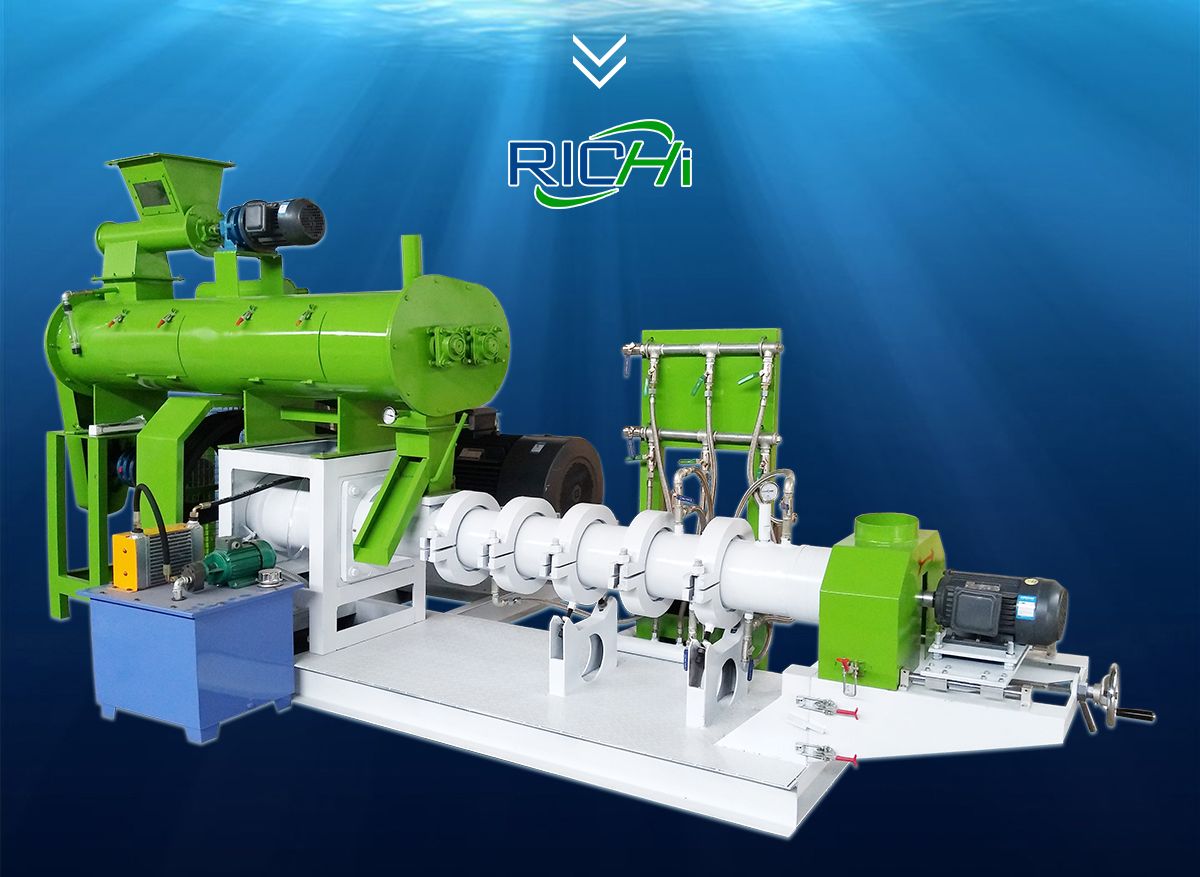

Pet Food Extruder Machine

Pet food extruder machine is suitable for processing all forms of manufactured feed: dry food (sometimes called kibble), semi-moist products and treats.

Common pet food ingredients include flour, meal, grits, meat, fats, minerals, amino acids and vitamins, often with the addition of flavor enhancers, texturing agents and preservatives.

The growing industry dictates frequent product changes, both in ingredients and aesthetics, to suit market trends and demands. The adaptability of pet food extrusion equipment easily accommodates process innovation and variation, without significant changes in machine configuration.

- capacity: 0.15-12T/H

- Price: 4,000-200,000 USD

- Type: dog food extruder machine, cat food extruder, Ornamental fish food extruder, extruded rabbit food machine, etc.

- Applicable customers: extruded pet food manufacturers, pet feed mill, dog food production line, cat food production line, fish feed production line, etc.

What is pet food?

Pet food refers to food specially provided for pets and small animals with protein and fat as the main raw materials, including water, protein, crude fat, crude ash, crude fiber, nitrogen-free extract, minerals, trace elements, amino acids, vitamins, etc.

It is a high-end animal food between human food and traditional feed. It has the advantages of comprehensive nutrition, high digestion and absorption rate, scientific formula, quality standards, convenient feeding and use, and prevention of certain diseases.

With the continuous improvement of people’s living standards and the prosperous development of the pet industry, consumers have put forward higher requirements for the production of pet food.

RICHI keeps up with the market development trend, continuously strengthens its independent innovation capabilities, upgrades and develops pet food extruder machines, pet food processes, technologies and equipment to meet customers’ diverse formula needs, help customers improve product competitiveness, provide strong support for high-quality pet food production, and promote the sustainable development of the pet industry economy.

