Agri Pellet Machinery

Agri pellet machinery offers an ideal solution for those who want to produce pellets from agricultural waste materials.

Due to its wide range of sources, low production costs, easy storage and transportation, high combustion efficiency, and harmless emissions, agricultural waste pellets are used globally It has been widely used in the range.

What’s Agri pellet machinery?

Agri pellet machinery is equipment for processing agricultural waste pellets. The agriculture pellets product made exclusively from natural, carefully selected raw materials from agricultural waste, pressed under high pressure and formed into pellets.

After compression molding, the volume of agricultural waste is greatly reduced, making it easier to transport, store and use. Pellets processed by agri pellet machine can be widely used in home heating, industrial heating, power supply, feed processing, organic fertilizer processing, animal litter and bedding processing and other fields.

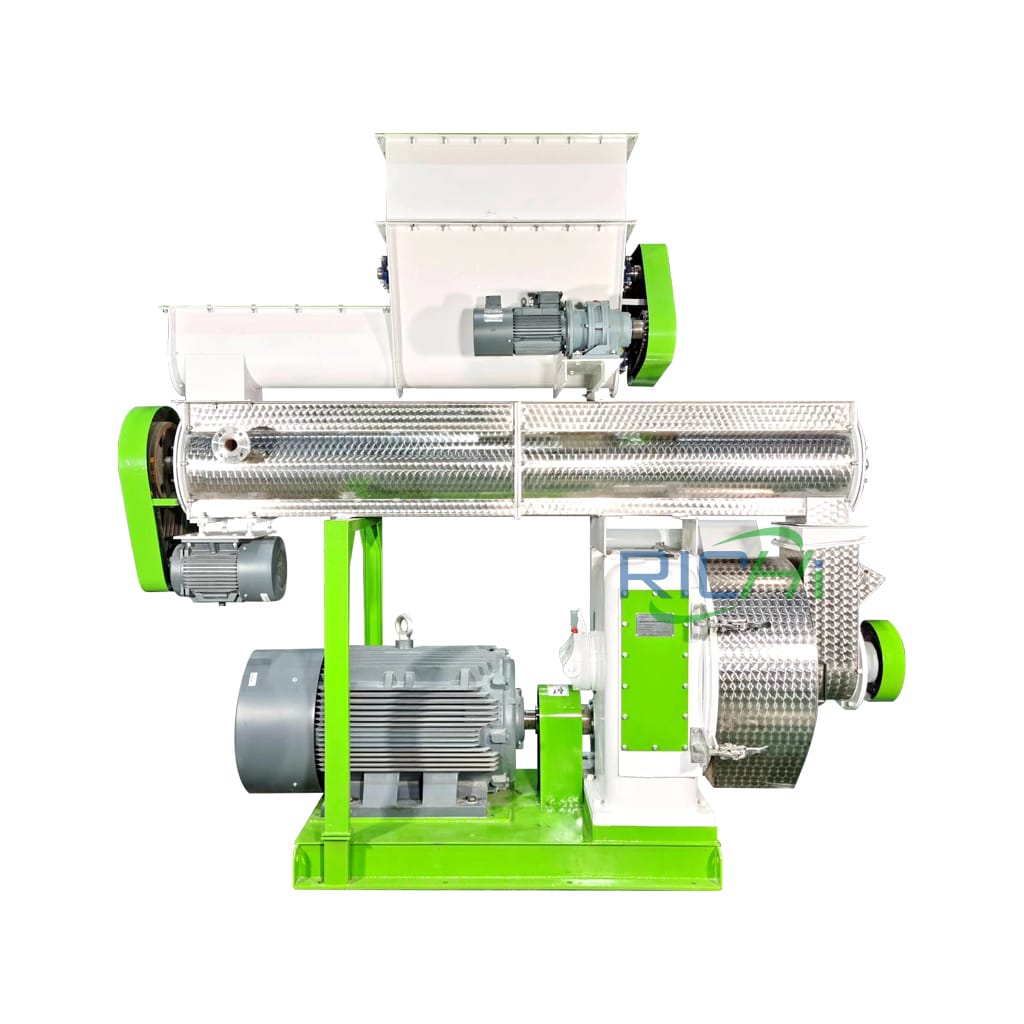

- Capacity: 0.3-12 T/H(single machine)

- Price: 10,000-100,000 USD

- Applicable customers: farms, biomass pellet plants, fuel pellet plant, animal feed mill plant, straw pellet production line, alfalfa pellet production line, rice husk pellet plant, organic fertilizer production plant, cat litter company, efb pellet plant and any other companies and individuals who want to start agriculture pellet production business.

