Animal Feed Pellet Press

The SZLH350 animal feed pellet press, used to create pellets from powdered material, is one of the most important machines in industrial production.

The animal feed pellets press usually used to produce animal feed pellets. It is mainly used in small/medium-scale commercial feed production with the features of long working life, high output and low consumption.

- Model: SZLH350

- capacity: 5-7T/H

- power: 55KW

- Price: FOB 20,000-25,000 USD

The work of pressing the wet mash into a pellet is done through the die in the main mill. RICHI SZLH350 animal feed pellet presses are simple and solid machines, with high reliability and very low maintenance costs, offer the possibility of pelleting between 1.8 – 12mm pellet diameters.

With feed pellet press models with a die diameter with 350mm and motor power 55 kW, the most suitable size can be offered to the need.

Features of SZLH350 animal feed pellet press

- SZLH350 animal feed pellet press has a high starting point, which is derived from European German technology and has pioneered the Chinese gear-driven pellet press.

- Since 2010, it has been upgraded on the original technology to improve the efficiency of the pellet press and enhance stability.

- High-precision gear transmission, its output is about 15-20% higher than that of belt drive type.

- The large gear and gear shaft adopt hardened tooth surface and gear grinding technology, with high precision and life of up to 15 years.

- The improvement of overall technology makes the daily maintenance cost of SZLH350 animal feed pellet press much lower than that of belt type.

- The feeder adopts “O-type” cylinder, which not only improves the uniformity of feeding, but also effectively prevents steam from rising.

- The conditioner increases by 15% on the basis of CPM model, which improves the maturation of materials.

- The welding throwing scraper on the head of the tempering blade accelerates the fusion of materials and steam and improves the maturation.

- High-precision gear direct drive, strong overload resistance, general blockage can be restored without stopping the machine.

- The rear end of the main shaft is improved to bearing support to ensure that the hollow shaft and the main shaft axis are parallel, the main shaft does not shake, and the production capacity is improved.

- Double-layer and three-layer conditioner SZLH350 animal feed pellet presss can be customized to produce high-quality livestock and poultry aquatic feed.

Advantages of SZLH350 animal feed pellet press

- Stable two-motor timing gear drive, large torque but low noise;

- The optimized area-to-power ratio of ring die, maximum output;

- Stable production and uniform pellets obtained.

- Wide pellet feed range: φ2.0mm-φ12mm;

