Wood Pellet Manufacturing Plant For Sale

The 15-20 t/h wood pellet manufacturing plant range offers customized solutions for a wide variety of different agricultural and forestry wastes. The wood pellet plant is mainly used for processing wood fuel pellets, wood cat litter pellets and biomass blended fuel pellets.

With the improvement of environmental awareness and the development of the biomass energy industry, the wood pellet plant constructions has become a hot topic for many investors. Wood pellet plants can convert forest waste into high value-added biomass fuel, solving the problems of waste disposal and environmental protection.

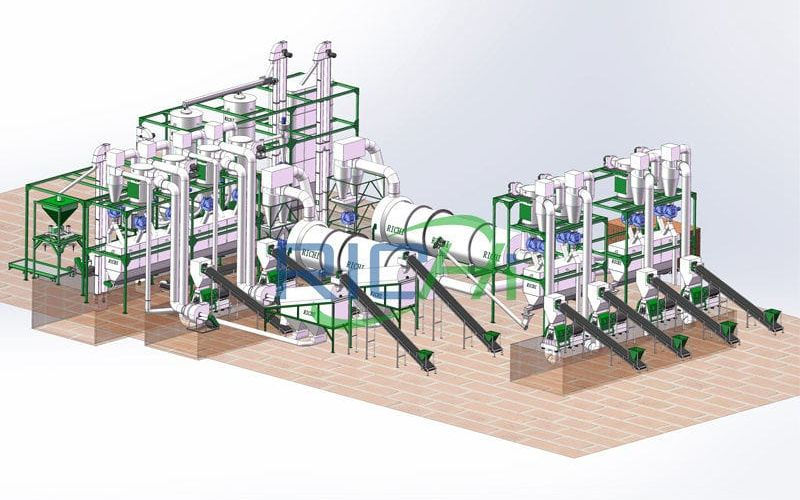

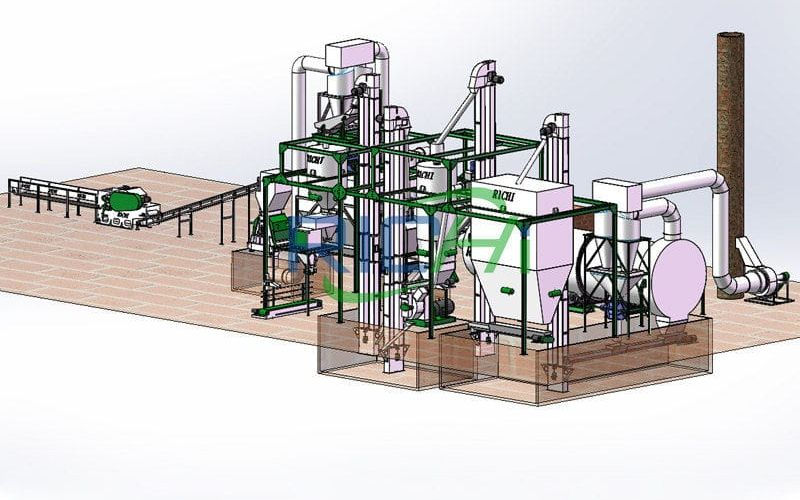

Richi Machinery specializes in wood pellet manufacturing plant for sale, undertakes all phases of the wood pellet plant design, budget, equipment and material procurement, construction, trial operation, and acceptance, and finally submits a complete wood pellet manufacturing plant project that meets the functions and conditions of use to the global customer, and undertakes the quality, full responsibility for schedule, cost and safety.

- Capacity: 15-20 T/H

- Cost: 300,000 – 1,500,000 USD

- Applicable customers: biomass pellet plants, wood plants, sawdust factory, power plants, cat litter plants, furniture factories, etc.

We customize every wood pellet manufacturing plant project to fit the clients needs and requirements, we are also manufacturers and suppliers of equipment, and complete pellet lines, such as belt dryers, wood pellet mills, hammer mills, etc.

When you decide to go modular and hire RICHI team for the wood pellet mill plant construction, you will get all of the benefits of traditional construction at a fraction of the price and much better lead times.

Wood pellet manufacturing plant types

The wood pellet manufacturing plants we provide include the following:

- Sawdust pellet manufacturing plant for sale

- Chips pellet manufacturing plant for sale

- Log pellet manufacturing plant for sale

- Leaf pellet manufacturing plant for sale

- Various wood waste pellet manufacturing plant for sale

- Wood and agricultural waste mixed pellet manufacturing plant for sale

- …

Applicable raw materials

The wood pellet manufacturing plant is suitable for processing all types of forestry waste and agricultural waste.