RICHI is able to supply special designs and productions according to customers’ demands. With us you can find your individual solution that corresponds your ideal end product for every application in the stationary area. RICHI agriculture pellet mill products convince with powerful performance, efficiency and specific configuration !

There are many types and huge quantities of wastes in agricultural production, but only a small part of the agricultural wastes are utilized, and agricultural resources are seriously damaged and wasted. In addition, the planting and breeding industries only focus on the utilization of grain, meat, eggs, milk and other products, and ignore a large number of by-products.

These wastes are both valuable resources and serious sources of pollution. If they are discharged into the environment without proper treatment, they will seriously pollute the environment. The agri pellet machinery and agricultural waste pellet production line system designed and developed by RICHI are the main ways to explore the comprehensive utilization and recycling of agricultural and forestry waste, which can promote green ecological development.

Types of Agri pellet machinery

01 Different applications

Classified according to the application of agri pellet machinery, it can be used as fuel pellet equipment, feed pellet machine, organic fertilizer pellet machine, and animal litter pellet machine.

Fuel pellet making machine

(No conditioner required) Agriculture Fuel pellet machine can use various crop wastes such as straw, rice husk, palm waste, bamboo, miscanthus, coffee husk, etc. to process high calorific value biomass pellets for heating or power generation.

Animal Feed pellet making machine

(Requires conditioner) Agri pellets are rich in nutrients such as cellulose and protein and are a high-quality feed. Alfalfa, cassava, straw, sunflower shells and other raw materials can be used to process livestock and poultry feed.

Organic fertilizer pellet making machine

(No conditioner required) Agricultural waste can be converted into organic fertilizer through agriculture organic fertilizer pellet making machinetechnology. Various animal manures and various crop wastes can be used.

cat litter pellet machine

(Determine whether to configure a conditioner according to the raw materials) Cat litter pellet machine can use soybeans, bean dregs, green tea, straw, husk and other agricultural products to process cat litter and various animal bedding pellets.

02 Different raw materials

Classified according to the different applicable raw materials, agri pellet machinery can be divided into straw pellet machines, husk pellet machines, grass pellet machines, etc.

There’s no question. No matter the pellet processing needs of your operation—or what unique agri materials you’re working with, you need a custom agriculture pellet processing plant design.

Whether we are custom-engineering your process or providing the agriculture pellet machines, drying equipment, crushing equipment, and screening equipment you need to operate profitably and efficiently, RICHI is dedicated to helping you process pellets successfully.

Characteristics of agri pellet machinery

RICHI agriculture pellet machine adopts a gear transmission system with ideal transmission ratio, large driving torque and stable transmission. It is equipped with ring dies with various hole diameters and thicknesses, which users can choose according to different needs to obtain better technical and economic benefits.

- Using advanced variable frequency motor for feeding, equipped with overload protection device and magnetic plate iron removal device; high output, low noise, easy operation and maintenance.

- The transmission gear tooth blank is normalized and heat treated after water forging to improve the hardness of the tooth surface; the tooth surface is carburized, and the carburized layer is as deep as 2.4mm to enhance the wear resistance and extend the service life of the parts; the hard tooth surface is Silent precision grinding and trimming process make the operation quieter and more stable.

- High quality imported bearings and oil seals are selected in the transmission part of the whole machine to ensure high efficiency, stability and low noise.

- Compensation snake spring coupling with advanced international level has novel structure, compact, safe and low fault performance.

- Increase efficiency and high output. High degree of automation, strong applicability.

Our products differ according to the hourly production capacity requested by the customer. We have a serious reputation and recognition in the agri pellet machinery production sector by completing the machinery productions we undertake on the delivery date and well above the expected quality levels. Our goal is always to build quality and always go forward.

Advantages of agri pellet machinery

RICHI agriculture pellet making machine has the following obvious advantages:

Improve production efficiency

One of the advantages of RICHI agriculture pellet granulator is its ability to improve production efficiency. Compared with similar equipment, it can operate more stably, reducing equipment failure and production pause time, thereby ensuring that the production line can operate more stably. RICHI crop pellet machines can also help pellet processors quickly complete production tasks, improve production efficiency and output, and save time and labor costs.

Reduce maintenance costs

RICHI agriculture pellet press machine can reduce maintenance costs.

- On the one hand, due to the low failure rate of RICHI pellet machines, pellet processors do not have to spend a lot of money to repair and maintain equipment, thereby reducing maintenance costs.

