Fuel Pellet Making Machine

The fuel pellet making machine is mainly used to process wood fuel pellets, biomass fuel pellets and other flammable organic matter pellets.

What is fuel pellet making machine?

The ring die fuel pellet making machine is the current mainstream equipment for fuel pellet processing, with the advantages of high output and strong adaptability to raw materials.

It mainly uses forest waste (such as tree trunks, wood chips, sawdust, wooden pallets, bark, leaves, branches, etc.), agricultural waste (such as straw, peanut shells, sunflower seed shells, rice husks, coconut shells, bamboo, bagasse, reeds) , hay, miscanthus, etc.), as well as other materials with a certain calorific value (such as coal, waste paper, cow dung, horse dung, organic waste in industrial production and urban organic waste, etc.) as fuel raw materials.

Pelleted fuel pellets are mainly used in industrial boilers and large power plants as well as home heating.

- Capacity: 0.3-12 T/H (single machine)

- Price: 10,000-100,000 USD

- Applicable customers: fuel pellet plant, wood pellet factory, biomass pellet plants, lumber mills, farms, power plants, farms, industrial enterprises, etc.

What raw materials are suitable for fuel pellet making machines?

Fuel pellet machine is an efficient device that converts different raw materials into pelletized fuel. Fuels made from different raw materials have their own unique characteristics and application scenarios. The raw materials suitable for fuel pellet mills come from a wide range of sources, including wood, crop waste, livestock and poultry manure, urban organic waste, etc.

forest waste

Wood raw material mainly comes from forestry waste and wood processing residues. This fuel has the advantages of high calorific value, stable combustion, and low ash content, and is suitable for high-temperature, high-load combustion equipment such as large boilers and industrial kilns. In areas with developed forestry, wood biomass fuel can also promote the recycling of forestry waste and reduce environmental pollution.

agricultural waste

Agricultural crop waste is also an important source of biomass fuel, such as straw, rice husk, etc. This type of fuel has the characteristics of large output, wide distribution and easy collection, and is suitable for use in rural and small industrial boilers. The utilization of crop waste can not only solve rural energy problems, but also reduce environmental pollution caused by burning straw in farmland.

Animal manure

Manure fuel is made by drying and fermenting livestock and poultry manure. This fuel is environmentally friendly, renewable, and low-carbon, and is suitable for biomass power generation, biomass pyrolysis and other fields. The manure fuel can not only realize the resource utilization of livestock and poultry waste, but also reduce greenhouse gas emissions and promote sustainable development of agriculture.

Other organic waste

Organic waste is also one of the important sources of biomass fuel. This type of waste can be made into biomass fuel with high calorific value after sorting, crushing, drying and other treatments. The application of urban organic waste biomass fuel is mainly concentrated in the fields of biomass power generation and biomass heating, which can effectively alleviate urban energy pressure and reduce environmental pollution caused by landfills.

In addition to the above common raw materials, there are also some special biomass fuels, such as algae biomass fuel, microbial biomass fuel, etc. These fuels have unique advantages and application prospects, such as fast growth rate, high photosynthesis efficiency, and strong environmental adaptability. They are an important direction for the future development of biomass fuels.

According to the type of raw materials, fuel pellet making machines can be divided into the following types:

