wood pellet machine Canada

- 2-3T/H Wood Pellet Making Machine For Sale Canada

- 3-3.5T/H Wood Pellet Mill For Sale Canada

- …

Products and services we provide:

- A complete set of equipment and accessories for wood pellet production system.

- A full set of services for wood pellet production system: design, research and development, manufacturing, transportation, installation, commissioning, training, after-sales, etc.

The RICHI wood pellet machine Canada projects are carefully designed for customers based on on-site surveys or actual customer requirements, which fully reflects the rationality, effectiveness and applicability of the design. Its outstanding features are large output, low wear, and low operating costs.

Strong technical strength and perfect service system are the guarantee for customers to choose and use with confidence. RICHI can provide overall solutions and turnkey services to meet customers’ different process requirements.

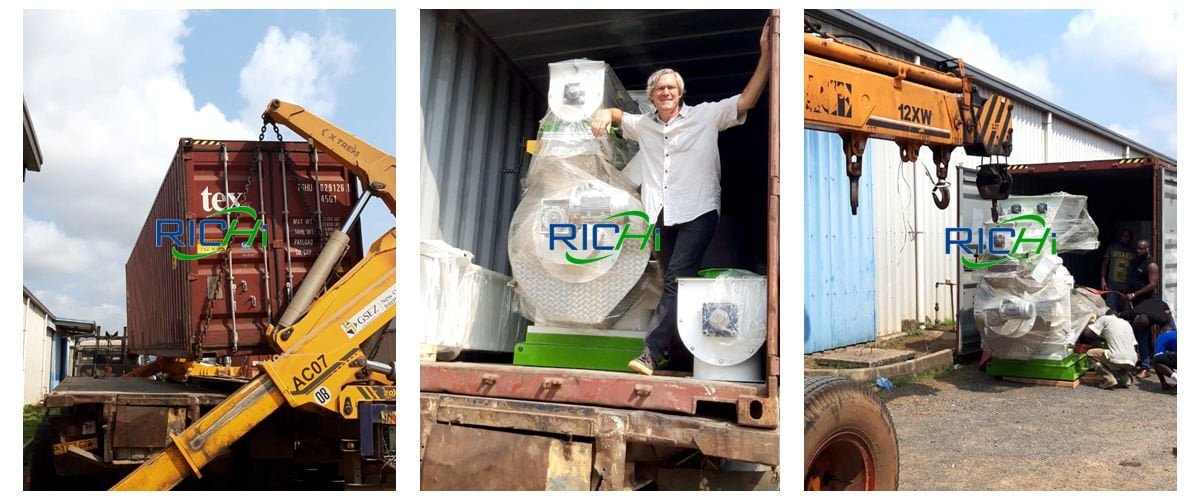

Currently, we have completed the following wood pellet mill plants in CANADA:

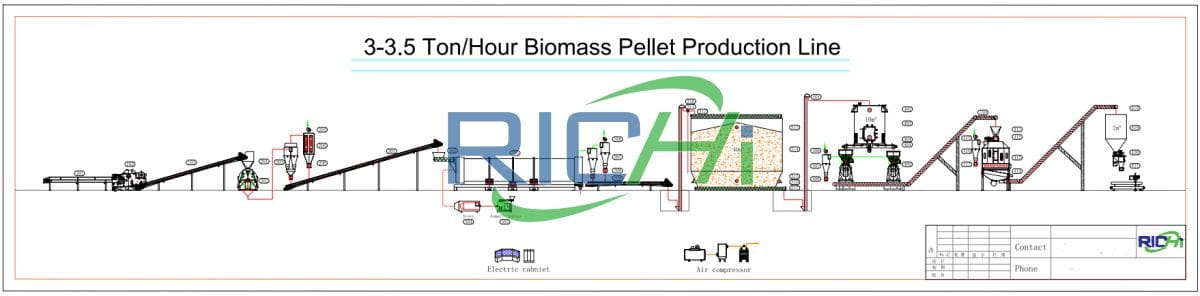

3-3.5T/H wood pellet machine Canada project

- Project time: 2022.12.06

- Project Amount: 300,000 USD

- Raw material type: hard trees, saw dust, log trees

- Raw material moisture: 45% of moisture

- Packing: 15kg bag & ton bag

- Equipment configuration: JLBX-218 Wood chipper, SFSP66*60 Wood crusher, ф1800*180000 Drying machine, MZLH520 Wood pelletizer, SKLN14*14 Cooling machine, TDZS63 Vibrating screener, DCS-50 Packing machine, etc.

