Livestock Feed Production Line solution

Livestock feed production line is a feed manufacturing system used to process different types of cattle feed, sheep feed, pig feed, rabbit feed, horse feed, camel feed, mule feed, deer feed and other livestock animal feed.

According to different livestock feed product needs, the livestock feed line can process products of different forms such as pellet feed, mash feed, premix feed, etc. Livestock feed processing line can also be called livestock feed mill and livestock feed plant.

- Capacity: 1-160T/H

- Price: 10,000-5,000,000 USD

- Feed Type: livestock pellet feed, livestock mash feed, livestock premix feed

- Suitable stock type: Cows, sheep, pigs, rabbits, horses, deer and camels in different growth stages

- Applicable customers: livestock feed processors and livestock farms, livestock feed industry investors

RICHI Machinery is a high-tech enterprise specializing in feed machinery engineering, forage machinery, storage equipment engineering, and automation control. We can provide global feed processors with various high-quality feed production stand-alone equipment and accessories such as crushing, mixing, pelleting, cooling, crushing, grading, and quantitative packaging.

Specializing in undertaking various types of complete set livestock feed production line design, production and manufacturing, installation, commissioning, old feed mill renovation and other services.

Types of livestock feed production line

According to the type of feed products, we can provide customers with livestock feed production lines including the following:

- Single livestock feed production line (only processing cattle, sheep, rabbits, pigs and other livestock feed)

- Poultry and livestock feed composite production line (one production line can be used to produce feed for chickens, ducks, cattle, sheep, etc. at the same time)

- Aquatic products and livestock feed composite production line (one production line can be used to produce fish, shrimp feed and livestock feed at the same time)

- Premix and livestock feed composite livestock feeds production line (one production line can be used to produce premix and livestock feed at the same time)

goat feed production line

rabbit feed production line

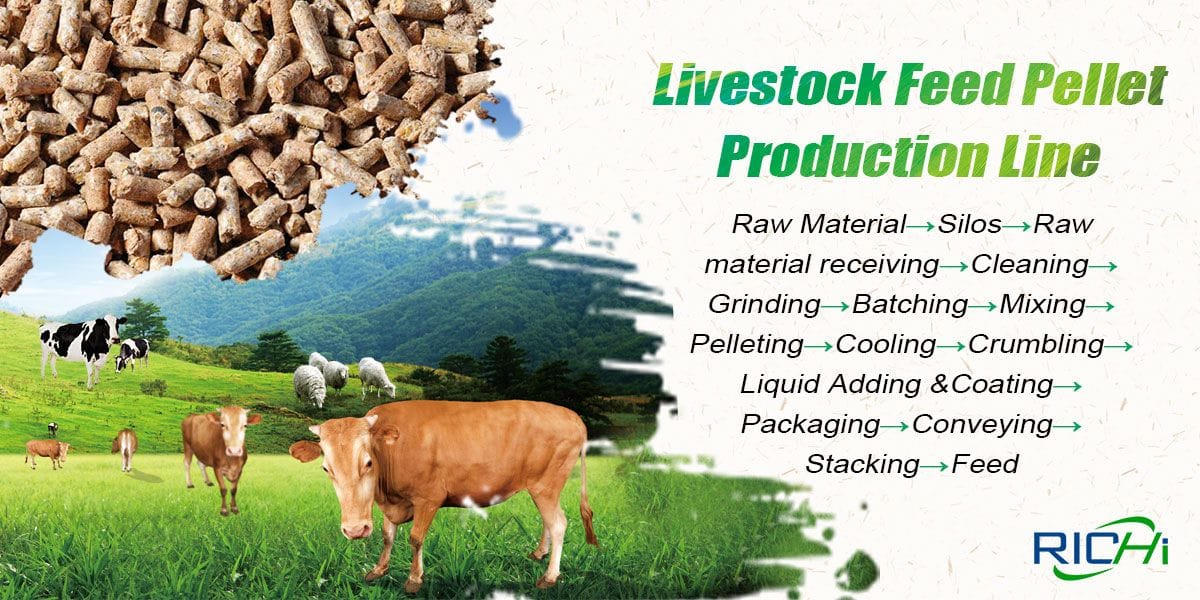

How to make livestock feed? ——livestock feed production line process

01 Receipt of raw materials

In the actual livestock feed production process, feed contains a lot of content, so most of the raw materials are collected in bulk. Therefore, during the transportation and storage of these raw materials, corresponding requirements must be met to prevent The impact of raw material quality on feed.

(Livestock feed ingredients: soybeans, soybean meal, corn, fish meal, amino acids, mixed meal, additives, whey powder, oil, meat and bone meal, and may also add alfalfa, timothy grass, hay and other grass raw materials.)

02 Cleaning of raw materials

During the use of raw materials, they need to be cleaned, which is an important step in improving livestock feed quality and increasing the quality of feed processing technology. At present, magnetic separation equipment is mainly used to remove iron from the raw materials.

At the same time, a screening process is also required to prevent stones, stones, and large debris from affecting the livestock feed machinery and livestock.

03 Raw material crushing

After completing the cleaning of raw materials, the most important step in production of livestock feed is crushing. This is an important step to allow the feed to be processed into the required shape. In specific operations, the degree of crushing of livestock feed raw materials will be selected according to different needs.