- HARDWOOD

- SOFTWOOD

- WOOD CHIPS

- WOOD SAW DUST

- WOOD LOG

- WOOD PALLETS

- TRUNK

- BRANCHES

- LEAVES

- OFF CUTS

- STRAW

- PADDY HUSK

- PEAT

- SOYA HUSK

- BAGASSE

- WOOD WASTE

- BAGGASE

- MUSTARD

- COTTON STALK

- COTTON HULL

- PALM KERNAL

- PALM EFB

- JULIFLORA

- COCONUT

- BAMBOO

- COFFEE SHELL

- MSW COMPOST

- fERTILIZER

- PEANUT SHELL

- …

Different scale wood pellet manufacturing plant for sale

Maybe you are interested in wood pellet manufacturing plant with other production capacities:

- Small Wood Pellet Plant (0.3-1 T/H)

- Wood Pellet Line (1-2 T/H)

- Wood Pellet Plant Design (2.5 T/H)

- Complete Wood Pellet Plant (3 T/H)

- Wood Pellet Processing Equipment (4 T/H)

- Wood Pellet Processing Plant (5 T/H)

- Wood Pellet Production Plant (6-7 T/H)

- Wood Pellet Making Equipment (7-8 T/H)

- Wood Pellet Manufacturing Equipment (8-10 T/H)

- Wood Pellet Factory (12-15 T/H)

- wood pellet making line (20-30 T/H)

- Turnkey Wood Pellet Mill (30-40 T/H)

- Large Wood Pellet Mill (40-50 T/H)

- . . .

How to make wood pellets? Process flow of wood pellet manufacturing plant

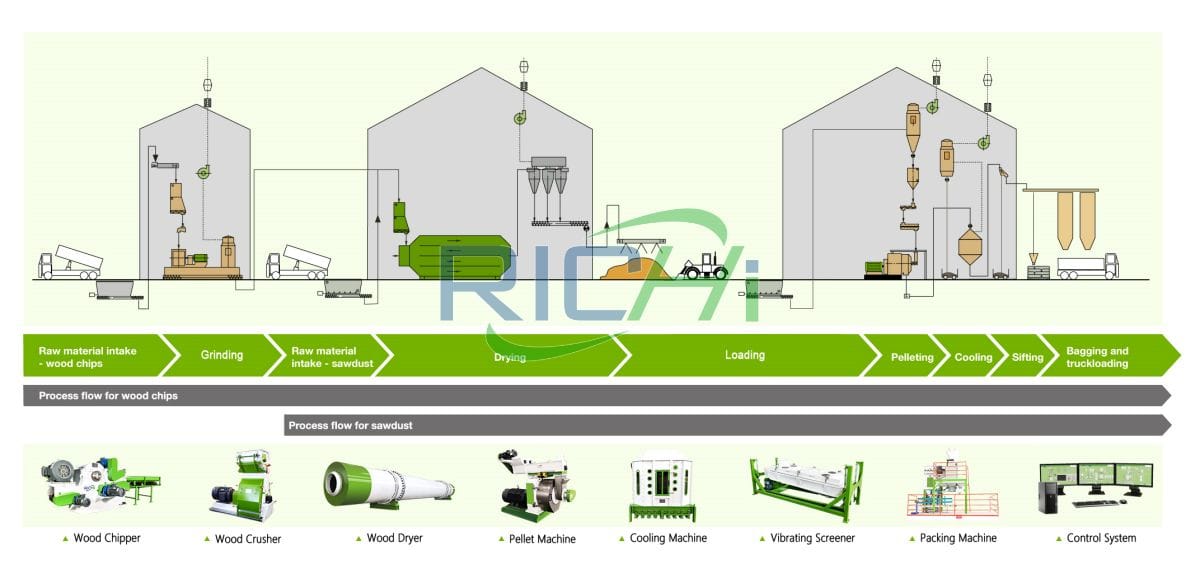

RICHI wood pellet manufacturing plants usually include these processes: Material Preparation Section – Drying Section – Grinding Section – Pelleting Section – Cooling Section – Bagging & Storage Section

Most pellets are produced in large-scale wood pellet plants. If you’re considering making your own pellets, this guide will teach you how to make wood pellets and better teach you how to choose wood pellet making equipment.