- wood fuel pellet making machine

- wood sawdust pellets solid fuel making machine

- wood pallet fuel pellet machine

- biomass fuel pellet machine

- Straw pellet machine

- Rice husk pellet machine

- Bamboo pellet machine

- Peanut shell pellet machine

- EFB pellet machine

- Bagasse pellet machine

- coal pellet making machine

- Walnuts shells fuel pellet machine

- Coconut shell fuel pellet machine

- coffee grounds fuel pellet machine

- Cartons fuel pellet machine

- paper pellet machine

- Leaves pellet machine

- olive oil pomace fuel pelletizer

- Grass fuel pellet machine

- Cow dung fuel pellet machine

- Horse manure fuel pellet machine

- …

Technical characteristics of fuel pellet making machines

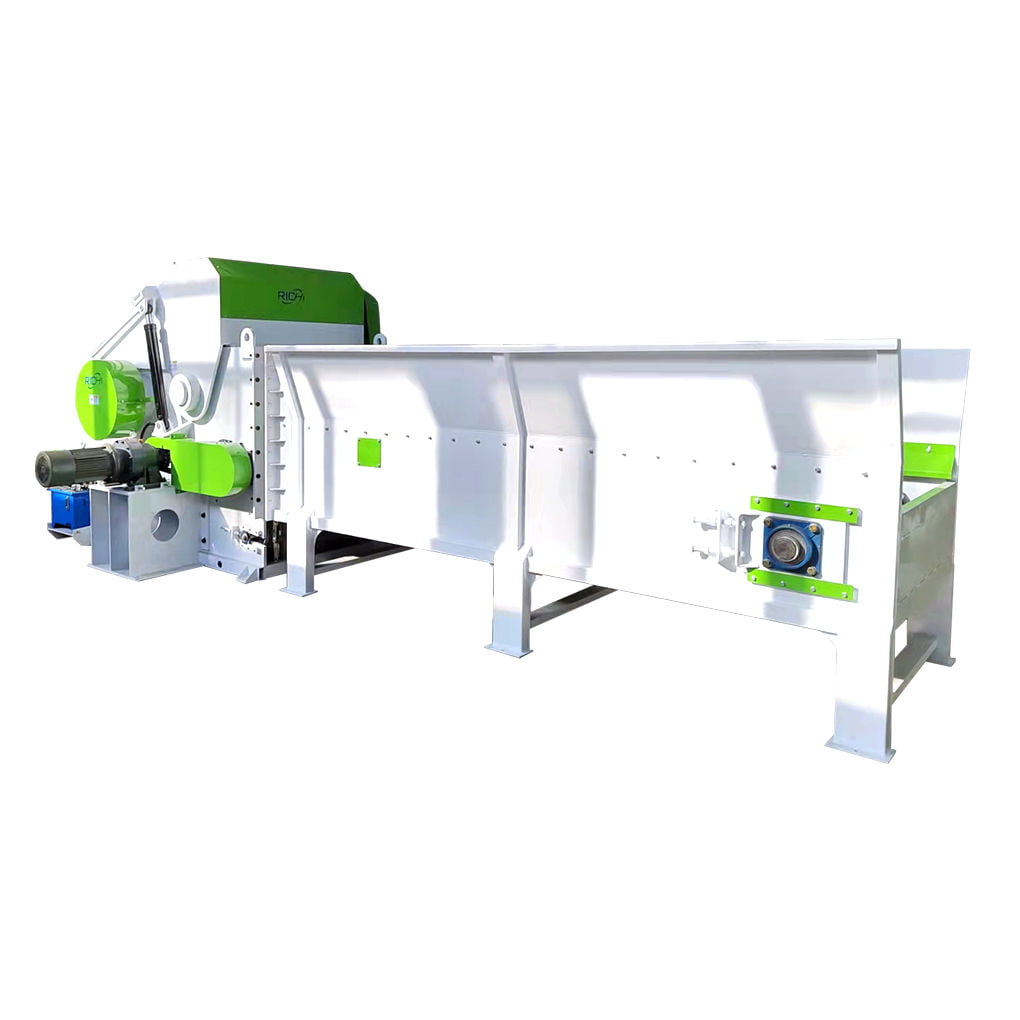

RICHI ring die pellet fuel maker machine is a pellet forming equipment developed and manufactured based on the diversification of biomass raw materials in the market, which is convenient for using a variety of agricultural and forestry wastes as raw materials.

This equipment has solved the problem of difficulty in forming various thick and thin fibers and poor forming effect. It has been recommended by many well-known particle processing companies as a new generation of environmentally friendly new energy equipment. It has stable product performance and stable output.

- The horizontal fuel pellet mill effectively solves the shortcomings of difficulty and poor efficiency in pelletizing many raw material fibers. The power drives the ring die to rotate at high speed through the gearbox and cooperates with the pressure roller to extrude the raw materials to form rod-shaped pellets;

- The product adopts high-strength and high-precision gear transmission, which ensures smooth, reliable and long-lasting operation;

- Independent frequency conversion feeding system ensures the stability of feeding;

- The oil pump cools and dissipates heat, which greatly reduces the temperature of the gear oil inside the transmission device and ensures the normal operation of the machine;

- The transmission is efficient, stable, and low noise. The ring die adopts a removable hoop type. The feeding is controlled by frequency conversion to ensure uniform feeding. This wood pellet machine has a novel, compact structure, easy installation, and low failure rate;

- The bearings used in this pellet machine all adopt high-efficiency silent bearings, and a cooling and lubrication system is added, which has a longer service life and safer operation.