04 Ingredients process

The batching process is an important part of livestock feed manufacturing. Scientific batching according to needs can give the feed greater nutritional value. There are currently three main ways of batching, manual batching, automatic batching, and micro-weighing batching. The three ingredients methods have corresponding usage space.

05 Mixing process

After completing the batching of raw materials, the raw materials need to be mixed, which is an important link to ensure the quality of various feed processing.

Especially in the production of premixes, this section has extremely high demands for ensuring the quality of premixes. Complying with this method will promote the development of mixing technology.

Generally speaking, in the mixing process, the order of feeding is very important, mainly the carrier and trace elements. The homogenization of the carrier and trace elements in the mixing can ensure that the working quality of the equipment is improved.

06 Granulation process

This process is the final step of the finished product, which determines the appearance and use of the feed. In the pelleting process, the steam engine is mainly used to make the powdered feed moist and stand up, and then the pelleting operation is performed.

07 Cooling section

The moisture content of the granulated feed is as high as 16% to 18%, and the temperature is as high as about 80%. It is prone to mildew, breakage and deformation during storage and requires cooling. Using a counter-flow cooler, the temperature of the cooled material can be monitored in real time, and the cooling air network is optimized to ensure the predetermined cooling effect.

08 Screening section

After the pellet feed is crumbled, some powder clumps and other unqualified pellets will be produced. Therefore, the crumbled pellet feed needs to be screened into products with neat pellets and uniform size. According to customer needs, one-layer, two-layer, and three-layer screen structures can be selected to make the finished particles meet customer and market needs.

09 Packaging and storage

The packaging and warehousing process is the last step in feed processing. Operation according to the prescribed processing technology and reasonable quality control are important links in livestock feed quality control.

According to different finished feed, automatic packaging scales of different specifications are selected for accurate measurement, fast and efficient, and a mechanical palletizing system can be optionally configured, which greatly improves the degree of automation and saves costs for customers.

How to process livestock feed? According to the different product needs of different customers, our livestock feed production line designs may be different. The above livestock feed production process can process pellet feed, powdered feed, and premix. When processing powdered feed and premix, only steps 1 to 5 are required.

Automatic Livestock feed machinery for livestock feed production line

livestock Feed Grinder machine

Used in livestock feed grain materials crushing section.

Capacity:

3-25 T/H

Main Power:

30-160 KW

livestock Feed Mixer machine

Used in livestock feed raw materials mixing section.

Capacity:

250-2000 KG

Main Power:

4-55 KW

Bale breaker

For grass-containing livestock feed production.

Capacity:

1-20 T/H

Main Power:

30-90 KW

Grass crusher

For grass-containing livestock feed production.

Capacity:

0.3-3 T/H

Main Power:

22-93 KW

livestock Feed Pellet machine

Used in livestock feed raw materials pelleting section.

Capacity:

1-48 T/H

Main Power:

22-315 KW

livestock Feed Extruder

Used in extruded livestock feed production process.

Capacity:

1-12 T/H

Main Power:

0.75-355 KW

Pellet Cooler Machine

Used in livestock feed pellet cooling section.

Capacity:

3-25 T/H

Main Power:

30-160 KW

vibrating screening machine

Used in livestock feed pellet grading section.

Capacity:

3-20 T/h

Main Power:

1.5-5.5 KW

Automatic Bagging Machine

Used in livestock feed pellet packing section.

Capacity:

6-12 Bags/Min

Main Power:

1.1-5 KW

grass dryer machine

Used in the drying section of grass-containing livestock feed.

Capacity:

Customizable

Rotate speed

3-8 R/Min

pellet crumbler machine

Used to reduce the particle size of finished pellets.

Capacity:

2-20 T/H

Roller:

2-3

Storage Silos

Used in storage section for livestock feed raw materials.

Capacity:

10-10000 Ton

Application:

Store Grain

livestock feed production line projects

In the past 30 years, RICHI has won the trust of customers with its excellent quality, superior livestock feed technology and excellent service. Over the years, we have established long-term and stable cooperative relationships with many group and livestock feed enterprises around the world, and our livestock feed mill equipment have been sold at home and abroad.