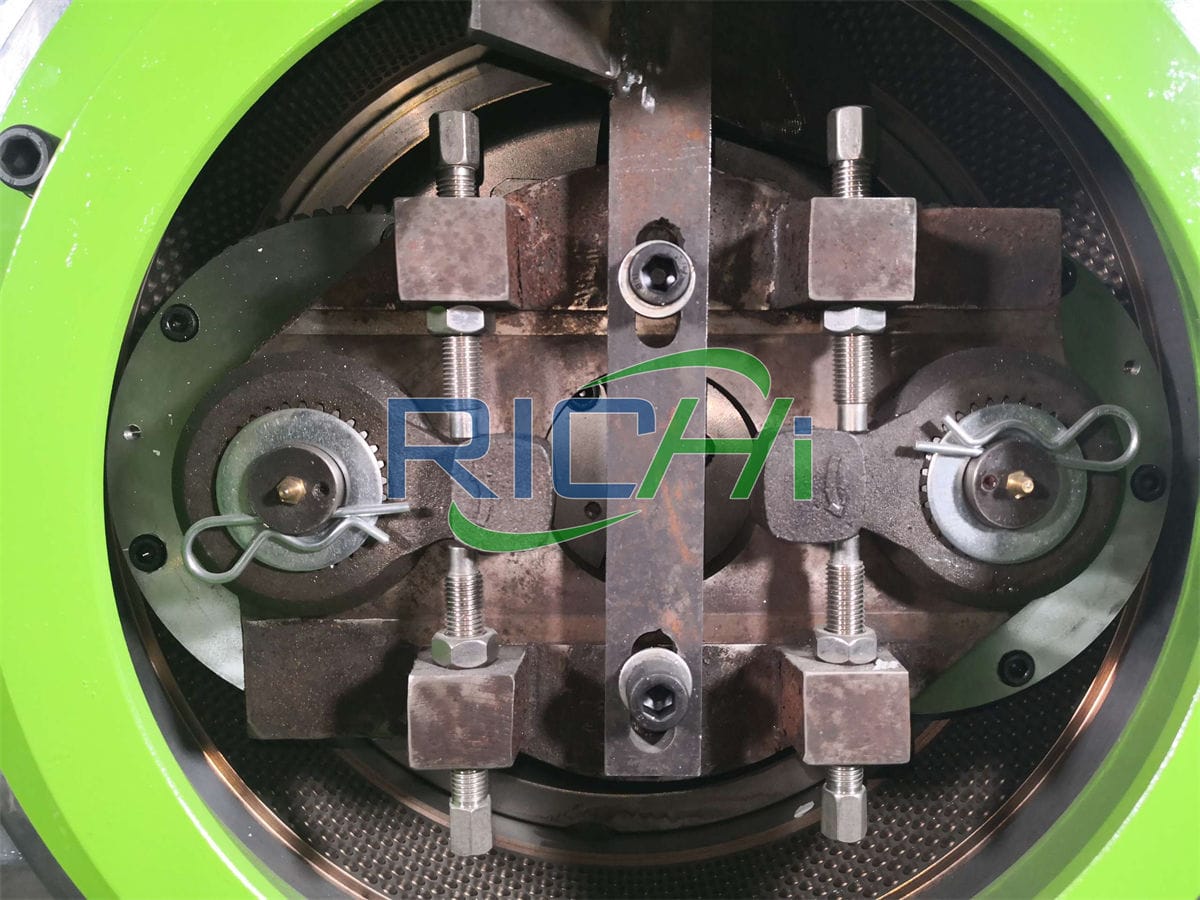

- Hydraulic system for die changing and roller adjusting, quick and precise operation;

- Auto-lubrication system and die& roller lifting device, saving labor cost;

- On-site touchscreen control system is optional;

- CE standard design and available stainless steel conditioner for feed;

- Humanized design and safety.

- Including SZLH350 animal feed pellet press size, ring die, roller, conditioner, and steam system. Hydraulic system, auto-lubrication system, die & roller lifting device and etc.

Structure and composition of SZLH350 animal feed pellet press

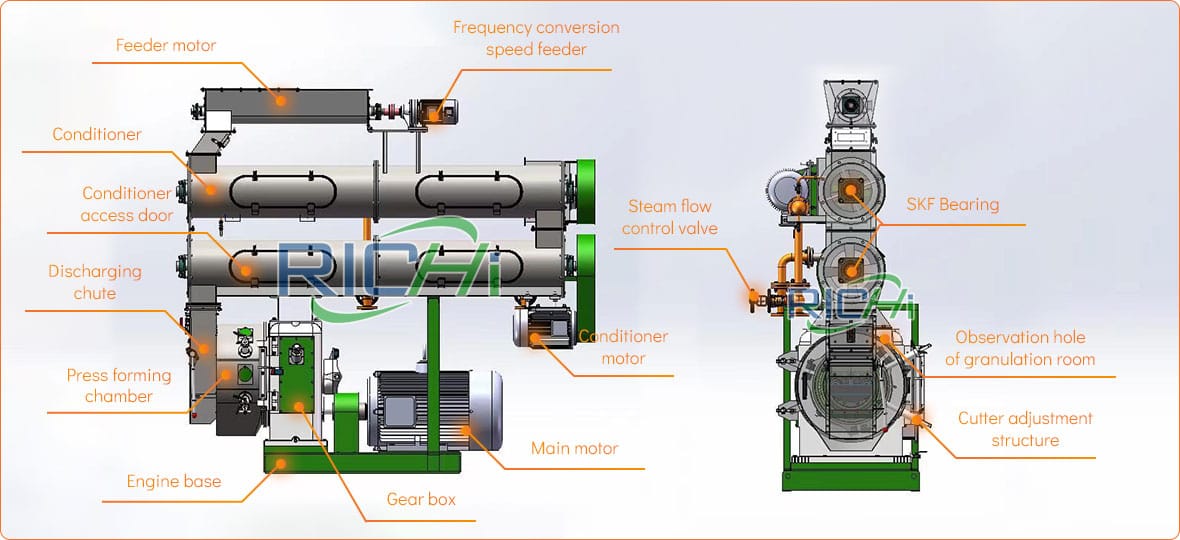

- Gearbox: including main shaft, hollow shaft, gear shaft, 5 bearings, large gear, safety pin assembly.