- On the other hand, the RICHI agriculture pelletizer machine has a longer service life, which can extend the service life of the equipment and reduce the frequency and cost of equipment replacement and equipment maintenance.

Ensure safe operation

RICHI agriculture pellet mill machine can ensure the safety of agri pellet machinery operators. RICHI pellet machines have a lower accident rate during operation and can provide good protection measures and safety functions to ensure the safety of employees during work, effectively avoid accidents and injuries, and reduce the risks and loss of agri pellet processing enterprises.

Improve product quality

RICHI agri pellet making machine can help companies improve product quality. RICHI granulator can complete the production process more accurately and accurately, thereby producing more objective and excellent products and improving the competitiveness of the product. In addition, RICHI agriculture pellet processing machines can also ensure product production stability and consistency, thereby improving product quality and meeting product specification requirements.

To sum up, the advantages of RICHI agri biomass pellet mill machines include improving production efficiency, reducing maintenance costs, ensuring employee safety and improving product quality.

When selecting an agri pellet machinery, should pay attention to the quality and performance of the equipment so that they can give full play to the advantages of the equipment and obtain more benefits.

working principle of agri pellet machinery

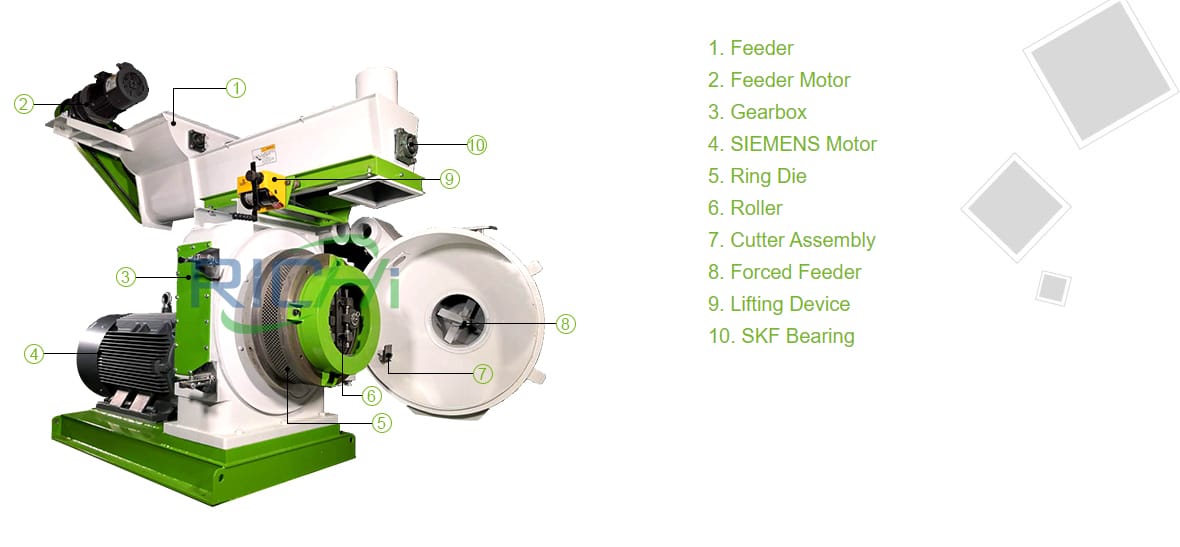

The basic working parts of the agriculture waste pellet machine are composed of a roller and a die.

Among them, the pressure roller can rotate around its own axis, and its outer periphery is processed with teeth and grooves to facilitate the pressing of materials and prevent slipping. The die is designed with a certain number of forming holes.

Its working principle is that under the action of the pressure roller, the agri raw material entering between the pressure roller and the die is pressed into the forming hole and then extruded.

The granular shaped pellets are cut into certain lengths by a cutting knife at the discharge port.

Technical parameters of agri pellet machinery

| Model | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH768 | MZLH858 |

| Output (t/h) | 0.3-2 | 0.5~4 | 1.0~6.0 | 2.0~8.0 | 2.5~10 | 3-12 |

| Main motor power (kw) | 22 | 37 | 90 | 132 | 250 | 280 |

| Main motor series | 8P | |||||

| Ring die diameter (mm) | 320 | 350 | 420 | 520 | 762 | 858 |

| Finished pellet diameter (mm) | 6-12mm | |||||

| Device Configuration | Ring die material: 42CrMo Stainless steel feeder: with anti-caking function Door of pelleting room: 6mm /SUS304 Forced feeding: Worm gear reducer Gear box: HT250 Gear: 42CrMo Gear shaft: 42CrMo Spindle: 42CrMo Empty shaft: 42CrMo Bearings: The gear shaft and main shaft bearings are SKF, and the pressure roller bearings are domestic high-quality bearings Oil seal: Germany/Taiwan Overload mechanical protection: safety pin Serpentine spring coupling drive Lubrication system: Configurable automatic oil injection system | |||||

