bagasse pellet machine

Bagasse pellet machine is a special equipment used to process bagasse fuel pellets, bagasse feed pellets and bagasse fertilizer pellets.

Using bagasse pellet mill to process pellets has many advantages and can save a lot of costs to a certain extent. Bagasse pellets occupy a place in the pellet market with its unique advantages and have broad development prospects.

- Capacity: 0.3-10T/H

- Bagasse Pellet Machine Price: 10,000-100,000 USD

- Pellet Size: 2-12mm

- Application: biomass pellet plant, animal feed mill plant, aqua feed plant, sugar factory, bagasse farms, fertilizer pellet plant, etc.

- Note: It can process a single raw material or multiple raw materials.

As a professional bagasse pelletizing system solution provider, we can provide customers with high-quality bagasse pellet machines and a complete set of bagasse pellet production line equipment, as well as provide detailed technical support.

According to the specific requirements of the customer, the supporting overall design and construction plan is tailor-made.

Application of bagasse pellet machine

RICHI’s bagasse pellet machine is mainly used for biomass fuel pellet processing, livestock and poultry feed processing, aquatic feed processing, and organic fertilizer pellet processing.

Currently, bagasse pellet mills are mainly used in the following fields:

- fuel pellet plant

- Biomass pellet plant

- full automatic Cattle feed plant

- poultry feed plant

- Pig feed mill

- Fish feed production line

- Shrimp feed mill

- Organic Fertilizer Production Line

- …

The applications of bagasse pellet mill are mainly those shown above.

Sugarcane bagasse uses:

In addition to being used as fuel for power generation and animal feed, sugar cane waste biomass can also be used to make paper, artificial panels, activated carbon, dietary fiber, thermoplastics, biodiesel, and produce ethanol, xylitol, enzyme preparations, edible fungi, citric acid, Amino acids, etc.

For RICHI, our business only involves bagasse pellet processing type applications.

Why start bagasse pellet production?

In the sugarcane industry, there are many sugar mills in Southeast Asia. For every 10 tons of sugarcane crushed, a sugar mill produces nearly 3 tons of wet bagasse.

How to deal with bagasse is becoming increasingly important. Few factories burn bagasse fiber as fuel, and when burned in large quantities, it produces enough heat energy to meet all the needs of a typical sugar factory.

The remaining bagasse can be processed into biomass pellets, used as raw material for bagasse pulping, and exported abroad as fuel, which can bring economic benefits to the factory.

Bagasse pellet machine type

According to the main applications of bagasse pellet machines, the bagasse pellet making machines we can provide are mainly divided into the following two categories:

Bagasse pellet machine for fuel

Bagasse fuel pellet machine is the core and indispensable part in a complete bagasse pellet plant. It is a kind of ring die biomass pellet machine. The capacity of this ring die pellet machines can range from 300 to 4500kg/h.

- Capacity: 0.3-4.5T/H

- Power: 37-280 KW

- Model: MZLH

- final pellets: 6-12mm

Bagasse pellet machine for animal feed

The bagasse feed pellet machine can make feeds for animals such as chicken, cattle, pig, sheep etc, from bagasse and other raw materials, such as sorghum, maize, soya meal, rice and wheat etc.

- Capacity: 1-45T/H

- Power: 22-315 KW

- Model: SZLH

- final pellets: 2-8mm

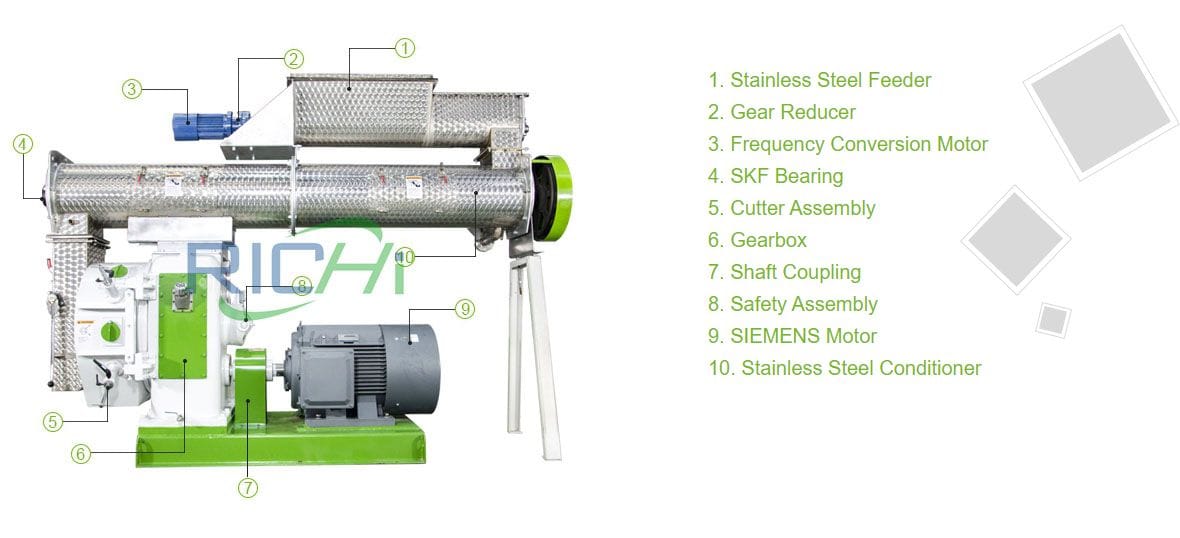

Features and advantages of bagasse pellet machine

- The bagasse pellet machine uses a strong gear box transmission system, has ideal transmission efficiency, rotation steady, output high, noise low, no oil leak pollution, maintenance cost low;

- This series pellet machine has φ1.5-φ12mm many kinds of aperture and thickness link model;

- The user can willfully select according to different need to obtain the best technology and economic efficiency;

- Fixed stainless steel pelletizing knife equipment, adjustment is more intuitive;

- Quick-discharge anchor ear link model, can match coordinated type pressure roller regulating mechanism and link mold hoisting equipment;

- We have both gear box and belt transmission pellet mill for sale;

- Low cost, convenient operation and maintenance;

- High yield, energy-saving and environmentally friendly.

