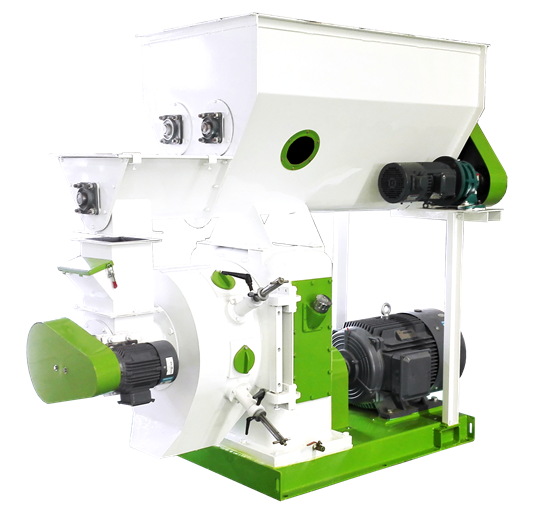

Organic Fertilizer Pellet Mill

MZLH350 organic fertilizer pellet mill is suitable for organic fertilizer processing business with an output of 3-4t/h.

- Capacity:3-4T/H

- Price: 20,000-30,000 USD

- Application: Organic fertilizer factory, compound fertilizer factory, chemical fertilizer factory, breeding farm, sugar factory, sewage treatment plant, waste disposal site, food processing plant, slaughterhouse, etc.

what’s organic fertilizer pellet mill?

The special MZLH350 organic fertilizer pellet mill is a type of granulator. It is used to granulate various organic matter after fermentation. It breaks through the conventional organic matter granulation process. There is no need to dry and crush the raw materials before granulation, and it can be directly batched. Processing spherical particles can save a lot of energy.

This MZLH350 organic fertilizer pellet mill is suitable for granulating organic fermentation fertilizers from livestock and poultry manure, composting fertilizers, green manures, sea fertilizers, cake fertilizers, peat, soil fertilizers, three wastes, microorganisms and other urban domestic waste organic fermentation fertilizers, the final product is columnar pellets or round pellets.

The qualified granulation rate of this machine is as high as over 95%, and it is adaptable to a variety of different formulas. The compressive strength of organic fertilizers is higher than other types of granulators, and the pellet size uniformity can be adjusted according to user requirements.

How to make full use of organic waste resources is an important issue in establishing a resource-saving society, promoting circular economy and developing organic agriculture. The agricultural production fields in many countries are the main consumers of chemical fertilizers.

The production of chemical fertilizers consumes a large amount of non-renewable resources such as coal, electricity, and natural gas. The organic fertilizer pellet making machine is an indispensable equipment for the production of chemical fertilizers.

Granular organic fertilizer produced from solid organic waste can achieve the purpose of saving non-renewable resources and protecting the environment. It has huge social benefits and is in line with the industrial policies of energy conservation and emission reduction in each country.