agri pellet machinery projects

agri pellet machinery In canada

- raw material: flax straw

- pellet type:fuel

- project date: 2021.9.21

- Pellet Size: 8-10mm

agri pellet machinery In uSA

- raw material: hemp & alfalfa grass

- pellet type:cow feed

- project date: 2020.10.19

- Pellet Size: 8mm

agri pellet machinery In Indonesia

- raw material: crop waste

- pellet type:fuel

- project date: 2020.06.18

- Pellet Size: 10mm

agri pellet machinery in Pakistan

- raw material: poultry manure

- pellet type:organic fertilizer

- project date: 2020.09.01

- Pellet Size: 6-10mm

agri pellet machinery In india

- raw material: rice husk

- pellet type:fuel

- project date: 2022.05.11

- Pellet Size: 6-10mm

agri pellet machinery In Thailand

- raw material: straw

- pellet type:fuel

- project date: 2021.12.20

- Pellet Size: 8-10mm

agri pellet machinery In Ghana

- raw material: peanut shell

- pellet type:livestock feed

- project date: 2022.02.11

- Pellet Size: 8mm

agri pellet machinery In Vietnam

- raw material: bamboo

- pellet type:fuel

- project date: 2021.03.26

- Pellet Size: 8-10mm

agri pellet machinery In russia

- raw material: sunflower seed shells

- pellet type:poultry feed

- project date: 2023.07.17

- Pellet Size: 6-10mm

agri pellet machinery In south africa

- raw material: wheat straw

- pellet type:livestock feed

- project date: 2020.07.20

- Pellet Size: 8-10mm

agri pellet machinery In Uzbekistan

- raw material: hay grass

- pellet type:cattle sheep feed

- project date: 2019.05.10

- Pellet Size: 8mm

agri pellet machinery In malaysia

- raw material: chicken manure

- pellet type:organic fertilizer

- project date: 2022.07.23

- Pellet Size: 8-10mm

agri pellet machinery price

Generally speaking, the agri pellet machinery cost is usually between US$10,000-100,000.

The price of agriculture pellet machines from each manufacturer is different, and there are many factors that affect the price of agriculture pellet mill s. Here are some common factors:

- Raw material cost:

Agriculture pellet milling machine manufacturing usually requires the use of various metals, plastics and other raw materials. The price fluctuations of these raw materials will directly affect the price of the machinery. - Labor costs:

The manufacturing of agri pellet machinery requires workers to perform assembly, testing and other tasks. Changes in labor costs will also have an impact on the price of machinery. - Technical level:

The application of high-tech technology will improve the performance and efficiency of the agri pellet machinery, but it will also increase R&D and production costs, thus affecting the price of the machinery. - Equipment and facilities:

The manufacturing of agriculture pellet mills requires the use of various equipment and facilities, including production lines, instruments and equipment, etc. The purchase and maintenance costs will also affect the price of the machinery. - Market competition:

The machinery market is highly competitive, and competition between different brands and suppliers will affect the price level of machinery. - Sales regions and channels:

Market demand and sales channels in different regions will also affect the pricing strategy of the agriculture pelletizing machine. - Supply and demand relationship:

The balance between supply and demand will directly affect the price of the agri pellet machinery. If demand is higher than supply, prices may rise; if there is excess supply, prices may fall. - Policies and regulations:

Government policies and regulations have a certain impact on the machinery manufacturing and sales industry, such as tariff policies, environmental protection requirements, etc. These factors will also affect the price of the agri pellet machinery.

These factors interact and comprehensively affect the price of the agriculture granulator. The importance of the above factors may vary depending on the type of machinery and market environment.

Therefore, when purchasing agri pellet machine, you must compare equipment from different manufacturers, but please remember that any comparison must be based on the quality of the equipment.

Raw materials suitable for agri pellet machinery

The raw material suitable for agriculture pellet manufacturing machines is agricultural waste. What is agricultural waste? Agricultural waste refers to useless, surplus or waste generated in the agricultural production process, including but not limited to the following:

1. Planting industry waste

This type is the main raw material used for processing agri pellets. Solid waste in the planting industry refers to the solid waste generated from the crops themselves during the planting, harvesting, trading, processing, utilization, and consumption of crops. It mainly includes crop straws and processed residues from vegetables, fruits, etc. Its characteristics are: There are many kinds and the production is large.