technical parameters Of bagasse pellet machine

The following are the technical parameters of bagasse fuel pellet machine and bagasse feed pellet machine:

parameters of Bagasse fuel pellet machine

| Model | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH768 | MZLH858 |

| Output (t/h) | 0.3~0.5 | 0.5~0.7 | 1.0~1.5 | 2.0~2.5 | 2.5~4 | 4~5 |

| Main motor power (kw) | 22 | 37 | 90 | 132 | 250 | 280 |

| Main motor series | 8P | |||||

| Ring die diameter (mm) | 320 | 350 | 420 | 520 | 762 | 858 |

| Finished pellet diameter (mm) | 6-12mm | |||||

| Device Configuration | Ring die material: 42CrMo Stainless steel feeder: with anti-caking function Door of pelleting room: 6mm /SUS304 Forced feeding: Worm gear reducer Gear box: HT250 Gear: 42CrMo Gear shaft: 42CrMo Spindle: 42CrMo Empty shaft: 42CrMo Bearings: The gear shaft and main shaft bearings are SKF, and the pressure roller bearings are domestic high-quality bearings Oil seal: Germany/Taiwan Overload mechanical protection: safety pin Serpentine spring coupling drive Lubrication system: Configurable automatic oil injection system | |||||

parameters of Bagasse feed pellet machine

| model | SZLH250 | SZLH320 | SZLH350 | SZLH420 | SZLH508 | SZLH558 | SZLH678 | SZLH768 | SLZH858 |

| Output (t/h) | 1~2 | 3~4 | 5~7 | 8~12 | 10~18 | 15~25 | 20~30 | 25~40 | 28~45 |

| Main motor power (kw) | 22 | 37 | 55 | 110 | 160 | 180/200 | 220/250 | 250/280 | 315/355 |

| Main motor series | 4P | ||||||||

| Feeder power (kw) | 1.1 | 1.5 | 1.5 | 1.5 | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 |

| Conditioner power (kw) | 1.5 | 2.2 | 3 | 7.5 | 11 | 11 | 11 | 11 | 15 |

| Ring die diameter (mm) | 250 | 320 | 350 | 420 | 508 | 558 | 673 | 762 | 858 |

| Finished pellet diameter (mm) | 2~12 | ||||||||

| Equipment Configuration | Ring die material: stainless steel Door cover of granulation room: 6mm /SUS304 Feed chute: 3mm /SUS304 Gear box: HT250 Gear: 42CrMo Gear shaft: 20CrMnTi Spindle: 42CrMo Empty shaft: 42CrMo Bearing: Import Oil seal: Germany/Taiwan Overload mechanical protection: safety pin Serpentine spring coupling drive Using Siemens Motor | ||||||||

Bagasse pellet machine projects

Nearly 30 years experience in pellet mill manufacturing, installation and commissioning, RICHI bagasse pellet machine has exported to more than 130 countries around the world, including Russia, Germany, Indonesia, Canada, UK, Nigeria, Thailand, India, Australia, South Africa, Pakistan, Kuwait, United States, Japan, Philippines, Portugal, etc.

Bagasse pellet machine in Australia

This customer uses waste bagasse to process fuel pellets and sells them to surrounding residents.

- Project Date: 2020.11.25

- Pellet Size: 8mm

Bagasse pellet mill machine in Thailand

The company uses bagasse to generate electricity, run machinery and provide electricity to nearby villages.

- Project Date: 2019.10.11

- Pellet Size: 8-10mm

Bagasse pellet machine in Indonesia

This customer processes bagasse pellets and uses them as biomass boiler fuel in their own factory.

- Project Date: 2023.06.02

- Pellet Size: 6-10mm

Bagasse pelletizer machine in USA

This customer ammoniated sugarcane bagasse into high-protein feed, which can meet the needs of ruminants.

- Project Date: 2020.01.17

- Pellet Size: 4-8mm

Bagasse pellet machine in Japan

This customer uses “strong bagasse” produced by fermentation of sugarcane bagasse, rice bran, etc. to feed cattle cows, which will help reduce animal feed costs.

- Project Date: 2022.08.25

- Pellet Size: 5-6mm

Bagasse pellet mill in Argentina

This customer improved the palatability of bagasse through biological fermentation, also increased the protein and fat, which is widely used to increase the milk of dairy cows.

- Project Date: 2021.09.09

- Pellet Size: 4-6mm

Bagasse pellet mill in China

The customer uses sugarcane bagasse, urea, molasses and cassava flour as raw materials to feed cattle through a proper mixture, which alleviates the lack of cattle feed in winter.

- Project Date: 2022.10.03

- Pellet Size: 3-5mm

Bagasse pellet machine in cuba

This customer uses sugarcane bagasse to feed rabbits. Compared with grass feed, feeding sugarcane bagasse reduces the feed cost, but can achieve the same effect as grass meal.

- Project Date: 2022.04.19

- Pellet Size: 3-6mm

Bagasse pellet maker in India

This customer symbiotically fermented sugarcane bagasse with multivitamins and used this product as a feed additive to feed laying hens, increasing their egg production by 50%.

- Project Date: 2021.09.17

- Pellet Size: 2-6mm

Bagasse pellets machine in Brazil

This customer uses high-temperature and high-pressure extrusion to process sugarcane bagasse as feed pellets materials for cattle, sheep, and fish.

- Project Date: 2022.08.02

- Pellet Size: 5mm

Bagasse pellets machine in Mali

The customer uses chemically treated sugar to degrade lignin and process the bagasse into pellet feed to feed cattle and sheep ruminants.

- Project Date: 2023.08.11

- Pellet Size: 6mm

Bagasse pellets mill in Vietnam

This customer uses expanded bagasse + sugarcane leaf silage as roughage, which can be directly used as roughage for beef cattle, and the feeding effect is good.

- Project Date: 2021.10.08

- Pellet Size: 4-6mm

How to choose bagasse pellet machine?

Regarding how to choose the right bagasse pellet maker machine, here are some reasonable suggestions to help you find a satisfactory and reliable supplier.

- No matter which manufacturer you want to buy a bagasse pellet machine from, please remember that quality comes first. A good quality wood pellet machine can not only ensure stable production, but also save some unnecessary maintenance costs.