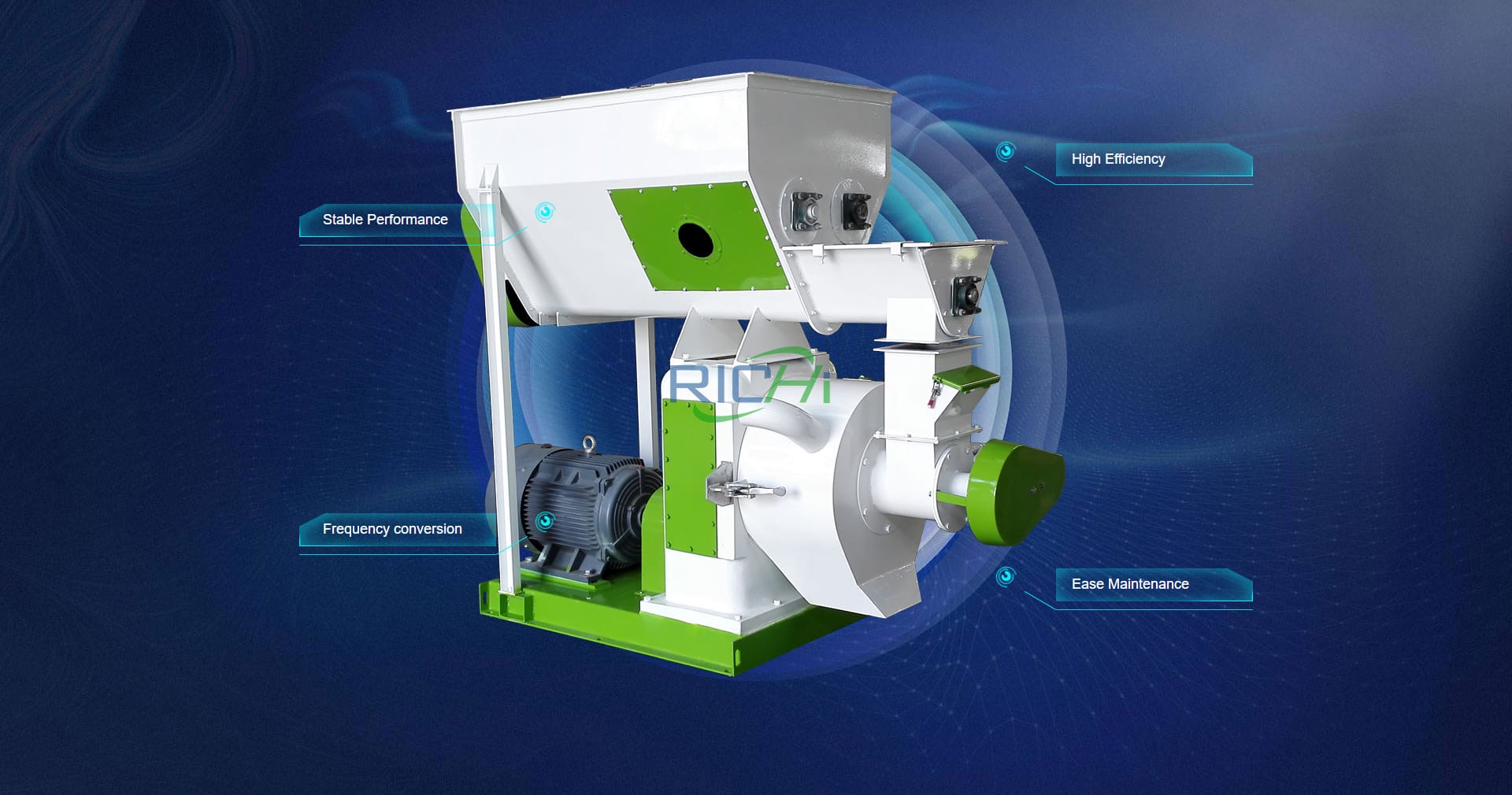

Technical characteristics of MZLH350 organic fertilizer pellet mill

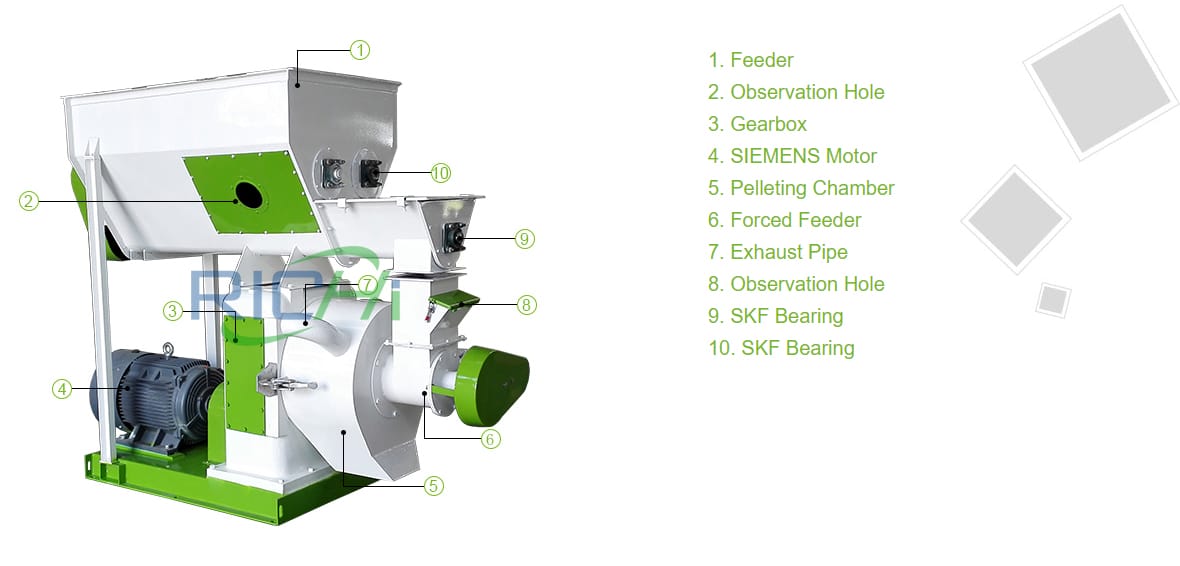

- Adopts a one-stage gear transmission mechanism, and the transmission efficiency is higher than other transmission forms;

- The gear set adopts a large grinding number helical gear design and is made of high-strength forged alloy steel, with high load-bearing capacity and long life;

- The transmission system uses imported brand bearings, with high safety factor design and more stable operation;

- The gear set adopts precision grinding and tooth surface modification processing, resulting in low operating noise and higher transmission efficiency;

- The ring die adopts a hoop-type installation structure, and a special hoop disassembly and assembly method is designed to increase the disassembly and assembly efficiency of the ring mold.

- External thin oil circulation cooling system can effectively lubricate and cool the main transmission bearing operating temperature;

- The automatic grease lubrication system can add grease regularly and quantitatively without stopping the machine, reducing labor and making the equipment operation more reliable;

- Electric die roller lifting device improves on-site disassembly and assembly efficiency of ring die, pressure roller and other parts.

How does the MZLH350 organic fertilizer pellet mill work?

When the raw materials enter the granulator, they will first go through the process of compression and extrusion.

There are usually one or more pairs of rollers inside the granulator, and the raw materials are compressed and squeezed under the action of the rollers. This can create a certain pressure inside the raw material, reduce the gaps between the particles, and increase the density and strength of the particles.

