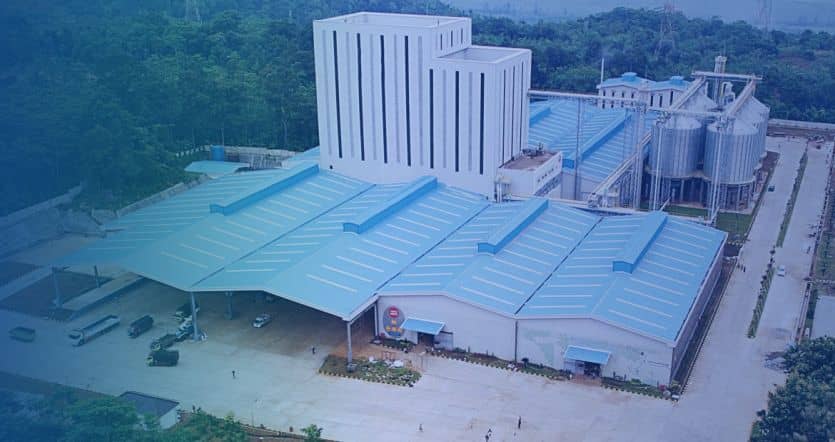

PELLETIZING PLANT APPLICATION

Tailor-made all kinds of complete sets of pelletizing plant solutions to meet the different pellet application.

PELLET PLANT videos

With the increasing prosperity of industries such as feed, biomass, fertilizer, cat litter, urban waste recycling, the trend of intelligence is becoming more and more obvious, which requires RICHI to provide more comprehensive and systematic solutions.

CHOOSE YOUR PELLET PLANT APPLICATION

Whether you are choosing the right development direction or looking for new opportunities, we can always help you.

Wood Pellet Production Line

In the field of wood pellet production, our wood pellet production line solutions are trusted by countless customers around the world. RICHI is one step ahead in the sector by designing wood pellet production line, which is the core of the wood pelleting plant construction project. Wood (pine, larch, fir, oak, etc. ), wood chips, sawdust, hull, tree branches, tree leaves and similar forest residues are used as materials. Need to know more? We are ready to advise you on how to design the most optimal pelleting line for your wood pellet manfuacturing plant.

You will benefit from exposure to the latest RICHI technologies and a deep understanding of the value chain. Personalized small wood pellet plant solutions will help you increase overall productivity.

We are committed to providing you with reliable support for the rapid implementation of 1-2t/h wood pellet line project construction. You’ll benefit from our extensive experience.

Our comprehensive estimation of the performance of your target complete wood pellet plant and its value chain allows us to identify and quantify the best construction options.

Our goal is to analyze your needs, provide multiple design solutions, and implement the best sustainable wood pellet plant solutions to meet the needs of efficient wood pelletizing.

Working with experienced RICHI experts, we can quickly recommend long-term wood pellet processing equipment solutions to help you achieve a consistently reliable and stable process.

We help you complete the construction of the entire wood pellet processing plant and understand the operation and performance status of the complete set of wood pellet equipment.

We hope to help you achieve your goals. Whether it is discovering new opportunities, stabilizing or improving the 6-7 t/h wood pellet production process, your success is our goal!

We aim to be your close partner, proactively supporting your production operations and designing, maintaining and optimizing your wood pellet line equipment and processes.

Our 8-10 t/h wood pellet manufacturing equipment could meet the needs of different market segments. Improve the operation rate and enhance output to bring you a worry-free operating experience.

From design of 12-15 t/h wood pellet factory process plan to the installation and commissioning of the equipment, will incorporate our concepts of automation and standardization.

We provide comprehensive solutions in wood pellet manufacturing plant layout design, engineering design, machinery manufacturing, factory construction and automation control systems.

RICHI adopts advanced design concepts and technologies, has a senior design elite team, skilled construction team and rich experience in 20-30t/h commercia pellet mill plant engineering project.

biomass Pellet Production Line

RICHI aims to minimize operating costs and maximize quality with the biomass pellet production line equipment, which has a long-lasting and more rigid structure, specially designed for biomass pelleting. Trees, wood, chips, sawdust, bark, branches, leaves and similar wood residues, straw, grass, stems, hull-sheath, fruit seeds, paper-cardboard, residue and garbage, industrial wastes can be used as materials. (Pellets can be produced from a single product or by mixing several products ).

straw pellet plant (for fuel)

1-90T/H straw pellet plant from RICHI Machinery, used for making environmentally friendly biomass fuel cereal straw pellets or quality bedding for animal horse, rabbit, pig, etc.

solution.jpg)

straw pellet production line (for feed)

RICHI straw feed pellet production line is one of our main feed type pellet system. Tailor-made complete straw pellet equipment solutions for cattle, cow, horse, goat, etc.

