Corn stalk pellet machine

Corn straw pellet machine is a biomass pellet equipment used to process straw pellets. It has the advantages of high productivity, low requirements on the moisture content of raw materials, and does not require any additives or binders during the molding process. It is suitable for corn straw pellet production of various scales.

According to the different needs of the market, RICHI corn stalk pellet machine can produce different products such as corn stalk fuel pellets and corn stalk feed pellets.

Among them, the produced feed pellets can be used as feed for cattle and sheep in winter and spring and stored. The fuel pellets can be processed into straw pellets that can replace charcoal and become a new renewable fuel energy source, which has been widely promoted.

- Corn stalk pellet machine Capacity: for fuel pellets 0.6-10 T/H, for feed 1-42 T/H, for fertilizer 1-12 T/H

- Corn stalk pellet machine price: 10,000-100,000 USD

- Pellet size: 2-12mm

- Application: straw pellet plant (fuel), Straw pellet production line (feed), fuel pellet plant, biomass pellet plant, animal feed mill plant, organic fertilizer pellet factory, etc.

RICHI Machinery is one of the world’s largest and most advanced straw pellets machine manufacturers. We can provide you with customized corn straw pellet production solutions with different outputs, different raw materials, and different processes.

If you are interested in our pellet machine and biomass pellet plant construction, please feel free to contact us!

(Note: This page will mainly explain to you the content of the fuel straw pellet machine. If you want to process feed or organic fertilizer, please refer directly to our animal feed pellet machine and organic fertilizer pellet machine.)

Features Of corn stalk pellet machine

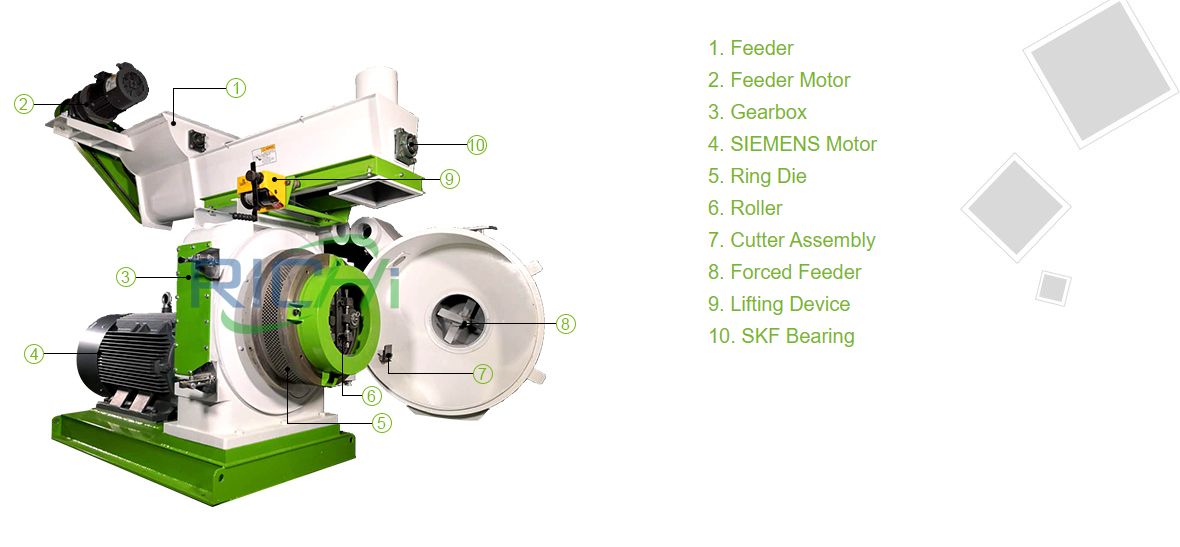

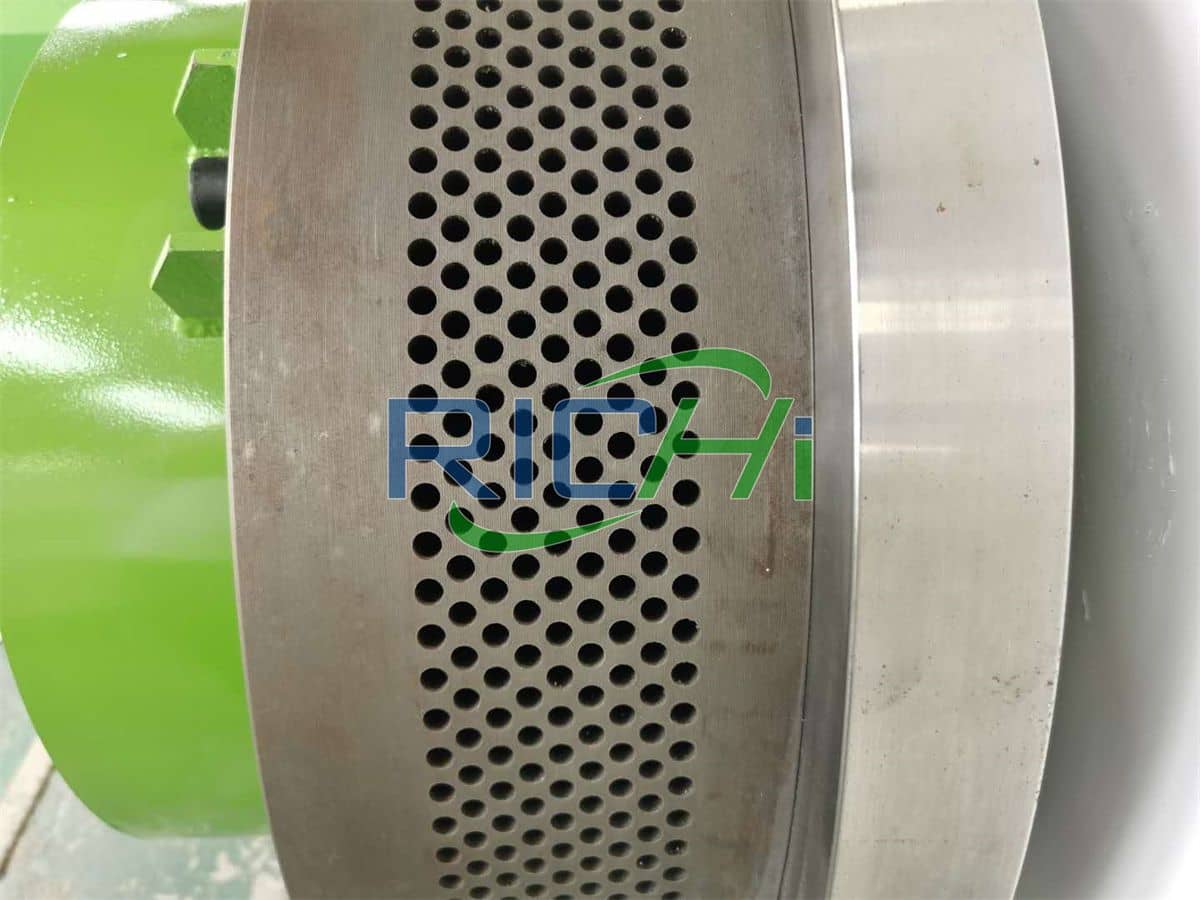

Corn stalk pellet machine uses the roller-die principle to compress various biomass straw raw materials into pellet fuel. The main structure includes a base, forming motor, coupling, feeder motor, forced feeder, blower, and discharge mouth and molding chamber.

- Suitable for processing various agricultural and forestry waste pellets.