After compression and extrusion, the raw materials enter the cutting and granulation stage. Compost pellet making machines are usually equipped with blades or molds that can cut and granulate raw materials as needed.

The design of the blade or die affects the shape and size of the final pellets. By adjusting the parameters of the blade or mold, granular products of different specifications can be prepared.

Specifications of MZLH350 organic fertilizer pellet mill

| Model | MZLH350 |

| Output (t/h) | 3-4 |

| Main motor power (kw) | 37 |

| Main motor series | 8P |

| Ring die diameter (mm) | 350 |

| Finished pellet diameter (mm) | 2-12mm |

| Device Configuration | Ring die material: 42CrMo Stainless steel feeder: with anti-caking function Door of pelleting room: 6mm /SUS304 Forced feeding: Worm gear reducer Gear box: HT250 Gear: 42CrMo Gear shaft: 42CrMo Spindle: 42CrMo Empty shaft: 42CrMo Bearings: The gear shaft and main shaft bearings are SKF, and the pressure roller bearings are domestic high-quality bearings Oil seal: Germany/Taiwan Overload mechanical protection: safety pin Serpentine spring coupling drive Lubrication system: Configurable automatic oil injection system |

MZLH350 organic fertilizer pellet mill price

The price of MZLH350 organic fertilizer pellet mill is generally 20,000-30,000 USD

In organic fertilizer processing, the most commonly used machine is fertilizer pellet machine. Nowadays, organic fertilizer pellet machines are in great demand, and many organic fertilizer processors are considering replacing equipment or joining the industry. Today we will introduce you to some factors that affect the price of granulators so that you can buy good quality crushing equipment.