Lucerne /alfalfa pellet production line is a grass feed system that uses fresh alfalfa, dry alfalfa and alfalfa powder to process grass-containing feed for cattle, sheep, horse, deer, and rabbit, etc.

For different needs, RICHI can design fuel type rice husk pellet plant and feed type rice husk pellet plant solution for customers. For different needs. These are the most mainstream applications currently.

EFB pellet production line / PKS pellet plant is used to make palm waste pellets, provides alternative renewable energy solution for shortage of wood based pellet. The most common end products are EFB pellets and PKS pellets.

Bamboo pellet production line is used for processing bamboo fuel. Its applicable raw materials mainly include bamboo wood, bamboo leaves, stalks and recycling of bamboo powders after production of bamboo products.

For making bagasse into fuel, or animal feed, bagasse pellet plant and bagasse pellet machine are required. With RICHI sugarcane bagasse pelletizing solution and make a giant profit. Start making your own pellets now !

Peanut shell pellet production line is a kind of pelletizing unit that compresses peanut shells into animal feed or biofuel. This application is especially suitable for customers from countries with a lot of peanut cultivation.

Hay pellet production line is used to process various types and forms of hay such as timothy hay, alfalfa hay pellets, teff grass hay, orchard grass hay, oat hay, etc. into pellets, for feeding ruminants, cattle, sheep, horses, rabbits and other herbivorous animals.

Grass pellet production line is mainly used to process timothy pellets, alfalfa pellets, orchard grass pellets, teff pellets, hay pellets, miscanthus pellets, wheatgrass pellets, etc. We can also provide solutions for grass fuel pellet production lines.

Raw materials suitable for miscanthus pellet production line include miscanthus grass, maiden grass, chinese silver grass, japanese silver grass, giant miscanthus, etc. Pellets from the system are divided into fuel pellets and feed pellets.

hemp pellet plant

Hemp pellet production line is mainly used to process hemp feed pellets suitable for herbivore animals and herbivore pets. Based on the restrictions on the hemp uses, a few customers are studying the prospects of hemp fuel pellet processing.

RICHI plays a pioneering role in the biomass pelletizing industry with its experience in corn stalk pellet production line. If you are looking for equipment and solutions for processing corn stalk pellets, corn fuel pellets, corn straw feed pellets, this is what you are looking for.

If your raw materials are paddy straw, dry rice straw, rice flour straw, rice hay, you can press them into pellets with our rice straw pellet production line, for processing cattle, sheep, and horse feed, or you can process them into fuel pellets or organic fertilizer pellets.

Wheat straw pellet production line usually uses wheat stalk, reusable wheat straw, wheat straw hay, chopped wheat straw, chopped wheat straw, baled wheat, dry wheat straw, green wheat stalk, grain straw as raw materials to process cattle, sheep and horse pellet feed or pellet fuel.

If you want to process cotton pellets, cotton stalk pellets for biofuel or animal feed, cotton pellet production line is currently the most ideal choice. Applicable raw materials include raw cotton stalks, dried cotton stalks, cotton boll floral stem, cotton flower stems, cotton branches, etc.

animal feed production line

Animal feed production line solution can create the perfect animal feed is essential, tailored to the specific needs of different livestock poultry pet at various stages of their lives. RICHI Machinery has years of experience in high-quality engineering of animal feed production line solutions for the feed production market within feed machine for both livestock, poultry and pet. We have customers in numerous countries around the world and are a reliable partner no matter the scale of the animal feed plant.

RICHI has many years of experience in designing and building cattle feed plants all over the world for commercial feed company or poultry farms. Our solutions and equipment cover the processing of chicken feed, duck feed, goose feed, quail feed and other poultry feeds.

Customizable design for the whole cattle feed mill, suitable for both beef cattle and dairy cow feed production. Our solutions are extensive. In addition to the processing of conventional grain cattle pellet feed, we can also process grass-containing feed, fermented feed, and cattle mixing feed.

RICHI manufactures and sells top quality custom livestock feed plant and machines for all cattle, sheep, rabbit, pig, horse, camel species. A detailed analysis of your goals is the basis for a tailor-made, future-proof stock feed mill solution adjusted to your specific requirements.

Your entire process is covered from start to finish, and our rock-solid pet food machine lets you operate your pet feed mill at the lowest possible cost. A detailed analysis of your goals is the basis for a tailor-made, future-proof solution adjusted to your specific requirements.

Richi Machinery is a highly recommended company involved in the manufacturing of the swine feed machines in the industry. We specialize in designing and constructing complete pig feed production line.