- When purchasing a bagasse pelletizer machine, be sure to confirm whether the manufacturer’s after-sales service is timely and reliable, because customers may encounter unexpected situations that they cannot handle at any time during the production process.

At this time, if the manufacturer cannot help you deal with it in time, the customer will be very disappointed. May face the risk of discontinuation of production. - Ease of operation is also an important factor, because if a bagasse biomass pellet mill is too complicated to operate, it will lose many customers because not all customers are engineers.

- Fully consider the safety of the bagasse pelleting machine. A bagasse pelletzing machine produced by a reliable manufacturer will be very safe.

Customers don’t have to worry about flying screws during the production process that will hurt you or damage other equipment. Reliable manufacturers will conduct complete safety tests before the equipment leaves the factory. - Ask the manufacturers some professional questions and require them to respond within a limited time. Whether a complete solution can be provided within a limited time is also a test of the manufacturer’s technical strength.

- If they can promise to replace parts free of charge during the warranty period.

- Every customer hopes to buy satisfactory equipment at the lowest price. As far as the current market is concerned, the price of pellet machines is almost transparent.

If the price given by the manufacturer is significantly lower than the market price, then the manufacturer should be abandoned decisively. Don’t cause yourself more trouble just for the sake of petty gains.

At present, there are more and more bagasse pellet mill manufacturers, and the quality of their products is also uneven. Customers should spend some time doing research to choose the best biomass pellet machine manufacturer. (Find RICHI on YouTube)

Advantages of bagasse pellets

Bagasse pellets made by bagasse pellet machine are used in many places because of their convenience and comfort. They have the following advantages:

- High return on investment

The cost of raw materials is low, the investment in equipment is small, and the operation is simple. Ordinary people can operate the equipment with simple training, labor costs are extremely low, and coal prices fluctuate greatly. These factors ensure a better return on investment. - Wide range of applications

Bagasse pellets are easy to use and store. It can be used for heating, domestic stoves, hot water boilers, industrial boilers, biomass power plants, etc. to replace firewood, coal, fuel oil, and liquefied petroleum gas. It is also suitable for family units; the combustion effect is good and can meet the needs of cooking, heating, and bathing, especially the daily necessities of biomass power plants. - Environmental benefits

Bagasse pellets are good for the environment, bagasse pellets are carbon neutral, meaning that the carbon dioxide emissions it produces during growth are absorbed by itself. They do not release other air pollution gases into the air. - Renewable

Unlike coal, natural gas and other fossil fuels that are consumptive (it takes a long time to form), bagasse pellets are renewable because sugarcane grows every year and we can have a continuous supply of raw materials. - Turn waste into treasure

In the context of global energy shortage, sugarcane bagasse pellets represent the transformation of “waste” into wealth. Sugarcane is fully utilized, and in addition, it also increases farmers’ income.

If you see the prospect of processing bagasse pellets, you can start to explore the feasibility of implementing some bagasse pellet production projects. You are very welcome to contact us for details and learn more project information!