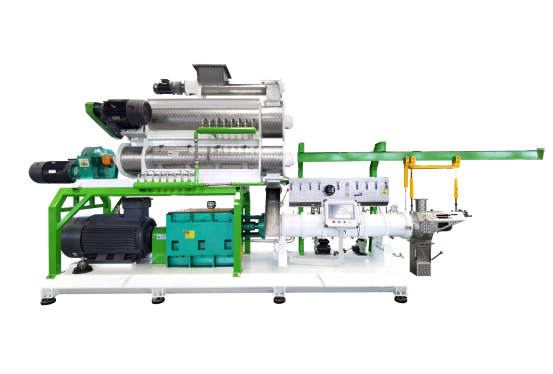

Performance and characteristics of pet food extruder machine

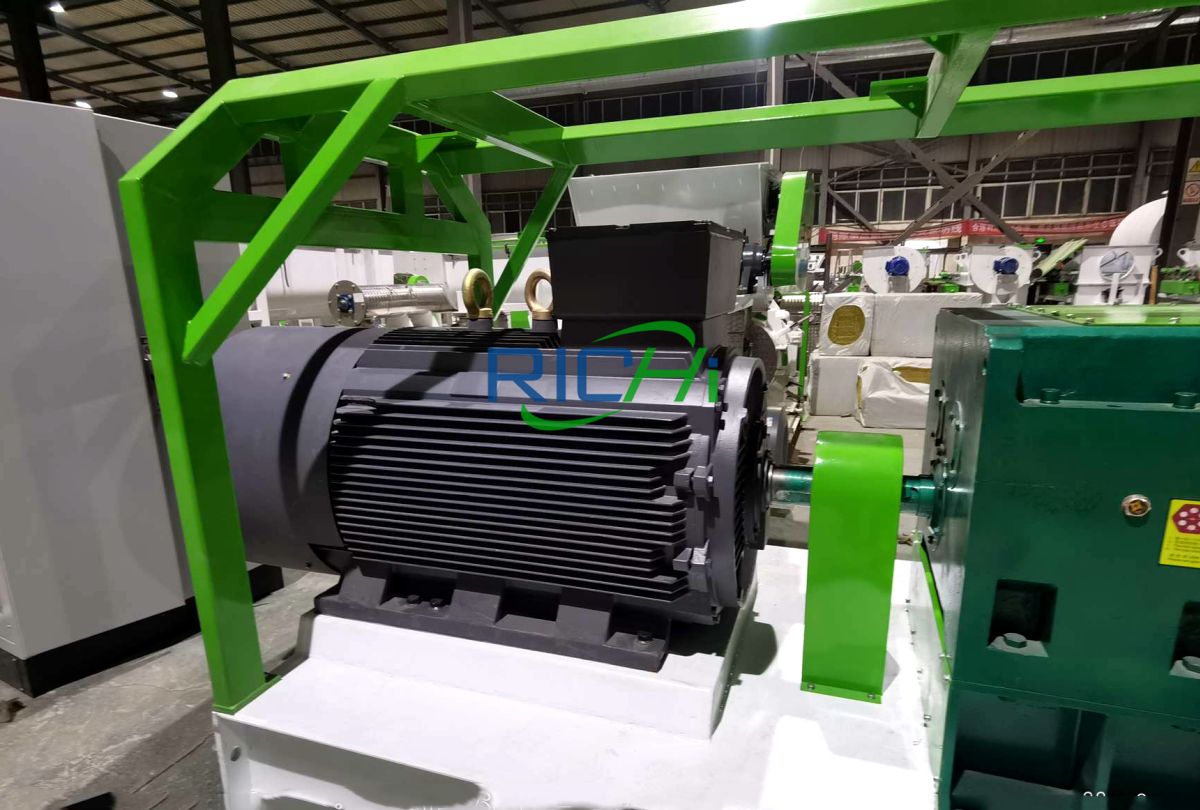

The twin screw pet food extruder produced by RICHI has stable performance, low power consumption, high efficiency, and adopts advanced control systems, which can be accurately processed according to different types of raw materials and formulas.

This twin screw extruder model also has some unique features, such as high pressure, strong adaptability, and easy maintenance, which makes it widely used in the processing industries of pet food, aquatic feed, pig feed, cattle feed, etc.

- PLC+touch screen control system, easy to operate and simple;

- The main engine adopts frequency conversion control, and the screw speed can be adjusted, which is suitable for different formulas (sinking material, semi-floating material, floating material);

- The fully meshed, zero-clearance twin-screw mechanism can effectively control the shear force and ensure that the curing time of all materials in the extruding cavity is consistent with the particle expansion coefficient;

- The appearance of the pellets is neat, the diameter of the mold is φ0.6mm-20mm; the vertical gear reducer drives the arch breaking device;

- The bearing in the transmission box adopts SKF bearing to ensure long-term stable operation;

- Effectively distribute the reasonable shear force in different areas of the extrusion cavity, and effectively increase the output under the premise of ensuring high quality;

- The new fully wear-resistant alloy (38CrMoAi) screw and the inner sleeve of the metal expansion cavity can effectively reduce the wear and tear and ensure the long-term stable operation of the equipment under the condition of high production capacity and high quality;

- The cutting part adopts a movable cutter seat, and the blade is made of spring steel, which fits well with the template. The cutter is driven by a frequency conversion motor, which can control the length of the product;

- The turbulent discharge device discharges the material to make the extruded puffed material more beautiful.

RICHI provides a fully equipped test facility for new product process and formulation testing for all applications. Experienced engineers are on hand to assist with pet food extruder machine customization, die design, system controls and the selection of associated extrusion equipment.