- The biofuel pellet machine has compact structure, safety, low noise, low failure rate and small floor space;

- The ring die used in the fuel pelletizer is precision manufactured from high-grade stainless high-nickel steel. The unique compression ratio design is reasonable, which ensures better product quality, longer service life of the ring die, and minimizes production costs.

Advantages of fuel pellet making machine

Our fuel pellet maker machine has the following advantages:

High efficiency and energy saving:

The wood fuel pellet machine uses advanced processes and technologies to efficiently convert raw materials into granular biomass fuel and improve energy utilization efficiency. At the same time, multiple auxiliary equipment can also be configured to form a fuel pellet production line with a high degree of automation, which can reduce manual operations and save human resources.

Environmentally friendly and sustainable:

The pellet fuel produced by the fuel pellet making machine has the characteristics of low emissions and high calorific value, and can replace traditional fossil fuels. The use of biomass fuel can reduce dependence on fossil energy, reduce carbon emissions, and is environmentally friendly and sustainable.

Multifunctional

The wood fuel pellet mill can be used to process a variety of raw materials at the same time. It can not only process wood chips, but also be used to pellet various raw materials such as straw, peanut shells, coconut shells, municipal waste, and industrial waste. This provides a feasible way for the comprehensive utilization of waste.

working principle of fuel pellet making machine

Molding fuel is made by drying and pulverizing various dispersed raw materials with no certain shape to a certain particle size, and then extruding them into regular, larger-density rods, blocks, and balls under certain conditions of temperature, humidity, and pressure.

The density of these solid materials formed by compression can reach 1.1~1.4t/m3, and the volume is 6~8 times smaller than before compression. The energy density is equivalent to that of medium-quality bituminous coal.

During the combustion process, the furnace temperature is high, the firepower is long-lasting, and the combustion characteristics are obviously improved.

Technical parameters of fuel pellet making machine

| Model | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH768 | MZLH858 |

| Output (t/h) | 0.3~0.5 | 0.5~0.7 | 1.0~1.5 | 2.0~2.5 | 2.5~4 | 4~5 |

| Main motor power (kw) | 22 | 37 | 90 | 132 | 250 | 280 |

| Main motor series | 8P | |||||

| Ring die diameter (mm) | 320 | 350 | 420 | 520 | 762 | 858 |

| Finished pellet diameter (mm) | 6-12mm | |||||

| Fuel Pellet Machine Configuration | Ring die material: 42CrMo Stainless steel feeder: with anti-caking function Door of pelleting room: 6mm /SUS304 Forced feeding: Worm gear reducer Gear box: HT250 Gear: 42CrMo Gear shaft: 42CrMo Spindle: 42CrMo Empty shaft: 42CrMo Bearings: The gear shaft and main shaft bearings are SKF, and the pressure roller bearings are domestic high-quality bearings Oil seal: Germany/Taiwan Overload mechanical protection: safety pin Serpentine spring coupling drive Lubrication system: Configurable automatic oil injection system | |||||

fuel pellet making machine projects

Richi Machinery has successfully completed thousands of fuel pellet machine and fuel pellet line design and engineering projects, including retrofits and new plant installations.

fuel pellet machine in australia

- Raw material: wood & straw

- project date: 2023.02.01

- Pellet Size: 6-10mm

fuel pellet machine in canada

- Raw material: wood chips

- project date: 2022.9.21

- Pellet Size: 8-10mm

fuel pellet making machine in uSA

- Raw material: wood waste

- project date: 2021.10.19

- Pellet Size: 8mm

fuel pellet machine in Indonesia

- Raw material: crop waste

- project date: 2020.06.18

- Pellet Size: 10mm

fuel pellet making machine in germany

- Raw material: sawdust

- project date: 2023.06.17

- Pellet Size: 6-10mm

fuel pellet making machine in U.K.

- Raw material: sawdust

- project date: 2022.03.20

- Pellet Size: 8-10mm

fuel pellet making machine in poland

- Raw material: wood & Paper

- project date: 2013.05.10

- Pellet Size: 8mm

fuel pellet making machine in malaysia

- Raw material: biomass & manure

- project date: 2022.08.23

- Pellet Size: 6-10mm

Wood fuel pellet machine price

The fuel pellet making machine costs usually between 10,000 and 100,000 US dollars.

Generally speaking, the price of wood fuel pelletizer equipment is affected by many factors, including production line specifications and models, manufacturers, equipment quality, technical level, market demand, raw material prices, transportation and installation costs, after-sales service, regional differences, and additional features and customization options.