2. Aquaculture waste

This type refers to the solid waste generated during the livestock and poultry breeding and processing process, which mainly includes livestock and poultry manure, livestock and poultry house litter, waste feed, scattered hair and other solid waste, as well as livestock and poultry breeding wastewater with a high solid content, etc.

The continuous expansion of the scale of the livestock and poultry breeding industry will inevitably lead to the generation of a large amount of breeding and processing production waste.

3. Domestic garbage and waste

Rural domestic waste refers to solid waste generated in daily life or activities that provide services to daily life within the rural area. It is mainly garbage generated by farmers’ daily life, mainly kitchen waste, waste plastics, waste paper, etc.

If these agricultural wastes are not properly processed or recycled, they will cause environmental pollution and resource waste. For different agricultural wastes, RICHI Machinery has developed different agri pellet machinery and pellet production line systems, which can help turn agricultural waste into treasure.

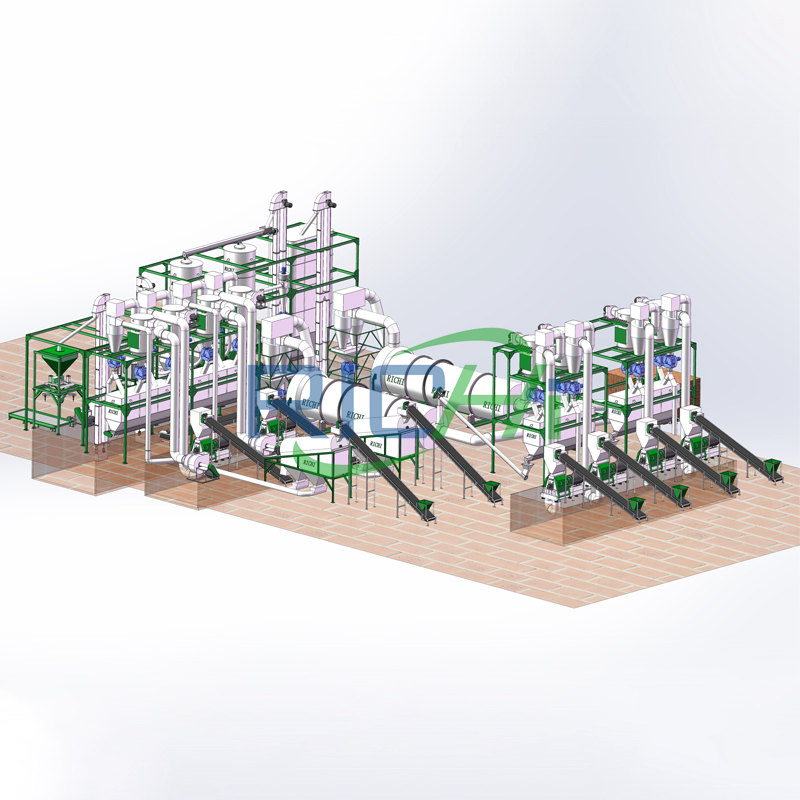

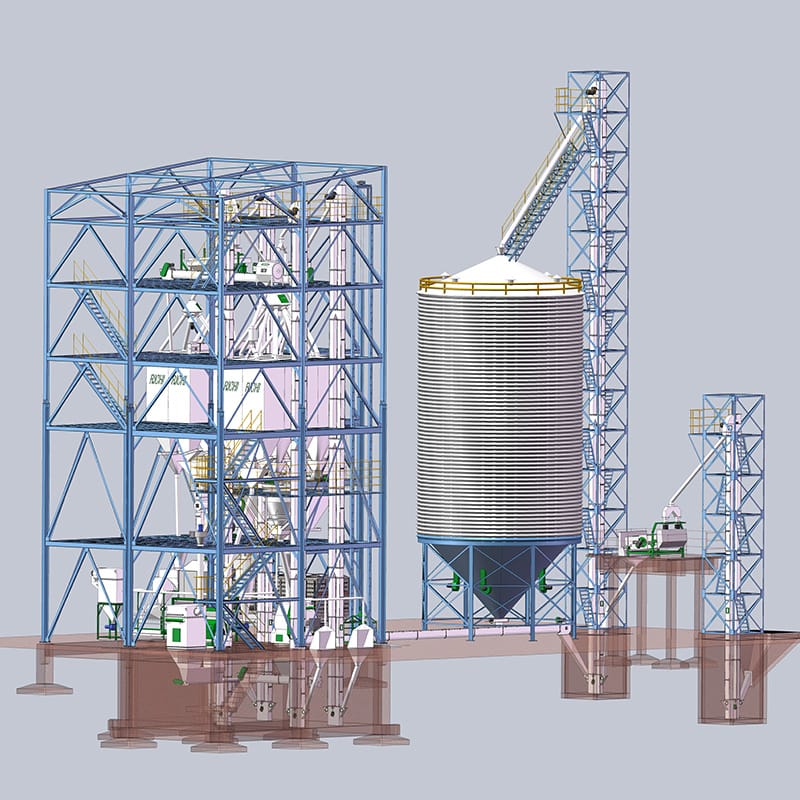

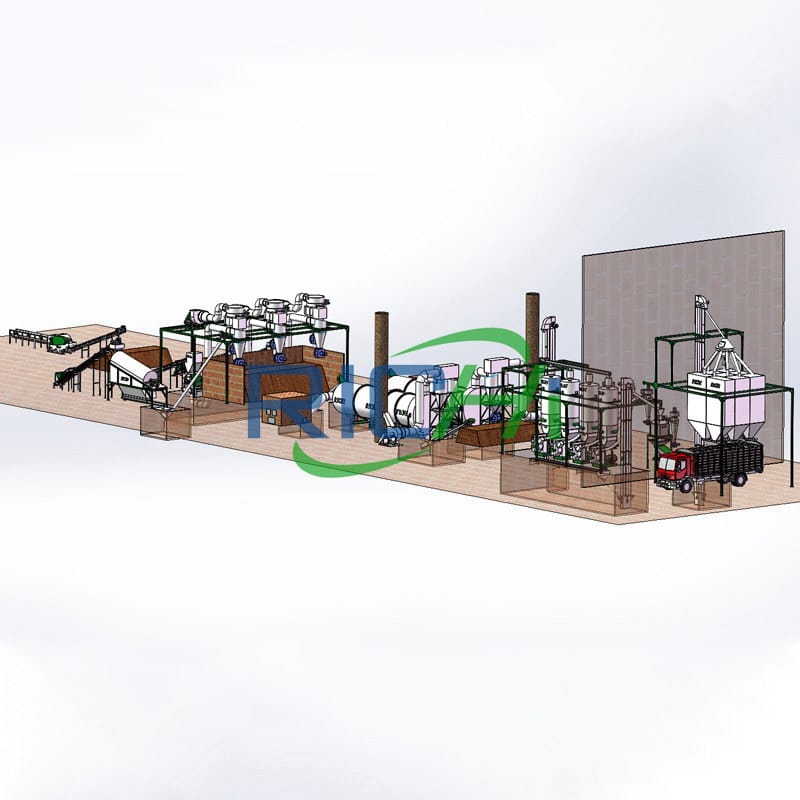

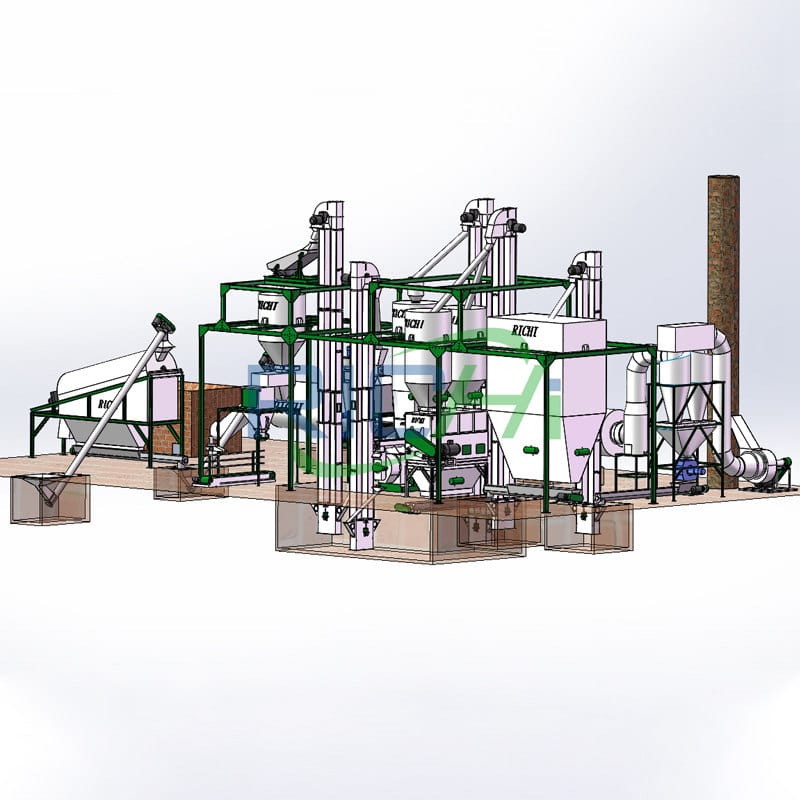

Different agricultural pellets production process design

Biomass pellets are solid particles made of biomass materials, such as straw, rice husk, bamboo, palm waste, bagasse, grass, miscanthus, alfalfa, etc., which are cleaned, crushed, dried, granulated, cooled, Use after screening and other processing.

With RICHI you receive an individual solution, adjusted for your personal needs and requirements. From the shredder over screening to bagging and storage, you will receive a suitable solution for every agriculture pellet plant section. We also offer you the best problem solution for high demands, for example: for architectural, confined area sizes.

There are differences in the process flow for processing different types of agricultural waste pellets. The following are the processing process designs for several common pellet types:

Agriculture Fuel pellet process

Cleaning – crushing process – granulation process – cooling process – screening process – packaging/storage

Application: biomass pellet production line

Agriculture Feed pellet process

Cleaning – crushing process – mixing process – granulation process – cooling process – screening process – packaging/storage

Application: animal feed production line

Organic fertilizer granule process

Fermentation process – mixing process – granulation process – drying process – cooling process – screening process – packaging/storage

Application: organic fertilizer production line

Agriculture Cat litter pellet process

Crushing process – mixing process – drying process – granulation process – cooling process – screening process – packaging/storage

Application: cat litter production line

All processes can be customized. No matter how special the process you need or how complex your factory structure is, RICHI can promise to provide you with a satisfactory agriculture pellet process plan and a full set of technical support. All solution design and technical support are free of charge, which is our greatest sincerity to our customers around the world.

Every member of our highly-trained engineers knows what it takes to build high quality agriculture pellet plants, and get it to market efficiently and cost-effectively. Our knowledgeable team will consult with you to determine an innovative solution for your application.

Complete Agri pellet machinery list

The agriculture pellet production line requires a series of agri pellet machinery to complete the entire process from raw material processing to final product packaging. These devices mainly include:

Bale breaker

Capacity:

1-20T/h

Main Power:

30-90KW

agriculture waste Hammer Mill

Capacity:

3-25T/H

Main Power:

30-160 KW

Straw Grass Crusher Machine

Capacity:

0.3-3T/H

Main Power:

22-93KW

Mixing Machine

Capacity:

250-2000KG

Main Power:

4-55KW

agriculture waste Dryer

Capacity:

Customized