Advantages of pet food extruder machine

RICHI has been committed to the research and development and production of feed machinery, and the pet food extruder machine launched is one of its excellent products.

The heating device and compression system used in this machine can be flexibly adjusted according to different processing requirements. The production process is stable and the finished product is evenly discharged, which greatly improves the efficiency of pet food processing.

Designed to food grade standards

- The part in contact with the material is made of wear-resistant stainless steel, and the whole machine has a long service life;

- The whole pet food extrusion equipment adopts a clean design, with no dead corners, and it is more convenient to clean;

Excellent equipment performance

- Special high meat slurry screw configuration and fresh meat processing system, the fresh meat addition ratio is more than 120%;

- With an online bulk density adjustment system, the product bulk density is adjustable and the appearance is more beautiful;

Fully automatic control system

- Effectively realize the processing management of multiple formulas;

- Precise addition of water vapor can realize online monitoring of the equipment operation status;

Stable, reliable and effective

- The overall barrel bushing is forged, abandoning traditional castings, greatly reducing the risk of cracks;

- With torque limiting function.

The pet food extrusion machine produced by RICHI Machinery is an economical, efficient, stable and easy-to-maintain extruded feed processing equipment. Its appearance provides a feasible method for processing various grades of pet feed, which is of great significance to the development of pet feed technology.

Working principle of pet food extruder machine

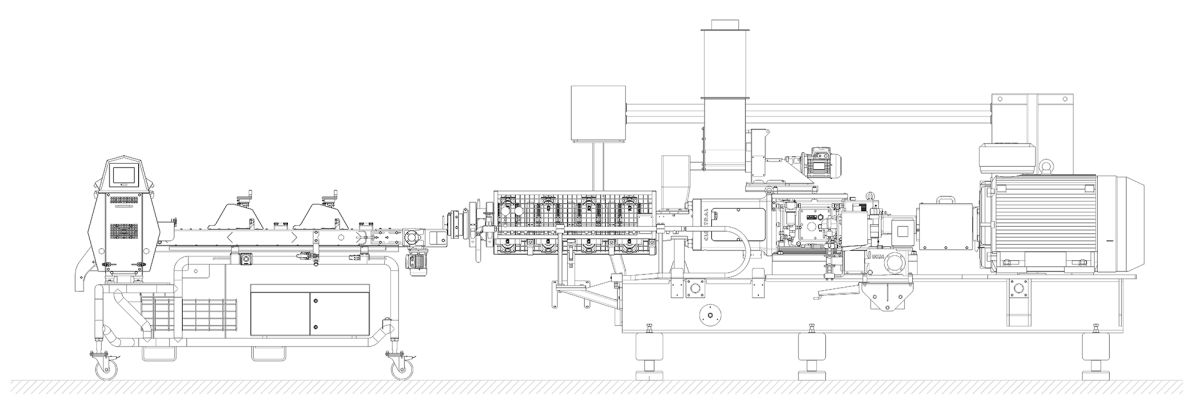

The pet food extruder machine is the core working part of the entire extrusion extruder, which is mainly composed of extrusion screw, sleeve and die head. Its working principle of pet food extrusion process is as follows:

- Loose raw materials enter the barrel from the hopper, and are transported forward along the screw groove as the screw rotates; due to the resistance of the machine head, the solid material is gradually compacted;

- And at the same time, the material is subjected to external heating from the barrel and strong stirring, mixing, friction and shearing of the material between the screw and the barrel, the temperature rises, the pressure increases, and the material becomes molten;

- As the volume of the screw groove at the end of the extrusion chamber becomes smaller, the material continues to heat up and the pressure rises, so that the material is cooked, and a series of complex biochemical reactions such as starch gelatinization, fat and protein denaturation occur, and the organization is further homogenized;

- Then, the material is instantly extruded from a die hole of a certain shape, and suddenly drops from high temperature and high pressure to normal temperature and pressure, wherein the free water vaporizes rapidly under this pressure difference, evaporates from the material organization structure, and causes the material to expand instantly, thereby obtaining a loose and porous structure.