- Mold transverse direction. Vertical feeding, no arching, easy heat dissipation. The mold is installed statically and horizontally, the corn straw pellet machine is easy to fix and the machine operates smoothly;

- The main machine box is precision cast from high-quality steel with uniform thickness and tight structure; it is then carefully processed by a CNC machining center imported from Switzerland, with zero error in processing accuracy, provide stronger support for normal operation.

- The bearings and oil seals used in the transmission part are all imported high-precision bearings and imported wear-resistant and temperature-resistant fluorine rubber oil seals, and a special lubrication oil return system is added, the oil circuit is circulated for cooling, and automatic timing oil lubrication is provided. Ensure the bearings are fully lubricated for safer and more reliable operation.

- The ring die has two layers and can be used both upper and lower, reducing costs and increasing efficiency.

- Using gear direct transmission, the transmission rate reaches more than 98%. The equipment has low energy consumption, stable operation and large output.

- The density of the products pressed by this corn stalk pellet machine can reach 0.8~1.2g/cm3, and due to its high strength, the surface is relatively smooth, the calorific value is also high, and the pellet quality is good.

- The ring-die corn stalk pellet machine does not require an external heat source, that is, it can be formed without heating during the molding process of compressed corn straw pellets.

Our corn stover pellet machine technology has the advantages of low energy consumption, high efficiency, good curing effect, and high product quality. This corn stalk pellet machine has become the trend of models used for densification molding of corn stover biomass pellets in the future.

Technical Parameters Of corn stalk pellet machine

| Type | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH768 | MZLH858 |

| Output(t/h) | 0.7-4 | 1~6 | 2~10 | 3~15 | 4~30 | 5~40 |

| Main motor power(kw) | 22 | 37 | 90 | 132 | 250 | 280 |

| Main motor series | 6/8P | |||||

| Forced Feeder (KW) | 1.1 | 1.5 | 1.5 | 1.5 | 2.2 | 3 |

| Conditioner Power(kw) | 2.2 | 4 | 7.5 | 7.5 | 11 | 15 |

| Ring die diameter (mm) | 320 | 350 | 420 | 520 | 762 | 858 |

| Finished pellet diameter (mm) | 6-12mm | |||||

| Device Configuration | Ring die material: 42CrMo Stainless steel conditioner Door of pelleting room: 6mm /SUS304 Forced feeding: Worm gear reducer Gear box: HT250 Gear: 42CrMo Gear shaft: 42CrMo Spindle: 42CrMo Empty shaft: 42CrMo Bearings: The gear shaft and main shaft bearings are SKF, and the pressure roller bearings are domestic high-quality bearings Oil seal: Germany/Taiwan Overload mechanical protection: safety pin Serpentine spring coupling drive Lubrication system: Configurable automatic oil injection system | |||||

Production Requirements For corn stalk pellet machine

The moisture content of raw materials and the aspect ratio of ring die holes are the basic process conditions for corn straw pelleting.

- When the screen hole diameter is not larger than 6mm, the raw material moisture content is between 20% and 30%, and the ring die hole length-to-diameter ratio is 5:1, the corn straw forming rate is high and the forming process is stable.

- Test data shows that when the screen aperture is 6mm, the raw material moisture content is 25%, and the ring die hole aspect ratio is 5:1, the comprehensive power consumption reaches the optimal value, and the power consumption per ton of forming pellets is less than 100kwh.

Different biomass raw materials have different requirements for molding conditions.

For ordinary biomass straws such as corn straw, the corn based straws pelleting process is easier to control, the molding rate is higher, and the power consumption per ton of material can be kept at a reasonable level, which is practical application conditions.

Corn stalk pellet machine projects

Corn stalk pellet machine in Argentina

- project date: 2020.09.05

- Pellet Size: 6mm

Corn stalk pellet machine in Brazil

- project date: 2021.9.26

- Pellet Size: 8mm

Corn stalk pellet machine in USA

- project date: 2020.10.15

- Pellet Size: 6-8mm

Corn stalk pellet machine in Indonesia

- project date: 2020.06.16

- Pellet Size: 8-10mm

Corn stalk pellet machine in Russia

- project date: 2023.07.11

- Pellet Size: 6-10mm

Corn stalk pellet machine in India

- project date: 2020.07.24

- Pellet Size: 8-10mm

Corn stalk pellet machine in South Africa

- project date: 2019.05.17

- Pellet Size: 8mm

Corn stalk pellet machine in Mexico

- project date: 2022.07.29

- Pellet Size: 8-10mm

How to choose corn stalk pellet machine?

The purchase of corn straw pellet machine is an important link related to the efficiency and quality of the biomass pellet production line. The following are some tips for purchasing a corn stalk pellet making machine:

- Production demand analysis:

Before purchasing a corn stalk pellets machine, you must first fully understand your production needs. Taking into account factors such as production scale, sales type, power consumption (or transformer), etc., determine the specifications and production capacity of the corn straw pellet machine required. - Equipment quality and brand reputation:

Choose well-known brands and suppliers with good reputation to ensure reliable quality of equipment. Corn stalk pellet mill machines should use high-quality materials and advanced manufacturing processes to ensure the stability and durability of the equipment. - Equipment performance and technical indicators:

Pay attention to the performance and technical indicators of the maize stover pellet machine, such as production capacity, energy consumption, etc. Choose corn fuel pellets equipment that meets your own production needs and has higher performance to improve production efficiency and product quality. - Supporting equipment and function expansion:

Consider the compatibility and synergy between the corn stalk pelletizer machine and other equipment to ensure the smooth operation of the entire production line. At the same time, consider the functional scalability of the equipment so that it can be upgraded and modified as needed. - Maintenance and after-sales service:

Understand the supplier’s after-sales service system and technical support capabilities. Ensure that suppliers can provide timely maintenance and upkeep support to ensure long-term stable operation of equipment. - Cost-benefit analysis:

Conduct a cost-benefit analysis by comprehensively considering equipment price, maintenance costs, energy consumption and other factors. Choose a corn stalk pellet machine that meets your needs in terms of performance and quality at a reasonable price. - Visit and test machine:

Visit the supplier’s production factory as much as possible to understand the actual production conditions and quality control of the equipment. Carry out a test run to observe the operating effect and pellet quality of the equipment to ensure that the equipment meets expected requirements. - Refer to user reviews and experiences (customer cases):

Refer to the reviews and experiences of other users to understand the actual use of the equipment and user satisfaction, so as to better choose a suitable corn stover pellet machine.

In short, when purchasing a corn stalk pellet machine, you need to comprehensively consider production needs, equipment quality, performance indicators, maintenance services, cost-effectiveness, etc.

Through careful selection and comparison, you can definitely choose a high-quality corn stalk pelleting machine that suits your production needs and improve production efficiency and product quality.

Videos of corn stalk pellet machine

Why invest in corn stalk pellets production industry?

This is related to the importance of peanut shell pellet machine and straw compression molding technology.

Straw raw materials, their bulk density is much smaller than wood. For example, the bulk density of corn straw is equivalent to 1/8 of wood, and the bulk density of wheat straw is less than 1/10 of wood.

The low density of straw raw materials will cause difficulties in storage and transportation, limiting the economy and feasibility of large-scale utilization.

Compression molding of straw corn biomass can greatly increase the density of the raw materials, reaching more than 1*10³kg/m³, which is convenient for transportation and storage. The density is equivalent to that of coal with a medium calorific value.

And at the same time, its combustion characteristics are changed, making it close to coal. In agriculture, it can completely replace conventional energy sources such as coal and liquefied gas and become an energy source for rural cooking.

In industry, it can replace coal in biomass power plants, industrial boilers, and kilns. Therefore, straw compression molding has become the key to resource utilization of crop straw.