In November 2022, we received customer inquiries:

“Hi, we would like to have quotation regarding machinery, wood pellet machinery. we use wood residues from hard trees, saw dust. And Log trees that are not suitable form lumber as raw material. 45% of moisture. 3 tons and more/ per hour for the capacity. we intend to operate 8h/day. 6days a week. the product (wood pellet) will be put inside 15 kg bags. but we could consider the option of large bags (one tone). thank you.”

One month later, on December 6, 2022, the 3-3.5T/H wood pellet machine Canada project was signed. The occupied area of the project is 2600 ㎡ and the building area is 2600 ㎡. The total investment of the project is 300,000 US dollars, the main product is biomass pellets, the annual output is 15,500 tons, the number of employees is 10, the annual working days are 300 days, 8 hours a day,

In terms of design, this wood pellet line has fully considered the hardness of hematite, and at the same time, the output has not been affected, which ensures the efficiency of mechanical crushing and granulation, and reduces the cost for customers. It is a classic production line configuration in wood pellet processing.

Construction scale and composition

The 3-3.5T/H wood pellet mill for sale Canada project factory area is roughly rectangular.

The north of this pellet mill for sale canada project is other factories, the south is other factories, the west is open space, and the east is open space. The production workshop is mainly equipped with packaging area, production area, office area, etc.

public system

The raw and auxiliary materials of pellet mill canada project are all purchased, mainly in bulk. Input and output of materials (including products) in the factory mainly by forklift.

The power consumption is supplied by the municipal power grid, and there is no generator for equipment. The estimated power consumption of the project is about 180,000 KW/a.

01 Equipment For 3-3.5T/H Wood Pellet Machine Canada Project

| Device name | QTY |

|---|---|

| MZLH wood pellet machine | 2 |

| Wood slicer | 1 |

| Wood Chip Grinder | 1 |

| U-screw conveyor | 1 |

| Pulse dust collector | 3 |

| Drying machine | 1 |

| Cyclone | 2 |

| Bucket elevator | 1 |

| 40m³ Storage bin | 1 |

| Wood pellet cooling machine | 1 |

| Vibrating screen | 1 |

| Packer | / |

| MCC Control Center ;Mimic control panel | 1 |

02 3-3.5T/H wood pellet process flow

In the whole wood pellet production line, the crushing of raw materials, the screening and cleaning of unqualified pellets, and the molding of materials are three relatively important processes. They are directly related to the quality of the whole process, the level of production efficiency and the degree of energy saving. directly affect the economic benefits of the enterprise.

This 3-3.5t/h wood pellet machine Canada project processing technology mainly includes raw material crushing, drying, conveying, mixing, feeding, forming, cutting, cooling, measuring and packaging, etc. It can be divided into 3 sections as a whole, namely, raw material pretreatment section, pelleting section, and other supporting section, as follows:

①Raw material pretreatment section

The raw material pretreatment section includes raw material receiving, crushing, drying, mixing and other processes.

- Raw material reception:

Biomass raw materials are transferred from the stockyard to the feeding shed, stacked in sequence along the direction of the feeding conveyor belt, and ready for feeding. At the same time, some raw materials are temporarily stored to ensure continuous and sufficient supply of raw materials in one shift. - Coarse crushing:

Since many wood raw materials are large in size, they cannot be directly used for molding processing. The main task of the coarse crushing process is to crush the large-sized raw materials into short and fine granular raw materials for secondary fine crushing. - Scraper conveying:

The raw materials are conveyed from the crushing process to the water drop mill. After secondary crushing, the particle size is less than 5 mm, and then sent to the drying drum to reduce the moisture content to below 15%. - Transportation:

The raw materials are temporarily stored in a 40-cubic raw material warehouse with a bucket elevator.