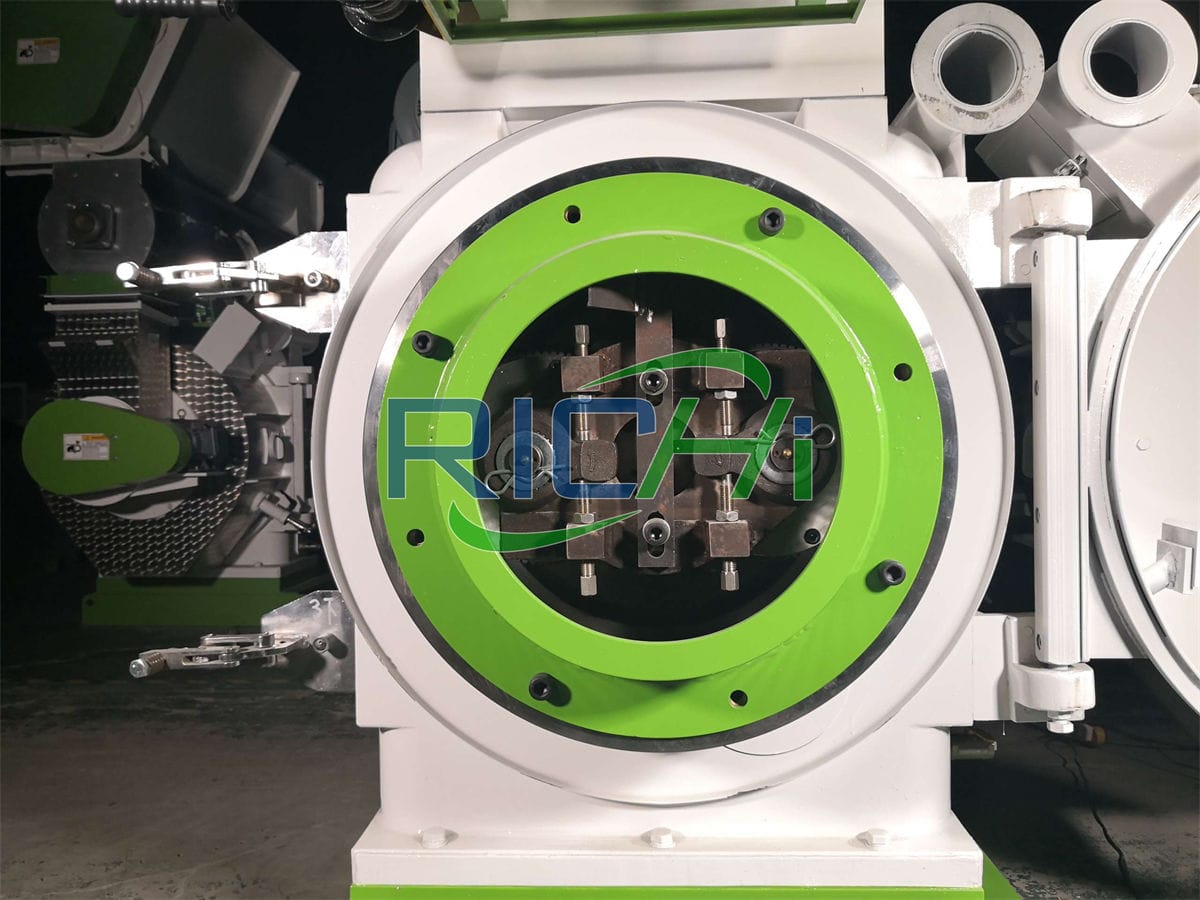

- Granulator room: roller assembly, ring die, cutter, scraper, material basin, feed chute, manual

- Feed port, bypass handle.

- Motor, coupling + gear reduction.

- Modulator: modulator, motor, belt drive.

- Frequency conversion feeder: motor (frequency conversion motor + frequency converter-does not change voltage, only changes frequency, and then changes motor speed), reducer

Working principle of SZLH350 animal feed pellet press

The modulated crushed material is fed evenly into the two pressing areas in the ring die, that is, the wedge-shaped space formed by the two rollers and the ring die, through the chute through the die cover by gravity, the centrifugal force generated by the rotation of the ring die, and the action of the feeding scraper.

Under the strong extrusion of the ring die and the roller, the material is gradually compacted, squeezed into the die hole of the ring die and formed in the die hole.

Since the extrusion of the material between the die and the roller is continuous, the formed material is continuously discharged from the die hole in a columnar shape and then cut into particles of the required length by the cutter.