- Production costs of equipment: The choice of materials is directly related to the price of organic fertilizer pellet mill. The better the steel and the more expensive the equipment, the higher the price. In addition, the labor costs of R&D equipment, sales costs, procurement costs, etc. will more or less have a certain impact on the price.

- Manufacturer: The greater the strength of the manufacturer, the better their costs. Their MZLH350 organic fertilizer pellet mills have good quality, good performance and high cost performance. As for those manufacturers with strength and complete after-sales service systems, although the cost of the equipment they produce is higher, the quality and service are much better.

- Equipment model: Granulators of different specifications also have different prices. The output, volume, and discharging granularity of each machine are different, which determines the price of this machine. The price difference between small and large manure pellet mills is tens of thousands of dollars or more.

- User needs: In different periods, there are different supply relationships between supplies. In the case of large market demand and insufficient supply, if the demand is insufficient, the market price of related equipment will be higher. When supply exceeds demand, equipment prices will fall further.

When users choose a MZLH350 organic fertilizer pellet mill manufacturer, they should conduct an on-site inspection of the entire organic fertilizer production line so that they can select the equipment with the highest performance-price ratio.

Featured organic fertilizer pellet mill project

organic fertilizer pellet mill In Vietnam

- Country: Vietnam

- Production: 2500 t/a

- Ingredients: industrial waste

- project price: 80,000 USD

organic fertilizer pellet mill In Mexico

- Country: Mexico

- Production: 10,000 T/A

- Ingredients: livestock manure

- project price: US$110,000

organic fertilizer pellet mill In United States

- Country: United States

- Production: 50,000 T/A

- Ingredients: poultry litter

- project price: US$430,000

organic fertilizer pellet mill In Lithuania

- Country: Lithuania

- Production: 35,000 T/A

- Ingredients: food waste

- Project price: 410,000USD

organic fertilizer pellet mill In Thailand

- Country: Thailand

- Production: 55,000 T/A

- Ingredients: chicken manure

- Project cost: 570,000 USD

organic fertilizer pellet mill In indonesia

- Country: indonesia

- Production: 10,000 T/A

- Ingredients: animal manure, straw

- Project cost: 190,000 USD

organic fertilizer pellet mill In canada

- Country: canada

- Production: 6,000 T/A

- Ingredients: livestock manure

- Project cost: $160,000

