Cattle Feed Pellet Machine

The cattle feed pellet machine is widely used in cattle feed plant, and is suitable for granulation processing of grass powder, molasses pre-addition, calves and complete compound feed at various stages, crude fiber, and concentrated feed. Differentiated configuration and personalized customization can be carried out according to user needs to achieve high-quality production.

The machine repertoire for the compound feed sector currently comprises more than 10 types of cattle feed pellet mills with different sizes that meet our customers’ requirements.

We have lots of experience with supplying and installing pellet plants all over the world, and we can supply cattle feed pelleting machines in different sizes. The capacity varies from 1 to 48 tons/hour.

Features of cattle feed pellet machine

- Precise system-wide moisture control and effective use of steam (measured steam utilization rate > 92%) ensure the quality and productivity of the granulation system;

- The application of forced feeding technology and special pressure roller configuration ensures the high hardness requirements of ruminant pellets;

- High-strength ring die design, the power per unit area is increased by 15%, and the quality of pellets is further improved;

- Regional and seasonal adjustments are made according to formula and production mode to ensure efficient production of ruminant feed;

- The steam shaft end of the conditioner is added internally, without overflow and diffusion, and all contact and absorb with the material;

- External liquid addition system, auxiliary configuration of molasses and second fluid addition technology, to meet different needs of liquid addition;

- The application of automation such as automatic lubrication and electric lifting greatly reduces labor costs and improves production efficiency;

- The application of forced feeding technology and special pressing roller configuration enables smooth pressing of low bulk density and complex materials;

- Achieve an output of 1-48T/H per hour (10%-100% grass powder addition), and increase efficiency by 15%-20%;

- Ring dies and pressure rollers are the major expense of the granulator loss, which exceeds 50% of the loss cost of the granulation system;

- The use of special ring dies and pressure rollers for ruminant reduces the frequency of replacement, which can save you hundreds of thousands of dollars a year;

- The use of wear-resistant paddles and scrapers for ruminant forage formula reduces the frequency of replacement and reduces operating costs. The overall operating cost can be reduced by more than 10%. (Maybe you are interested in starting an animal feed mill plant)

A number of adjustments and innovations have been made in core pelletizing systems and functions, from the whole to the details, fully demonstrating Richi Machinery’s strong manufacturing capabilities and skilled craftsmanship.

If you want to know about the cattle feed pelleting machine with high efficiency, high output, high quality and more stability, please click the button below for details. You can also specify your requirements for tailored services (optional).

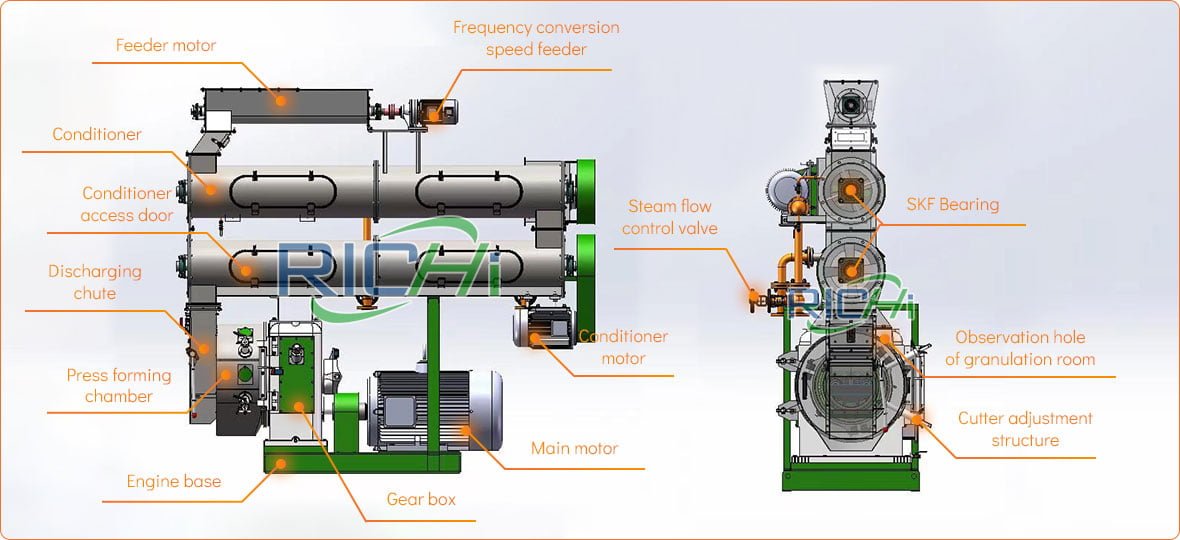

Working principle of cattle feed pellet machine

The ring die cattle pellet mill is one of the key main equipments in the pellet feed production line. The feed from the powder state to the pellet formation needs to be completed through four areas:

- The material is conveyed into the modulator through the speed-regulating feeding auger. In order to obtain a good granulation benefit (increase the output and quality), after adding hot steam for conditioning, the chute-shaped feeding pipe passes through the ring die cover, With the help of gravity and the centrifugal force generated by the rotation of the ring die, the material is tightly attached to the ring die cover and the inner wall of the mold (feeding area).