Complete set corn stalk pellet machine plant Construction

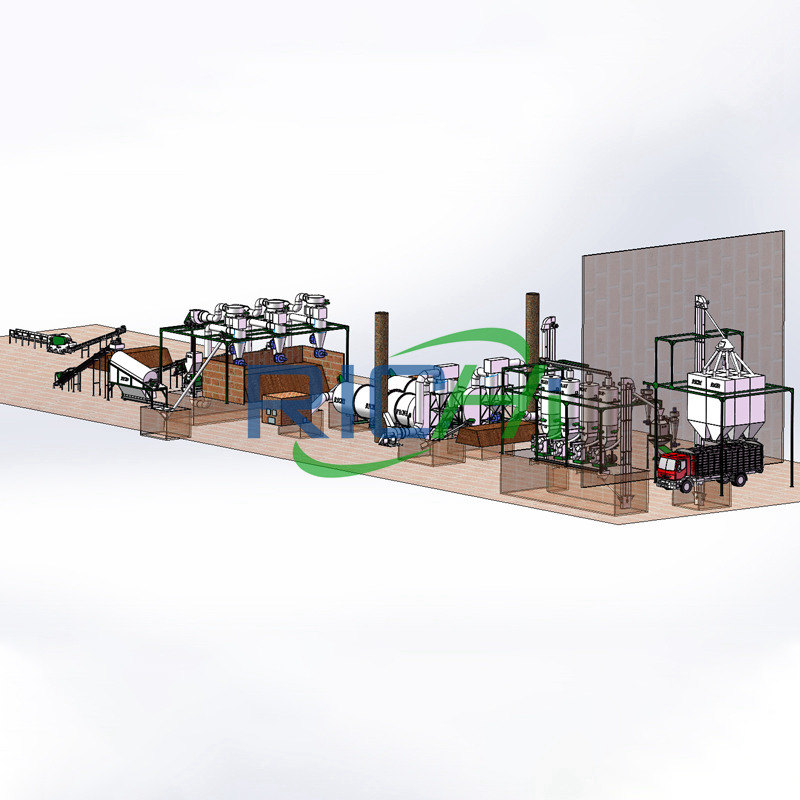

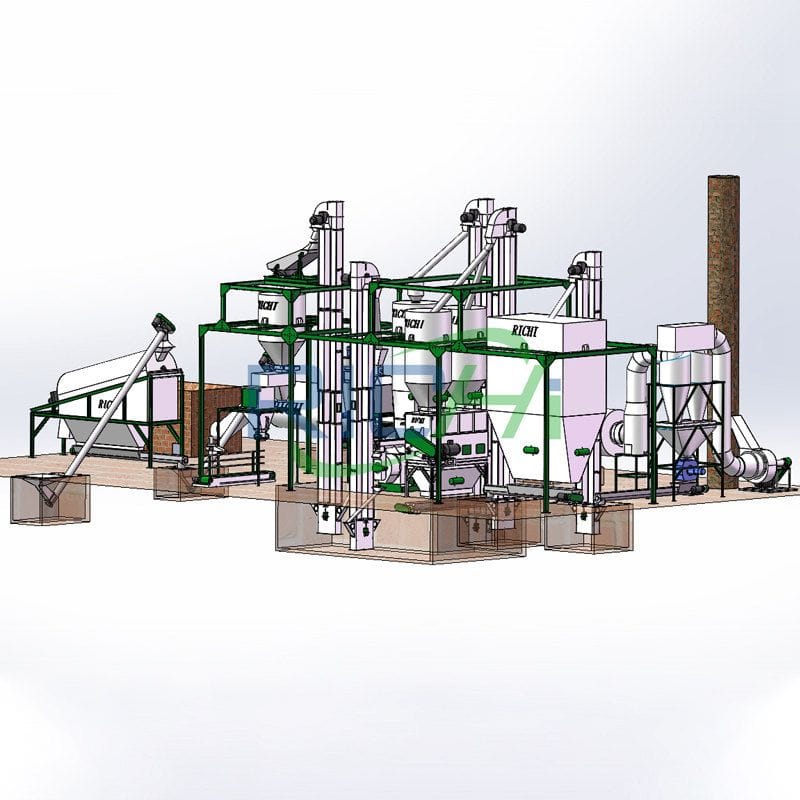

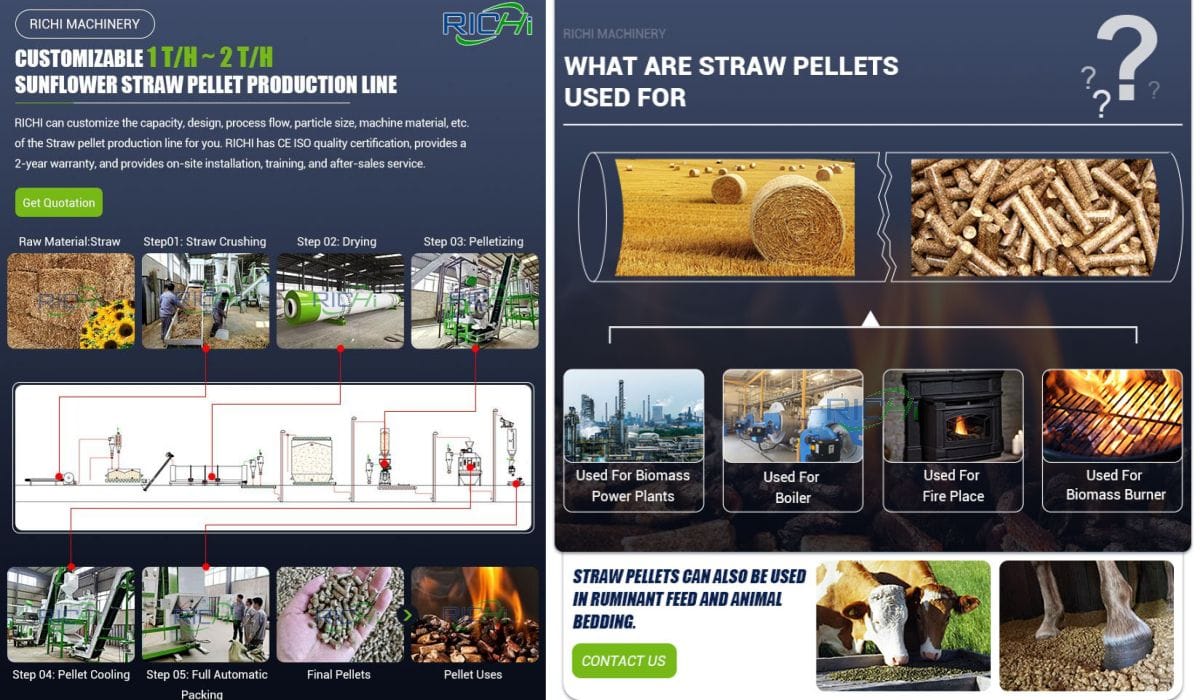

The multifunctional straw pelleting production line developed by RICHI has multiple functions in one system, wide adaptability, stable performance, long service life, and can work continuously for a long time.

The granulation rate is increased from 95% to over 98%, and the output is increased from 600 kilograms per hour to 90 tons.

Corn stover biomass pellets are processed through crushing, drying, mixing, granulation, cooling, screening, packaging and other processes to form long cylindrical pellets with a diameter of 6-12mm and a length of 10-30mm. Finally, they are cooled, dried to reach safe moisture and packaged.