organic fertilizer pellet mill In Pakistan

- Country: Pakistan

- Production: 30,000 T/A

- Ingredients: cow manure, Bagasse

- Project cost: $385,000 USD

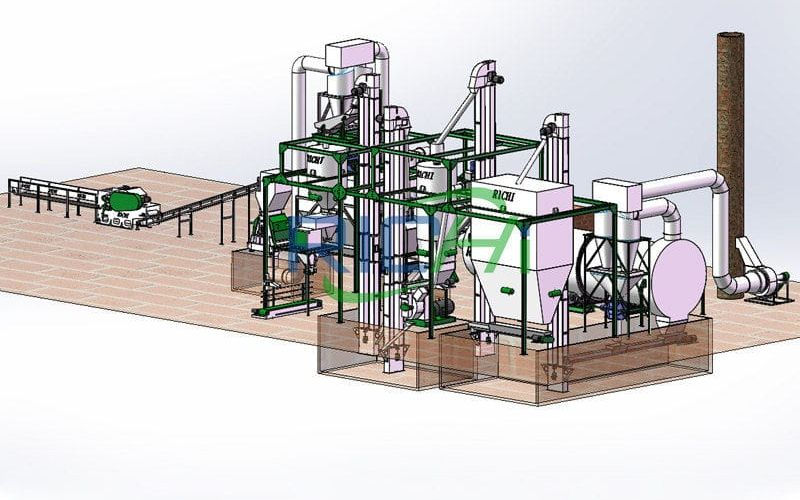

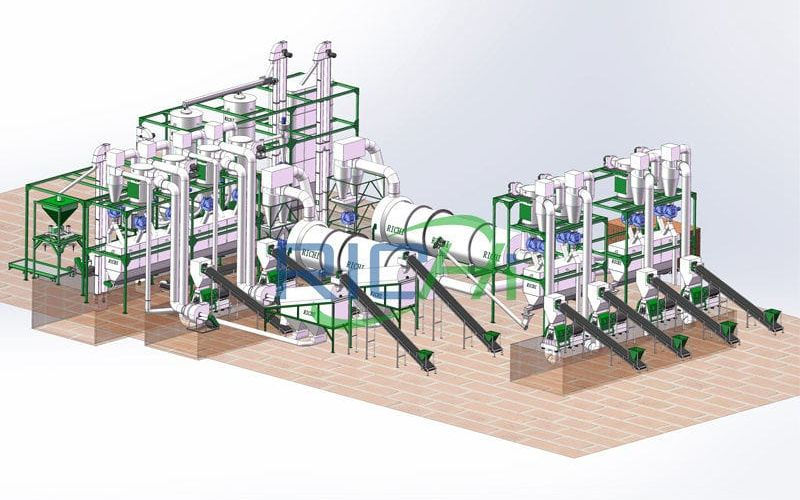

How to process organic fertilizer pellets? Complete 3-4 t/h organic fertilizer pellet process flow

The organic fertilizer production process flow is as follows:

1. Fermentation process

Livestock and poultry manure centralized treatment plants or organic fertilizer production companies will use special vehicles to collect livestock and poultry manure from various farms on a regular basis to avoid secondary pollution of roads and roads, and the recovered livestock and poultry manure will be directly entered into the fermentation area. After primary fermentation and secondary aging, it is stacked.

First, the odor of livestock and poultry manure is eliminated. During primary fermentation, straw, plant leaves, weed powder and other plant stems and leaves should be added in proportion. At the same time, fermentation bacteria should be added to decompose the crude fiber so that the particle size after crushing meets the particle size requirements for granulation production.

2. Mixing and granulation process

The fermentation materials that have completed the secondary aging and stacking process are crushed and entered into the mixing and stirring system. Before mixing and stirring, according to the formula, add N, P, K and other trace elements into the mixing and stirring system, start stirring, and mix the mixed materials. Material conveying to granulation system for pelleting, use an organic fertilizer pellet mill.

3. Drying and cooling process

After the granulation passes through the dryer, it enters the cooling system. After the material is brought to normal temperature, screening begins. The granules that meet the requirements enter the packaging machine for packaging. The granules that do not meet the requirements are crushed by the crusher and returned to the organic fertilizer granulator. Continue to granulate.

After the above procedures, livestock and poultry manure becomes the main raw material of organic fertilizer and enters the sales market for direct sale.

whole set organic fertilizer pellet mill plant list

Compost Turner

Turning height:

0.5-2.0 m

Motor:

32-300 KW

Compost Grinder

Capacity:

3-25T/H

Main Power:

30-160KW

organic Fertilizer Mixer

Capacity:

250-2000 kg/P

Main Power:

4-30 KW

organic fertilizer Dryer machine

Capacity:

Customized

Rotate Speed:

3-8 R/Min

organic fertilizer pellet mill

Capacity:

1-12T/H

Main Power:

37-280KW

Why process organic fertilizer?