- Under the action of the shifting knife, the material is fed evenly and continuously, and the wedge-shaped space (pressing area) formed by each pressing roller and the ring die.

- Because the gap between the working surface of the outer wall of the pressure roller and the working surface of the inner diameter of the ring die is only 0.1-0.3mm, and this gap is basically horizontal, a certain extrusion force (extrusion zone) is formed.

- Due to the feeding of the material, under the strong extrusion between the die and the roller, the material is compacted, extruded into the die hole, and formed into a (forming area) in the die hole.

The material is continuously fed into the pressing zone, then extruded into shape, continuously extruded from the die hole, and cut into various required particle lengths by a cutter with an adjustable distance between the knife edge and the outer wall of the ring die. (Related product: poultry feed pellet making machine)

Model And Parameters of cattle feed pellet machine

SZLH250 cattle Feed Pellets Machine

| Capacity(T/H) | 1.5-2.5 |

| Main Motor Power(kw) | 22 |

| Feeder Motor Power(kw) | 0.75 |

| Conditioner Power(kw) | 1.5 |

| Dia.of Ring Die(mm) | 250 |

| Transmission form | Belt drive |

SZLH320 cattle Feed Pellets Machine

| Capacity(T/H) | 4-5 |

| Main Motor Power(kw) | 37 |

| Feeder Motor Power(kw) | 1.5 |

| Conditioner Power(kw) | 2.2 |

| Dia.of Ring Die(mm) | 320 |

| Transmission form | Gear drive |

SZLH350 cattle Feed Pellet Machine

| Capacity(T/H) | 6-8 |

| Main Motor Power(kw) | 55 |

| Feeder Motor Power(kw) | 1.5 |

| Conditioner Power(kw) | 3 |

| Dia.of Ring Die(mm) | 350 |

| Transmission form | Gear drive |

SZLH420 cattle Feed Making Machine

| Capacity(T/H) | 10-13 |

| Main Motor Power(kw) | 110 |

| Feeder Motor Power(kw) | 1.5 |

| Conditioner Power(kw) | 7.5 |

| Dia.of Ring Die(mm) | 420 |

| Transmission form | Gear drive |

SZLH508 cattle Feed Pellet Machine

| Capacity(T/H) | 12-18 |

| Main Motor Power(kw) | 160 |

| Feeder Motor Power(kw) | 2.2 |

| Conditioner Power(kw) | 11 |

| Dia.of Ring Die(mm) | 508 |

| Transmission form | Gear drive |

SZLH558 cattle Pellet Making Machine

| Capacity(T/H) | 22-28 |

| Main Motor Power(kw) | 180/20 |

| Feeder Motor Power(kw) | 2.2 |

| Conditioner Power(kw) | 11 |

| Dia.of Ring Die(mm) | 558 |

| Transmission form | Gear driveve |

SZLH678 cattle Feed Pellet Making Machine

| Capacity(T/H) | 28-32 |

| Main Motor Power(kw) | 220/250 |

| Feeder Motor Power(kw) | 2.2 |

| Conditioner Power(kw) | 11 |

| Dia.of Ring Die(mm) | 678 |

| Transmission form | Gear drive |

SZLH768 cattle Feed Pellet Processing Machine

| Capacity(T/H) | 32-38 |

| Main Motor Power(kw) | 280/315 |

| Feeder Motor Power(kw) | 2.2 |

| Conditioner Power(kw) | 11 |

| Dia.of Ring Die(mm) | 768 |

| Transmission form | Gear drive |

SZLH858 cattle Feed Pellet Making Machine

| Capacity(T/H) | 42-48 |

| Main Motor Power(kw) | 280/315 |

| Feeder Motor Power(kw) | 2.2 |

| Conditioner Power(kw) | 15 |

| Dia.of Ring Die(mm) | 858 |

| Transmission form | Gear drive |

Customizable Design:

Richi Machinery can customize the cattle pellet machine according to the actual needs of customers, including voltage, electrical components, door opening method, product color matching, and can also customize different conditioners, conditioner layers according to customer cattle feed formulas and poultry feed making process, etc.

| Conditioner layers | one or two layers |

| Ring Die Compression Ratio | 1:6:1:9 |

| Requirements Before Entering Pellet Machine(mm) | 3.0-5.0 |

| Number of pressing rollers | 2 |

| Final Pellet(mm) | 6~12 |

| Pellet Length(mm) | 12-18 |

Cases Of cattle Feed Pellet Machine

Cattle pellet Feed Machine in india

Cattle Feed making Machine in USA

Cattle Feed pellet Mill in Canada

Cattle Feed Machine in South Africa

Cattle pellet Machine in Indonesia

Cattle Feeds Machine in Russia

Requirements for cattle feed pellet machine operation

—— RICHI MACHINERY ——

If the gap between the roller molds is too small, the die and the pressure roller are easy to wear, and the super noise is large; if the gap is too large, the extrusion of the material will be affected. Generally controlled at 0.05~0.30 mm. Feeler gauge can be used for adjustment, and visual inspection without feeler gauge is also possible.