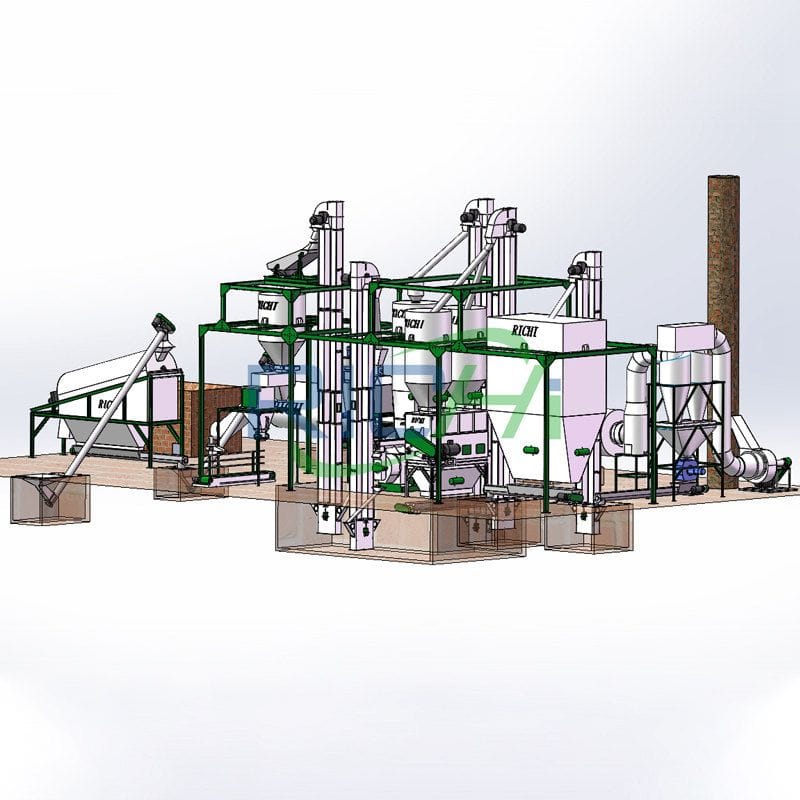

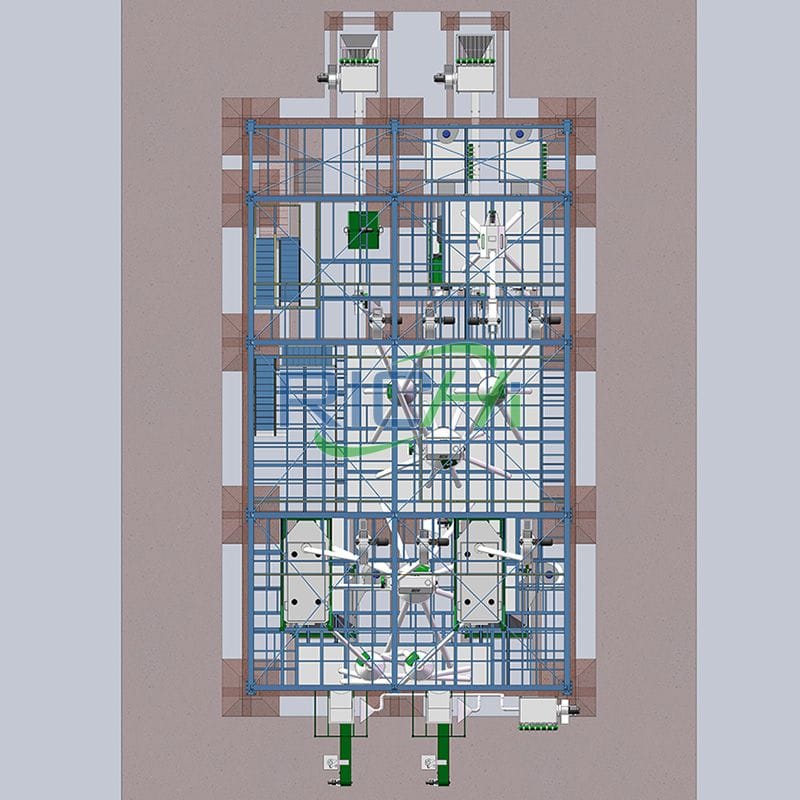

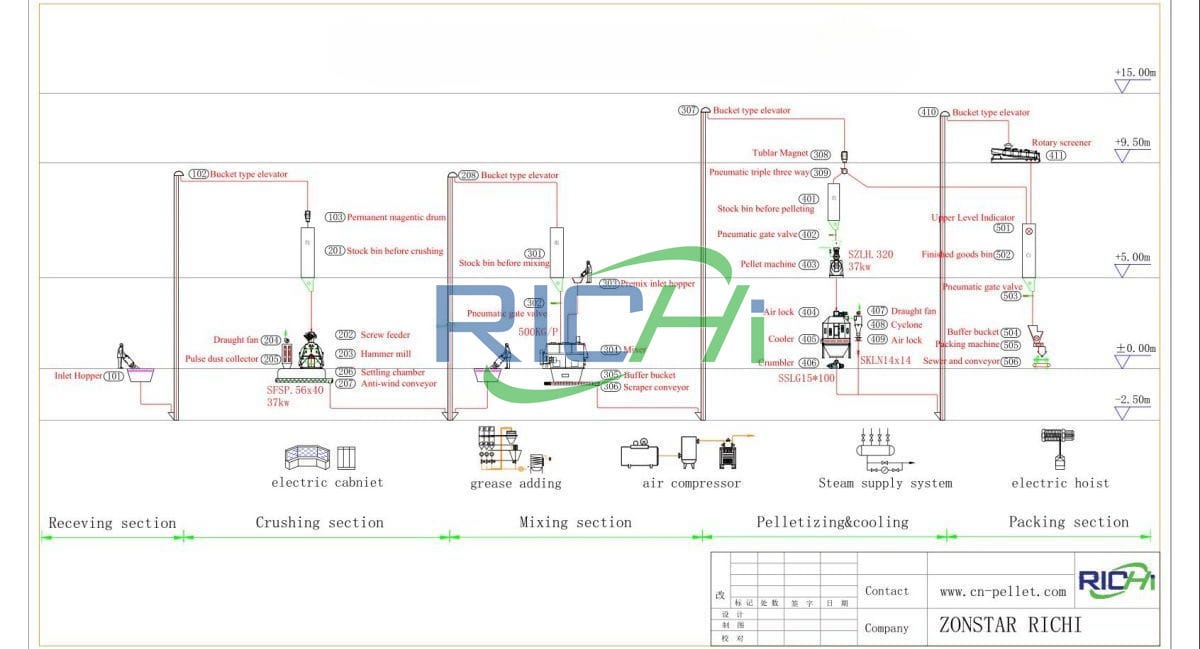

How to build complete bagasse pellet machine system?

Processing different bagasse pellets corresponds to different bagasse pellet production processes, and there will also be different selections of bagasse granulators and supporting equipment.

Below, RICHI will list the two most common bagasse pellet production technologies for you: energy bagasse pellet production technology, and feed bagasse pellet processing technology.

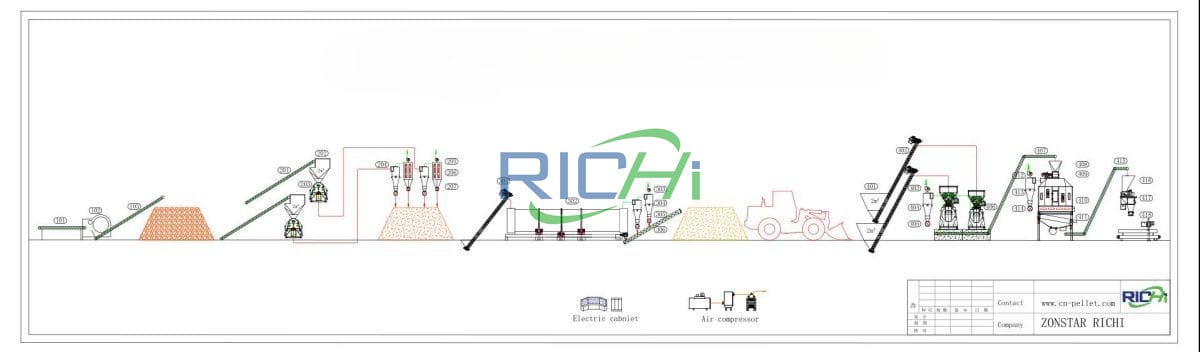

01 complete bagasse pellet machine system for biofuel:

Using bagasse as raw material to produce biomass pellets has certain advantages in terms of raw materials, technology and application.

RICHI can provide customized design, equipment processing, civil engineering solutions, installation, commissioning and after-sales service for 1-90t/h bagasse pellet production line.