By providing customers with value-for-money services, we will enable each customer to achieve maximum use value for their broiler feed machine and broiler feed production lines.

We manufacture hen feed mills ( feed plant and machinery ) both in Mash & Pellet. We design, construct and install the whole plant, and provide full life cycle after-sales service for your project.

RICHI supplies premix feed mill equipment to premix producers in a six-state area. We are committed to providing high quality, high efficiency premix feed plant system and whole plant construction plan.

dog food production line

Dog food production line is factory construction solution for manufacturing pet food. This solution contains all the technology needed in the extrusion process, from the intake all the way through to the bagging of the ready dog feed.

cat food production line

Cat feed mill is designed to produce extruded dry cat food in wide diversification in physical properties, shape and density to feed various cat species. Our cat food machines are manufactured in strict accordance with our process to ensure quality.

RICHI compound feed mill plant has wide capacity scope: 1-160 t/h. It is suit for the production of various compound animal feed such as chicken, cattle, fish, pig, shrimp, sheep, poultry, rabbit, etc, also suit for pet food.

mash feed plant

Mash feed mill is suitable for produce powder feed for laying hens, pig feed and fish, etc. It’s made up from modules combined with focus on simplicity in operation, energy efficiency, flexibility in processes and high controllability.

fish feed Production Line

A fish feed production project from RICHI is a complete aqua feed plant construction solution were we start by converting your requirements and needs into a project specification. The first step to ensure a successful RICHI aqua feed production line solution is an analysis focusing on the customer’s needs and future goals. RICHI delivers a total fish shrimp feed mill solution with analysis, design and installation to help you all the way from idea to delivery of the finished project.

1.5-2 T/H fish feed processing line adopts advanced aqua feed technology and is divided into low, medium, high and other design schemes.

3-4 T/H floating fish feed production line is mainly used for extruded feed pellets production in compound aqua feed factories.

4-5T/H floating fish feed plant is widely used in many countries of the world and can be used for the processing of floating fish feed, pet food and other extruded feed.

RICHI focus on 6-7 fish feed plant solutions. We are committed to providing stable and reliable fish feed equipment and engineering to the global client.

Every 8-10 t/h aqua fish feed mill plant project undertaken by RICHI is a prototype project, which has a comprehensive competitive advantage over its peers.

Strong R&D team and innovative technical concepts, three-dimensional digital 10-12 t/h aqua fish feed factory design, precise planning, and one-step implementation.

12-14 T/H fish feed manufacturing plant configuration is carefully designed according to the on-site investigation situation or the actual requirements of customers.

16-20T/H fish food factory can process fish feed and pet food, and can also be upgraded to a combined feed mill for shrimp, livestock and poultry premix and other feed products at the same time.

organic fertilizer Production Line

RICHI offers process solutions to those organic fertilizer production line and organic fertilizer making machines that turn waste into a cost-effective raw material containing beneficial components for plants. The composted wastes are passed through the dryer and sterilizer, and purified from all harmful bacteria, fungi etc. In addition to its use as natural fertilizers, organic fertilizers are also used be produced by pelleting, which also provides transportation and storage advantages.

chicken manure pellet production line

We are experts in chicken litter making machines, providing not only complete sets of chicken manure fertilizer machines but also complementary chicken manure pellet plant services.

horse manure pellet production line

Our horse manure pellet plant can improve your fertilizer or fuel pellet production efficiency & product quality, ensure efficient operation and create value for customers.

cow dung pellet production line

Cattle dung pellet plant is newly designed and developed to make manure into organic fertilizer for increasing of soil fertility. It can also be used for the processing of cow manure fuel pellets.

pig manure pellet production line

Welcome to consult the price of pig manure fertilizer pellet production line, equipment model, drawings, processing flow, delivery, installation and other information.

special Pellet Production Line

This special pellet production line solution is suitable for processing known special raw materials (e.g. waste paper, waste tires, plastics) and granules for special purposes (e.g. cat litter, rat poison, air purification). Our solution is state-of-the-art equipment for pellet plants, with our own in-house research and development department ensuring solutions suitable for your specific needs. In RICHI Machinery, you will find a partner with more than 30 years of experience, which means we have the knowledge to find the best possible solution for you.

tofu cat litter pellet plant

Tofu cat litter pellet line is used to produce cat litter, which is made from soybean byproduct, is an eco-friendly, clay-alternative that absorbs odors in a cat’s litter box. It’s the best choice for cat litter business.

Bentonite clay creates a clumping pet litter that is convenient for cat owners. We offer a range of bentonite cat litter production line solutions that cater to customers in many markets.

After years of painstaking design and improvement of multi-series paper pellet production line equipment, it is suitable for various paper pellet production and has stable performance.