Rotate Speed:

3-8 R/Min

agriculture waste pellet mill

Capacity:

0.3-42T/H

Main Power:

37-280KW

- Crusher machine: Used to crush and grind raw materials to a size suitable for subsequent process steps. Depending on the raw materials, the configuration of the crushing system is also different. There are many types of crushers, such as hammer crushers, grass crushers, straw crushers, slicers, etc. The appropriate model can be selected according to different requirements and material properties.

- Dryer machine: Used to remove moisture from biomass raw materials. Drum dryers are commonly used. Heat source is optional and can be customized.

- Pelletizer: It processes the processed materials into regular shapes and is the core equipment in the granule production line. There are many types of agriculture pellet machines. Depending on the type of granules to be processed, you can choose feed agri pellet machinerys, fuel agri pellet machinery, organic fertilizer agri pellet machinery, cat litter agri pellet machinery, etc.

- Cooler machine: Cool down the newly processed particles to prevent problems such as cracking of the agriculture pellets.

- Screening machine: used to screen impurities in raw materials and screen particles in the later stage to ensure uniform quality and specifications of the pellets. Common screening equipment includes trommel screens, vibrating screens, etc.

- Packaging machine: It is the last link of equipment in the agriculture pellet production line to package the classified pellets.

In addition, depending on the type of agriculture pellets to be processed, the scale of the agriculture pellet production line and the process requirements, other auxiliary equipment is also required, such as conveyors, dust removal equipment, fermentation equipment, conveying equipment, storage silos equipment, etc.

Together, these devices form a complete agriculture pellet processing line, ensuring smooth production from raw materials to final products.

agri pellet machinery video

How to choose agri pellet machinery manufacturer?