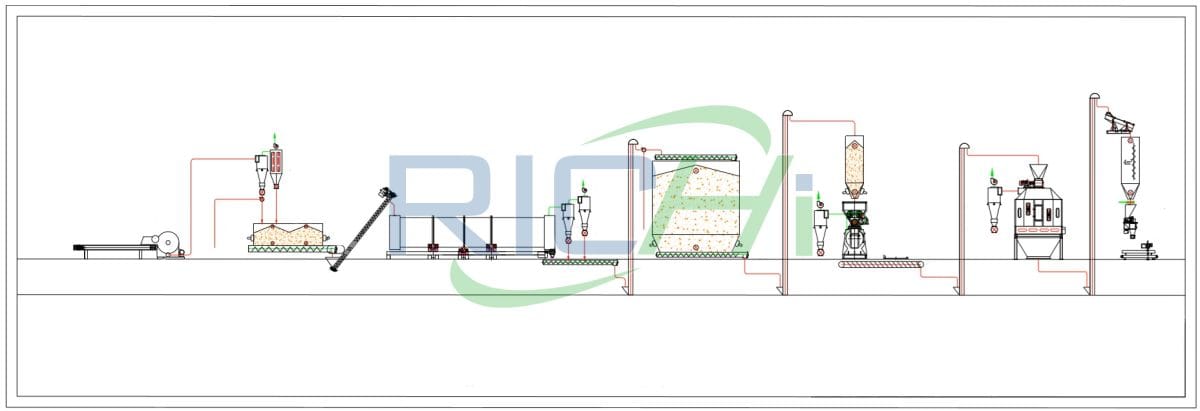

01 The specific corn stalk pellet production process is described as follows:

Collect crop waste (straw, etc.) – drying – crushing – ingredients – hot pressing – forming – granulation – bag making – storage

Made from corn stalks. The raw materials are dried to a suitable moisture content, and then the dried raw materials are crushed using a crusher. After adding water to the powder raw materials, use a mixer to mix evenly and control the moisture content. The homogeneous mixture is softened by steam and transferred to a corn stalk pellet machine for extrusion and granulation.

The straw pellets are transported to the cooler for cooling and screening. The finished product is packed in special polypropylene laminated woven bags.

02 corn stalk pellet production line layout principles

According to the location of the project and surrounding conditions, in accordance with national specifications and production process flow requirements, and in conjunction with the site topography, Richi Machinery ensure smooth process flow and convenient connection.

Strictly abide by relevant standards and specifications to ensure safe production, consider fire prevention, sanitary safety distance and maintenance requirements, carry out reasonable functional zoning according to local conditions, strive to have a compact and reasonable layout, save land, and unified planning, which is conducive to production management and environmental protection.

03 Supporting Equipment For corn stalk pellet machine

Bale breaker

Capacity:

1-15T/H

Main Power:

30-150KW

corn stalk crusher Machine

Capacity:

0.3-3 T/H

Main Power:

22-93 KW

Hammer Mill crusher

Capacity:

3-25T/H

Main Power:

30-160KW

Featured corn stalk pellet machine system solution

How to start a Complete 1.5 t/h corn stalk pellet mill line?

—— RICHI MACHINERY ——

- Annual output: construction scale is 2500t/a,

- Total investment: 60,000 USD

- Total area: 3700m².

- Construction content: 1F production workshop, steel structure, H=6, construction area 350m²; material yard, covering an area of 800m²; 1 warehouse, 1F, H=3.2, building area, 200m²; 1 office, 1F, H=3.5, construction area 40m².

- Raw material consumption: straw 3125t/a, moisture content 20%~30%

- Power consumption: 370000kwh/a

- Work system: This project has a capacity of 6 people, and the annual production days are 180. The company’s work system is 10-hour production in one shift, and there is no production at night.

- Main equipment: 1 forklift, 2 conveyors, 1 crusher, 1 corn stalk pellet machine, 1 cooler, 2 sets of bag dust collectors

1.5 t/h corn straw pellet making process:

- Transshipment and unpacking: After the collected raw materials are transported into the factory, they are unpacked and stored in the material yard. After the natural drying moisture content reaches less than 10%, they are transported to the production workshop for crushing.

- Crushing: The raw materials are crushed in the production workshop.

- Granulation and molding: After crushing, it is transferred to the corn stalk pellet machine.

- Cooling: The temperature of the corn straw pellets at the outlet of the corn stalk pellet making machine is 80-90°C. The biomass pellets are sent to the cooler for cooling through the conveyor.

- Packaging and warehousing: After the biomass pellets are cooled, they are manually packaged and bulk materials are stored. The products are transported to the warehouse for storage. The products are produced and sold immediately without large-scale storage.

2 T/H wood chips and corn stalk pellet machine line design

—— RICHI MACHINERY ——

- Annual production: 15,000 tons

- Project investment: 150,000 USD

- Land area: 4000m² and the construction area is 3200m²;

- Work system: 15 people, a 24-hour work system in three shifts, and 300 days of work per year.

- Construction content and scale: It mainly builds production workshops, including production area, crushing area, raw material area, finished product area and ancillary facilities.

- Consumption of raw materials: straw 7525t/a, waste wood 7525t/a, the maximum storage capacity in the factory is 3000t

- Energy consumption: water 180m³/a, electricity 1.8 million kW·h/a

- Main equipment: 3 crushers, 2 wood pellet making machine, 2 corn stalk pellet machines, 8 feeders, 7 conveyors, 6 auxiliary equipment, and 2 transformers.

2 T/H wood chips and corn stalk pellet making Process flow:

- Crushing: Some of the raw materials of the project (mainly straw) need to be crushed. A forklift is used to transport the raw materials from the raw material area to the hopper of the crusher. The raw materials enter the crusher through the conveyor belt for crushing. Some old wood raw materials are large and need to be sawed, and then enter the crusher for crushing.

- Transportation: The materials collected by the cyclone dust collector are transported to the raw material area through a closed conveyor belt for temporary storage; a forklift is used to transport the raw materials from the raw material area to the hopper of the conveyor belt, and the raw materials are transported to the biomass corn stalk pellet machine through a closed conveyor belt.

- Pelleting: The materials recovered by the cyclone dust collector enter the biomass wood corn stalk pellet machine and are extruded into the pellet equipment. Into finished products, the diameter of the pellets is between 6mm~12mm and the length is between 1~15 cm.

- Cooling: The formed corn stalk pellet is naturally cooled through a closed conveyor belt, so that its temperature can reach the conditions for packaging and storage, and is transported to the finished product area.

- Packaging, finished products, and storage: The cooled biomass corn straw pellet fuel is packaged in different specifications according to customer needs, which is the finished product and stored in storage for sale.

8T/H Wood waste and corn stalk pellet machine line design

—— RICHI MACHINERY ——

- Annual output: 20,000 tons

- Total investment: 320,000 USD

- Covering area: 13052.3m² (mostly idle land and vegetation);

- Main construction content: including production workshop, raw material warehouse, finished product warehouse and supporting facilities.

- Pellet specifications: diameter 8-10mm, length 20-50mm, high calorific value 3450-4200kcal/kg, moisture content 12~18%, density >1.12kg/m³, ash content <1.5%. Mainly bagged and 10kg packaged.

- Raw material consumption: straw 6000t/a, chaff 6000t/a, waste boards (mainly wooden boards) 8000t/a

- Energy consumption: power consumption 5 million kwh/a, water consumption 148.5m³/a

- Work system: 11 people, the annual working days are 300 days, and the production shift system is 1 shift, each shift is 8 hours.

- Main equipment: 4 wood and corn stalk pellet machines, 3 crushers, 1 wood chipper, 1 bag dust collector, 2 belt conveyors.

8T/H Wood waste and corn stalk pellet plant Process flow:

- Feeding: Purchase dry straw, chaff, etc. as required. Raw material requirements: low moisture content, no gravel, iron filings, sediment, plastic and other impurities.