②Pelleting section

The pellet forming section includes quenching and tempering feeding, forming processing, cutting and other processes.

- Conditioning and tempering feeding:

The powder in the raw material warehouse is tempered and mixed, and continuously and stably transported to the molding equipment. - Pelleting:

The raw material is extruded by a wood granulator. - Cutting off:

There is an adjustable gap cutter in the wood pellet making machine, which cuts the extruded fuel according to the user’s needs, which is convenient for packaging, storage and transportation.

③Other supporting sections

Other supporting sections of 3-3.5t/h wood pellet machine Canada project include cooling, dust removal, air compression, water addition, measurement and packaging and other processes.

- Cooling:

The temperature of the molded fuel just out of the solid molding machine is 75-85℃, which is easy to break and not suitable for storage and transportation.

The task of the cooling process is to cool down the processed high-temperature fuel so that its temperature can reach the conditions for packaging and storage.

The whole process is equipped with a combined cooler, which takes away the heat and moisture of the solid molding fuel through the cooling process. - Screening:

The cooled pellets are sent to the sieving machine, and the qualified and unqualified pellets are screened out. Qualified granules enter the packaging section, and unqualified granules return to the crushing section for re-granulation. - Dust removal:

Cyclone separation and pulse dust removal are used to remove dust in the production and processing process to meet the specified standards. - Measurement and packaging:

Measure the finished product to achieve machine packaging.

Note:

- First of all, we need to know that the complete set of 3-3.5t/h wood pellet machine Canada project not only has biomass wood pellet machine, but also is equipped with other different pretreatment equipment according to the type of raw material and the humidity.

For example, if the raw material is small wood chips, then a wood shredder is needed to crush it into wood chips below 5mm; if the raw material is sawdust, then there is no need to crush or crush it. - Secondly, look at the moisture content of raw materials, that is, humidity. If the moisture content of the raw material is 15%-20%, it can be granulated directly into the wood pelletizer machine. If the moisture content of the raw material is high, the dryer must be used before granulation.

- Finally, arrange the design according to the customer’s specific requirements. For example, the degree of automation, hoping to save labor and high automation intensity, requires automatic cooling, automatic packaging, and automatic feeding. In short, the complete set of equipment for the wood pellet production plant is not a fixed model, and can be customized according to different customer needs.

As governments around the world rush to implement policies to address the topic of climate change, Canada continues to be a preeminent producer and exporter of high-quality industrial-grade biomass used in global energy markets. Canada’s wood pellet exports to the world have grown steadily in recent years, both in value and volume.

Now, wo have large and small pellet mill for sale Canafa, if you also want to build wood pellet making machine in Canada, please feel free to consult Richi Machinery!