Indonesia

3-5T/H livestock feed production line in Indonesia

- Feed Type: cattle feed

- Date: April 19th, 2018

- The install period: 30 Days

- Workshop size(L*W*H): 10m*5m*12m

- livestock feed production line price: 110,000USD

the Philippines

3-4T/H livestock feed production line in the Philippines

- Feed Type: pig feed & rabbit feed

- Date: Nov 11st, 2019

- The install period: 45 Days

- Workshop size(L*W*H): 60m*24m*12m

- livestock feed production line price: 150,000 USD

Saudi Arabia

15-16T/H livestock feed production line in Saudi Arabia

- Feed Type: cow feed & poultry feed

- Date: March 23th, 2018

- The install period: 60 Days

- Workshop size(L*W*H): 16m*8m*12m

- livestock feed production line price: 480,000 USD

United States

10T/H livestock feed production line in United States

- feed type: cattle & pig feed

- Date: May 2019

- Feed Pellet Size: 3-8 mm

- The install period: 40 Days

- livestock feed production line price: 380,000 USD

Argentina

5 t/h livestock feed production line in Argentina

- feed type: cattle & fish feed

- Date:2021.10.12

- Feed Pellet Size:2-8 mm

- The install period:50 Days

- livestock feed production line cost:184,500 USD

El Salvador

5 T/H livestock feed production line In El Salvador

- feed type: cattle premix feed

- Date:2020.11.13

- Control Mode:Full Automatic

- The install period:90 Days

- livestock feed production line price:450,000 USD

Uzbekistan

0.8-4T/H livestock feed production line in Uzbekistan

- feed type: cattle & sheep & chicken feed

- Date:May 29, 2021

- Pellet Size:2-8mm pellet, mash

- MAIN POWER:283 KW

- livestock feed production line cost:85000-95000USD

Russia

40-50T/H livestock feed production line in Russia

- feed type: cattle & goat & chicken & fish feed

- Date:June 2019

- Feed Size:2-5mm pellets, mash feed

- The install period:10 months

- livestock feed production line cost:1,800,000USD

Vietnam

25T/H livestock feed production line in Vietnam

- feed type: cattle & fish feed

- Date:June 2020

- Pellet Size:1.5-8mm, powder feed

- The install period:60 Days

- livestock feed production line:800,000 USD

If you want to find more information on livestock feed equipment cost and livestock feed production line construction guide, contact RICHI online for price & support!

Customized livestock feed production line design

RICHI can customize various livestock feed engineering services for domestic and foreign customers, including: pig feed engineering, cattle feed engineering, sheep feed engineering, rabbit feed engineering, deer feed engineering, etc.

Our engineering team has rich design and construction experience and professional installation and commissioning knowledge, and can provide customers with comprehensive personalized livestock feed production line solutions.