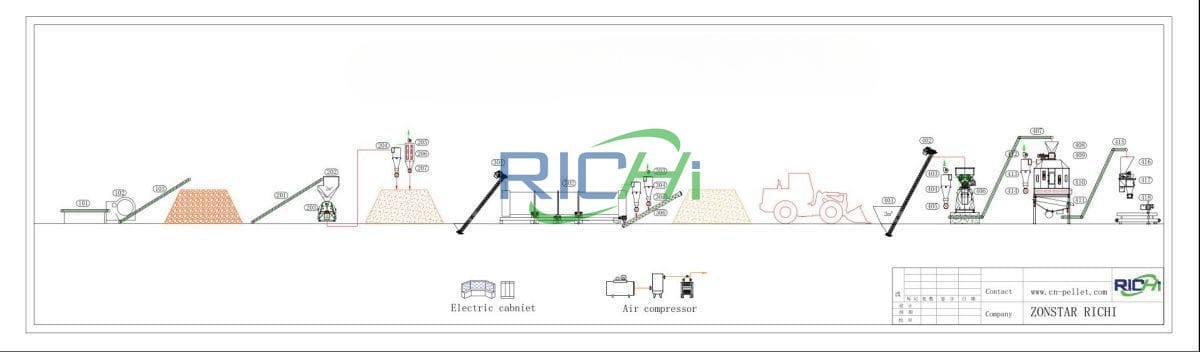

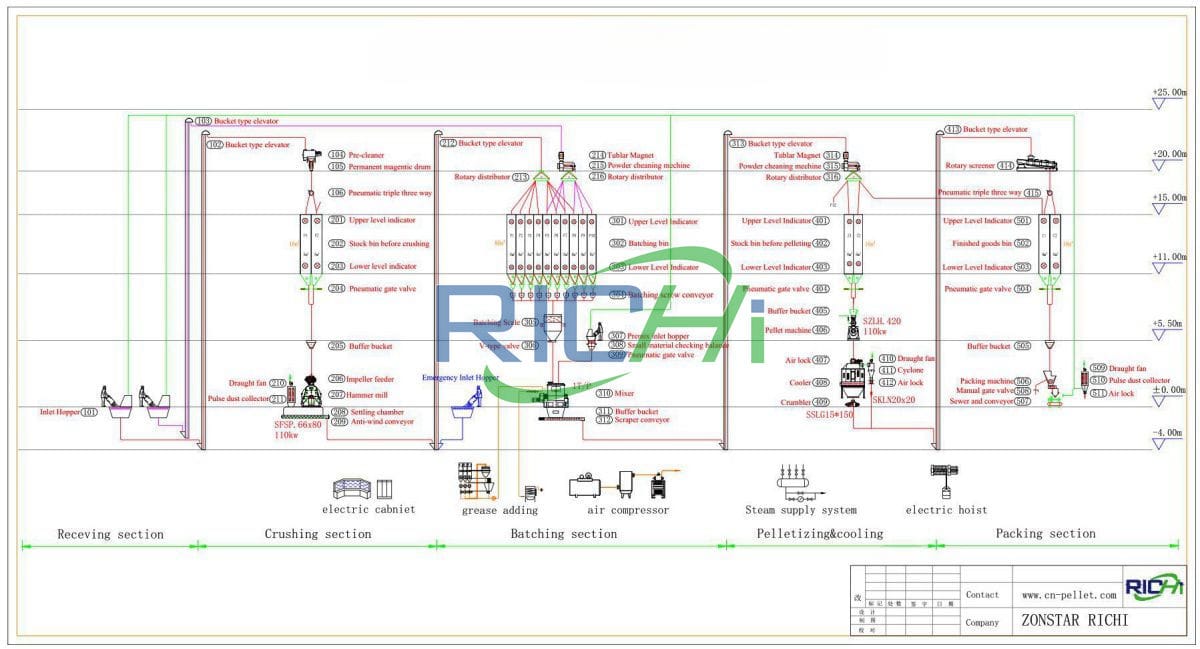

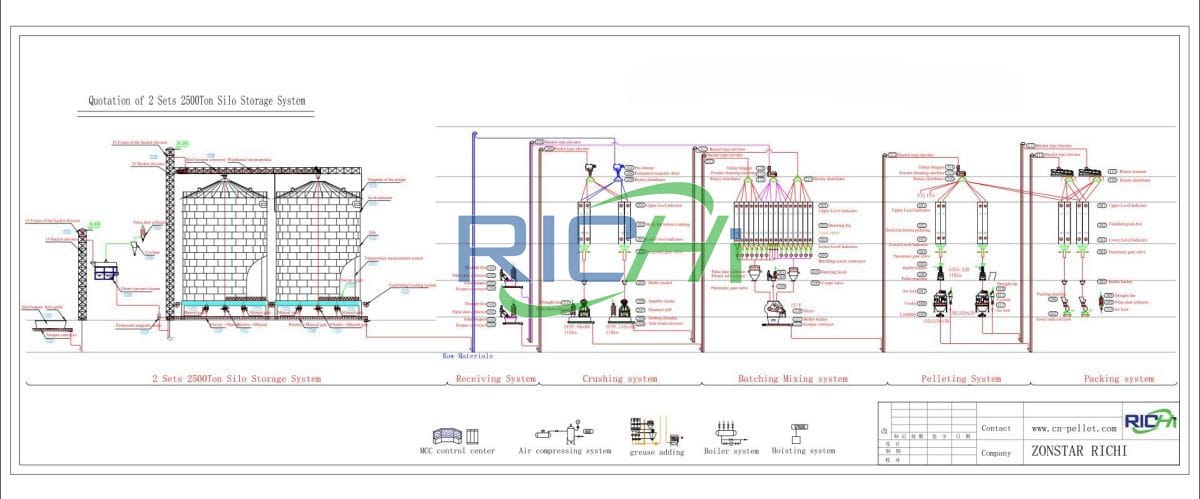

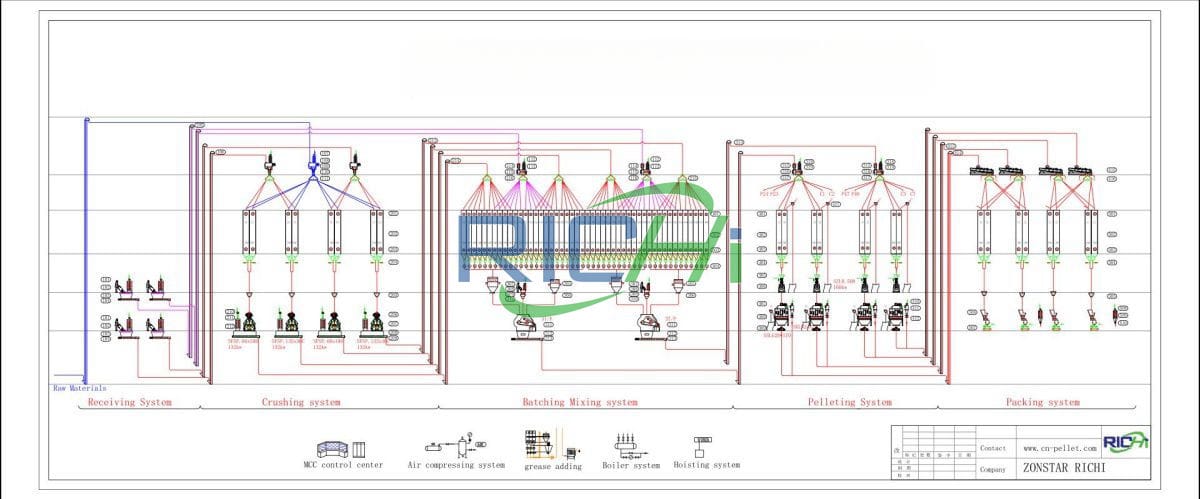

The biomass bagasse fuel pellet machine system usually includes: crushing-drying-pelletizing-cooling-screening-packing and other sections.

Featured biomass fuel bagasse pellet plant design:

1-2 t/h sugar cane waste biomass pellet plant design

- Main equipment: crusher, bagasse pelletizer, U-Screw Conveyor, Pulse Dust Collector, cooler, bagging machine, etc.

- price: 120,000-250,000 USD

3 t/h sugar cane waste biomass pellet plant design

- Main equipment: crusher, Pulse Dust Collector, bagasse pellet machine, cooling machine, dryer, packing machine, etc.

- price: 180,000-300,000 USD

6-7 t/h sugarcane bagasse pellets plant design

- Main equipment: crusher machine, belt conveyor, bagasse dryer, bagasse pellet machine, cooler, bagger, etc.

- price: 220,000-450,000 USD

8-10 t/h sugarcane bagasse pellets plant design

- Main equipment: chipper, hammer mill, bagasse pellet mill, pellet cooler, screener, bagging machine, etc.

- cost: 400,000-800,000 USD

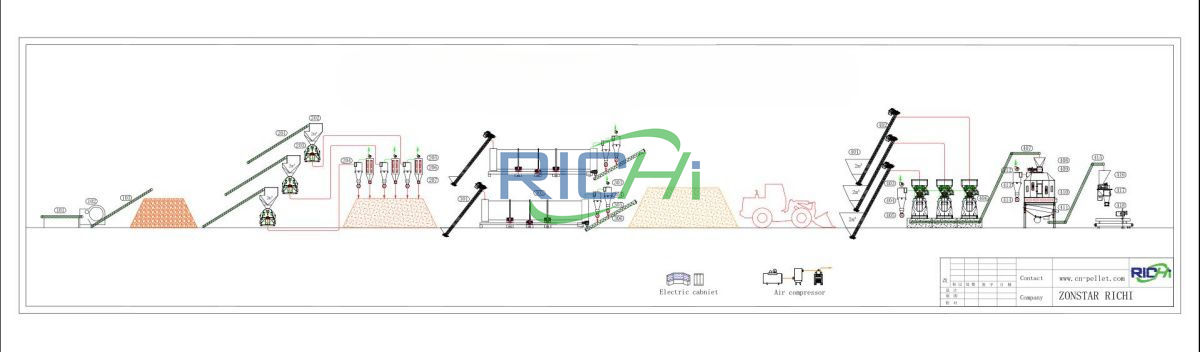

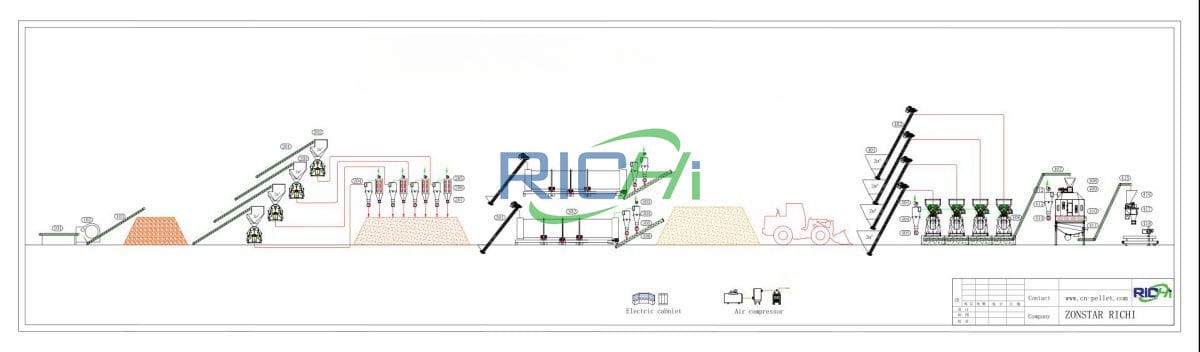

02 complete bagasse pellet machine system for animal feed:

The process flow of bagasse feed pellet production line usually includes: crushing, mixing, granulating, cooling, screening, packaging and other sections. Sugarcane bagasse is a good feed ingredient.

During the processing process, different processing methods can be selected to produce feed suitable for different types of livestock and poultry.

Through these processing methods, sugarcane bagasse can not only be effectively utilized, but also the nutritional value of feed can be improved, feeding costs can be saved, and dual benefits of economic and ecological benefits can be achieved.

RICHI can provide customized design, equipment processing, civil engineering solutions, installation, commissioning and after-sales service for 1-160t/h bagasse feed pellet production line.

Featured animal feed bagasse pellet plant design:

3-4 t/h feed sugarcane pellets plant

- Main equipment: feed hammer mill, mixer, bagasse pellet machine, cooling machine, screening machine, packing machine, etc.

- bagasse pellet plant price:50,000-120,000 USD

8-12 t/h feed bagasse pellet plant

- Main equipment: feed grinder, feed mixer, bins, bagasse pellet machine, cooler machine, crumbler, screener, packing machine, etc.