Parameters of pet food extruder machine

| NAME | CAPACITY | MODEL | QTY | POWER(KW) | |

| SINGLE | AMOUNT | ||||

| Anti-caking bin | 1.5-2T/H | PGC900/700 | 1 | 1.50 | 1.50 |

| Inverter feeder | WLQ219×1200 | 1 | 1.50 | 1.50 | |

| DDC-conditioner | DC400*300-244 | 1 | 11.00 | 11.00 | |

| Twin screw extruder | RCPH120*2 | 1 | 75.00 | 75.00 | |

| PLC Controlling System | 1 | 0.00 | |||

| Anti-caking bin | 3-4T/H | PGC900/750 | 1 | 1.50 | 1.50 |

| Inverter feeder | WLQ219×1200 | 1 | 1.50 | 1.50 | |

| Conditioner | DC420-244 | 1 | 7.50 | 7.50 | |

| DDC-conditioner | DC400*300-244 | 1 | 11.00 | 11.00 | |

| Twin screw extruder | RCPH120*2 | 1 | 90.00 | 90.00 | |

| PLC Controlling System | 1 | 0.00 | |||

| Anti-caking bin | 4-5T/H | PGS900/800 | 1 | 1.5+0.3 | 1.80 |

| Inverter feeder | WLQ219-1300 | 1 | 1.50 | 1.50 | |

| Conditioner | DC500/244 | 1 | 11.00 | 11.00 | |

| DDC-conditioner | DDC500/400/244 | 1 | 11.00 | 11.00 | |

| Twin screw extruder | RCPH150*2 | 1 | 160.00 | 160.00 | |

| PLC control system | 1 | 0.00 | |||

| Anti-caking bin | 6-7T/H | PGS900/800 | 1 | 1.5+0.3 | 1.80 |

| Inverter feeder | WLQ219-1300 | 1 | 1.50 | 1.50 | |

| Conditioner | DC500/244 | 1 | 11.00 | 11.00 | |

| DDC-conditioner | DDC500/400/244 | 1 | 11.00 | 11.00 | |

| Twin screw extruder | RCPH150*2 | 1 | 200.00 | 200.00 | |

| PLC control system | 1 | 0.00 | |||

| Anti-caking bin | 8-10T/H | PGS900/800 | 1 | 2.2+0.3 | 2.50 |

| Inverter feeder | WLQ219-1300 | 1 | 2.20 | 2.20 | |

| Conditioner | DC600/300 | 1 | 15.00 | 15.00 | |

| DDC-conditioner | DDC500/300-300 | 1 | 15.00 | 15.00 | |

| Twin screw extruder | RCPH185*2 | 1 | 315.00 | 315.00 | |

| PLC control system | 1 | 0.00 | |||

| Anti-caking bin | 10-12T/H | PGS900/800 | 1 | 2.2+0.3 | 2.50 |

| Inverter feeder | WLQ219-1300 | 1 | 2.20 | 2.20 | |

| Conditioner | DC600/300 | 1 | 15.00 | 15.00 | |

| DDC-conditioner | DDC500/300-300 | 1 | 15.00 | 15.00 | |

| Twin screw extruder | RCPH185*2 | 1 | 355.00 | 355.00 | |

| PLC control system | 1 | 0.00 | |||

Similar product——single screw pet food extruder Machine

RICHI series single-screw pet food extruder machines have been used worldwide for the production of premium quality pet food in various forms and shapes. With the precise cutting device, ensuring a smooth pellet surface..

The unique design of the screw and barrel liner can generate a higher degree of cooking. With the incorporation of numerous innovative designs, high-quality materials, and precise manufacturing processes, RICHI single-screw pet food extruders can perform energy-efficient extrusion cooking.

In addition to pet food, this equipment can also produce high-quality extruded aqua feed with good water stability. Floating, slow sinking, and sinking extruded aqua feed for 1.0 to 30 mm extrudates. Special processing for small pellets with a nice appearance.

- Capacity: 0.15-4T/H

- Price: 4,000-40,000 USD

Cases of pet food extruder machine

pet food extruder for sale Russia

- Project time: 2022.11.16

- Capacity: 10-12 T/H

- Feed type: dog & cat

- pet food extruder machine used: RCPH185*2 (power 355KW)

pet food extruder for sale Indonesia

- Project time: 2023.06.02

- Capacity: 2 T/H

- Feed type: dog

- pet food extruder machine used: RCPH120*2 (power 75KW)

pet food extruder for sale Iran

- Project time: 2023.10.19

- Capacity: 3 T/H

- Feed type: dog & fish

- pet food extruder machine used: RCPH120*2 (power 90KW)

pet food extruder for sale Thailand

- Project time: 2023.02.16

- Capacity: 3 T/H

- Feed type: dog & aqua

- pet food extruder machine used: RCPH120*2 (power 90KW)

pet food extruder for sale Uzbekistan

- Project time: Nov 21th, 2021

- Capacity: 10T/H

- Feed type: dog feed

- pet food extruder machine used: RCPH185*2 (power 315KW)

pet food extruder for sale india

- Project time: 2022.05.22

- Capacity: 3-4 T/H

- Feed type: pet & fish feed

- pet food extruder machine used: RCPH185*2 (power 355KW)

pet food extruder for sale Ecuador

- Project time: 2023.08.12

- Capacity: 4 T/H

- Feed type: pet & fish feed

- pet food extruder machine used: RCPH185*2 (power 355KW)

pet food extruder for sale Bengal

- Project time: 2023.04.15

- Capacity: 8 T/H

- Feed type: dog & fish feed

- pet food extruder machine used: RCPH185*2 (power 355KW)