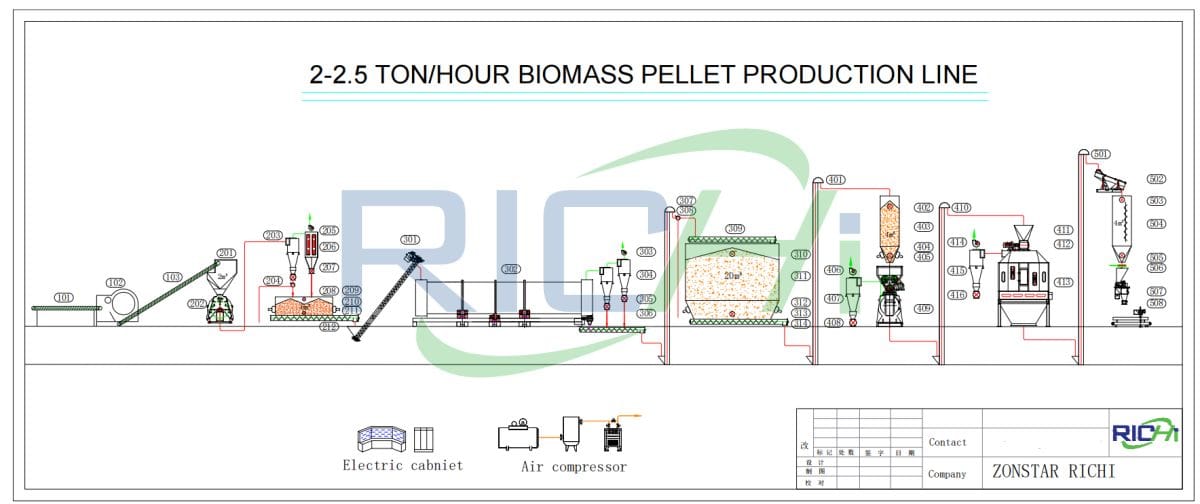

2-2.5 t/h wood pellet machine Canada project

- Date: August 3, 2018

- Capacity: 2-3T/H

- Pellet Size: 8-10mm

- The install period: 45 Days

- Raw material consumption: wood chips 2000t, wood chips 3000t, wood scraps, 7000t

- Power consumption: 150,000 kWh/a

- Water consumption: 800t/a

- Capacity: 12000t/a

- Guiding Price: Start with 200000 USD

This wood pellet mill Canada project was signed on 2018.08.03. The raw material of this customized wood pellet machine Canada project is 50% moisture wood chips , 50% moisture sawdust, and the final size requirement is 8-10mm.

According to customer requirements, the main wood pellet manufacturing equipment we configured (total power:385kw) includes wood chipper machine, wood hammer mill for wood sawdust, shifter, wood chip dryer, storage bin, wood pellet machine, wood pellet wood co bagging machine and other auxiliary equipment.

In this 2-3 t/h wood pellet machine for sale Canada project cooperation, exquisite wood pellet manufacturing process design and strong production team are very critical factors to impress customers.

The final wood fuel pellets are mainly used for export, and have high quality requirements. Environmental protection and energy saving are integrated into the design of the wood pellet plant business plan.

01 Project composition

The total area of the pellet mill for sale Canada project is 4000m2, and the construction will be carried out relying on the existing factory buildings. The composition of the project includes main works, auxiliary works and public works.

The project client has an existing vacant abandoned workshop. The entire production workshop is in a regular convex shape.

The entrance and exit of the workshop are located in the northwest corner of the workshop. The raw material area is located in the north of the workshop. The finished product area and production area are located in the west of the workshop. The semi-finished product area is located in the workshop. The central part and the east side are vacant and not in use.

- Production area: 1F construction area 600m², steel frame structure

- Finished product area: 1F construction area 300m², steel frame structure

- Material area: 1F construction area 500m², steel frame structure

- Semi-finished product area: 1F construction area 1000m², brick-concrete structure

- Crushing workshop: 1F construction area 200m², steel frame structure

- Vacant area: 1F construction area 700m², steel frame structure

- Office: 80m²

- Parking lot and loading platform: 500m²

02 Equipment list of 2-2.5 t/h wood pellet machine Canada project

| NAME | MODEL | QTY |

|---|---|---|

| Wood chipper | JLBX-216 | 1 |

| Wood crusher | SFSP 66*80 | 1 |

| Cyclone | ф1000 | 1 |

| Pulse dust collector | TBLMa.36b | 1 |

| U-Screw conveyor | TLSSU30 | 1 |

| Wood drying machine | ф1500*150000 | 1 |

| Bucket elevator | TDTG40/23 | 1 |

| Storage bin | 4m³ | 1 |

| Wood pelletizer | MZLH520 | 1 |

| Cooling machine | SKLN14*14 | 1 |

| Vibrating screen | TDZS63 | 1 |

| Packing machine | DCS-50 | 1 |

| Belt and sewing machine | DCS-50 | 1 |

| MCC Control Center ;Mimic control panel | / | 1 |

03 2-2.5 t/h wood pelletizer for sale Canada project Process Design

- Chipping: The purchased waste wood scraps are crushed by a wood chipper, so that the raw materials are broken into smaller flakes and rods.