- bagasse pellet plant price: 150,000-300,000 USD

20 t/h bagasse feed pellet plant

- Main equipment: silo system, feed milling machine, batching scale, mixer, bagasse pellet mill, cooler machine, screener, packer, etc.

- bagasse pellet plant cost: 250,000-580,000 USD

40 t/h feed bagasse pellet plant

- Main equipment: feed hammer mill, feed mixer, bagasse pellet machine, cooling machine, screening machine, packing machine, etc.

- bagasse pellet plant cost: 450,000-850,000 USD

Auxiliary equipment for bagasse pellet machine

Whether it is processing bagasse fuel pellets or bagasse feed pellets, the bagasse pellet machine is only the core equipment, not the only equipment.

Generally speaking, if you want to process bagasse pellets, you also need equipment such as crushers, mixers, bagasse dryers, bagasse pellet coolers, screening machines, and automatic bagging machines.

hammer mill Machine

Capacity:

3-25T/H

Main Power:

30-160KW

mixer machine

Capacity:

250-2000KG

Main Power:

4-55KW

biomass Dryer

Capacity:

Customized

Rotate Speed:

3-8 r/min

Faqs of bagasse pellet machine

Is the bagasse pellet machine mainly used for processing fuel or feed?

Currently, bagasse pellet mills are commonly used to process bagasse fuel. Because bagasse combustion produces low sulfur dioxide emissions, only using a water film dust collector can make the flue gas emissions meet the standard, thereby reducing emission costs.

At the same time, the electricity or steam generated can be used by sugar factories and exported. There have been many studies on bagasse boilers to make their combustion efficiency more and more efficient.

In terms of feed processing, more and more customers are focusing on this field. Because as an alternative raw material, the low cost and high efficiency of bagasse are very worth looking forward to.

Sugarcane bagasse is a by-product of sugarcane sugar processing. Although it contains a large amount of cellulose, lignin and hemicellulose, direct feeding will affect the feed intake and digestibility of ruminants, but these problems can be solved through biotechnology.

What are the advantages of developing a fuel bagasse pellet machine production line?

1. Raw material advantages

In recent years, with the improvement of sugar production technology, the production of bagasse in many countries has been further improved.

In addition, the demand for it in the paper and board industries is small, so bagasse can ensure sufficient supply as a raw material for biomass pellets.

For traditional biomass pellet raw materials, such as wood chips, there are problems such as scattered raw material supply, difficulty in collection, wide variety, and unstable properties.

The actual production process needs to be adjusted according to the properties of the raw materials.

In comparison, bagasse is directly supplied by sugar mills, with sufficient raw material supply and relatively stable properties. Subsequent processing and production do not require frequent adjustment of operating parameters, and the production efficiency is high.

2. Process advantages

In terms of bagasse pellet machine and bagasse pellet plant technology, sugarcane pellets have very obvious advantages over the most common wood pellets. Wooden raw materials are strong and need to be torn before crushing.

This process consumes huge energy and labor costs. Bagasse has small particles and low strength and can be crushed without tearing, which can greatly save processing costs.

In addition, bagasse is more fluffy than wood, and can fully contact with flue gas during the drying process to dry thoroughly, and the drying cost is relatively low.

3. Application advantages

Sugar production companies produce a large amount of bagasse as a by-product every year.

- Due to the high moisture content of bagasse, its transportation cost is high and the transportation distance is limited.

- Due to policy and environmental constraints, there are not enough paper mills and power plants to digest bagasse, resulting in a large surplus of bagasse.

While many other industries have high demand for energy, high-value processing of bagasse to prepare bagasse biomass pellets can be easily transported overseas or used in local specialty industries.

It is expected to solve the problem of excess bagasse, alleviate environmental pressure, and increase the sugar industry’s demand and economic benefits.

What are the standards for bagasse biomass pellets from the bagasse pellet machine?

Regarding the quality standards of pellet products, there are relevant regulations in the industry standard NY/T 1878-2010 “Technical Conditions for Biomass Solid Molded Fuel”.

| Item | Pellets fuel (herbs type) | Pellets fuel (wood type) |

| Diameter/Maximum cross-section size (D) (mm) | ≤25 | ≤25 |

| Length(mm) | ≤4D | ≤4D |

| Molded fuel density (kg/m³) | ≥1000 | ≥1000 |

| Moisture content (%) | ≤13 | ≤13 |

| Position calorific value (MJ/Kg) | ≤10 | ≤6 |

| Broken rate (%) | ≥13.4 | ≥16.9 |

For biomass pellet fuel, there are clear limits on its diameter and length. If it is too long and too thick, it may cause problems such as uneven feed to the biomass burning boiler.

In order to ensure that the fuel has sufficient thermal efficiency, there are clear regulations on pellet density, crushing rate and calorific value.

This requires the raw materials to be crushed as thoroughly as possible and the particles to be pressed as tightly as possible to ensure that the product has good heating properties.

Moisture content is one of the most important indicators affecting the calorific value of biomass. The lower the moisture content of the fuel, the higher the combustion efficiency, but it means that the drying cost will increase.

The specific drying indicators still need to be evaluated and determined. In the industry standards The moisture content of pellet fuel is required to be ≤13%.

In addition, ash content is also an important indicator of the quality of biomass pellet fuel. Its content directly affects the coking problem of biomass boilers. Specifying ash content is of great significance to inhibit boiler coking and reduce equipment maintenance costs.

I want to buy a bagasse pellet machine and start a biofuel bagasse pellet plant business in Brazil. Is there any prospect? How to carry out?

Bagasse in Brazil is used to provide energy for cogeneration plants or national grid, but there are still around 25 million tons which are not used.

If those 25 million tons of sugar cane waste can be transformed into pellet fuel, it will make great benefit and profit to meet the growing demand of pellet fuel on the market.

- For making bagasse into fuel, a pellet mill is required.

- Firstly, the bagasse is processed into powder.

- There are a die and a set of rollers inside the pellet mill. The rotary roller will press the bagasse powder out of the hole of the die into small granules.

- Outside of the mill, there will be cutters to shorten the granule with the length between 3 and 5 cm.