- Organic fertilizer contains a large amount of organic matter and has an obvious effect of improving soil and fertilizing;

- Organic fertilizer contains a variety of nutrients and contains a comprehensive balance of nutrients;

- Organic fertilizers have low nutrient content and need to be applied in large quantities, while chemical fertilizers have high nutrient content and need to be applied in small quantities;

- Organic fertilizers made by organic fertilizer pellet mill are derived from nature. There are no chemical synthetic substances in the fertilizers. Long-term application can improve the quality of agricultural products;

- During the production and processing of organic fertilizers, as long as they are fully decomposed, after application, they can improve the drought resistance, disease resistance, and insect resistance of crops, and reduce the use of pesticides;

- The advantage of organic fertilizer is that it is rich in organic matter and various nutrients. It can not only directly provide nutrients for crops, but also activate potential nutrients in the soil, enhance microbial activity and promote material transformation. The application of organic fertilizers can also improve the physical and chemical properties of the soil, increase soil fertility, and prevent soil pollution, which chemical fertilizers do not have.

Making full use of the scientific accumulation and rational application of organic fertilizer sources can not only reuse agricultural waste, reduce the investment in chemical fertilizers, protect the rural environment and create a good agricultural ecosystem, but also achieve the purpose of fertilizing the soil to stabilize and increase yields, increase production and income.

How to choose organic fertilizer pellet mill?

- First, the needs and goals of the project need to be clarified.

This includes determining the functions and performance metrics that the fertilizer granulation equipment is intended to achieve, as well as the intended environment and conditions of use. At this stage, it is necessary to fully communicate with the project team and relevant stakeholders to understand their needs and expectations. - Market research and selection comparison.

It is necessary to collect information on various equipment, understand the characteristics, advantages and disadvantages of different equipment, and make appropriate comparisons and evaluations. At this stage, consider consulting professional engineers and manufacturers for further information and advice. - The next step is to formulate the standards and conditions for compost granulating machine selection.

Based on the project requirements and market research results, the standards and conditions for equipment selection can be clarified, including performance, quality, cost, maintenance and service requirements. - Equipment screening and testing then takes place.

According to the standards and conditions for organic fertilizer pellet mill selection, preliminary equipment screening can be carried out to determine several suitable alternative equipment. Field testing and evaluation can then be conducted to verify that the equipment meets project needs and standards. - The final step is determining the final equipment selection.

Based on the results of equipment testing and evaluation, the final equipment selection can be determined, confirmed and communicated to relevant stakeholders. During the organic fertilizer pellet mill selection process, care needs to be taken to maintain transparency and fairness to ensure that the equipment selected is the most suitable for the project needs.

In short, equipment selection is a complex process that requires comprehensive consideration of many factors.

Through appropriate market research and evaluation, as well as full communication with relevant stakeholders, the equipment that best suits the project needs can be selected to provide strong support for the smooth implementation of the project.

Equipment selection is a crucial process in various industries. In the manufacturing industry, equipment selection is directly related to product quality and production efficiency.

How to choose an organic fertilizer pellet mill manufacturer?

Organic fertilizer pellet granulator has always been the core issue in the organic fertilizer processing process, and choosing a suitable organic fertilizer granulator manufacturer has become the primary task to solve this problem.

Innovative technology

When choosing an organic fertilizer pellet mill machine manufacturer, innovative technology is one of the primary factors to consider. The organic fertilizer granulator machine is not only a simple granulation system, but also combines automation and intelligent technology to solve the problem of organic fertilizer granulation through innovative means.

A manufacturer with leading technological level can provide you with more comprehensive organic fertilizer granule processing solutions.

Product reliability

When choosing an organic fertilizer pellet mill manufacturer, product reliability is crucial. An excellent organic fertilizer granulator not only needs to be innovative in design, but also needs to be guaranteed in quality. A stable and reliable organic fertilizer granulator can not only increase the service life, but also reduce maintenance costs and provide users with a better user experience.

Customized services

Organic fertilizer processing needs vary from person to person, so it is particularly important to choose a manufacturer that can provide customized services for organic fertilizer granulators and organic fertilizer production lines.