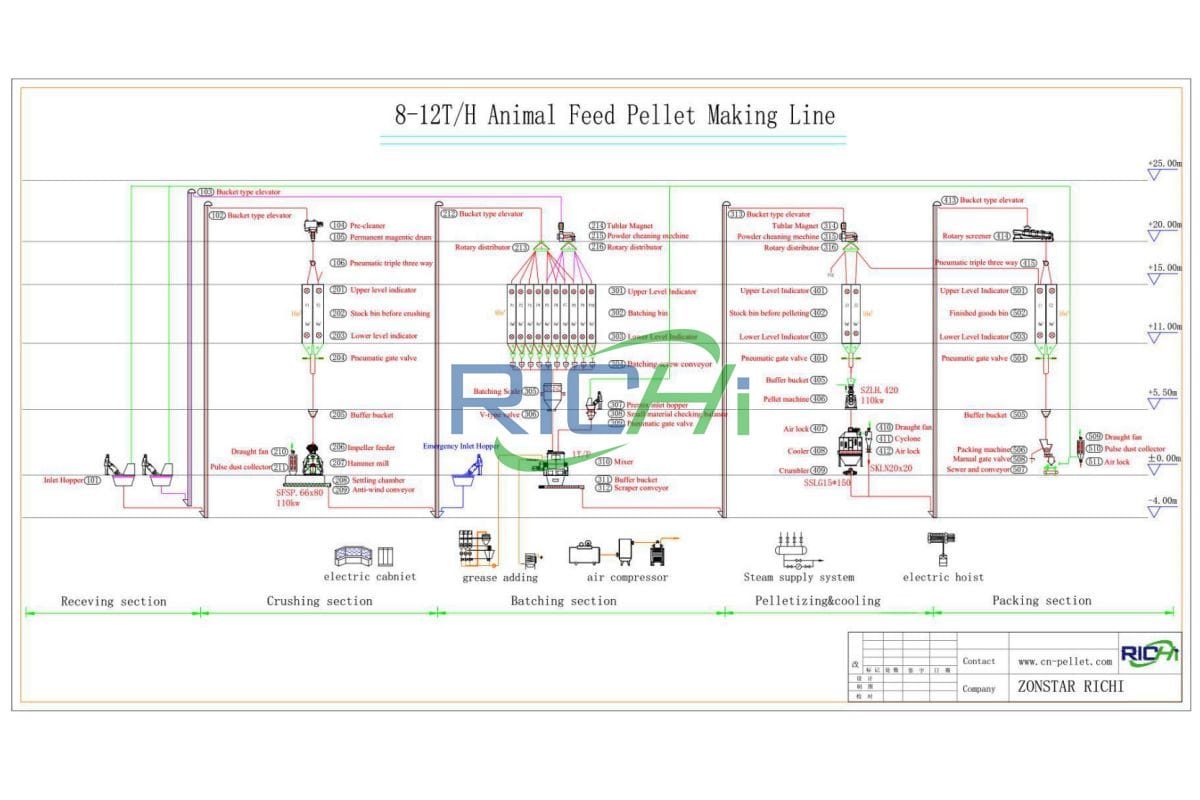

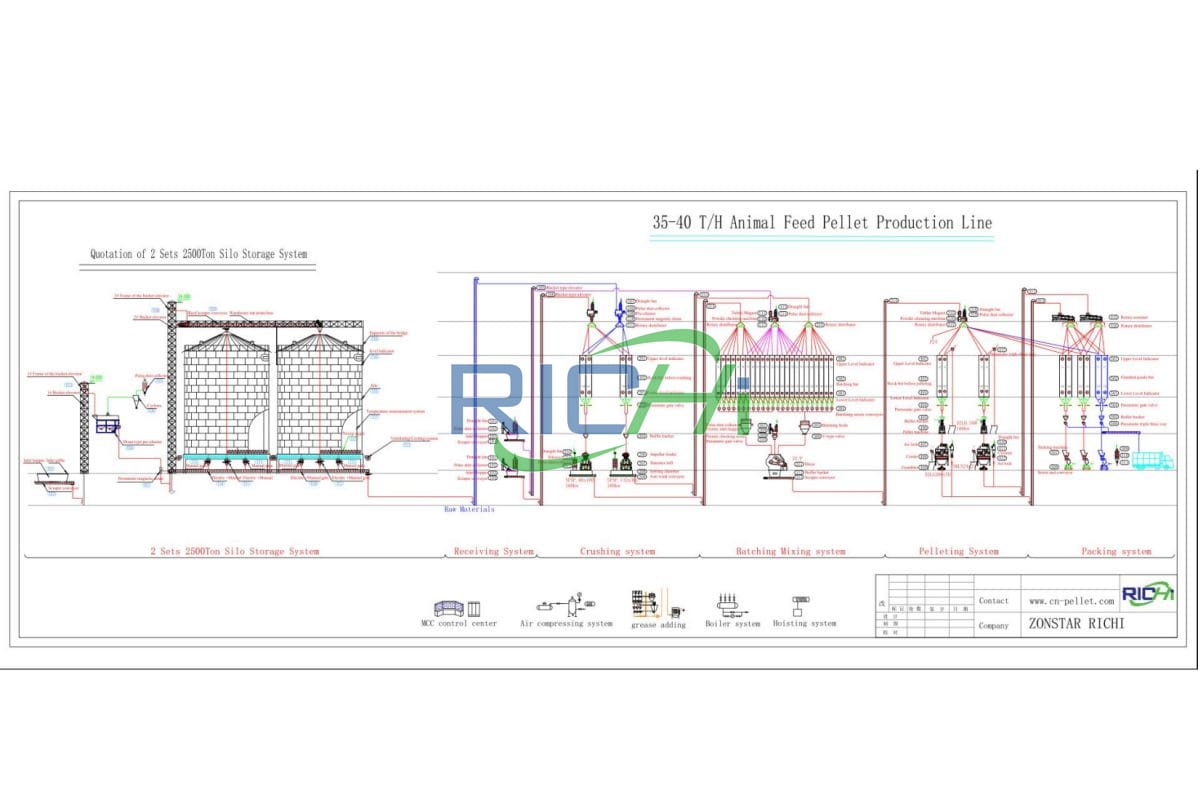

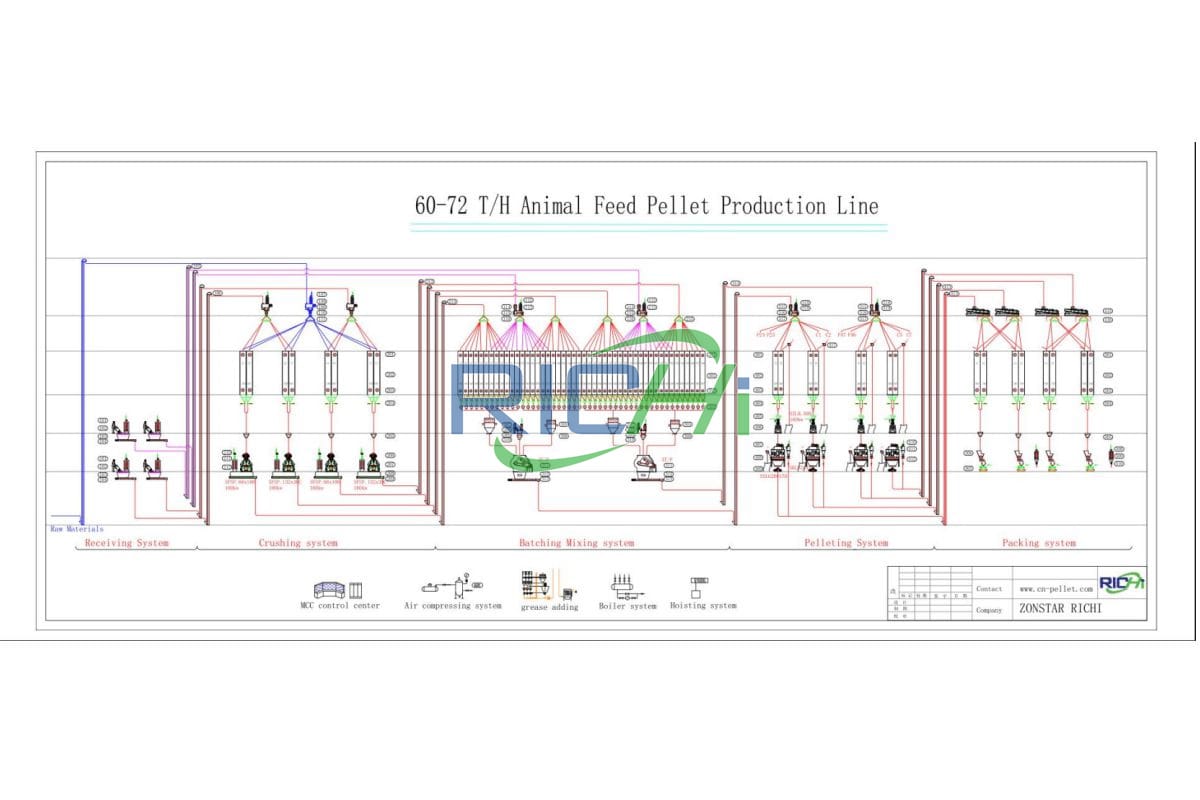

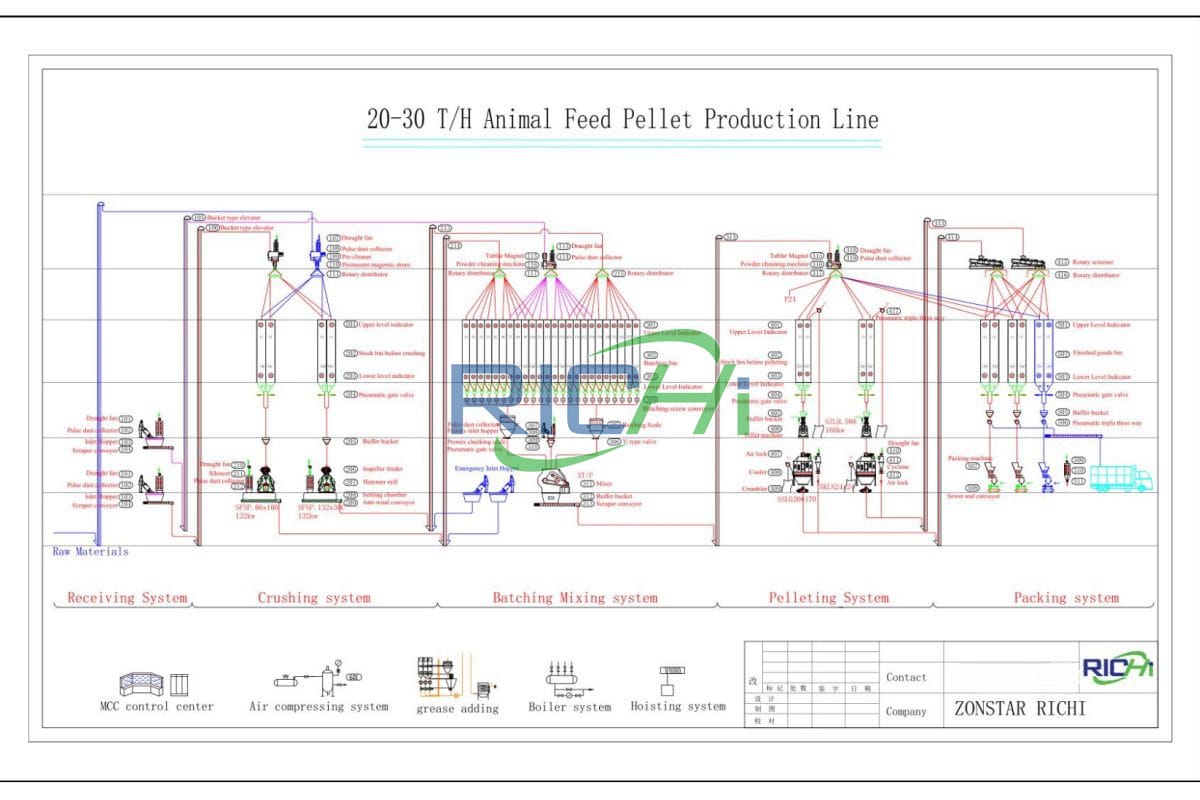

The following is a livestock feed production process flow chart with different outputs that we have designed for different customers:

8-10T/H livestock feed production line design

For Argentina Project

30-40T/H livestock feed production line design

For Kazakhstan Project

60T/H livestock feed production line design

For Russia Project

20T/H livestock feed production line design

For South Africa Project

Featured livestock feed production line solutions

RICHI livestock feed making lines have different configurations based on raw material formulas, feed product requirements, and production scale. Whether it is a new livestock feed plant or the renovation and upgrade of an existing livestock factory, we can provide customized design and livestock feed milling equipment engineering construction services:

10 T/H livestock feed production line for pig feed

The processing characteristics of the high-grade suckling pig feed line project are fine grinding fineness (screen aperture 1-2mm), high maturity requirements (the raw materials are matured through the expander first), low tempering temperature (using low-temperature granulation), and the diameter of the finished pellets is about 4-6mm).

Generally speaking, most of the raw materials are fully expanded (the raw materials are highly matured), and then secondary crushing, secondary mixing, and then low-temperature granulation are used. The high-grade suckling pig feed produced by this process has excellent quality, good palatability, and suckling pigs love to eat it; it is easy to digest, easy to absorb, and does not cause diarrhea; it has high nutritional level and good production speed, so that the suckling pigs can grow stably and quickly after weaning.

1T/H livestock feed production line for sheep feed

Use manual weighing of ingredients. The raw materials are pre-cleaned and pre-weighed manually. The raw materials that need to be crushed are directly put into the crusher in batches. The crusher uses manual feeding. The crushed raw materials and the powder that does not need to be crushed enter the feeding port together according to the formula proportion, and then mixed by a mixer.