- Crushing: The loader loads the material to the sealed conveyor line, and transports it to the crusher via a belt for crushing to obtain crushed materials with larger particle sizes. An iron removal device is installed at the outlet of the crushed materials to remove iron from the crushed materials (waste plates). of iron and other impurities. The crushed material is loaded by the loader and transported to the pulverizer by a belt for crushing to obtain crushed material with a particle size <10mm. The crushed material is sent to a closed bin for storage via a closed conveyor belt.

- Granulation: The wood corn stalk pellet machine is a key equipment of the corn biomass fuel production line. After the crushed raw materials pass through the biomass wood corn stalk pellet mill machine in a closed environment, finished biomass fuel pellets with a diameter of 8mm and a length of 20-40mm are formed.

- Packaging: The pressed and formed products are packaged and transported to the finished product warehouse.

How to set up 10T/H Wood and corn stalk pellet machine combined line?

—— RICHI MACHINERY ——

- Annual output: 48,000 tons

- Total investment: 420,000 USD

- Construction project content: This project covers an area of 5336m2, with a construction area of 2651m2. The main construction contents include production plants, offices, staff dormitories and canteens, etc.

- Main raw material consumption: waste wood 15000t/a, straw 5000t/a, chaff 5000t/a, sawdust ash 23000t/a

- Energy consumption: power consumption 8 million kwh/a, water consumption 787.5m³

- Pellet fuel specifications: length 30-50mm, diameter 8-10mm

- Working system: 22 people, working 300 days a year, 16 hours a day, working hours from 6:00 to 22:00, and no production at night. Employees have room and board in the factory.

- Main equipment: 1 crusher, 1 pulverizer, 2 screens, 3 biomass wood corn stalk pellet machines, 3 belt conveyors, 1 multi-function shuttle, 1 forklift, and 1 fan.

10T/H Wood and corn stalk pellet plant process

- 1st Crushing: After the raw materials enter the factory, they are placed in the raw material warehouse. A forklift is used to transport the raw materials to the vicinity of the wood chipper and straw crusher. The wood and straw are manually moved to the belt conveyor connected to the crusher. The crushed materials enter the next process through the belt conveyor.

- 2nd Crushing: The crushed materials and chaff are sent to the hammer mill crusher through a belt conveyor for further crushing.

- Screening: The materials produced in the crushing stage enter the screener through a closed pipe for screening.

- Granulation: The screened materials or sawdust ash are transported to the corn stalk pellet machine and pressed into pellet shapes in the corn stalk pellet machine

- Cooling: The temperature of the molded material can reach 60~80°C. The material is transported to the finished product warehouse and naturally cooled for cooling.

- Packaging: The finished products are packaged, and unqualified products can be reused as raw materials, reprocessed, and recycled. During the packaging process, there are waste packaging bags whose quality does not meet the requirements.

How to start a 3-4T/H wood chips and corn stalk pellet machine combined line?

—— RICHI MACHINERY ——

- Building area: 4300 square meters

- Total investment: 130,000 USD.

- Main construction content: production workshop, raw material warehouse, finished product warehouse, and supporting facilities. The production workshop is 1200m², the raw material warehouse is 400m², the finished product warehouse is 700m², dormitory building (including canteen) ) 300m², office and accommodation building 250m²,.

- Raw material consumption: 4000 t/a wood chips, 3000 t/a straw, 2000 t/a waste boards

- Energy consumption: power consumption 100,000 kwh/a, water consumption 300.5m³

- Working system: There are 6 employees in this project, all of whom are provided with board and lodging in the project. The annual working day is 300 days, and they work 8 hours a day.

- Main equipment: 1 feeding belt conveyor, 1 wood chipper, 1 discharging belt conveyor, 1 electric control cabinet, 1 crusher, 1 belt conveyor, 1 corn stalk pellet machine, 1 granule conveyor belt 1 set of strips, screening machine, 1 drying kiln, 1 cyclone separator, 1 baling machine

3-4T/H wood chips and corn stalk pellet Production Process

- The process of this project is relatively simple. Waste boards (2000t/a) are chipped and then screened with straw (4000t/a) and sawdust (3000t/a). After screening, the fine materials enter the drying kiln for drying, and the coarse materials enter the crusher for crushing. After crushing, they are re-screened.

- The raw material wood chips (accounting for 40% of the raw material) are first screened, and the fine materials that pass the screening are dried and cyclone separated to reduce the moisture content of the raw material to 15% to 20%.

- Then a corn stalk pellet machine is used to process the dried fine materials into biomass fuel pellets with a diameter of 8mm and a length of 20~40mm.

- After natural cooling, it is poured into 25kg finished product bags through a packaging machine.

Faqs Of corn stalk pellet machine

If I want to process corn straw pellet feed, what corn stalk pellet machine specifications are available?

The following are the parameters and specifications of the corn stalk pellet machine for feed production:

| Model | Capacity(T/H) | Main Motor Power(kw) | Feeder Motor Power(kw) | Conditioner Power(kw) | Dia.of Ring Die(mm) | Final Pellet(mm) |

|---|---|---|---|---|---|---|

| SZLH250 | 1-2 | 22 | 0.75 | 1.5 | 250 | 2~12 |

| SZLH320 | 3-4 | 37 | 1.5 | 2.2 | 320 | 2~12 |

| SZLH350 | 5-7 | 55 | 1.5 | 3 | 350 | 2~12 |

| SZLH420 | 8-12 | 110 | 1.5 | 7.5 | 420 | 2~12 |

| SZLH508 | 10-18 | 160 | 2.2 | 11 | 508 | 2~12 |

| SZLH558 | 15-25 | 180/200 | 2.2 | 11 | 558 | 2~12 |

| SZLH558D | 14-22 | 160/180/200 | 1.5 | 7.5 | 558 | 2~18 |

| SZLH678 | 20-30 | 220/250 | 2.2 | 11 | 678 | 2~12 |

| SZLH678D | 15-25 | 200/220/250 | 2.2 | 11 | 673 | 2~18 |

| SZLH768 | 25-40 | 280/315 | 2.2 | 11 | 768 | 2~12 |

| SLZH858 | 25-42 | 280/315 | 2.2 | 15 | 858 | 2~18 |

If I want to process corn straw organic fertilizer granules, what models can you provide?

Organic fertilizer corn stalk pellet machines and fuel corn stalk pellet machines belong to the same category, and both use model MZLH series pellet machine. But their capacity of pellets is different.

The following are the technical parameters of the corn stalk pellet machine for organic fertilizer:

| Model | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH768 | MZLH858 |

|---|---|---|---|---|---|---|

| Power (KW) | 37 | 55 | 90 | 132 | 250 | 280 |

| Capacity (T/H) | 1-2 | 3-4 | 5-6 | 7-8 | 9-10 | 10-12 |

| Final Pellet (mm) | 2-6 | 2-6 | 2-6 | 2-6 | 2-6 | 2-6 |

| Weight(KG) | 2500 | 3500 | 4000 | 4500 | 5000 | 5500 |

Why can’t we use the same corn stalk pellet machine to process corn stalk fuel and corn stalk feed?

There are fundamental differences between pellet fuel and feed, namely the quality requirements. Density is an indicator of the quality of pellet products. According to the literature, the density of feed pellet products is usually 0.5-0.75g/cm³. Compared with pellet fuel, the density requirements are relatively low.

Therefore, the pressure and temperature requirements of feed corn stalk pellet machines are not high, so the loss and life of core components are not as strict as those for pellet fuel.

Compared with feed pellets, fuel pellets have higher density requirements. Generally, the density is greater than the density of water. Therefore, the required pressure and temperature are also higher, so the loss and life of core components such as ring dies must be considered.