- Besides pelletizing, there are still other processes including crushing and drying the raw material, and cooling and packaging the pellets.

- That is to say, besides pellet mill, other auxiliary accessories are needed together with crusher, dryer, cooler and packaging machine to make up a total pellet making production line.

In addition to the above equipment, RICHI Machinery will provide you with a series of services such as solution design, manufacturing, civil engineering, installation, commissioning, and after-sales services.

How to use bagasse pellet machine to produce 10 t/h bagasse pellets?

To process 10 tons of bagasse pellets, you need not only a granulator, but also a lot of equipment. You also need us to configure a suitable process and equipment layout for you.

Generally speaking, the production of 10t/h sugarcane sugarcane bagasse pellets is divided into several steps:

- Crushing: Use a high-efficiency bagasse pulverizer to crush the raw materials into powder with a particle size of 3-5mm.

- Drying: The moisture of fresh bagasse is about 48~50%. Ensure that the moisture of bagasse is dried to 10-15% to solidify the bagasse. Use a sugarcane bagasse dryer for drying. As one of the professional bagasse dryer manufacturers, we can provide a variety of customized dryer products.

- Granulation: The bagasse powder materials are fed into the bagasse pellet machine, and they will be compressed into pellets through the movement of the mold and a set of rollers inside the mill.

- Cooling: Use pellet cooling machine. This unit can save floor space and processing time. Cooling the pellets makes them easier to package and ship.

- Packaging: After the bagasse pellets are cooled, they are screened and qualified pellets are packaged in a packaging machine for easy storage and transportation.

As a biomass raw material, sugarcane bagasse is uniformly transported to the bagasse yard by the belt of the pressing workshop.

The source is concentrated and the collection method is simple, saving a lot of raw material collection costs; the bagasse composition is stable and suitable for industrialization and large-scale production.

Why use bagasse pellet machine to process bagasse fuel pellets?

Sugarcane bagasse is used as raw material, and through processes such as crushing, drying, additive mixing, and extrusion, it is made into granular, new clean fuel that can be burned directly.

Its products can be used as the best substitutes for traditional energy sources such as coal, diesel, and natural gas.

Because after using the bagasse pellet machine to process the bagasse into pellets, the bagasse pellets will have the following advantages:

- High return on investment.

The cost of raw materials is low, the investment in equipment is small, and the operation is simple. Ordinary people can operate the equipment with simple training, labor costs are very low, and coal prices fluctuate greatly. These factors ensure a better return on investment. - Wide range of applications.

Bagasse pellets are easy to use and store. It can be used for heating, domestic stoves, hot water boilers, industrial boilers, biomass power plants, etc. to replace firewood, coal, fuel oil, and liquefied petroleum gas. It is also suitable for family units; the combustion effect is good and can meet the needs of cooking, heating, and bathing, especially the necessities of biomass power plants. - Environmental benefits.

Bagasse pellets made by bagasse pellet machine are good for the environment. Bagasse pellets are carbon neutral, meaning that the carbon dioxide emissions they produce are absorbed by themselves during the growth process. They do not release other air-polluting gases into the air. - Renewable.

Bagasse pellets unlike fossil fuels such as coal and natural gas which are consumable (formed over a long period of time), bagasse pellets are renewable because sugar cane grows every year, so we can provide an unlimited amount of raw material. - Turn waste into treasure.

As energy demand increases and fossil fuels decline, no one can guarantee price stability. However, the cost of bagasse pellets can be controlled. In the context of global energy shortage, bagasse pellets represent the transformation of “waste” into wealth. Sugarcane is fully utilized, and in addition, it also increases farmers’ income.

What’s the calorific value of sugarcane bagasse pellets?

The calorific value is the primary indicator used by most manufacturers to evaluate biomass raw materials.

Usually, the calorific value of wood pellets is generally above 4000 kcal/kg, while the calorific value of straw pellets is between 3000 and 4000 kcal/kg.

The calorific value of bagasse pellets is similar to that of straw pellets, slightly lower than that of wood pellets, and the amount of pellet raw materials required to provide unit heat is larger.

At the same price, many people prefer to use wood pellets, which is understandable. But for those who can obtain bagasse resources at very low cost, choosing bagasse pellets is obviously more beneficial.

In addition, increasing the caloric value of pellets is an important way to enhance the competitiveness of bagasse pellet products.

In production, the caloric value of pellet products can be increased by compounding bagasse with wood chips with high calorific value.

In addition, increasing the drying intensity according to the actual situation will reduce the moisture content of the product and also enhance the combustion efficiency of the pellets.

Is the bagasse feed pellet production field worth investing in?

The development of sugarcane by-products as non-grain feed resources can not only alleviate the conflict between humans and animals competing for food, but also save feed costs and avoid the environmental pressure caused by the littering of sugarcane by-products, which is in line with the ecological civilization construction goals of many countries.

The crude protein content of sugarcane by-products is not low compared with other common crop straws. Although its fiber content is high, it can be improved through physical, chemical, biological methods and composite treatments.

In the future, further in-depth research can be conducted on the collection of by-products, improvement of processing equipment and optimization of compound processing, and can be extended to the feed utilization of other agricultural and by-products to effectively solve the problem of lack of conventional roughage.

All in all, sugarcane by-products are characterized by rich nutritional value and huge yields, and are worthy of vigorous promotion in ruminant production applications.

Start your Bagasse pellet production business

Bagasse is the main by-product of the sugarcane sugar industry. It is the fibrous residue of the sugarcane stem after crushing the sugarcane and extracting the juice. It is a kind of agricultural solid waste and a renewable resource.

Specific to a country, a region or an enterprise, how to utilize bagasse resources is not only a technical issue, but also an economic issue.

In many sugarcane-producing countries, a large amount of bagasse remains in each crushing season. Using bagasse to prepare pellet fuel can not only effectively digest bagasse, but also create economic benefits and reduce emissions. It is an effective way to save energy and increase efficiency.

If you have sufficient bagasse waste or have channels to purchase a large amount of low-priced bagasse, you may wish to consider purchasing a bagasse pellet machine and bagasse pellet production line to start this bagasse pellet processing business that is sure to make a profit!