Here are some factors that may affect the price of wood fuel pellets mill equipment:

- Specifications and models:

Different specifications and models of fuel pellet making machines have different processing capabilities and functions, so the price will vary depending on the specifications and models of the equipment. - Manufacturer:

Different manufacturers may have different advantages in technology, quality and service, so the manufacturer of the wood pellet fuel machine will also have an impact on the price. - Equipment quality:

The quality of wood pellet fuel maker equipment directly affects its performance and life. High-quality fuel pellet machines usually cost more, but can provide more stable performance over long periods of operation. - Technical level:

Advanced technology and design usually increase the cost of the equipment, but may also improve its efficiency and performance. - Market demand:

Fluctuations in market demand will affect the supply and demand relationship of pellet fuel maker equipment, thereby affecting prices. When supply exceeds demand, prices may fall; when demand exceeds supply, prices may rise. - Raw material prices:

Fluctuations in the prices of raw materials required to manufacture fuel pellet making machines may directly affect the manufacturing cost of the equipment, thereby affecting the price. - Transportation and installation costs:

The transportation and installation costs of the equipment will also affect the final price, especially for long-distance transportation. - After-sales service:

Providing comprehensive after-sales service and warranty may increase the overall cost of the device slightly, but it is usually an important consideration for users. - Regional differences:

Factors such as market conditions, taxes, and regulations in different regions may also lead to differences in fuel pellet machine prices. - Additional features and customization options:

If a device has additional features or can be customized, this may increase its price.

RICHI always prices based on the quality and technical level of its products. And we provide free technical support for the entire life cycle of the fuel pellet making machine and provide a full range of services such as transportation, installation and commissioning, repair and maintenance, and original accessories.

All fees are in line with industry standards and are globally consistent prices. If you are interested in our products and want to know the prices of fuel pellet machines with different outputs and models, please contact us to get an accurate equipment quotation.

How to choose a fuel pellet making machine manufacturer?

As an important equipment in the fuel pellet processing industry, the pellet fuel maker machine is crucial to choose a high-quality fuel pellet machine manufacturer. In the current market, there are many types of fuel pellet machines with different prices and uneven quality.

It is not easy to choose a fuel pellet machine manufacturer suitable for your pellet processing business. RICHI will introduce you to how to choose a high-quality fuel pellet machine manufacturer and help you make a wise choice among many brands.

First of all, product quality is an important consideration when choosing a fuel pellet machine manufacturer. The fuel pellet machine is an equipment directly related to pellet processing, so its quality has a crucial impact on the normal operation of the pellet processing business and the quality of the pellets.

When purchasing a fuel pellet machine, you can learn about the product quality control system and whether it has obtained a quality management system certification by on-site inspection of the manufacturer’s production process, testing methods, raw material procurement, etc.

Secondly, when choosing a high-quality fuel pellet machine manufacturer, you need to consider brand reputation. A manufacturer with a good reputation can often provide customers with more reliable products and services. You can learn about the manufacturer’s reputation and user reviews on industry forums, social media and customer evaluation platforms, and use this as a reference to choose a suitable fuel pellet machine manufacturer.

In addition, the after-sales service of the fuel pellet making machine is also one of the key factors in choosing a manufacturer. Good after-sales service can ensure the maintenance and upkeep of equipment during use, solve problems such as equipment failures, and provide customers with professional technical support.

Therefore, when choosing a fuel pellet machine manufacturer, you can communicate with the manufacturer to understand its after-sales service system, including warranty policy, maintenance services, etc., to judge whether the manufacturer’s after-sales service is perfect.

In addition, price is also one of the factors that needs to be considered when choosing a fuel pellet machine manufacturer. The price of fuel pellet machines varies greatly depending on brand, model, function, quality and other aspects.

When choosing a fuel pellet machine manufacturer, you need to weigh price and product quality, and choose a product with a higher price/performance ratio. Only products with reasonable prices and reliable quality are the best choices.

Finally, when choosing a fuel pellet machine manufacturer, you can consider consulting industry experts or seeking recommendations from relevant companies. Understand the actual production capacity, product quality and after-sales service of the fuel pellet machine manufacturers, comprehensively consider various factors, and then make the best choice for your pellet processing business.

When choosing a fuel pellet making machine manufacturer or supplier, it is necessary to conduct multi-faceted investigations and comprehensive evaluations.