In addition, binders need to be added during the molding process of feed pellets, therefore, the requirements for the strength of core components are also reduced.

Therefore, the research on the ring-die corn stalk pellet machine for producing straw pellet fuel is not applicable to the corn stalk pellet machine for producing animal feed.

corn stalk pellet machine for livestock and poultry feed

corn stalk pellet machine for fuel

What are the economic benefits of turning corn straw into pellet fuel?

Next, take a Chinese corn straw pellet fuel production line project we have done as an example to conduct a simple economic benefit analysis. The designed annual production scale of this project is 6,000 tons/year.

(1) Consumption indicators and prices of main raw materials

At present, the price of corn straw per ton is 300 yuan (RMB). The price of water and electricity is estimated based on market prices. The following table lists the total consumption and price of corn straw pellet fuel raw materials and energy.

| Item | annual consumption | Unit price (tax included) |

| corn stalk (moisture content 40%) | 9232 tons | 300 RMB |

| electricity | 715508 kwh | 0.54 RMB |

| water | 40 tons | 3.9 RMB/ton |

(2) Main raw material consumption indicators and prices

The moisture content of corn straw pellet fuel is calculated to be 21%. Because corn straw is lost during production, the calculation yield of raw materials is 65%. The company currently has 12 employees, with a monthly salary of 2,500 yuan per person.

(3) What are the economic benefits of turning corn straw into pellet fuel?

The production cost of corn straw pellet fuel is about 920 yuan per ton, and the Chinese market price is about 1,200 yuan per ton. In foreign markets, biomass pellet fuel is also very popular, with a price of 230 US dollars per ton. The net profit in China’s domestic market is approximately 280 yuan/ton, which has good economic benefits.

Break-even point calculation:

P=annual fixed cost/(annual sales revenue-annual total variable cost-sales tax and surcharges)=47.4%.

According to the break-even analysis, as long as the annual production capacity is not less than 47.4%, the company can achieve profitability and has a certain ability to resist risks.

(4) Benefit analysis

- Reduce the space ratio:

The production process of corn straw fuel includes a corn stalk pellet machine system (compression molding process). The finished fuel is a high-density, lightweight corn stalk pellet product that is easy to package, transport, load, unload, and store, reducing transportation and storage costs for enterprises. - Improve production efficiency:

Due to the light weight of biomass briquette fuel, the labor intensity of workers during the feeding process is greatly reduced, and the labor cost per unit of energy is reduced. - Fast burning speed:

Biomass pellet ignite easily and burn quickly. Therefore, it can effectively increase the burning rate of a well-designed furnace, taking less time to release heat than coal does. - Low cost of supporting facilities:

Since most biomass contains extremely low sulfur content, combustion produces very little sulfur dioxide. Therefore, there is no need to install a separate desulfurization device, but only a flue gas dust removal device that meets national standards, thereby reducing the capital input of energy-consuming enterprises. - High recovery rate of ash:

The ash produced by the combustion of corn straw pellet fuel can be recycled and reused as fertilizer and chemical raw materials, thereby further reducing business costs. The ash contains elements such as magnesium, potassium, calcium, and sodium, and can be used as a high-quality crop fertilizer.

The cinders produced after coal combustion have almost no use value, and the processing and optimization of cinders still require a certain cost. It can be seen that biomass briquette fuel has certain added value. - Reduce carbon dioxide emissions:

The carbon dioxide produced by burning biomass fuel comes from the raw material itself. Unlike fossil fuels, the increase in the total amount of carbon dioxide in the atmosphere comes from the burning of solid carbon in fossil fuels. The use of biomass pellet fuel reduces acid gas emissions, and biomass fuel has low sulfur characteristics.

When they are burned, the emissions of acidic substances (such as sulfur dioxide) are much lower than fossil fuels, so they have no significant impact on air quality; the main pollutant when burning biomass pellet fuels is soot, and energy utilization companies can use efficient biomass burner, and install a dust removal device in the exhaust part to fully meet atmospheric emission standards.

As the demand for clean energy continues to increase due to economic development, the proportion of biomass pellets in the energy field will become higher and higher.

After scientific development, the rational utilization of biomass briquettes is an important manifestation of the energy industry. It could ameliorate the global energy shortage and over-reliance on coal, oil and other fossil fuels. It is an integral part of clean energy sector.

What are the characteristics of corn straw pellet fuel?

Tests show that the calorific value of corn straw is similar to the calorific value of Class II bituminous coal. The surface of the corn straw pellet fuel produced by the corn stalk pellet machine system is smooth, and its physical properties fundamentally meet the requirements of transportation, packaging and storage.

As traditional fossil fuels gradually decline, biomass energy will play an important role. The development and development of biomass energy not only has obvious environmental benefits, but can also make up for the shortcomings of traditional energy sources.

- Compared with other biomass energy technologies, corn straw pellet fuel has a wide range of raw material sources, large output, low production cost, easy implementation, and good combustion performance. It is also the best product to replace electricity, oil, natural gas, and coal.

- The operating cost of corn straw pellets is low. As an efficient, energy-saving and environmentally friendly thermal energy, compared with fuel, natural gas and electricity, the operating cost can be saved by 40% to 50%.

The ring die compression ratio is 4.5. What are the optimal pelletizing conditions for the corn stalk pellet machine?

- In the molding of corn stalks, as the compression ratio of the ring die increases, the density of the pellets increases, the energy consumption increases, and the output increases;

- when a certain compression ratio is reached, the density of the molded pellets increases less, the energy consumption increases accordingly, but the output decreases. dropped.

In a ring die with a compression ratio of 4.5, the corn straw particle size range is maintained at 1mm ~ 5mm, and the moisture content is maintained at 12% ~ 18%, the best effect is achieved. At this time, the pellet density and output are maximum and the energy consumption is small. (Find RICHI on YouTube)

How does the corn stalk pellet machine work?

The ring die corn stalk pellet machine compresses the corn straw pellets by pressing the straw pellets into the ring die holes through the pressure wheel, and the friction provided by the die holes causes extrusion to compress the corn straw pellets.

The ring die and pressure wheel are the core components of the corn stalk pellet machine.

Its working principle is that the motor drives the main shaft through the belt drive, and the main shaft drives the pressure wheel and the feed screw to rotate, and the biomass maize stover particles are pressed into the ring die through the rotation of the pressure wheel.

In the ring die hole, in order to reduce the relative sliding between the biomass straw particles and the pressure wheel, certain teeth or grooves are processed on the outer surface of the pressure wheel.

Although there are two types of lamination molding, flat die and ring die, the ring die corn stalk pellet machine has become the mainstream model among the current pelleting machines due to its compact, simple structure and easy use. The ring die series corn stalk pellet machine has a higher output and is generally 0.6-10t/h, low energy consumption.

Moreover, the requirements for the properties of the biomass straw raw material itself are also lower, and the molding and curing effect is better. Compared with other models, the advantages are very obvious.

During the densification molding process of corn straw:

- When its density is less than 1.1g/cm³, its density is proportional to the pressure;

- When the density exceeds 1.1g/cm³, as the pressure continues to increase, the change in density is not obvious.

- When the pressure is low, the material is not extruded densely, the density of the molded block is small, the surface is rough, cracks are prone to occur, the strength is low, and the optimal density required for combustion cannot be achieved;

- When the pressure exceeds 60MPa, the density of the molded block is suitable, the surface quality is good, the strength is high, the molding effect is good, and the density of the molded block with good combustion effect is between 0.9~1.1g/cm³.

Comparing corn stalks and corn stalk pellets before and after compression, from the perspective of material combination, it is concluded that the raw material granules are combined in the form of a “solid bridge”. The increase in compression temperature can activate the effect of moisture, making the together with lignin, protein, starch and fat, it becomes a natural binder and helps in the formation of pellets.