The mixed materials can be directly entered into the finished product warehouse as powder products, or can be entered into the granulation section for granulation and cooling processing, and finally are manually weighed and packaged.

The total power of the feed line is about 75KW; the unit occupies an area of about 10×5.5×7m; it needs to be equipped with a 0.2T boiler.

20T/H livestock feed production line for cattle feed

The characteristics of livestock feed are moderate grinding fineness (screen aperture 2-4mm), moderate ripening and conditioning requirements (cattle feed granulators mostly use double-layer conditioners), and large diameter of finished particles (pellet diameter is about 2.5-4mm).

The double SZLH420 stock feed production line for cattle feed is designed to produce 20T/H per hour, using two crushing lines, one batching and mixing line, two pelleting lines and two baling lines. The total power of the equipment is about 725KW; the construction area of the production area is about 16.5×16.5×28m; it is equipped with a 2T boiler.

30T/H livestock feed production line for ruminant feed

The characteristics of ruminant livestock feed are coarse grinding fineness (sieve mesh diameter 4-8mm), low ripening and conditioning requirements (the ruminant feed pellet machine uses a single-layer conditioner), and large diameter of the finished pellets (pellet diameter is about 4-10mm) .

The double SZLH420 stock feed line for ruminant fed is designed to produce 20-30T/H per hour, using two crushing lines, one batching mixing line, two pelleting lines and two packaging lines. The total power of the equipment is about 700KW; the construction area of the production area is about 21×17.5×28m; it is equipped with a 2T boiler.

20 t/h livestock feed production line for biological fermentation feed

The design scale of this project is 2 tons of mixer per batch, 8 hours of production per shift, and 300 working days per year. The annual output of fermented feed in a single shift is 48,000 tons. It adopts biological fermentation process and goes through raw material receiving section, crushing section, batching section, mixed fermentation section, drying and cooling section, secondary cooling section, packaging section, auxiliary section, etc.

The livestock feed production line covers an area of about 22x11m (excluding the fermentation and drying workshop) and is about 18.5m in height. The four floors above the ground are the steel structure main workshop, which adopts the form of a partial pit.

6T/H livestock feed production line for premix

The designed mixing volume of the automatic premix production line is 1 ton/batch (approximately 6 tons per hour). The carrier and small materials are separated and automatically weighed and batched by a separate computer. A stainless steel single-shaft paddle mixer and a pre-mixed material are used. Special automatic packaging scale for mixing.

The total power of the equipment is about 63KW; the construction area of the production workshop is about 12×11×33m. The entire animal feed line has a compact design, reasonable structure, meets environmental protection requirements, and can be designed according to customer requirements.

15 T/H livestock feed production line for concentrated feed

The processing feature of concentrated feed is that it does not contain a pelleting line, the ingredients are mixed to minimize grading, and are packaged directly. This concentrate production line is designed to produce 15 tons per hour and uses a crushing line, double-scale automatic batching, a mixing line, and a finished product packaging line.

The total power of the equipment is approximately: 230KW; the construction area of the production area is approximately: 10×11×24m (height).

INote: The above livestock feed plans are for reference only. According to the characteristics of raw materials and formulas, as well as the requirements for output and livestock feed manufacturing process, the design and equipment configuration of livestock feed production lines are diverse and need to be customized according to the actual situation of the customer!

livestock feed production line cost

The investment cost of a livestock feed production line mainly depends on a variety of factors, such as production scale, factory size, facilities, production line machines and geographical location.

| Capacity | livestock feed production line price (USD) |

| 1-2 T/H | 10,000-50,000 |

| 3-4 T/H | 50,000-120,000 |

| 5-7 T/H | 70,000-250,000 |

| 8-10 t/h | 150,000-300,000 |

| 12-20 t/h | 250,000-580,000 |

| 25-40 t/h | 450,000-850,000 |

| 50-60 t/h | 900,000-1,400,000 |

| 60-80 t/h | 1,450,000-1,800,000 |

| 80-100 t/h | 2,000,000-2,800,000 |

Factors to consider when investing in livestock feed production lines:

- First, setting up a livestock feed production line requires purchasing land, which is probably the largest part of the investment cost. In cities, land prices are higher, so land costs may be higher. In addition, factory buildings need to be constructed, including production workshops, warehouses, and offices.

- Secondly, setting up a livestock feed mill also requires purchasing machinery and equipment. This includes mixers, grinders, packaging machines, etc. In addition, raw materials such as chemicals and additives need to be purchased, which will be another cost.

- Thirdly, setting up a stock feed mill also requires hiring employees. This may include production line workers, technicians, managers, etc.

- Finally, setting up a livestock feed line also requires marketing and sales activities. This may include things like advertising, promotions and sales force fees.

The larger the livestock feed making line, the more factors affect the investment cost. Therefore, before investing in building an animal feed mill plant for livestock cattle pig goat, please be sure to do a project feasibility analysis to determine whether the stock feed line you invest in has economic value!

Advantages of livestock feed production line

The complete livestock feed production line is a production method that uses automated equipment and scientific feed formula to produce high-quality feed. It has the following advantages:

- Precise formula to ensure feed quality:

RICHI complete livestock feed production line adopts scientific feed formula and performs precise processing through automated equipment to ensure the balance and adequacy of various nutritional elements in the feed.