Don’t just look at the surface, but have a comprehensive understanding of the manufacturer’s strength and product status. Only in this way can you choose high-quality fuel pellet machine equipment that meets your needs and ensure the stable operation of the pellet production line.

how to make pellet fuel? Complete fuel pellet machine system design

I believe many customers know that if they want to process fuel pellets, a fuel pellet making machine alone is not enough. The fuel pellet machine is the direct equipment for processing fuel pellets, not the only equipment.

So how to make fuel pellets? The processing flow of fuel pellets production usually includes: crushing, pulverizing, drying, granulating, cooling and packaging. Generally speaking, a complete fuel wood pellet production line requires 2-6 people to complete the process from crushing to packaging.

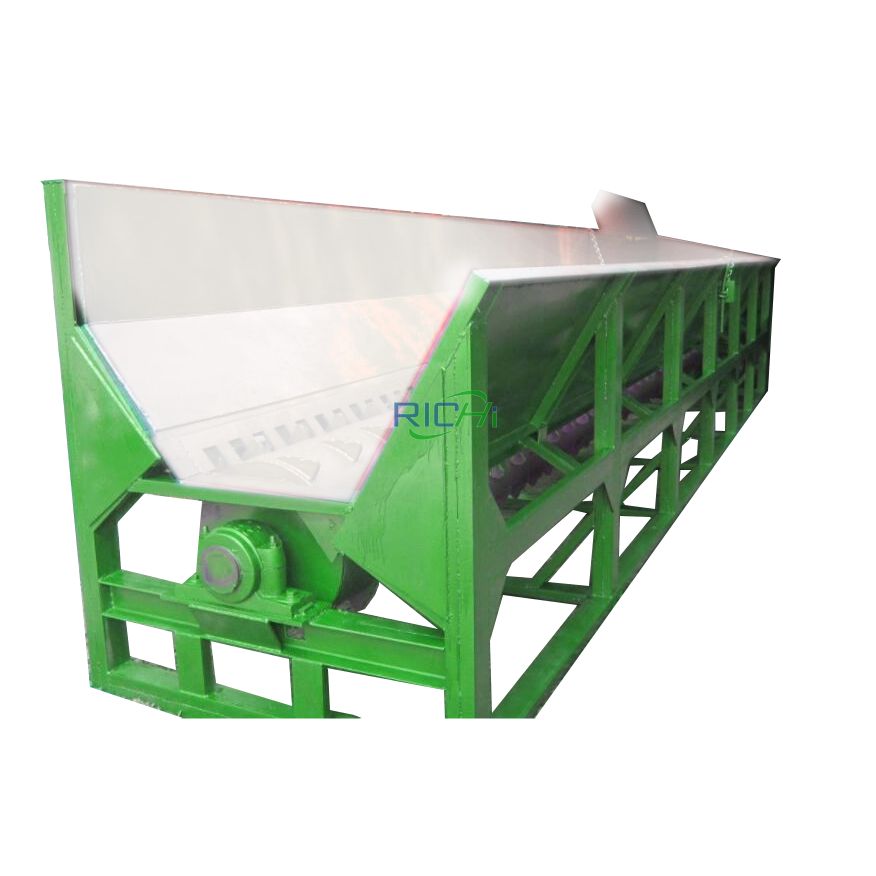

- First, the raw materials are processed by a crusher to crush them into sizes suitable for subsequent processing. Depending on the type and physical state of the raw materials, the crushing equipment used is different.

For example, if you want to crush very thick tree trunks, you need crushing equipment such as peelers, wood splitters, slicers, and wood pellet hammer mills; if you want to crush straw, you need equipment such as haymakers and straw crushers; If you need to crush wooden pallets, you need wood pallet crusher machine and wood chips hammer mill. - Remove moisture from raw materials through drying equipment to ensure efficient granulation process.

- The dried raw materials are fed into the fuel wood pellet mill machine for compression molding, and the fuel particles are made solid and dense through the action of high temperature and high pressure.

- Through cooling and screening, the pellets are cooled to room temperature and classified for storage and transportation.

- Qualified biofuel wood pellets after screening can be stored or transported in bulk, or particle packaging equipment can be used to package them for storage or sale.

RICHI has the design and build experience to create a custom design for your fuel pellet production plant site. From single pelleting systems to a complete fuel pellet production line system, we’ll put our broad industry knowledge to work, helping you simplify your decisions and achieve your production goals for a variety of materials. how to start a fuel pellet plant? Click here to view detailed solution!