Specifications of SZLH350 animal feed pellet press

| model | SZLH350 |

| Output (t/h) | 5~7 |

| Main motor power (kw) | 55 |

| Main motor series | 4P |

| Feeder power (kw) | 1.5 |

| Conditioner power (kw) | 3 |

| Ring die diameter (mm) | 350 |

| Finished pellet diameter (mm) | 2~12 |

configuration of SZLH350 animal feed pellet press

- Ring die material: stainless steel

- Door cover of granulation room: 6mm /SUS304

- Feed chute: 3mm /SUS304

- Gear box: HT250

- Gear: 42CrMo

- Gear shaft: 20CrMnTi

- Spindle: 42CrMo

- Empty shaft: 42CrMo

- Bearing: Import

- Oil seal: Germany/Taiwan

- Overload mechanical protection: safety pin

- Serpentine spring coupling drive

- Using Siemens Motor

Operation requirements of SZLH350 animal feed pellet press

| Animal feed types | Requirements Before Entering Granulator(mm) | Pellet Diameter(mm) | Pellet Length(mm) | Ring Die Compression Ratio | Conditoning Temperature(℃) | Conditoning Time(s) | Equipped Conditioner |

| Poultry chicken | 2.0-3.0 | 2-4 | 4-8 | 1:10—-1:13 | 150 | 60-120 | one layer/two-layer |

| Cattle | 3-5mm | 6-12 | 12-18 | 1:6:1:9 | 150 | 30-60 | one layer/two-layer |

| pig | 2-3 | 2-4 | 3-8 | 1:3.5—-1:5 | 150 | 60-120 | One layer/two layer |

| fish | 1.0-2.0 | 2-6 | 4-12 | 1:16—-1:18 | 150 | 90-180 | Two layer/three layer |

| shrimp | 95%≥80 mesh | 1.2-2.0 | 1.8-4 | 1:20—-1:25 | 150 | 120-180 | three layer |

| … | |||||||

animal feed pellet press projects

animal feed pellet press for sale France

- pellet press selection: SZLH350

- Feed Size:2-4mm pellets

- project cost: 25,000 USD

animal feed pellets press for sale Moldova

- pellet press selection: SZLH350

- Feed Size: 3-5mm pellets

- project cost: 270,000 USD

animal feeds pellet press for sale Russia

- pellet press selection: SZLH350

- Feed Size: 2-4mm pellets

- project cost: 17160 USD

animal feed pellet press for sale Uzbekistan

- pellet press selection: SZLH350

- Feed Size: 2-8mm pellets

- project cost: 160,000 USD

feed pellet press for sale Nigeria

- pellet press selection: SZLH350

- Feed Size: 2-10mm pellets

- project cost: 184,500 USD

animal pellet press for sale Gambia

- pellet press selection: SZLH350

- Feed Size: 1.5-6mm pellets

- project cost: 231,820 USD

animal pellet press for sale in Paraguay

- pellet press selection: SZLH350

- Feed Size: 2-3mm pellets

- project cost: 259,070 USD

feed pellet press for sale Bolivia

- pellet press selection: SZLH350

- Feed Size: 2-6mm pellets

- project cost: 240,000 USD

Application of SZLH350 animal feed pellet press

SZLH350 animal feed pellet press is mainly used for 5-7 tons per hour animal feed production line, or multiple equipment are used for feed production line with larger output.

This complete animal feed mill plant unit is best choice for 5-7t/h production capacity feed mill use. Its small size takes up small scale space and the ring die pellet mill promise relatively high production output.

Most importantly, the cost is relatively low compared to the same capacity animal feed pellet machine. For detailed price, please inform us your raw materials, animal and purpose and more. Then, we will offer you the customized equipment and the most favorable price!

If you want to get 5-7t/h animal feed production line solution, click the button below to get detailed solution design, equipment configuration list and feed processing line quotation.

Video of animal feed pellet press

FAQs of animal feed pellet press

How much does a SZLH350 animal feed pellet press cost?

The price of a SZLH350 animal feed pellet press is generally between FOB 20,000-25,000 USD.

With the rapid development of the feed industry, the demand for feed equipment is growing. These devices not only improve production efficiency, but also ensure feed quality and safety. However, the price of feed pellet mills varies depending on a variety of factors, including equipment type, scale, technology, materials, manufacturing process, brand, market supply and demand, etc.

1. Equipment type and scale

The price of a feed pellet press depends first on its type and scale. For example, large-scale animal feed mill equipment is usually more expensive than small stand-alone equipment because they have more functions and higher production efficiency. In addition, different types of feed equipment have different prices because of their different structures, technical requirements and uses.

2. Technical content

Modern feed pellet press are increasingly dependent on advanced technologies such as automation, intelligence, energy saving and environmental protection. These advanced technologies not only improve the production efficiency of equipment, but also reduce energy consumption and labor costs. Therefore, equipment with higher technical content is usually more expensive.

3. Materials and manufacturing process

The materials and manufacturing process of animal feed pellet presses also have a great impact on their prices. High-quality materials and advanced manufacturing processes can ensure the durability, stability and safety of the equipment, thereby increasing the service life of the equipment.

However, these high-quality materials and manufacturing processes usually increase the cost of the equipment, thereby increasing its price.