Through precise formula, the complete feed production line can produce high-quality, high-nutrition value feed, thereby improving the production performance and health level of livestock and poultry. - Automate production and improve efficiency:

RICHI livestock feed production line uses automated equipment for production, which avoids the tedious and inefficient processes in traditional manual production and greatly improves production efficiency.

In the complete feed production line, every link is realized through automated equipment. From the feeding of raw materials to the discharging of finished products, fully automated operations can be realized, greatly reducing production costs. - Reduce production costs:

RICHi livestock feed production lines can greatly reduce production costs.

First of all, through precise formula and automated production, the complete feed production line can reduce the waste of raw materials and energy consumption, thereby reducing production costs.

Secondly, the complete feed production line can improve production efficiency and production capacity, thereby reducing labor costs and equipment usage costs in the production process. - Improve feed quality and reduce disease incidence:

RICHI livestock feed production lines can ensure the consistency and stability of feed quality and reduce the risk of reduced livestock and poultry production performance and increased incidence of diseases caused by unstable feed quality.

Through scientific feed formulation and automated production, the complete animal feed production line can improve the health of livestock, reduce the incidence of diseases, thereby reducing the risks and costs of livestock breeding. - Improve product quality:

RICHI livestock feed production lines can improve the quality of livestock and poultry products, such as the delicious meat and rich nutritional ingredients, thereby enhancing the market competitiveness of the products.

The complete feed production line can formulate scientific and reasonable feed formulas according to different livestock and poultry needs to ensure that livestock are fully nourished, thereby improving product quality.

In addition, the automated production method of the feed complete production line can ensure the consistency and stability of feed quality, avoid errors caused by human factors, and ensure the quality stability of the product. - Improve enterprise competitiveness:

RICHI livestock feed production lines can improve the production efficiency and production capacity of enterprises, reduce production costs and product quality risks, thereby improving the market competitiveness of enterprises. The automated production method of the feed complete production line can reduce labor and time costs, improve production efficiency, and thereby enhance the market competitiveness of the enterprise.

In addition, through precise formula and scientific feed formula, the complete feed pellet production line can produce high-quality feed and livestock and poultry products, thus improving the market competitiveness of the enterprise.

Livestock feed production line Videos

Trend of Livestock Feed Production Line Technology

- Raw material receiving silo.

Silo-based raw material reception can better maintain and manage raw materials, avoid mildew and other undesirable factors in traditional warehouse storage, and better ensure the quality of raw materials. - The particle size of raw material crushing needs to be refined.

The finer the grinding particle size, the better the nutritional quality of the feed. Therefore, the grinding particle size is getting finer and finer in pursuit of feed quality. At the same time, the requirements for the technology and grinder of the grinding section are getting higher and higher. - Process independence and equipment cleaning.

Residual mildew in the equipment and cross-infection of raw materials during the production process have become important factors restricting higher quality feed. Therefore, the independence of the process and the cleaning function of the equipment have become factors that RICHI must consider when designing the feed line. - Pelletization of finished feed.

Due to its many advantages, pellet feed has replaced traditional powder and become the main force in finished feed. - Bulk finished feed.

With the formation of automatic feeding lines in the livestock and poultry industry, feed bulking has become a change in the feed cost section process. Bulk feeds not only connect well with the feeding lines, but also save a lot of costs.

How to choose a livestock feed production line?

- Understand production needs:

Before purchasing a livestock feed production line, you need to understand your own production needs, including feed type, production scale, equipment configuration, etc., so as to choose a complete set of feed production line that suits you. - Choose a brand:

Choose a livestock feed line from a well-known brand. The brand manufacturer has a professional technical team and after-sales service team that can provide customers with high-quality products and services. - Understand the performance of livestock feed making equipment:

When purchasing livestock feed pellet production line, you need to understand the performance indicators of the equipment, including production capacity, energy consumption, floor space, stability, etc., and choose equipment that meets your needs. - Visit the manufacturer:

When purchasing livestock feed production line, you can go to the manufacturer for an on-site visit to understand the livestock feed production process and quality control of the equipment, thereby improving the reliability and satisfaction of the purchase. - Consider after-sales service:

When purchasing a complete livestock feed milling line, you need to consider after-sales service issues and choose a manufacturer with a complete after-sales service system and technical support that can provide timely and professional service support for the use and maintenance of the equipment.

As an important tool for modern livestock breeding, the livestock feed production line can improve the stability and utilization of feed quality, reduce production costs, and thereby improve the efficiency of livestock breeding.

When purchasing a complete feed production line, you need to consider production needs, brand, equipment performance, after-sales service, etc., so as to choose the livestock equipment that suits you and ensure the improvement of whole line production efficiency and production quality.

livestock feed production line Construction

The construction process of the livestock feed production line refers to the sequence of various tasks in the entire feed factory construction process. The basic construction procedures for livestock feed production lines are as follows:

- Project proposal stage

- Feasibility study stage (including project evaluation)

- Design stage

- Preparation stage for starting construction

- Construction stage

- Completion acceptance stage

Among the above 6 points, the first two stages are what customers need to complete. The structure and content of the feasibility study report include the following aspects:

- (1) Overview: Project background, project overview, problems and suggestions

- (2) Market forecast: product market supply forecast, product market demand forecast, product target market analysis, price status and forecast, market competitiveness analysis, market risk analysis

- (3) Analysis and evaluation of resource conditions: resource availability, resource quality, resource occurrence conditions, resource development value.