Customized services can not only meet the individual needs of users, but also better integrate different modular processes to provide more comprehensive solutions. A flexible and adaptable organic fertilizer pellet mill manufacturer will be your best partner.

Maintenance and service

A good fertilizer pellet mill not only needs to perform well during sales, but also cannot take it lightly in after-sales service. Choosing an organic fertilizer granulator manufacturer that pays attention to maintenance and service can provide users with more timely and comprehensive technical support to ensure that the organic fertilizer granulator is always in the best condition.

Customer evaluation

Customer evaluation is a key indicator to measure the comprehensive strength of an organic manure making machine manufacturer. Understanding the manufacturer’s reputation in the industry by reviewing user reviews and case sharing will help you gain a more comprehensive understanding of its product quality, service level and user satisfaction.

Choosing a well-regarded organic fertilizer granulator manufacturer will bring greater confidence to your organic fertilizer processing business.

Choosing the best organic fertilizer pellet mill manufacturer is a key step to achieve efficient and high-quality organic fertilizer processing. Innovative technology, product reliability, customized services, maintenance and service, and customer reviews, these five key factors will provide you with a wise choice guide.

In this rapidly developing field of organic fertilizers, we work together with RICHI Machinery to create a new future that is more environmentally friendly and sustainable. If you are interested in our concepts, welcome to learn more!

The Prospects of the Organic Fertilizer Business

Organic fertilizer refers to fertilizer made from animal and plant waste, crop straw, rapeseed residue, manure and other biomass through fermentation, composting and other treatments. Organic fertilizer has the advantages of high content, stable quality, non-toxicity, and friendliness to soil and plants. Therefore, organic fertilizer has a very broad prospect in agricultural production.

- First, organic fertilizers made by organic fertilizer pellet mill have high levels of nutrients.

Compared with chemical fertilizers, organic fertilizers contain richer beneficial elements, such as organic matter, trace elements and biologically active substances. These ingredients can effectively increase soil fertility, provide the nutrients needed by plants, enable plants to grow robustly and have strong immunity, and improve the yield and quality of crops.

- Secondly, organic fertilizer has the characteristics of stable quality.

Organic fertilizers undergo processes such as fermentation and composting to eliminate impurities, pathogenic bacteria, insect eggs and other harmful substances in waste and crop straws, making the quality of organic fertilizers purer and more stable. This not only prevents soil pollution and agricultural product residue problems caused by chemical fertilizers, but also improves crop quality and food safety.

- Additionally, organic fertilizers made by organic fertilizer pellet mill are soil and plant friendly.

Organic fertilizers can improve soil texture, increase soil water retention capacity, improve soil aeration, and improve soil fertility and structure. At the same time, organic fertilizer can also promote the activity of soil microorganisms, increase the organic matter content of the soil, and improve the persistence of soil fertility. In this way, not only can soil erosion and soil erosion be reduced, but the ecological environment of the soil can also be improved and the balance of the ecosystem can be protected.

- Finally, organic fertilizer has obvious advantages in terms of environmental protection.

Organic fertilizer is made from natural organic matter, does not contain toxic and harmful substances, and will not cause pollution to soil, water sources and the environment. In contrast, chemical fertilizers can easily cause soil pollution and damage to the ecological environment due to their chemical components. The use of organic fertilizers can reduce dependence on chemical fertilizers, reduce the impact of agricultural production on the environment, and promote sustainable development.

In short, organic fertilizer has broad prospects in agricultural production. As people have higher and higher requirements for food safety and environmental protection, the demand for organic fertilizers will gradually increase. Organic fertilizers can not only increase crop yield and quality, but also improve soil texture and ecological environment.

Therefore, the promotion and application of organic fertilizers will be an important direction for agricultural development and are expected to bring greater benefits and sustainable development to agricultural production. (Find RICHI on YouTube)