Taking the new mold and new roller as an example, when there is no material, it is better not to drive the pressure roller when the main engine rotates the die. In particular, it is emphasized that the new mold should be equipped with a new roller, and the gap should be smaller. In addition, the pressure roller should be filled with enough butter to avoid burning out the bearing due to excessive temperature.

At the same time, it is necessary to adjust the feeding scraper, otherwise it will be difficult for the material to enter between the pressing roller and the die, and some materials will be strung out from the die cover to form high-powdered pellets.

The adjustment result should be that the gap between the upper edge curve of the scraper and the die and the die cover is basically controlled at 2-3mm, and the position where the front end of the scraper extends into the die should not exceed the sinking groove of the inner hole of the die.

After all parts of the cattle feed pellet machine are adjusted, the granulation can be turned on. Open the cattle feed granulator, conditioner and feeder first, and the feeder should be in the feeding state at this time. In order to prevent the debris in the machine from entering the die, the discharge door outside the machine on the operation door should be opened to discharge the material mixed with impurities in the machine. After the miscellaneous materials are cleaned, the materials can be introduced into the die.

For the sake of prudence, you should hold the handle of the discharge door outside the machine with your hand, let part of the material enter the die first, and then observe whether there are particles coming out of the die smoothly, and pay attention to the change of current at the same time.

If the pellets can be produced normally, the current is relatively stable, the fluctuation range is not large, and the rated current is not reached, then the material flow can be increased and the steam volume can be increased at the same time. (Maybe you are interested in 5-20t/h cattle feed manufacturing plant cost)

Requirements for Ring Die of Cattle Feed Pellet Machine

Whether the material can be extruded through the die during the granulation process depends on the pressure and friction that can be generated in the die hole. This is related to the coefficient of friction between the material and the wall of the die, the moisture content, the particle size of the raw material, the temperature, the buffer time of the plastic deformation part of the material, and the compressibility of the material. These characteristics are closely related to the depth and diameter of the die hole.

Generally speaking, the compression ratio of the die aperture should be 1:8~13. If the compression ratio of the die is small, the effective length of the die hole is short, the pressure formed by the material in the die hole is small, and it is easy to extrude the ring die. (Related product: rabbit pellet making machine)

At this time, the output is high, but the produced particles are loose and have a high powder content. The appearance is not smooth; on the contrary, the longer the effective length of the compression hole, the greater the pressure of the material in the die hole, and the correspondingly produced granules have high compactness and smooth quality, which can reduce the powder content, but the output of the cattle feed pellet machine will decrease.

Of course, the power consumption per ton also increases accordingly. Therefore, when feed manufacturers produce pellets of different specifications and varieties, the aperture ratio of the ring die selected will be different.

Service For Cattle Pellet Feed Machine

By providing value-added services to customers, Richi Machinery will maximize the value of each customer’s equipment. By implementing the highest service standards in the industry, Richi Machinery will achieve the highest customer satisfaction.

- Installation time:

3-15 days - The longest working time in a row:

24 hours (The specific situation is mainly based on the actual working conditions on site, and the data will fluctuate.) - Wear parts life:

Special or patented technology improves the life of wear parts, shortens the replacement time of wear parts, and ensures that the economic interests of customers are not damaged. - Degree of electrical automation:

It can be operated unmanned on site, operated by few people on duty, can be monitored remotely, and can be inspected and tracked. - Safety factor:

Equipped with real-time monitoring system, equipped with temperature, flow, pressure and other sensors, overload automatic alarm to ensure stable operation of cattle feed pellet machine. - Technical training:

Engineers go to the project site for on-site training (during the global epidemic, all technical training will be conducted online) - After-sales service:

Commitment to give clear solutions and solve problems within “24” hours, and solve product failures within “36” hours. - Return visit service:

Regular customer return visits, on-site visits or online return visits (for reasons of the epidemic, mainly telephone visits and online return visits). (Maybe you are interested in feed mill plant in Uzbekistan )

When we say that RICHI cattle feed mill equipment are built to endure, we’re really talking about service. RICHI cattle feed pellet machine and related feed equipment is intentionally designed to be easily and efficiently serviced, with features such as wide compartment doors and ground level access to make maintenance more efficient. Because ease of service means back in service.