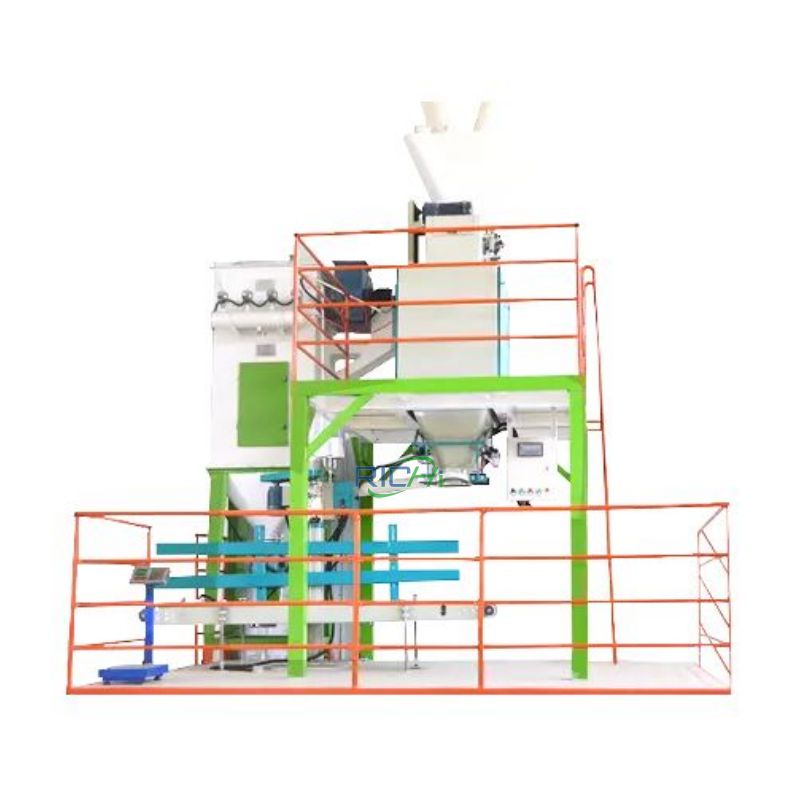

Application of pet food extruder machine ——pet food production line

Pet feed extruder is mainly used for the core process of cat and dog pet feed factories-expansion. If you want to complete all the stages from raw material processing to product packaging, you need to add coarse crushing, ultrafine crushing, batching, mixing, drying, cooling, spraying, screening, packaging and other processes.

After crushing and mixing, the powdered product can directly enter the process of puffing, cutting, drying, etc., but according to the needs, the micro-crushing process can be added, and then the puffing process can be carried out.

If the dried material needs to be sprayed with liquid (referring to oils and water-soluble vitamins), it should be sprayed with liquid first and then cooled, crushed, screened and metered for packaging.

In addition to pet feed production lines, pet food extrusion equipment can also be used in various aquatic and poultry livestock feed factories such as fish feed production lines, shrimp feed plant factories, chicken feed mill plant, pig feed mill factories, and cattle feed factories. Extruders can be used to process various types of animal feed.

At RICHI Machinery, we aim to obtain high quality feed in line with the needs of the pet food industry with the lowest possible operating and energy costs. Accordingly, we provide process solutions for pet food plants. We handle each and every process from raw material intake to packaging units.

Auxiliary equipment for pet food extruder machine

RICHI offers a full range of supporting feed mill equipment for pet food extruder machine – from raw material intake to finished feed bagging – as single unit or complete pet feed mill plant solution. The individual process machines offered are selected from the standardized and proven range of RICHI product families.

pet feed Grinder machine

Capacity:

3-25T/H

Main Power:

30-160KW

pet feed mixer machine

Capacity:

250-2000KG

Main Power:

4-55KW

Spraying Machine

Capacity:

3-15T/H

Main Power:

22KW

Video of pet food extruder machine

FAQs of pet food extruder machine

What’s pet food extruder machine Price?

The price of pet food extruder is generally between 4,000-200,000 USD.

In the production process of enterprises, pet food extruders are more and more widely used and have become one of the indispensable equipment in the feed processing industry. However, when enterprises purchase pet food extrusion machines, price factor is an important consideration.

Below RICHI will discuss the relevant issues of enterprises purchasing pet food extruders from two aspects: price factor and market analysis.

1. Specifications and size

The specifications and size of pet food extruder machines are one of the key factors affecting their prices. Pet food extruders of different specifications and sizes require different materials, processes and time costs in the production process. Generally, larger pet food extruders require more materials and longer production cycles, so the price is relatively high.

2. Technical requirements and functions

The technical requirements and functions of pet food extruder machines are also important factors affecting their prices. For example, some special industries may require pet food extruders with special functions such as high-precision temperature control and automatic control.

These special functions require higher technical levels and more complex production processes, so they will increase the customized purchase price.

3. Material selection

The material selection of pet food extruder machine is also one of the factors affecting its price. Different materials have different performance and prices, such as stainless steel, carbon steel, etc. Enterprises need to choose suitable materials according to their own needs and budget.

4. Production process and quality

Advanced production technology and strict quality control can ensure the stable performance and reliability of pet food extruder machines, but will also increase production costs. Therefore, production technology and quality are also one of the factors affecting the price of pet food extruders.

RICHI Machinery recommends that enterprises need to consider price factors and market analysis when purchasing pet food extruder machines. By understanding the key factors affecting the price of pet food extruders, enterprises can better choose suitable equipment and formulate reasonable procurement strategies according to market demand and trends.

At the same time, enterprises also need to pay attention to market competition and the development trends of emerging markets in order to maintain competitive advantages in the market.

For processing pet feed, should I use a single screw pet feed extruder or a twin screw extruder?

If it is to produce pet feed, a twin screw extruder is more suitable than a single screw extruder.

1. Advantages and Disadvantages of Single Screw and Twin Screw pet food extruder machines

In fish feed processing, both single screw extruders and twin screw extruders can be used to make feed. However, they each have different advantages and disadvantages.

(1) Single Screw Extruder

Single screw pet food extruder machine is a common extrusion machine, which is mainly composed of a rotating screw and a screen structure. The advantages are simple structure, easy operation, and suitable for processing ordinary types of feed. The disadvantages are low production efficiency and easy to cause problems such as clogging.

(2)Twin Screw Extruder

Twin screw pet food extruder machine is a more advanced extrusion machine, which uses two screws to rotate synchronously to gradually extrude the feed material from the feed port. The advantages are high processing efficiency, the ability to produce higher quality feed, and less prone to problems such as clogging. The disadvantages are complex structure and high maintenance costs.