There are many agri pellet machinery manufacturers on the market. If you look carefully, you will find that some are real manufacturers, and a large part are listed or agents. Prices, quality, etc. are uneven in the market. So, for granule processors, how to choose a good agri pellet machinery manufacturer?

- Understand the strength of the manufacturer:

When choosing a manufacturer, you need to understand its size, qualifications, experience, etc. Choosing a manufacturer that has strength, a long operating history, and a sound factory in all aspects can ensure the quality of the product and the reliability of the after-sales service. - Examine product quality:

Quality is one of the key factors in choosing an agri pellet machinery manufacturer. It is necessary to carefully check the manufacturer’s equipment quality, materials and processes to ensure that product quality meets safety standards and usage requirements. - Examine the manufacturer’s service:

The manufacturer’s service is also one of the important factors in choosing a manufacturer. It is necessary to understand the manufacturer’s after-sales service, technical support, maintenance and other services to ensure that the manufacturer can provide timely and professional services. - Refer to the manufacturer’s reputation:

The agri pellet machinery manufacturer’s reputation is one of the important indicators to measure its credibility and reliability. You can learn about the reputation and credibility of manufacturers through the Internet, industry associations and other channels, and choose manufacturers with good reputations. - Compare prices:

There may be differences in prices between different manufacturers. You need to compare according to your own budget and needs, and choose a manufacturer with a high price/performance ratio. Of course, this is not absolute. RICHI reminds everyone again to compare prices on the basis of quality. - Understand the manufacturer’s design capabilities:

Agri pellet machinery and complete agriculture pellet manufacturing plant systems require professionalism and design. The manufacturer’s design capabilities are also one of the important factors in choosing a manufacturer. It is necessary to understand the manufacturer’s engineering team, design experience and innovation capabilities to ensure that the manufacturer can provide a design solution that meets needs and is competitive. - On-site inspection:

Before choosing an agri pellet machinery manufacturer, it is recommended to conduct an on-site inspection of the manufacturer’s production capacity, equipment status, production process, quality management, etc., in order to have a more comprehensive understanding of the manufacturer’s strength and product situation.

The above is the purchasing guide summarized by RICHI Machinery for everyone. Of course, there are many aspects to consider when choosing a suitable agri pellet machinery manufacturer. It is recommended to conduct a comprehensive evaluation and comparison to ensure the performance and quality of the equipment and improve the safety and competitiveness of the granulation process and system.

Why start agri pellet production business?

1. Market prospects

With the increasing awareness of environmental protection, the agri pellet production project has attracted more and more attention. This project processes agri waste such as straw, rice husks, and grass into fuel, feed, organic fertilizer, cat litter, or animal bedding.

This product is not only widely used in markets in various countries, but can also be exported to Europe and the United States, with broad market prospects. According to market analysis, the annual growth rate of this industry will exceed 30% in the next few years, and the overall market size is huge.

2. Development Trend

- Technology continues to improve

Agricultural waste granulation technology has developed rapidly in the past few years. More and more companies have begun to get involved in this field, and various technologies have been continuously improved and upgraded. In the future, with the continuous improvement of technology, the quality and efficiency of agri pellet making projects will be further improved.

- Favorable policies

In recent years, many countries have increasingly supported policies for green and environmentally friendly industries, and the agriculture pellet production project has also received policy support and rewards. In the future, policy support will continue to increase, which will play a positive role in promoting the development of the agri pellet production project.

- Increase environmental awareness

With the improvement of environmental awareness, people’s demand for green, environmentally friendly and sustainable products is also increasing. The agri pellet production line project conforms to modern environmental protection concepts, and its market prospects will become increasingly broad.

3. Investment advice

The agri biomass pelletizing plant project is an investment project with broad prospects. For investors, it is recommended to pay attention to the following aspects:

- Pay attention to technical content

There are many brands of pellet machines on the market, but their technical content is not the same. If you want to invest in an agri pellet factory project, you need to choose a pellet mill brand with good quality and advanced technology.

- Understand market demand

Before investing, you need to fully understand the market demand for agri pellets, grasp market trends, and understand product categories, quality requirements, specifications and other information.

4. Reasonably plan production capacity

Capacity planning is an important part of agri pellet processing plant project investment.

It is necessary to formulate reasonable production capacity planning based on market demand, investment affordability, technology, human resources and other factors to ensure the smooth implementation of the project.

In general, the agri pellet machinery plant project has high market prospects and investment value. Investors can choose the investment direction that suits them according to their own circumstances. (Finder us on YouTube)