The following is an example of log wood pellets. The steps for using log wood pellets from various trees such as pine, fir, beech, oak, and eucalyptus are as follows:

Peeling Section

The equipment used to peel the logs is the RICHI tooth roller peeling machine. Peeling can increase the combustion calorific value of the finished pellets, reduce the ash residue after combustion, and reduce emissions.

Slicing Section

After the trunk of the log is peeled, it is cut into small wood chips by a slicer. The size of the wood chips is 20-30mm and the thickness is about 5-10mm, and then enters the subsequent processing section.

Crushing

The wood chips cut into blocks are fed into the crusher and finely powdered into 3-4mm wood chips. This section works without dust emission. After the materials are crushed, they are pneumatically transported and discharged by the negative pressure suction of the fan.

Drying

Before making wood pelletss, the raw materials must be dry. Depending on the raw materials used, the moisture content should be between 13% and 15%. In order for the granulation process to work properly, the raw materials should have the right amount of moisture. Drying the raw materials to the right moisture content is critical to making high-quality pellets.

Granulation

Finally, the granulation process is carried out, and the diameter of the processed finished granules is 6-10mm. RICHI’s MZLH series wood pellet making machine can process various biomass wood pellets.

Cooling and packaging

After granulation and cooling, it is packed and packaged. The temperature of the pellets after cooling is generally not higher than room temperature 5℃, and the moisture content of the wood pellets after cooling is less than 10%, which is convenient for storage. RICHI can adjust packaging equipment according to customers’ requirements for finished product packaging. It can also be stored in bulk or in steel warehouses.

The pre-treatment process for each raw material is different. If you have any questions, please contact us at any time. We will customize the wood pellet manufacturing plant according to your raw materials and provide comprehensive technical support for your wood pellet production line construction!

Main equipment for wood pellet manufacturing plant

All equipment relevant to building a wood pellet manufacturing plant can be offered by RICHI Machinery, i.e. log splitter, wood chipper, crusher, dryer, pellet mill, cooler, screener, bagging machine.

wood Debarker

Suitable for large, medium and small paper mills, pulp mills, wood chip mills, wood processing plants, forestry plants, lumber yards, and artificial board plants.

Capacity:

5-15 T/H

Main Power:

7.5-11 KW

Wood splitter

It is mainly used to split tree stumps, large branches, large log sections and hard wood. It is an indispensable equipment for primary processing of wood.

Capacity:

3-12T/H

Main Power:

10-20 KW

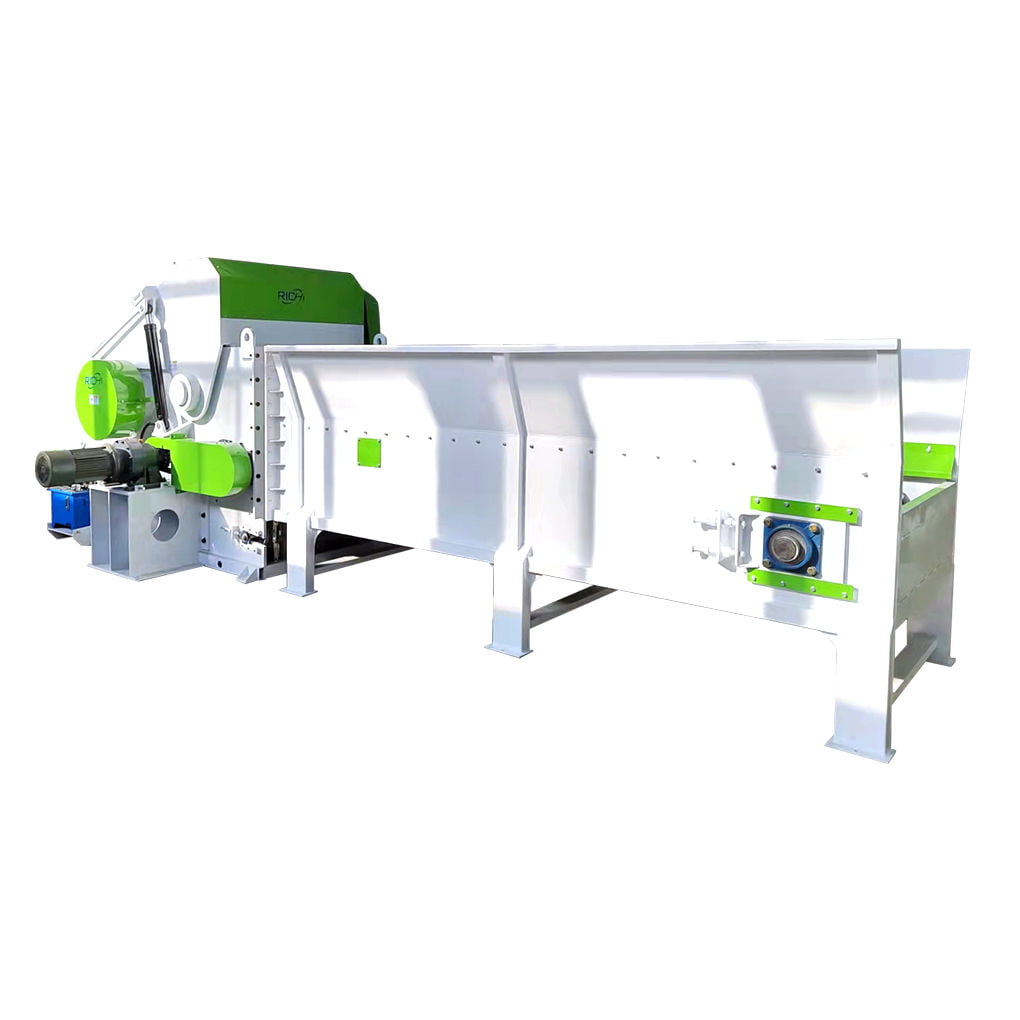

Wood Chipper Machine

It can be used to process limbs, barks, wood scrapes logs, crotches, and planks of larger sizes into small size wood chips. It is the most widely used wood crusher.

Capacity:

3-18 T/H

Main Power:

4-110 KW

Wood pellet Hammer Mill

It can reduce the size of raw materials from 10-30mm to 2-5mm with hammers and toothed plates, so that they are suitable for making pellets.

Capacity:

3-25T/H

Main Power:

30-160 KW

wood pallet crusher

These durable crushing machines effectively reduce the size of wood pallets into smaller chips, manageable fragments, facilitating easier disposal or recycling.

Capacity:

3-20T/H

Main Power:

55-110 KW

wood chip Dryer

Used to remove the excessive water in the wood raw materials, and make them qualified for making wood pellets. The most commonly used is the three-cylinder dryer.

Capacity:

Customized

Rotate Speed:

3-8 R/Min

wood pellet mill

For processing dry raw materials into granules. It features high efficiency, low unit energy consumption, long service life, high cost, large size and weight.

Capacity:

0.3-10 T/H

Main Power:

37-280 KW

Pellet Cooler Machine

Used to reduce the temperature and moisture of the wood pellets. The process can improve the hardness of pellets, convenient for subsequent screening and packaging.

Capacity:

1.5-18 T/H

Main Power:

0.75-2.05 KW

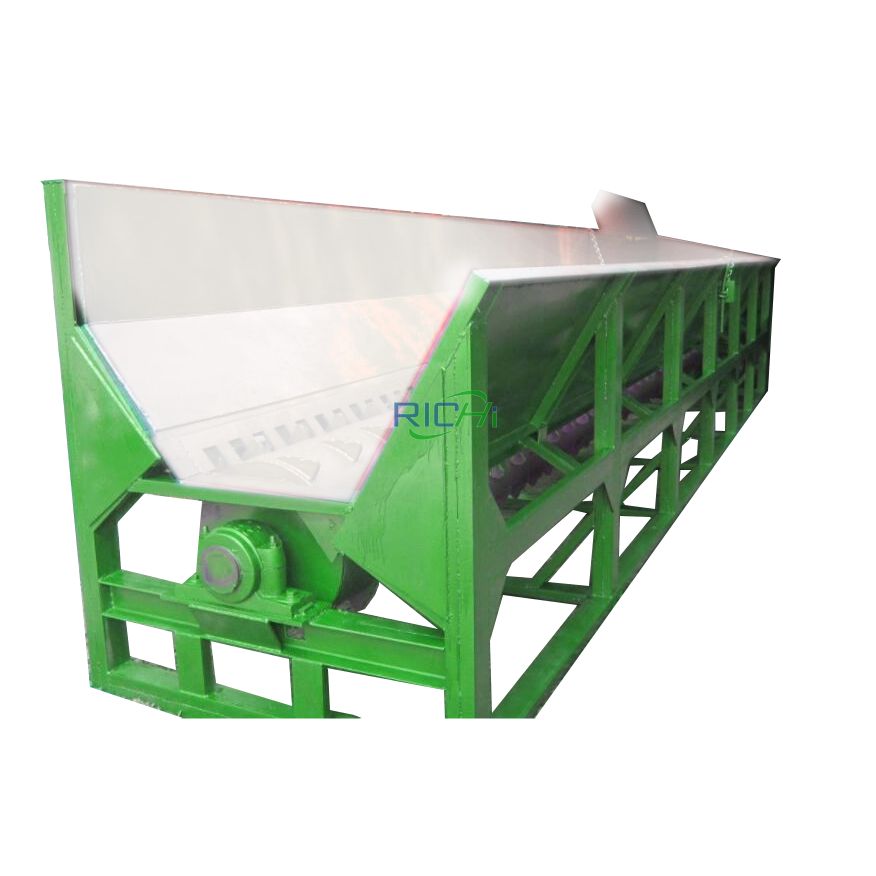

vibrating screening machine

Used to screen out qualified wood pellets. The qualified ones will be packaged and sold, and the unqualified ones will be re-pelletized.

Capacity::

3-20 T/H

Main Power:

1.5-5.5 KW

Automatic Bagging Machine

It is necessary for storage and selling, can realize automatic weighing, packing, conveying and sewing. It applies to different bags and weights.

Speed::

6-12 Bags/Min

Main Power:

1.1-5 KW

As a manufacturer specializing in wood pellet manufacturing plant for sale, RICHI Machinery is a professional manufacturer and supplier of wood pelletizing system with advanced machinery, strong development strength and perfect after-sales service. Establishing a wood pellet production plant is a profitable project, do something about it now!

wood pellet manufacturing plant for sale worldwide

RICHI offers equipment and solutions for wood pellet manufacturing plant with cases across Asia, Africa, the Americas, and the European continent. Our expertise in these regions makes us a first choice when customers choose partners.

wood pellet manufacturing plant for sale United States

- Country: United States

- Production: 50,000 T/A

- Ingredients: wood branches, chips, sawdust

- wood pellet manufacturing plant cost: US$550,000

wood pellet manufacturing plant for sale indonesia

- Country: indonesia

- Production: 10,000 T/A

- Ingredients: furniture factory waste

- wood pellet manufacturing plant cost: US$270,000

wood pellet manufacturing plant for sale Vietnam

- Country: Vietnam

- Production: 2500 t/a

- Ingredients: wet tree stump, trunk

- wood pellet manufacturing plant cost: 180,000 USD

wood pellet manufacturing plant for sale brazil

- Country: brazil

- Production: 35,000 T/A

- Ingredients: wood sawdust and chips

- wood pellet manufacturing plant cost: 410,000 USD

wood pellet manufacturing plant for sale Austria

- Country: Austria

- Production: 10,000 T/A

- Ingredients: wood pallet and sawdust

- wood pellet manufacturing plant price: 190,000 USD

wood pellet manufacturing plant for sale poland

- Country: poland

- Production: 55,000 T/A

- Ingredients: wood chips

- wood pellet manufacturing plant price: 770,000 USD

wood pellet manufacturing plant for sale canada

- Country: canada

- Production: 6,000 T/A

- Ingredients: wood sawdust

- wood pellet manufacturing plant price: $160,000

wood pellet manufacturing plant for sale germany

- Country: germany

- Production: 30,000 T/A

- Ingredients: wood sawdust, log

- wood pellet manufacturing plant price: $785,000 USD

Below we will list some of our cases for you. We hope this information will be a useful reference for you.

16-18 t/h wood pellet manufacturing plant for sale

—— RICHI MACHINERY ——

- Annual output: 50,000 tons

- Total investment: approximately US$750,000.

- Construction content: Covering an area of 3,717 square meters, it is equipped with production workshops, office and living areas, factory roads, etc., as well as employee canteens and dormitories.

- Raw material consumption: 54225t/a. The main raw materials of this project mainly come from agricultural and forestry wastes and industrial wood wastes. Such as fork boards, furniture scraps, construction flooring, branches, sawdust, etc.

- Work system: 13 employees, 312 days a year, 10 hours a day.

- Annual power consumption: 300,000 kilowatt-hours. The electricity load is the third-level load. Some second-level loads use dual power supplies. The power supply voltage of the electrical equipment is 380/220V, three-phase four-wire system.