2. How to choose the right screw model

Choosing the right screw model is the key to producing high-quality fish feed. Here are a few factors to consider:

(1)Feed material

Different feed materials require different types of screws. For example, for harder feed, a screw with a shallow groove can make production smoother.

(2)Production efficiency

If you need to improve production efficiency, a twin-screw pet food extruder machine is a better choice. Especially for large-scale feed plants, using a twin-screw extruder can greatly improve production efficiency.

(3)Cost

The maintenance cost of a twin-screw pet food extruder machine is high. If the budget is limited, you can consider using a single-screw extruder, which is more cost-effective.

In short, the choice of single-screw or twin-screw extruder needs to be evaluated according to specific production needs, and the most suitable pet food extruder machine model is found to achieve good production results and economic benefits.

Do you have a pet feed processing project with a capacity of 2 or 3 tons? How to design the process?

The following is an example of a 2-3 tons per hour pet feed production line project we have done.

- Since the raw materials of pet food have high fat and oil content, it is difficult for the grinder to crush a single raw material with high fat content if the conventional process of first powdering and then mixing is adopted, so the process of mixing and then powdering is generally adopted.

- In this process, in order to ensure that the material after expansion is not deformed and broken, a Z-shaped elevator is specially designed. Compared with the conventional bucket elevator, the biggest advantage is to avoid particle breakage, and it can also effectively avoid cross contamination caused by bottom residue.

- The process flow mainly includes: 12-bin automatic batching storage group, first mixing, coarse crushing, fine crushing, second mixing, premix storage, expansion, drying, vacuum spraying, cooling, finished product storage, packaging, palletizing and other main processes.

- In terms of equipment material: the whole pet food production line is made of high-quality carbon steel material, and the expansion machine, dryer, vacuum spraying, and grease tank are made of 304 material.

- In terms of control system: at the request of customers, centralized control system for batching, crushing and mixing, computer batching; independent touch screen touch for expansion, drying and vacuum spraying.

- Other aspects: open bridge cables, compressed gas supply system, transformer power supply system, steam supply system, material storage system, oil filling system, and water supply system were all discussed in depth.

After the entire production line was delivered, the customer hired a professional installation team to assemble the equipment according to the installation drawings provided by our company. The installation progress was slow due to the mask factor, but the equipment installation accuracy was not rough.

On the contrary, there was more time for communication and discussion. The best solution was selected for each detail installation, laying a good foundation for the subsequent equipment joint debugging and testing.

- 12-bin batching system: equipped with 500kg/batch batching scale, equipped with double-wing gate, weighing accuracy: ±1%

- First mixing equipment: use double-shaft high-efficiency mixer, large bottom door, mixing uniformity, low residual coefficient

- Coarse crushing equipment: equipped with 2.0 aperture screen, main motor 55kw, running bearing installation temperature detection

- Fine crushing equipment: 132kw ultrafine pulverizer, crushing fineness 80 mesh screening rate 85%, production capacity 2.5 tons/h

- Second mixing: use double-shaft high-efficiency mixer, large bottom door, mixing uniformity, low residual coefficient, built-in oil spray nozzle, evenly arranged, weighing tank batch weight, high measurement accuracy.

- Premixed material temporary storage, equipped with double dragon discharge to prevent arching.

- Extrusion equipment: Equipped with RCPH120*2 twin-screw pet food extruder machine, 2-layer steam conditioning, single-axis modulation + DDC, uniform modulation, high degree of maturation, pet food extruder machine equipped with 110kw main motor, gearbox uses SKF bearings, equipped with high temperature alarm, screw length-diameter ratio 19.5mm, full building block combination screw, special configuration for pet materials.

- The screw uses alloy material, the extrusion chamber uses a bimetallic structure, and has a built-in alloy wear-resistant bushing. The extrusion chamber uses steam heating and water cooling, and PLC automatic temperature control. Touch screen control, visible parameters, online adjustment.

- Drying equipment: The dryer uses a circulating belt drying, with a bandwidth of 2 meters. It uses a split assembly structure for the first time. The transmission part uses a 304 chain plate, zero residue, and zero damage.

- Spraying equipment: Use vacuum spraying equipment, single-axis paddle mixing structure, with oil, slurry and powder adding functions. This vacuum spraying system is independently developed by RICHI. Its highlight is the addition of automatic powder adding function. The entire system has been patented.

- The batch mixing capacity of this equipment is 300kg/batch, and the single mixing time is 5-8 minutes. The vacuum value working range is -5-8bar, and the limit vacuum value is -9.5bar. The oil adding system, slurry adding system, and powder adding system, the main materials are all centralized PLC controlled, automatic operation.

- Mixing uniformity: 97%, residual degree ≤1%. All valves and valve seals use imported valves. Guarantee the vacuum value. The maintenance door has a pressure resistance of 6bar. High sealing value.

- Cooling equipment: Use a replica cooler with a built-in material balancing structure and a special material discharge flow control mechanism to increase the material residence time and maximize the cooling effect. The material temperature after cooling is ≤45 degrees.

- Storage silos and automatic mixing silo group: 4 40m³ finished product silos are used, equipped with discharge regulating valves and vibration discharge devices, which can realize online automatic mixing of 4 kinds of materials to meet the packaging requirements of different materials.

- Automatic packaging system: equipped with automatic packaging systems such as packaging scales, heat sealing machines, belt packaging machines, and automatic palletizers. Meet the packaging requirements of different categories and different bag types.