What factors will affect the processing quality of the corn stalk pellet machine?

Corn stover yields are large and widely distributed. Among its biomass components, up to 42% is carbon, which is considered a very reliable emerging fuel.

(1) Moisture content of raw materials

Different moisture contents affect the compression molding of biomass pellets. If the moisture content is too low or too high, it will have an adverse effect on the molding of corn stover biomass pellets.

If the moisture content is too high, the materials will fall apart and fail to form fuel. Generally speaking, the most suitable moisture content of raw materials is 12% to 15%.

(2) Heating temperature

Heating temperature is also one of the important factors affecting molding.

By heating, the lignin and other low molecular substances contained in the raw materials can be softened. The temperature at which the lignin softens plays an important role in bonding. In addition, high temperatures will also make the raw material itself softer and easier to compress.

(3) Pressure size

The main factor in forming corn stover biomass pellet fuel is compression, and the size of the pressure directly affects the molding effect.

- If the pressure is too high, the raw materials will be crushed;

- But if the pressure is too small, the corresponding product and its required performance will not be obtained. In the range of 200 bar~400 bar, it can meet the corn stalk pellet machine molding requirements of most raw materials, with smooth surface and moderate density.

(4) Fuel characteristics

From the perspective of corn stover biomass fuel production, it is first necessary to have a comprehensive understanding and mastery of the basic characteristics of corn straw, which is also one of the theoretical foundations of the corn straw pellet production process.

About 42% of the biomass component of corn stover is carbon, so it is a very reliable emerging fuel. The calorific value of corn straw is 15.55kJ/g, which belongs to the calorific value standard of Class II bituminous coal.

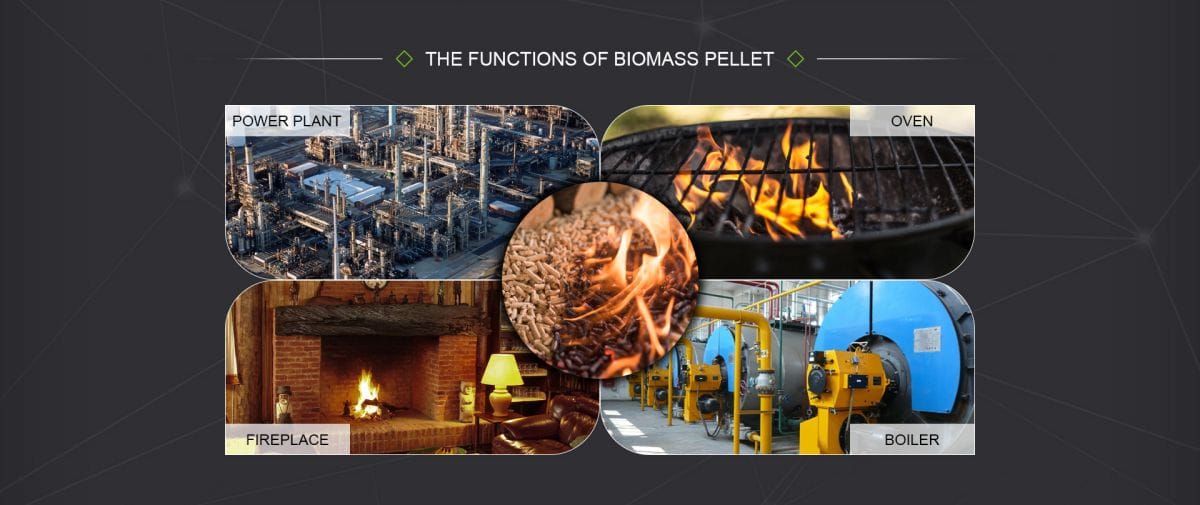

What are the applications of corn based straws pellet fuel?

The application scope of corn straw pellet fuel mainly includes two aspects:

(1) On the one hand, in the industrial field, most waste can be reused and made into pellet fuel to replace non-renewable energy sources, such as coal, oil, etc., and can be used in waste-to-energy power plants, various industrial boilers, etc. Corn stover pellet fuel can be added to large boilers as fuel instead of having to use coal to produce flue gas as the plant’s source of heat energy.

- The dust removal rate and desulfurization rate of small and medium-sized boilers are lower than those of large coal-fired boilers. Therefore, small coal-fired boilers must be gradually banned. For thermal energy and natural gas users, using corn straw pellet fuel is a relatively economical choice. Part of the purchased raw materials replaces coal, and the other part is processed into corn based straws pellet fuel. This can not only reduce business costs, but also reduce environmental pollution;

- Carbonized corn straw pellet fuel is subjected to secondary activation treatment to produce industrial activated carbon that can be widely used.

(2) On the other hand, in terms of people’s livelihood, corn straw pellet fuel made by corn stalk pellet machine is suitable for cooking and heating. In some cold countries, corn stalk pellet fuel is used for heating, which not only reduces fuel costs, but also achieves environmental protection effects. Comprehensive applications in countries around the world include the following aspects:

- In cities, it can be used for heating in hotels and restaurants, and can also be used in small restaurants to replace the use of coal. In northern cities, it can be used as collective heating for residents, and can also be used as fireplace fuel in villas.

- In rural areas, with the improvement of farmers’ living standards, the demand for high-quality energy is also increasing. Using densification molding technology to process straw into pellet fuel and use it for heating can reduce farmers’ heating costs and significantly reduce rural demand for energy. dependence on other energy sources;

- After the corn straw pellet fuel is carbonized, it can be used as barbecue, hot pot fuel and hand warmer instead of charcoal;

- Application of charcoal powder in fields can effectively increase soil temperature, soil fertility and prevent pests and diseases.

Does the corn stalk pellet machine have strict requirements on the size of the raw materials?

In general, under the same pressure, small-sized raw materials have greater compression and are easier to shape.

It can be seen from the principle of dense molding that the density of molding is mainly affected by the degree of mutual extrusion between straw particles and filling of the gaps between materials.

- The smaller the size of the particles, the easier they are to fill, and the greater the attraction and bonding force between particles. Therefore, under the same pressure, the bonding between particles is easier, which results in the molded product having high density, smooth surface, high strength and good molding effect;

- As the size of the straw material becomes larger, the filling capacity between the particles becomes lower, the contact between the particles becomes looser, the degree of embedding between the particles becomes worse, and the attraction between the particles becomes smaller. These will ultimately lead to the molding effect of the straw material poor.

Therefore, the corn stalk biomass pellet mill machine has high requirements for the crushed raw materials. Tests show that the raw materials with a length greater than 6mm should be less than 10%, and the molding rate is high, so it has higher requirements for crushing.

How to ensure the lowest power consumption of the corn stalk pellet machine?

Corn straw is the most important type of biomass that can be used.

RICHI used the corn stalk pellet machine system to test the power consumption of corn straw molding under different working conditions and found the lowest molding rate of corn straw.

The working conditions of electricity consumption provide a basis for the improvement of corn straw pelletizing process and the optimization design of molding equipment, and then provide scientific data for the pretreatment technology of large-scale resource utilization of biomass.

- When forming corn straw pellets, the power consumption is mainly concentrated in the two processes of crushing and pelleting. The power consumption accounts for more than 90% of the total power consumption, and the power consumption of pelleting is twice that of crushing. Therefore, the pelleting process should be the core during process design to minimize power consumption, thereby effectively reducing the power consumption of corn stalk molding.

- The density of corn stover biomass pellet fuel has a great impact on the power consumption during corn stalk pellet machine pelleting. Without affecting the use of corn stalk pellet fuel, the density requirements should be reduced as much as possible.