- Main production equipment: including feeding hopper and silo, double auger, template crusher, belt conveyor, pulverizer, rolling screen, wood granulator, rotary classification screen, material distribution auger, finished product silo, etc.

16-18 t/h wood pellet manufacturing plant Process flow:

- Raw material area: After the raw materials are purchased, they are transported to the raw material area by car for temporary storage. Agricultural and forestry waste and industrial wood waste are mostly in the form of larger blocks or plates, which must be manually sorted in the raw material area to remove impurities.

- Chipping: Use a chipper to crush agricultural and forestry waste and industrial wood waste. The main function is to initially process the raw materials into small pieces that are convenient for removing impurities.

- Impurity removal: The crushed raw materials are passed through a self-cleaning iron removal belt conveyor to remove large iron impurities in the raw materials. The waste materials are mainly iron nails.

- Crushing: The raw materials are transported to the pulverizer for further crushing, and the particle size after crushing is less than 5mm.

- Screening: After crushing, it is transported to a rolling screen through a belt conveyor for screening, and smaller nails are further screened out.

- Granulation: The pretreated raw material wood bran is transported to the granulator through a closed conveyor for granulation. The project adopts a normal temperature molding process, and the particle size of the granulation without adding binder is 6mm.

- Natural cooling: Under the friction of normal temperature extrusion, the temperature of the extruded particles is 55~65°C, which requires natural cooling.

- Screening: The cooled pellet fuel is screened using a screening machine to screen out substandard finished products to ensure the factory quality of biomass pellets. The screened out substandard finished products, that is, unqualified products, are returned to the crushing process for crushing and then granulation.

- Finished product: Send the qualified finished product particles after processing to the finished product area, and then they can be packaged and shipped.

18-20 t/h wood pellet manufacturing plant for sale

—— RICHI MACHINERY ——

- Annual output: 45,000 tons

- Wood pellet manufacturing plant investment: US$1.1 million

- Covered area: 1500m2

- Project content: 3 production workshops, one floor, each with a construction area of about 300m2, steel structure factory building, mainly equipped with raw material warehouse, crushing workshop, finished product warehouse, etc.

- Annual consumption of raw materials: sawdust*30,000t, rice husk, rice husk*15,000t

- Annual water consumption: 480t

- Annual power consumption: 300,000 kWh

- Work system: 20 people, 300 days of working time per year, one shift, 8 hours per shift.

- Main equipment: slicer, sawdust crusher, straw crusher, dryer, wood pellet extruder machine, cooler, ton bag scale, etc.

- Floor plan: The functional divisions of this wood pellet manufacturing plant project are clear, mainly divided into office areas and production areas. The office area is arranged on the southeast side of the factory, with a comprehensive building whose main functions are office and rest. The production area is located in the northwest of the factory, with three production workshops.

18-20t/h wood pellet manufacturing plant process design:

- Raw materials: Pile the purchased raw materials (straw, peanut shells, corn stalks and other agricultural and forestry waste) in the raw material warehouse for later use.

- Mixing: Mix the purchased raw materials according to production needs.

- Coarse crushing: Use a straw crusher to coarsely crush larger pieces of straw, corn stalks, etc.

- Fine crushing: Finely crush the dried raw materials to reach the length requirement of 3mm~7mm.

- Drying: The raw materials contain a certain amount of moisture and are dried using a dryer that uses wood pellets as fuel.

- Pelleting: The wood pellet machine pressurizes the evenly stirred raw materials into granules.

- Cooling: The temperature of the produced pellet fuel is relatively high and needs to be cooled by a cooler before packaging. If the temperature is too high for packaging, water droplets will easily occur and the pellets will loosen, which is not conducive to sales.

- Packaging: Use automatic packaging scales and automatic bag sewing machines to bag the products, and then roll them into the finished product warehouse or transport them directly to the point of sale.

20 t/h wood pellet manufacturing plant for sale

—— RICHI MACHINERY ——

- Annual output: 150,000 tons project

- Total investment: US$580,000.

- Occupied area: 4000 square meters

- Construction content: The main project of this project relies on the workshops and office buildings that have been built by the customer’s wood factory, and also builds new dormitories and 1# sun room, 2# sun room, fire pool, equipment room and other facilities. The actual land area of this project is 5308m2. 6 biomass pellet production lines will be built with a total output of 150,000 tons of wood pellets.