- (4) Construction scale and product plans: construction scale and product plan composition, comparison and selection of construction scale and product plans, recommended construction scale and product plans, and utilization of original facilities.

- (5) Site selection: site status, site condition comparison, recommended site plan, and utilization of the original site of the technical transformation project

- (6) Technical plans, equipment plans and engineering plans: selection of livestock feed production line technical plans, selection of major livestock feed equipment plans, selection of engineering plans, comparison before and after the transformation of technical transformation projects

- (7) Main raw material and fuel supply: main raw material supply plan and fuel supply plan

- (8) General plan, transportation and public auxiliary works: general plan layout plan, on-site and off-site transportation plan, public works and public auxiliary engineering plans, and utilization of original public auxiliary facilities in technical transformation projects

- (9) Energy saving measures: analysis of energy saving measures and energy consumption indicators

- (10) Water-saving measures: analysis of water-saving measures and water consumption indicators

- (11) Environmental impact assessment: investigation of environmental conditions, analysis of factors affecting the environment, and environmental protection plans

- (12) Labor, health, safety and fire protection: Risk factors and hazard degree analysis, safety and fire protection measures, health care measures, fire protection facilities

- (13) Organizational structure and human resource allocation: Organizational structure and its adaptability analysis, human resource allocation, employee training

- (14) Project implementation progress: Construction period, implementation schedule, and connection between construction and production of technical transformation projects

- (15) Investment estimation

- (16) Financing plan: Financing organization situation, capital financing, debt financing, financing plan analysis

- (17) Financial evaluation: basic data and parameter selection of financial evaluation, sales revenue estimation and cost estimation, financial evaluation report, profitability analysis, solvency analysis, uncertainty analysis, financial evaluation conclusion

- (18) National economic evaluation: shadow price and general parameter selection, benefit cost range and numerical adjustment, national economic evaluation report, national economic evaluation indicators, national economic evaluation conclusion

- (19) Social evaluation: analysis of the social impact of the livestock feed production line project, analysis of compatibility between the project and the location, social risk analysis, and conclusion of social evaluation

- (20) Risk analysis: identification of main risk factors of the project, analysis of risk levels, and social risk prevention countermeasures

- (21) Research conclusions and suggestions: overall description of the recommended plan, description of the advantages and disadvantages of the recommended plan, main comparison plans, conclusions and suggestions.

In addition to the above feasibility analysis stage, the subsequent processes: design stage, construction preparation stage, construction stage, and completion acceptance stage are all guided by RICHI engineers or completed directly by our construction team.

What our customers need to do is to search locally construction teams perform civil engineering, steel structure construction and equipment installation. Of course, depending on the contract type, our engineers will also go to the site to guide the livestock feed production line installation or directly dispatch the installation team to complete the entire installation work.

Site selection for livestock feed production lines

Livestock feed production line construction projects are usually proposed based on the long-term development plan of the industry or enterprise. The so-called long-term plan refers to the plan for more than 5 years for the business activities of the enterprise. Before preparing for the feed factory, the team should fully discuss but not limited to: the location of the new factory, product line composition, production process, raw material description, equipment description, etc.

RICHI here briefly introduces the issue of location selection for livestock feed production lines:

- In addition to considering the geological environment, cultural environment, physical resources, climate and other factors when selecting a livestock feed factory location, the surrounding business competition situation and transportation convenience should also be considered.

- Policy orientation should also be one of the factors considered by the preparatory team, especially for full-price feed companies. As the breeding area moves inward, it is even more necessary to be forward-looking in site selection. After fully considering the above information, participants should formulate corresponding copy for team discussion and reach a consensus.

- After site selection, unified consideration should be given to the area ratio, whether single-story factory buildings can be built, building density, green space ratio, building height, motor vehicle parking space configuration, non-motor vehicle parking space configuration, etc.

- At the same time, it should comply with the current relevant technical regulations and normative requirements such as local urban planning management technical regulations. All buildings (structures) must not exceed the building red line. Civil air defense, earthquake resistance, fire protection, etc. shall be implemented in accordance with the current relevant regulations of the relevant countries.

- Full consideration and discussion in advance will have a certain guiding role in the later graphic layout design and livestock feed production line process design, and will save the company from making many detours.

Why invest in livestock feed manufacturing business?

The livestock feed market has broad development prospects and huge market potential. The livestock feed market will develop in a high-quality, green, and diversified direction.

At the same time, with the continuous advancement and application of science and technology, livestock feed production will become more intelligent, precise and efficient.

In the future, as people pay more and more attention to food safety and environmental protection, and consumers’ demand for high-quality animal foods continues to increase, the livestock feed market will usher in a broader space for development. (Find RICHI on YouTube)

RCIHI service

Adhere to customer-centeredness, provide customers with overall and complete services, and tailor-made high-quality livestock feed production lines!

- Online and offline communication

- Confirmation of customer needs

- Customized solution design

- Professional transportation solutions

- On-site installation and commissioning

- Customer acceptance items

- Perfect after-sales service

- Complete accessories service