In addition to processing straw pellet fuel, what are the other applications of crop straw?

As a resource, crop straw can be used as fertilizer, feed, domestic fuel and raw material for industrial and sideline production.

(1) As fertilizer

Crop straw is mainly used as fertilizer in two aspects: direct utilization and processing utilization. Direct utilization generally takes the method of returning straw directly to the field, and processing and utilization mainly uses straw to compost organic fertilizer.

(2) As feed

In addition to direct feeding of crop straw as feed, there are also methods such as silage yellowing, ammoniation and saccharification.

Pools or plastic bags, etc., can achieve centralized and large-scale processing. In recent years, the use of specialized corn stalk feed pellet machine and equipment or straw feed production lines to process straw into pellet feed has developed rapidly.

(3) Others

Crop straws are also used as culture media for cultivating edible fungi, papermaking, producing fiber density boards, plant mulch films, tableware, packaging materials, seedling bowls, etc., as well as using straws to make chemical raw materials such as alcohol and refined starch.

How to use corn stalk pellet machine to process feed pellets?

This technology mainly uses a straw crusher to crush the straw after it is dried in the sun. Add other additives and mix well. After pouring into the hopper of the corn stalk pellet machine for feed, it is extruded by the grinding plate and the pressure wheel to form pellet feed.

Due to the friction and heating during the processing, the internal maturity of the maize stover is deep and transparent. The surface of the processed corn stalk pellet feed is smooth, with moderate hardness and consistent size. The diameter of the feed pellets can be adjusted according to the processing specifications.

The application of a complete set of corn stalk pellet machine plant can automatically complete the functions of straw crushing, lifting, stirring and feeding in sequence, and various effective additives can be added at any time, fully enclosed production, and high production efficiency.

At present, many small and medium-sized straw pellet feed processing enterprises adopt this technology. In addition, RICHI can also provide complete sets of straw concentrate feed processing and production technology suitable for large-scale feed production enterprises, with a higher level of automation control.

How to use a corn stalk pellet machine to process crop straw organic fertilizer pellets?

This technology uses high-temperature bacterial strain preparations to quickly compost wheat, corn, rice and other crop straws into efficient, high-quality organic fertilizer, which can then be processed into organic fertilizer granules using a straw organic fertilizer corn stalk pellet machine.

The principle is to use the bacterial strain preparations and various enzymes in the quick-corrosion agent to violently move at a certain humidity (about 65% of the water holding capacity of the straw) and a certain temperature (50°C ~ 70°C) to release energy.

- On the one hand, the fiber and protein of the straw will be quickly decomposed;

- On the other hand, a large amount of bacterial protein is formed, which is directly absorbed by plants or converted into humus.

Compared with corn straw pellets and pine and poplar pellets, which pellet is better?

Through combustion test research, it was found that the two types of pellet fuels can continue to burn for about 30 minutes and burn for 40 minutes.

The fire continues to decrease, indicating that corn straw pellets release more heat when burning than pine and poplar pellets;

At the same time, the ash produced after burning corn straw pellets is more than that produced after burning pellets made of pine and poplar wood, and the more ash produced can be made into high-quality fertilizer after optimized treatment.

Therefore, from this aspect, corn straw pellets are better than pine and poplar pellets.

But it must be clear that wood pellets have particular natural and market advantages. Which type of pellet processing business to develop ultimately requires a comprehensive analysis of raw material channels, raw material prices, pellet prices, market prospects and other factors. (Maybe you are interested in our wood pellet mill)

Can corn straw pellet fuel be stored for a long time?

When the initial state is at safe moisture and a certain density, biomass pellet fuel can be safely stored for a long time regardless of the storage method.

At present, most biomass pellet fuels are stored in bags and accumulated in warehouses. Ventilation should be paid attention to during the storage process. In addition, there are also forms such as piles and silos.

In terms of durability, the best resistance to breakage is when corn pellets are stored in the open air, and the worst is when wood pellets are stored in the open air.

What are the main differences between corn straw pellets fuel and wood pellet fuel?

With the naked eye, straw pellet fuel has more surface cracks than wood pellet fuel, and the surface is rough and easy to break. Wood pellets are stronger and not easy to break.

The crack spacing of biomass pellet fuel made from corn straw material is larger than that of biomass pellet fuel made from wood chips, and the crack gaps are wider.

Therefore, straw pellets are easier to break than wood pellets. However, this is a problem that can be improved by adjusting the particle processing process.

The straw pellet fuel is in the shape of irregular scales, while the wood pellet fuel is layered with a convex center, and the granules are bent to both sides. The reason is that the particle size distribution of the wood pellets is more uniform than that of the crushed straw granules, with more than 80% granules with particle size less than 1mm, and the granules after compression molding are arranged more neatly.

Judging from the current situation of raw material crushing particle size, when the pressure is the same, the particle density of straw pellet fuel is slightly worse. If the density of straw pellet fuel is increased, the pressure required for straw will be greater than that of wood chips.

In the production process of using straw to produce biomass pellet fuel, fine powder should be carried out after the straw is coarsely pulverized to make the straw powder particle size smaller and make the particle size distribution more uniform, which can improve the molding quality of biomass pellet fuel, but the cost increases accordingly.

Can anti-slagging additives be used when using a corn stalk pellet machine?

Using corn straw as raw material to prepare pellet fuel, adding 3% MgCO³, CaCO³, and Al²O³ additives can effectively resist slagging. Among them, adding 3% MgCO₃ has the best anti-slagging effect, and the slagging rate is basically zero; adding 3% CaCO₃ additive has a slagging rate lower than 2.25%, and the anti-slagging effect is significant. Adding 3% Al₂O₃ has a slagging rate The rate is 11.56%, and the anti-slagging effect is good.

Cost analysis and application prospects:

- When considering the large-scale promotion of anti-slagging additives, the cost of addition needs to be considered. According to the current average market price, an addition ratio of 3% can be obtained based on economic comparison. From high to low, MgCO₃>Al2O₃>CaCO₃. The lowest cost increase per ton of corn straw pellet fuel additives is CaCO₃, but its anti-slagging effect is slightly worse than MgCO₃;

- Although MgCO₃ has the best anti-slagging effect, its cost is too high and is not suitable for large-scale production and application. Therefore, the most cost-effective additive to resist slagging is CaCO₃.

Additives are added to straw pellet fuel to reduce the slagging of the fuel during combustion in the boiler, or the ash to become loose and brittle. This makes the ash easy to clean, thereby achieving the purpose of improving heat transfer efficiency and saving energy.

The use of anti-slagging additives does not affect the characteristics of the molded fuel, does not affect the normal operation of the boiler, does not change the main operating parameters, and does not cause corrosion and other hazards to the equipment. There is a large gap in the development market and broad application prospects.

Start your corn stalk pellet production business

As a clean and renewable energy source, corn straw pellet fuel has good environmental protection and energy-saving effects. It can effectively alleviate the shortage of petrochemical resources, promote the development of agricultural circular economy, and improve the urban ecological environment. It has broad development and application prospects.

RICHI corn stalk pellet machine technology makes full use of the binding properties of lignin to compress corn straw into granular pellet fuel. Designing, manufacturing and promoting corn straw forming technology and equipment can improve the utilization rate of corn straw resources and is of great significance in promoting the development of agricultural economy.

If you also want to get involved in the field of straw pellet processing, whether it is processing pellet fuel, pellet feed, pellet organic fertilizer or other special pellet types, you are welcome to contact Richi Machinery directly, and our professional technical consultants will send you detailed corn stalk pellet machine and corn stalk pellet plant quotations, operation videos, and project pictures.