill projects mainly require the following feed mill equipment:

hammer mill feed grinder

Used in cattle feed materials crushing section.

Capacity:

3-25 T/H

Main Power:

30-160 KW

Feed Mixer machine

Used in cattle feed raw materials mixing section.

Capacity:

250-2000 KG

Main Power:

4-55 KW

cattle feed Pellet mill

This is single layer conditioner cattle feed pellet machine.

Capacity:

1-48 T/H

Main Power:

22-315 KW

cattle Feed Extruder

Used in extruded cattle feed manufacturing process.

Capacity:

1-12 T/H

Main Power:

0.75-355 KW

cattle feed pellet machine

This is a double-layer conditioner pellet machine with better maturation

Capacity:

0.6-27T/H

Main Power:

22-315KW

straw grass dryer machine

Used in the drying stage of cattle feed processing containing grass raw materials.

Capacity:

Customizable

Rotate speed

3-8 R/Min

Bale breaker

For grass-containing ruminant and livestock cattle feed production.

Capacity:

1-20 T/H

Main Power:

30-90 KW

straw Grass crusher

Mainly used for crushing grass, straw, hay and related raw materials for ruminant.

Capacity:

0.3-3 T/H

Main Power:

22-93 KW

Pellet Cooler Machine

Used in cattle feed pellet cooling section.

Capacity:

3-25 T/H

Main Power:

30-160 KW

pellet crumbler machine

Used to reduce the pellet size of finished feed pellets.

Capacity:

2-20 T/H

Roller:

2-3

vibrating screening machine

Used in cattle feed pellet grading section.

Capacity:

3-20 T/h

Main Power:

1.5-5.5 KW

Automatic Bagging Machine

Used in cattle pellet & mash feed packing section.

Capacity:

6-12 Bags/Min

Main Power:

1.1-5 KW

When purchasing a complete set of cattle feed making machines, you need to make a selection based on factors such as production scale, process flow, and feed type. At the same time, it is also necessary to choose cattle feed equipment manufacturers with high technical levels and high-quality services to ensure the quality of cattle feed plant project and after-sales service.

cattle feed plant project video

Customize your Cattle feed plant project

In line with the business philosophy of customer satisfaction as the center, we proactively communicate with customers in a timely manner, select technicians or engineers with strong sense of responsibility and strong professional ability, and provide meticulous and thoughtful door-to-door services.

Solve customer problems in a timely manner and establish good cooperative relationships with customers.

Richi Machinery warmly welcomes friends from all over the world and welcomes friends at home and abroad to cooperate with us and develop your high-level cattle feed plant project.

Why choose RICHI Machinery?

At Richi Machinery, we believe there’s no substitute for experience. And we have well over 25 years of it.

We have been in business for 25+ years.

Our long-term business strategy lends stability to our client’s cattle feed plant projects.

We are innovators.

We don’t stand still—we are continually finding ways to improve the design and cattle feed plant project construction process to add value and save you money.

We are a lean organization.

Our clients work with just one project manager and one cattle feed plant project superintendent who have the authority to make decisions. This minimizes mistakes and expedites jobs, saving everyone time and money.

We have key employees with significant experience in the industry

Our key employees have an average of 10 years with the company. As a result, we deliver our jobs faster and help our clients get a return on their investment sooner than other companies in our industry.

We understand the importance of communication

We want to make sure our clients know what’s going on at all times. We anticipate problems to minimize client risk, and we listen to ensure that client needs are accurately reflected from proposal to cattle feed plant project completion.

We understand customer satisfaction includes being cooperative

We work as a team with the owner, subcontractors, and suppliers. We strive to make the construction process a pleasant experience for the client.

We are committed to quality

We see each cattle feed plant project as a reflection of our values and build each one as though it were for ourselves. We strive to do it right the first time, improving the investment value of our client’s property.

We work safely

We have minimal lost time due to injuries and our insurance costs are lower, which saves our clients money.

We work in tough environments

We understand the challenges, maintain flexibility in our work schedule, and minimize errors in order to deliver your cattle feed mill equipment on time and on budget.