The price of animal feed pelletizer press is affected by many factors, including equipment type, scale, technology, materials, manufacturing process, brand, market supply and demand, and after-sales service.

When purchasing an animal feed pellet press, feed processors should choose suitable equipment based on their own production needs, budget and long-term development plan.

At the same time, pay attention to the cost-effectiveness of the equipment and choose a brand with good after-sales service and maintenance system to ensure the stable operation and long-term benefits of the equipment.

How to choose animal feed pellet press?

- 1. Equipment quality: When purchasing animal feed pellet press, you should consider the quality and reliability of the equipment. Choosing reliable equipment can ensure better quality of your feed pellets and extend the service life of the equipment.

- 2. Equipment performance: The performance of animal feed pelleting press includes aspects such as pelleting efficiency, maturation time, and pellet quality. When purchasing equipment, you should understand the performance of the equipment and confirm that they meet your needs.

- 3. After-sales service: When purchasing a feed pellet pressing machine, you should consider the manufacturer’s after-sales service. A good manufacturer should provide comprehensive after-sales service, including support in equipment installation, commissioning, and maintenance.

- 4. Price: Price is one of the important factors to consider when purchasing a feed pellets press. When purchasing equipment, you should compare the animal feed pellet machine prices of different manufacturers and choose the equipment with the best cost-effectiveness.

If you want to confirm whether a feed pellet press manufacturer is formal, you can consider the following methods:

- Check the manufacturer’s qualifications: A formal feed pellet mill manufacturer should have relevant qualifications and certifications. You can check the manufacturer’s qualification certificate, production license and other documents to confirm whether the manufacturer has the qualifications to produce animal feed pellet presses.

- Investigate the manufacturer’s strength: You can visit the manufacturer on site to understand the manufacturer’s production scale, technical strength, management, etc. If the manufacturer has advanced production equipment, strong technical strength, and standardized management, then this manufacturer may be more reliable.

- Understand the manufacturer’s reputation: You can understand the manufacturer’s reputation, such as whether there is a bad record, customer evaluation, etc. If the manufacturer has a good reputation, then this manufacturer may be more trustworthy.

- Consult professionals: If you have questions about the formality of the feed pellet press manufacturer, you can consult professionals, such as brewers, equipment agents, etc. They can provide you with useful advice and information.

When purchasing a feed pellet press, you should choose a formal manufacturer and understand the manufacturer’s qualifications, strength, reputation, etc.

At the same time, you should also understand factors such as the performance and price of the equipment to ensure that the equipment you purchase meets your needs and budget. (Find RICHI on youtube)

What’s the Steps of animal feed pellet press selection?

- The first selection: It is based on the extensive collection of market supply information for feed pelleting presses.

- The sources of supply information include websites and B2B platforms, information provided by door-to-door sales staff of animal feed pellet press manufacturers, information collected from trade fairs, and information provided by agents or relevant professionals.

- Classify and collect this information, edit and index it, and select some animal feed pellet press models and manufacturers from them. This is the pre-selection process that provides information for equipment selection.

- The second detailed selection: It is based on the first pre-selection.

- First, investigate, contact and inquire about the pre-selected feed pellet press models and manufacturers, and understand in detail the various technical parameters, efficiency, precision, and performance of the products: the service quality and reputation of the manufacturer, the feedback and evaluation of the user’s products; the supply and delivery time; the ordering channels, prices and random accessories, etc., and keep good records of the investigation.

- Then analyze and compare, and select several promising models and animal pellet press manufacturers.

- The third selection:

- First, on the basis of the second selection, further contact with the selected models and manufacturers, and conduct special investigations and understanding when necessary.

- For key equipment that needs to be further implemented, it is necessary to go to the animal feed pellet press manufacturer or the user of this equipment for in-depth and detailed observation and understanding, and carry out necessary processing and experiments.

- Talk with the manufacturer for relevant issues (such as accessories, accessories, drawings, spare parts supply, equipment structure and accuracy, performance improvement possibility, price and preferential issues, delivery period, etc.), and make detailed records; you can also sign a memorandum of meeting or agreement with the manufacturer or agent.

- Then, the animal feed equipment, process technology, planning and user departments jointly evaluate and select the most ideal model and manufacturer as the first option (at the same time, the second and third options should also be prepared so that new situations in the ordering process are spare).

- Finally, the contract is formally signed.

- In this way, the whole process of animal feed mill equipment selection is completed. In the process of animal feed pellet press selection, for some key equipment, expensive, large quantity or equipment for the entire feed pellet production line;

- In addition to the above-mentioned multiple screening methods, necessary technical and economic analysis and evaluation should be used for optimization.