- Crushing: The coarsely crushed raw materials are transported by the conveyor to the sawdust crushing system in a closed state for crushing; the raw materials will generate dust when crushed and crushed. When the crusher is working, the raw materials are transported from the belt into the crushing chamber.

The high-speed rotating hammer flies to the tooth plate, and after colliding with the tooth plate and rebounding, it is hit by the hammer again. At the same time, the raw material is subjected to strong friction between the screen surface and the hammer.

The raw materials are gradually crushed. The crushing workshop of the project is fully enclosed. There is a suction port on the top of the workshop, and the dust is sucked into the bag filter through the suction port under negative pressure for treatment. - Pelleting: The material is conveyed to the wood pellet press in a closed state through belt conveyance, and the mixed material is extruded by physical high pressure in the mold of the wood pelleting machine to form a cylindrical shape, a biomass briquette fuel product;

- Cooling: When the biomass is discharged, the temperature of the molded fuel is high, the structure is relatively loose, and it is easy to break. It must pass through a counter-flow cooling system (air cooling), and then enter the screening system after cooling to room temperature.

- Screening: After the raw materials are pressed and formed, they enter the screening equipment, and the unqualified products will be crushed and then pressed again.

- Packaging: Qualified products are packed in woven bags and put into storage for sale.

In Canada, wood pellet production has grown modestly in recent years. In fact, the number of wood pellet producers in Canada is small, and there is still a lot of room for market development.

With the high combustion rate of biomass such as wood pellets, the pollution to the environment is much lower than that of coal, which attracts more countries to put it into use. After all, the high price of wood pellets is a strong incentive for pellet producers to invest, whether in Canada or elsewhere.

If you also want to build a Wood pellet mill canada project, please feel free to consult Richi Machinery!

Latest Pellet Machine & Pellet Plant Project

The business scope of RICHI MACHINERY covers the design, manufacture, installation and commissioning of biomass wood pellet equipment, feed equipment, organic fertilizer equipment, cat litter equipment and a complete set of engineering solutions.

Here are some of our latest wood pellet machine & pellet plant projects showcased:

At present, the wood pellet market is in great demand, and more investors are entering this industry. More and more existing wood pellet manufacturers are putting transformation and upgrading on the agenda. It is an ideal choice to enter the wood pellet industry, thanks to the wood pellet industry. The pellet industry has many internal and external advantages.

The wood pellet industry has rich raw material support, mature equipment, and is also strongly supported by policies from countries around the world. The wood pellet market has a large demand and attractive profit margins and other external factors. It can be seen that it is imperative to enter the wood pellet processing market with broad prospects!

If you also see the prospect of starting wood pellet machine Canada project or wood pellet plant in any country, please contact us to customize your pellet production line solution.

Popular wood pellet mill for sale canada

Service of Wood Pellet Machine Canada Project

Richi Machinery have more than 25 years of complete biomass wood pellet plant project service experience to help you develop your business in all aspects and realize personalized value.