- Automatic control automatic system: automatic control in the central control room, computer batching. Simulation screen display. Continuous screen operation control.

- Automatic oil filling system: automatic storage and insulation control of oil slurry.

- Other auxiliary machines: raw material screening, finished product screening.

Have you ever done a 1-ton pet food extrusion line project? Which model of pet food extruder machine is equipped?

Yes, some projects are equipped with RCPH120*2, and some projects are equipped with DSP135-B single-screw pet food extruder machines. These are determined according to the customer’s process requirements, product type and budget. Here is an example of a single-screw pet food extruder machine.

This project is a small-volume production line, and only produces cat food and dog food. The finished product particle size of cat food and dog food is large, and the grinding fineness of the raw materials is generally required to be 60 mesh (no ultra-fine grinding equipment is required, and micro-grinding equipment can be used), but the requirements for ripening and tempering are high, and the oil content is high (using a refueling method that combines a mixer + pet food extruder machine + powder spraying), and the finished product particle diameter ranges from about 2-8mm.

The pet feed production line has a designed capacity of 1T/H, and adopts a process of first batching and then crushing, that is, one batching, one pre-mixing, micro-grinding (grinding fineness 60 mesh), secondary mixing, puffing, drying and powder spraying, cooling, and finished product packaging. The total power of the equipment is about: 275KW; the construction area of the production area is about 9×13.5×14.5m (height); equipped with a 0.5T boiler.

Process design:

- Raw material receiving and cleaning section: This section is equipped with a feeding port, which is dust-free and has good dust removal effect;

- The first batching section: Since the raw material variety of this project is single (only 2-3 kinds of solid raw materials), only 4 batching bins are designed, and one batching scale is used for batching. The batching program independently developed by our company is controlled to achieve accurate fast and slow feeding, fast batching speed and high precision;

- The first mixing and crushing section: This section uses a double-shaft high-efficiency mixer for pre-mixing to improve the uniformity of the material before crushing;

- Micro powder section: Since the pet food extrusion machine has high requirements for the fineness of the raw materials, generally above 40 mesh, this section uses a micro pulverizer, which adopts wind-type discharging, batching Cyclone dust collector, pulse dust collector, and adjustable crushing fineness;

- (5)Second mixing section: This section uses a waiting mixing bin, implements batch metering, reduces the investment of the secondary batching system, a double-shaft high-efficiency mixer, and is equipped with a small material addition port;

- (6)Extrusion section: This section uses a pet food extruder machine, and a circular waiting extruder bin is set above the pet food extrusion machine, and is equipped with a disc feeder to prevent the material from arching and discharging smoothly; the extruded feed enters the dryer for drying;

- Spraying and packaging section: Post-grease spraying is a method of adding certain ingredients in pet food that are lost or damaged during the processing process in a specific way in the later stage of processing to prevent these ingredients from being lost or damaged.

Because the temperature of the material just out of the pet food extruder machine is very high, it needs to be cooled and finally enter the finished product packaging or bulk. Finally, it is packaged after cooling and screening through a pendulum cooling screen. - Dust removal system, dust removal at the packaging port, improve the working environment of workers; grease addition system, water addition system, improve feed palatability.

According to the needs of different customers, the solution can be optimized:

- This solution adopts the process of first mixing and then powdering, and the raw material warehouse is also used for mixing, which simplifies the process and saves costs. The number of silos and buffer hoppers can be adjusted according to customer needs. For example, setting up two feeding buffer hoppers can reduce the waiting time for mixing and improve efficiency;

- The micro-crushing process can choose more efficient and finer ultra-fine grinding equipment according to the specific production material conditions of the customer, but the cost will increase;

- The pet food extrusion machine is configured with a single-layer conditioner, and other forms of conditioners can be added as needed to further improve the maturity of the extruded material, but the cost will increase;

The finished product packaging equipment can be customized according to the customer’s packaging specifications and requirements. Generally, the finished product packaging of pet feed is divided into small packaging and large packaging, and different packaging equipment will be used.

How to choose the right pet food extruder machine?

Choosing the right pet food extruder machine is a critical decision that directly affects production efficiency, product quality and cost control. Here are some guidelines for choosing a pet food extruder.

- First, consider the type and scale of the product being produced.

Different products require different pet food extrusion equipment models and specifications. - Second, consider the production capacity of the pet food extrusion machine.

Select the appropriate extruder capacity based on the expected capacity requirements and production plan. Some manufacturers offer pet food extruders of different grades, and different capacities can be selected according to demand. - Third, consider the capacity stability and quality of the pet food extruder.

The stability and quality of the extruder directly affect production efficiency and product quality. Therefore, it is very important to choose a pet food extruder with excellent quality and reliability. This can be judged by checking the manufacturer’s reputation, word of mouth, and having a deeper understanding of the product’s quality control system. - Fourth, consider the energy consumption and environmental performance of the pet food extruder.

The pet food extruder machine consumes a lot of electricity during operation, and choosing a pet food extruder with lower energy consumption can help reduce production costs. At the same time, choosing an extruder that meets environmental standards can improve the image and competitiveness of the company. - Fifth, consider the after-sales service and technical support of the pet food extruder machine.

The extruder is a complex mechanical equipment that requires professional repair and maintenance. Therefore, it is very important to choose a manufacturer with a complete after-sales service and technical support system. You can learn more by consulting other customers who use the manufacturer’s equipment, or by visiting the manufacturer’s after-sales service and technical support team in person. - Finally, the price and cost performance of the pet food extruder machine need to be considered.