Equipment needed in a fuel pellet plant

The fuel wood pellet making line is composed of multiple links, including crushing, drying, compression molding, cooling, screening and other steps. Accordingly, each section needs to be equipped with different processing equipment.

Generally speaking, the main equipment of a fuel pellet production line includes slicers, hammer mills, dryers, fuel pellet making machines, coolers, screening machines, packaging scales, dust removal equipment, conveying equipment, etc.

wood Debarker

Capacity:

5-15 T/H

Main Power:

7.5-11 KW

Wood splitter

Capacity:

3-12T/H

Main Power:

10-20 KW

With the progress of society and economic development, humankind’s demand for energy is increasing day by day, but fossil energy sources such as coal, oil, and natural gas are continuously decreasing.

Raw materials such as agricultural and forestry wastes, industrial wastes, and municipal solid wastes have the characteristics of a wide range of sources of raw materials. Especially agricultural and forestry wastes are also renewable and have attracted more and more attention.

Among them, pellet fuel is compressed from crushed solid raw materials into cylindrical solid molded fuel through a fuel pellet making machine. The diameter is generally no more than 12 mm, the length is no more than 4 times its diameter, and the density after compression is 5 to 10 times the original.

It has the ability to store It has the characteristics of small space, convenient transportation, clean and environmentally friendly use, high thermal efficiency, and sustainable utilization, and has broad development prospects.

Pellets are generally not used immediately after production and need to be stored in the factory for at least 6 months. During this long period of time, what storage form is used and what are the requirements for temperature and humidity during the storage process? It is an important link to ensure that pellet fuel does not become moldy or deteriorate.

fuel pellet making machine Video

Application of pellet fuel

In terms of application scenarios, biomass wood fuel can be widely used in power generation, heating, industrial boilers, transportation and other fields.

- In the field of power generation, biomass power generation has the advantages of environmental protection, renewable, low carbon, etc., and is an important choice to replace traditional fossil energy.

- In the field of heating, biomass fuel can be used for home heating, urban heating, etc. to improve energy utilization efficiency and reduce environmental pollution.

- In the field of industrial boilers, biomass fuel can replace traditional fuels such as coal, reducing corporate energy costs and improving energy security.

In short, biomass wood fuels made from different raw materials have their own unique characteristics and application scenarios. By rationally utilizing these biomass resources, we can not only realize the resource utilization of waste, but also promote the optimization of energy structure and improvement of the environment.

In the future, with the continuous development and improvement of biomass fuel technology, its application in the energy field will become more extensive and in-depth.

Why start a fuel pellet business?

Pellet fuel is a renewable energy source that has the advantages of high heat, easy transportation and storage, safety and reliability. As people pay more attention to environmental issues and increase energy demand, the pellet fuel market has a very bright future.

In the field of industrial production, pellet fuel can be used for heating, drying, smelting, etc. In the agricultural field, pellet fuel can be used in agricultural production, livestock breeding, etc. In the field of residential life, pellet fuel can be used for heating, water heaters, etc. Therefore, the pellet fuel market is in great demand.

With the increasing awareness of environmental protection and the adjustment of energy policies, more and more countries and regions have begun to promote the use of pellet fuels.

For example, European countries, the United States, Australia and other countries and regions have listed pellet fuel as one of the renewable energy sources and have formulated policies to encourage the use of pellet fuel. With the implementation of these policies, the pellet fuel market prospects will be broader.

However, the pellet fuel market also faces some challenges. For example, the production cost of pellet fuel is high and requires a lot of capital and technical support. In addition, the production and use of pellet fuel will also produce some pollution and safety hazards, which need to be taken care of.

Overall, the pellet fuel market has very bright prospects. In the future, with the strengthening of environmental awareness and energy policies, the pellet fuel market will usher in greater development opportunities. (Find RICHI on YouTube)

Start your fuel pellet production business

For almost 30 years, we have been working within our industry to design and build the best fuel pellet making machine systems and services for fuel pellet producers.

We build relationships with the best wood fuel pellets manufacturers so we can translate those relationships into excellence for your business. Whether servicing a breakdown, designing a new fuel pellet process flow, or teaching your employees how to use your equipment, we will come to you with a customized plan of action.

Our goal is to keep your downtime to a minimum and your output at its peak. Whether you need an entirely new system for fuel pellet production, general fuel pellet making machine and pellet plant maintenance, or want us to look over the design of your current operations for optimization, you can trust the process to us. Emergency service is also available, so no matter the day or time, Richi Machinery is here to help.