- Working system: 20 employees, 3 shifts per day, 8 hours per shift, 24 hours of production per day, 300 production days per year.

- Annual water consumption: 750m3/a

- Annual power consumption: 1 million kw·h

- Consumption of raw and auxiliary materials: wood chips (moisture content 15~20%)21,980 t, wood chips (moisture content 15%)118,800 tons, wood board factory scraps (moisture content 15%) 10,000 tons

- Main production equipment: screening machines, drying ovens, conveyor belts, granulators, fans, forklifts, forklifts, wood board crushers, wood chip crushers, etc.

20 t/h wood pellet manufacturing plant Process flow::

- Natural drying: The purchased raw materials are stored in the raw material stacking area of the 2# workshop. The raw materials with a humidity of 15~20% need to be transported to the sun room for natural drying. The humidity of the raw materials after drying is 15%. After natural drying, they will be screened. process.

Raw materials with a humidity of 15% do not contain impurities such as iron blocks and stones. They do not need to be dried, screened or dried, and can be directly transported to the granulation process for granulation. The moisture content of the purchased wood board factory scraps is about 15%. After being crushed by the crusher, it enters the crusher and is crushed again into small particles of raw material. After crushing, it enters the granulation process for granulation. - Screening: The material enters the screening machine through a closed pipeline for screening. The raw material has a small particle size, less than 2.5mm, and can be directly entered into the granulation process through the conveyor belt for granulation. This process is mainly to screen out the larger particles contained in the raw material. Large iron blocks, stones and other impurities.

- Granulation: The dried material is transported to the silo for storage through a belt, and then transported from the silo to the pellet machine for granulation. The main working parts of the pellet machine are the laminating and pressing rollers.

The laminating wall is evenly distributed with die holes, and the mechanical and the friction between biomass raw materials and between biomass wood raw materials generates heat. The temperature of the material can reach about 70°C, softening the lignin and extruding it from the die hole to obtain a solid molded fuel with a certain shape and specification. No additives are used in the compression process, with the lignin acting as a binder. - Cooling: The product is obtained after the pellets are naturally cooled. Stacked in bulk in the finished product area.

20 t/h wood pellet manufacturing plant for sale

—— RICHI MACHINERY ——

- Annual output: 50,000 tons

- Total project investment: US$490,000.

- Construction scale and content: The project covers an area of 4318.95 square meters, with a total construction area of 2045 square meters. The construction content includes: coarse crushing and granulation workshop, office area and canteen, etc., as well as the construction of supporting projects such as electricity, water supply and drainage, and greening.

- Annual electricity consumption: 200,000 kW·h. The project does not include backup generators and boilers.

- Raw material consumption (t/a): agricultural and forestry waste*19640, municipal greening waste*11460, industrial waste (textile scraps*10000, leather scraps*8000, other high calorific value general industrial solid waste*933.45)

- Working system: 25 employees, working 8 hours a day, and the number of working days in the year is calculated as 300 days.

- Main equipment: loading and unloading machine, template crusher, slicer, crusher, granulator, packaging machine, etc.

- Layout: This 20 t/h wood pellet manufacturing plant project mainly includes a coarse crushing and granulating workshop (divided into production area, raw material area, finished product area), office area and canteen, etc. The office area is located in the north of the project, the canteen is located in the northwest of the project, and the coarse crushing and granulating workshop is located in Project South.

20 t/h wood pellet manufacturing plant Process flow:

This 20 t/h wood pellet manufacturing plant project uses raw and auxiliary materials: municipal greening waste (trunks and branches, fallen leaves, grass clippings, wood chips, etc.), agricultural and forestry waste (such as corn stalks, sugar cane leaves, straw, eucalyptus leaves, etc.), industrial waste (textile scraps, leather, etc.) General industrial solid waste with high calorific value such as scraps) are comprehensively utilized to produce biomass dense molding composite fuel.

The raw and auxiliary materials purchased by the 20 t/h wood pellet manufacturing plant project can be directly used in the coarse crushing process. The production process does not involve drying or drying processes. The raw and auxiliary materials do not need to be dried or dried. Therefore, there is no drying oven in the factory and no energy fuel is used for drying the oven. There is no need to add production water during the project production process.

- Coarse crushing: In order to make the raw materials easier to granulate, they need to be crushed (coarse crushing). The crusher is only equipped with an inlet and an outlet. After feeding, the inlet is closed to reduce dust escape. The outlet is connected to equipment. Comes with dust collector.