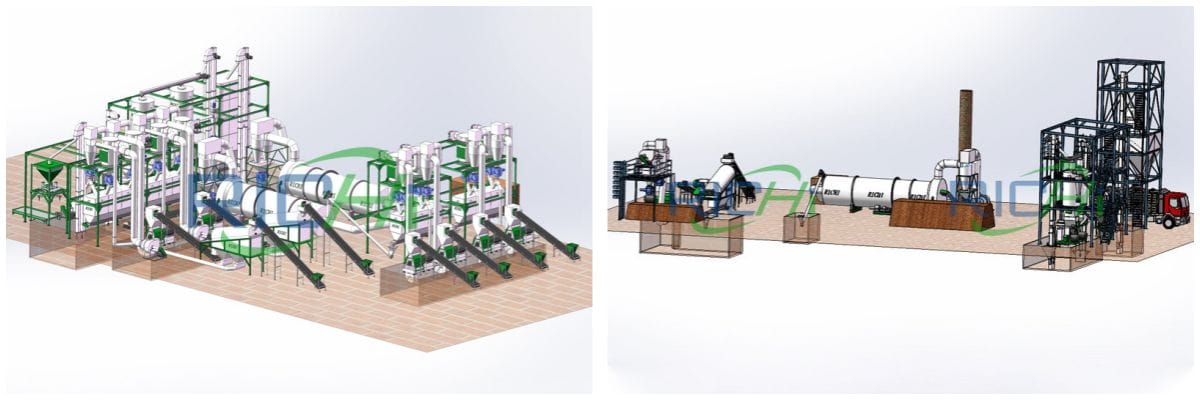

Personalized customization & provide 3D renderings

We can design wood pellets plant Canada project planning schemes according to the different needs of customers, and provide 3D renderings to enhance the user experience.

Help customers to accurately sort out their own needs, repeatedly scrutinize the rationality and scientificity of the process with customers, try to optimize the design of the product system, and meet customers’ reasonable personalized needs at all costs.

With perfectionism and ingenuity, we create a turnkey wood pelleting plant project, seek our own value for our customers. And use the ‘differentiated competitive strategy’ to improve our market competitiveness for our customers, so as to achieve strong alliances and common development.

On-the-spot investigation & adapting measures to local conditions

We design comprehensive problem solutions for biomass pellet manufacturing plant engineering according to different requirements of customers, different raw materials, and different sites. Our professionals go deep into the construction site and do a good job of planning.

In practice, we can truly adjust measures to local conditions, and adopt different wood pellet machine Canada project design schemes and construction methods according to different survey results to ensure that it is scientific and reasonable, economical and practical, and meets environmental protection. So as to create a safe, efficient and stable biofuel pellet plant for customers.

Professional team & door-to-door installation

Richi Machinery has a professional technical team with 25 years of practical experience in design, manufacture and installation. Unified management and unified training. Strict technical assessment is carried out every year, and it has rich on-site installation and maintenance experience, professional quality and high sense of responsibility.

With a high degree of professionalism, we help customers to quickly put into production and achieve production benefits, allowing customers to seize market opportunities and win at the starting line.

Technical Service & Whole Process Guarantee

Whether in pre-sale or after-sale technical support, we are always ready to provide customer satisfaction services. To ensure the highest work efficiency in a rigorous order, 24-hour reception of customers’ technical inquiries, on-site service, equipment maintenance, production failures, service complaints and a series of problems to improve customer satisfaction.

Through telephone consultation and door-to-door service, we can find and solve problems in a timely manner to ensure the rights and interests of customers. Provide professional and targeted services for different users, and escort customers throughout the process.

One-to-one guidance & worry-free production

After the installation and commissioning is completed, we will provide one-to-one technical guidance according to the actual situation of the customer. And be responsible for training the operators until the customer can fully operate the biomass pellet line and wood pellet machine production by himself. Truly ‘customer-centric’, to provide customers with excellent service.

Follow-up questions will be answered by professionals, and feedback will be recorded in a timely manner, and solutions will be provided. If there is a need for on-site guidance, the company will arrange relevant professionals to provide timely guidance at the designated location according to the specific circumstances.

Quick response & lifetime maintenance

In terms of service quality control, we insist on life-long service and infinite improvement. In addition to the warranty period, we provide customers with life-long service. As long as the equipment is in use, RICHI’s service to customers will not be terminated. In the service, we insist on the first response and the fastest speed to solve the problem.

At the same time, a product dynamic improvement system is established. After solving the typical problems reported by customers, the wood pellet machine canada project design will be improved immediately, and the product will be continuously improved. For the problems in the service process, the RICHI service process will be improved and optimized immediately after they are solved.

Want to buy pellet machine or start your wood pellet machine Canada project? Want to build wood pellet mill in Ontario or Alberta?

Feel free to contact Richi Machinery!