Fuel pellet production line is specially used to process biofuel pellets. All agricultural and forestry wastes or other special raw materials with a certain calorific value are suitable for this solution.

Coco peat pellet production line is a system for processing compressed coco coir. The pellets are mainly used as fertilizer or fuel. Suitable raw materials include coco coir, coir peat, coco pith, coconut coir fiber, coco fiber, coconut husk, etc.

Cassava pellets remain the most well known commodity of cassava origin. Building a cassava pellet production line is equivalent to building an animal feed plant. At RICHI, we believe in co-creating the perfect fit for your cassava feed mill plant needs.

Hop pellets processed by hop pellet production line can be used for both brewing and feed purposes. With a legacy of innovation, we collaborate closely with you to understand your unique challenges and goals (such as cryogenic granulation of hops).

waste tires pellet plant

All kinds of waste tires and rubber raw materials can increase their economic value through this waste tire pellet production line. Our team combines expertise with your insights to tailor solutions that seamlessly align with your operations.

RICHI News

Here you can find the latest RICHI pellet plant project news in various countries around the world.

- Cattle Feed Production Line Equipment “Expedition” To The United States

- Brazil 5 T/H Wood Pellet Production Line Shipped

- South Africa 30 T/H Feed Mill Project Is Under Construction

- 50 T/H Feed Processing Plant Project Started Construction In Vietnam

- Brazil 10 T/H Straw Pellet Production Line Put Into Operation

- Malaysia 5-6 T/H Wood Pellet Production Line Project Put Into Operation

- Algeria 100,000 T/A Livestock Feed Project Put Into Operation

Business Guidance

Here you can find equipment prices, production line costs, industry trends and other information

CUSTOMER SERVICE

By implementing the highest service standards in the industry, we will achieve the highest level of customer satisfaction.

customer consultation

We want to have a deep understanding of your industrial process, to know your exact needs of feed, wood, biomass, fertilizer, cat litter, rubber, plastic or other pellet processing.

pellet plant design

Based on your unique situation and industrial process, we will tailor complete pellet plant you need, and inform you of every detail that could facilitate operation, minimize total cost.

equipment manufacturing

The critical components of the of pellet plant equipment are built in our own workshops. Additional equipment is manufactured by our worldwide network of reliable partners.

equipment testing

We can provide customers with testing services from a single machine to a complete pellet plant system, and provide you with real actual data for “worry-free use.”

equipment delivery

In equipment packaging section, we adopt professional packaging and modular solutions to ensure the safe and non-destructive delivery of pellet plant equipment.

Project construction

Carry out civil & electric engineering,reasonable equipment layout. We are able to shorten the construction period, reduce cost and improve overall benefit of the project.

installation & commissioning

Whether you choose your own subcontractor for the erection phase or you want to install everything together with us, a Richi supervisor will be around to make sure everything is mounted in a safe and thorough way.

staff training

We provide comprehensive training for the technicians and operators of each pellet production line project. We can also continue to provide support for the technicians during latter project and machine operation.

project follow-up

When everything is up and running our Richiers will help you further whenever needed. We are ready to answer your call 24/7. We’ll also visit your pellet production plant regularly to learn about your needs.

1

Can You Provide Pellet Production line Turnkey Service ?

We offer a complete turnkey pellet processing plant service including project consultation, site survey, sample analysis to plan design, manufacturing, delivery, installation and commissioning, and maintenance guidance to ensure that all links are in place with customers in a timely manner solve customer needs.

2

Are You A Manufacturer or trading company?

We are pellet production line equipment manufacturer, not a middleman. All pellet plant equipment prices are ex-factory prices.

3

Can all kinds of biomass raw materials be processed with a set of biomass pellet production lines?

If the biomass pellets are used for the same purpose and have similar physical and chemical properties, then a biomass pellet plant can be used to process mixed pellets of these raw materials.

4

I want to process wood pellets and feed pellets at the same time. Do I need to build two pellet production lines?

Yes. Because the wood pellet production line and the feed pellet production line are two completely different process types. The process design, equipment configuration and granulation system used are different. Since the uses of pellets are also different, most common equipment cannot be shared. However, if there are customized requirements, equipment such as packaging scales can be designed as shared equipment.

5

What process technology does your aquatic feed production line use?

Our aquatic feed production line can usually adopt two kinds of extrusion process and pelleting process. The extrusion technology can be used to produce all types of aquatic feed, but due to investment cost and budget reasons, this process is mainly used for the processing of floating fish and ornamental fish feed. Many customers still use the pelleting process when processing sunken fish feed and shrimp feed. Our craftsmanship is customized according to customer needs, and everything is based on customer needs.