- Granulation (crushing, mixing, extrusion): The coarsely crushed materials enter the wood pellet press (all-in-one crushing, mixing, and extrusion molding machine) to complete the material crushing, mixing, mixing, and extrusion processes to produce densely molded products. Composite fuel. No chemical reagents such as adhesives are added during the granulation process of the product. It is only physically pressed under the high pressure of the equipment and no chemical reaction occurs.

- Packaging: The densely formed composite particles are packaged and ready for external sale.

If you want to manufacture wood pellets or start wood pellet manufacturing business, it is wise to make a wood pellet manufacturing business plan first. The plan shall include your raw material, your capacity, your budget, your funds, your workshop, and so on.

Basic construction process of wood pellet manufacturing plant

Building a wood pellet manufacturing plant requires going through a series of steps and processes. The following is the general wood pellet manufacturing plant construction process:

- Early preparation stage: including project feasibility study, market research, fund raising, land site selection, policy consultation, etc.

- Design and planning stage: Formulate the overall plan and design scheme of the wood pellet plant, including equipment configuration, production technology, plant layout, etc.

- Construction stage: Carry out construction work such as civil engineering, equipment installation, and pipeline layout.

- Operation and debugging stage: debug and test the equipment to ensure normal operation of the equipment, and conduct trial production of wood pellets.

- Production and operation stage: After formal production, wood waste processing and wood pellet production will be carried out and marketed.

wood pellet manufacturing plant cost

The investment scope of building a 15-20t/h wood pellet manufacturing plant will vary depending on the raw material ratio, process plan, automation level, and equipment brand of the project. The following is a rough investment scope:

Cost: 300,000 – 1,500,000 USD

It should be noted that the above investment range is for reference only, and the specific investment amount involves costs in many aspects. The following are the main investment cost components:

- Land purchase or lease:

Wood pellet plant construction require a certain scale of land for building factories, facilities and storing raw materials and finished pellets. Land costs will vary based on factors such as region, land size and use. - Construction of factory buildings and equipment:

Wood pellet manufacturing plants need to build factories, offices, process equipment, production lines, etc. Factory construction costs will vary based on factors such as size, structure and materials, and equipment costs will depend on equipment type, specifications and quantity. - Raw material procurement:

The raw materials for wood pellet manufacturing plants are mainly forestry waste and agricultural waste, such as sawdust, wood chips, tree trunks, wooden pallets, branches, leaves, etc. The procurement cost of raw materials will vary based on factors such as market supply and demand, transportation distance and supply stability. - Transportation and logistics:

Wood pellet manufacturing plants need to establish transportation and logistics channels with raw material suppliers and product sellers. Shipping and logistics costs will depend on factors such as distance, shipping method and volume. - Labor costs:

Wood pellet manufacturing plants require a certain number of employees for equipment operation, production management and marketing. Labor costs will depend on regional labor market conditions, number of employees and salary packages. - Licenses and permits:

Building a wood pellet manufacturing plant requires applying for relevant licenses and permits, such as environmental protection licenses, health permits, etc. Application fees for licenses and permits will vary based on regional and policy requirements. - Operation and management costs:

The operation and management of a wood pellet manufacturing plant requires certain costs, including equipment maintenance and upkeep, energy consumption, employee training and marketing, etc.

Building a wood pellet manufacturing plant requires a certain amount of capital investment, involving costs in many aspects, including land, plant and equipment construction, raw material procurement, transportation and logistics, labor costs, licenses and permits, etc. The investment cost will vary according to specific circumstances.

Before investing in a wood pellet manufacturing plant, investors should fully understand factors such as market demand, project feasibility, policy support and investment return, formulate a reasonable investment plan, and consult professionals for evaluation and suggestions to reduce investment risks and achieve a sustainable outcome, a win-win situation for sustainable development and economic benefits.

wood pellet manufacturing plant Video

Customize your wood pellet manufacturing plant

RICHI Machinery is mainly engaged in wood pellet manufacturing plant for sale, focused on the design and construction of turnkey wood pellet manufacturing plants for pellet production and the supply of equipment for them.

Some of our projects are related to high capacity pelleting plants, but we are also working and supplying a good number of smaller capacity plants.

The experience gained over the years has shown that offer cutting edge technologies and reliable solutions is the only way to obtain results under the highest standard of the industry.

Not matter where we are, we are committed to develop the strongest-performing solutions and deliver maximum value to each wood pellet manufacturing plant project.