The prices of extruders of different brands and specifications vary greatly, so it is necessary to fully compare the quotations and cost performance of different manufacturers. Before choosing, consult and compare multiple aspects with different manufacturers in order to choose an extruder that suits your needs and economic strength.

In short, choosing a suitable pet food extruder machine is a complex decision-making process that requires consideration of multiple factors. The above-mentioned criteria can be used as a reference for selection, but in actual selection, comprehensive weighing and judgment are required based on specific circumstances.

Choosing an extruder that suits your needs and economic strength can improve production efficiency and product quality, while reducing production costs and making the company more competitive.

What are the precautions when using a pet food extruder machine?

- First of all, you need to pay attention to the stable performance of the equipment. When using it, you need to strictly follow the instructions to ensure the smooth operation of the machine and avoid unnecessary accidents.

- Secondly, during use, it is necessary to strictly control the appropriate processing temperature to avoid adverse effects on the pet food extruder machine and ensure that the produced particles meet the quality requirements.

- Finally, the equipment should be thoroughly cleaned after use to avoid affecting the next use and damaging the life of the equipment.

In the pet food processing industry, pet food extruders play an important role, so we need to pay attention to many details. RICHI reminds you:

- First, when choosing a manufacturer, choose a well-known company because the equipment of these companies is qualified and reliable.

- Secondly, choose different pet food extruder machines according to the types of raw materials, formulas and products, understand the characteristics and parameters of the equipment, and avoid making wrong choices.

- Finally, for problems encountered during the use of pet food extrusion machines, the manufacturer should be contacted in time for inquiry so that the problems can be solved in time to ensure continuous and efficient production.

In order to avoid production problems of pet food extruder machines and maintain production efficiency and smooth progress, RICHI emphasizes regular inspection and maintenance of equipment.

Clean accessories and equipment, check and connect components, electronic control and heating performance, and meet the daily maintenance and use requirements of the equipment, so as to achieve a longer service life and minimize subsequent maintenance costs.

It is recommended to select equipment according to the production mode and annual utilization hour load, and consider the maintenance cost of the equipment and the importance of improving efficiency to ensure that the equipment finally selected can meet the requirements and production needs of the factory.

How to maintain and maintain the pet food extruder machine?

The pet food extruder machine is an important production equipment and must be regularly maintained and maintained to ensure that it is always in good working condition. In order to protect the life of the equipment and extend the service life, it is recommended to regularly maintain the mechanical, electrical and other components of the pet food extruder.

- Clean the rotating parts and fixed parts, apply lubricating oil, check, adjust and replace parts.

- In addition, the manufacturing materials, auxiliary equipment, etc. should also be maintained to ensure the normal operation of the overall production line.

- In the maintenance and maintenance process, operating skills are indispensable, and each step must strictly follow the operation manual. For this reason, it is recommended that operators strictly maintain the equipment according to the requirements and participate in the corresponding training to master the necessary operating skills. Regular equipment maintenance will keep the pet food extruder machine in a stable state in the next production and improve product quality.

- Finally, the backup of spare parts is also very important. During the maintenance plan, the required spare parts and accessories should be purchased or backed up in advance to ensure that production is not disturbed. High-quality raw materials and parts must be selected to ensure the efficient operation and service life of the equipment.

In short, the maintenance and care of pet food extruder machines is a production management process that cannot be ignored. Through regular maintenance and care, the life and service life of the equipment can be effectively guaranteed. It is recommended that every manufacturer should fully realize the importance of this issue and give it corresponding attention.

What is the prospect of pet food processing?

- First of all, people pay more and more attention to pet raising, and have regarded pets as part of the family, or even their own children.

With the change of family population structure, more and more people choose to keep pets for companionship and care. This change and change of concept also increases the demand for pet feed. - Secondly, people pay more and more attention to pet health and nutrition.

With the improvement of people’s living standards, the dietary requirements for pets are getting higher and higher. They are no longer satisfied with the basic sense of fullness, but hope to provide pets with more comprehensive, balanced, high-quality and healthy feed.

More and more studies have shown that the dietary structure and feed quality of pets are one of the key factors in pet health. Therefore, the pet feed industry is constantly launching new products with nutrition and health as the core to meet consumers’ demand for high-quality pet feed. - Thirdly, the market space for pet feed still has great development potential.

At present, the global pet feed market has reached thousands of dollars and is still growing at a rate of more than 20% per year. This means that the pet feed industry has huge market potential and will have a very broad future development space. - Finally, technological innovation in the pet feed industry is also an important support for its development prospects.

With the advancement of science and technology and the continuous innovation of raw material technology, the pet feed industry continues to seek breakthroughs and innovations, and launch new products that are more suitable for pet needs.

Many companies have begun to focus on improving the quality and formulation of feed, applying natural and organic raw materials to the manufacturing process of pet feed, and providing more reliable and healthy pet feed products.

In addition, the pet feed industry is also actively exploring new feed processing technologies, such as drying and pellet pressing, to improve production efficiency and product quality.

In summary, the development prospects of pet feed are very broad. With the improvement of people’s care for pets, the increase in demand for pet nutrition and health, and the expansion of the market scale, the pet feed industry will continue to flourish.

At the same time, technological innovation and market competition will also drive the pet feed industry towards higher quality and more diversified development. (Find RICHI on youtube)