Organic Fertilizer Granulator Machine

MZLH768 organic fertilizer granulator machine is used in 9-10t/h organic fertilizer granule processing system.

- Capacity:9-10T/H

- Price: 45,000-60,000 USD

- Application: Organic fertilizer factory, compound fertilizer factory, chemical fertilizer factory, breeding farm, farm, sugar factory, sewage treatment plant, waste disposal site, food processing plant, slaughterhouse, etc.

what’s MZLH768 organic fertilizer granulator machine?

Organic fertilizer granulation machine is mainly used to pelletize cow/chicken/pig/sheep manure into high-quality nutrient-rich fertilizer pellets.

This multifunctional fertilizer granulators can produce chicken/cow manure pellets, poultry feed pellets, and all kinds of organic fertilizer pellets. The raw materials contain chicken manure, cow manure, sheep dung, pig manure agri waste and can mix with all kinds of powder materials.

This MZLH768 organic fertilizer granulator machine can meet your 9-10 t/h or larger scale manure production requirements. Moreover, similar to disk manure pellet making machine, this machine can also be used for making compound fertilizer.

It can be connected with a fertilizer polishing machine to beautify the appearance of the finished pellets. Due to the high pelletizing rate and good strength, the pellet machine is an ideal device for today’s organic fertilizer pellets production, both for home use and commercial scale.

What is organic fertilizer?

Organic fertilizer made by MZLH768 organic fertilizer granulator machine specifically refers to various animal wastes (including animal manure; animal processing waste) and plant residues (cake fertilizers, crop straws, fallen leaves, dead branches, peat, etc.), using physics, chemistry, biology or a combination of the some treatment technologies require certain processing techniques (including but not limited to stacking, high temperature, anaerobic, etc.) to eliminate harmful substances (pathogens, pest eggs, weed seeds, etc.) and achieve harmless standards. A type of fertilizer formed that complies with relevant standards and regulations.

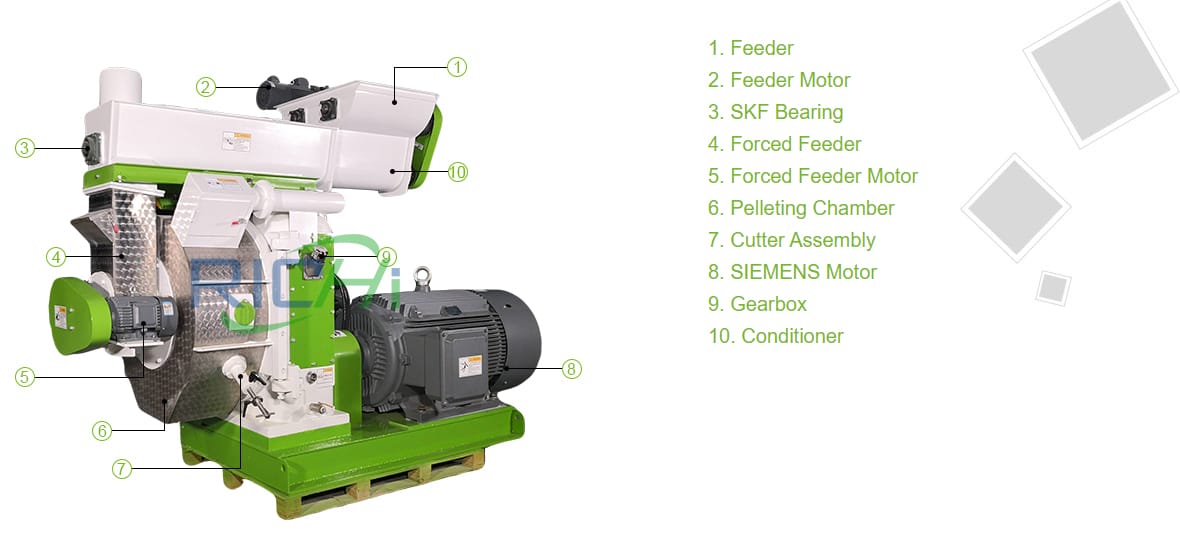

Technical characteristics of MZLH768 organic fertilizer granulator machine

- CPM model, internationally advanced, direct transmission system, efficiency increased by 20%, frequency conversion feeding to ensure uniform feeding of materials.

- Stainless steel door cover has strong anti-corrosion ability and long service life. The box body is processed by a machining center with high precision, large oil storage and low noise;

- Advanced and reliable overload protection device, quick hoop-type ring die disassembly, main parts of the bearings and standard parts are imported parts, movable pneumatic oil pump, convenient and timely, the main shaft is processed by German deep hole gun drilling, and can be put in place at one time , refuel smoothly;

- The transmission components of the whole machine (including the motor) use Swiss high-quality SKF bearings, internationally advanced power transmission couplings, internationally advanced steam regulating valve systems, machining centers to process the boxes, and German deep-hole drilling to process spindle oil holes;

- The gears are processed by precision grinding, which has low noise. The output is about 20% higher than that of belt drive. It adopts quick-release hoop type high-end ring die. The internal design and manufacturing quality have reached the international leading level.

advantages of MZLH768 organic fertilizer granulator machine

Ring die organic fertilizer granulating machine has the following obvious advantages:

- High efficiency: The organic fertilizer granulator adopts advanced working principles and structural design to achieve a high-efficiency pellet production process. It can process large quantities of raw materials quickly and evenly, improving production efficiency.

- Pellet quality is stable: Because the granulator machine for fertilizer has good extrusion and friction effects, it can make the particles dense and uniform during the formation process, thereby improving the quality stability of the particles.

- Strong flexibility: The fertilizer granulation equipment can adapt to different materials and process requirements. By adjusting the working parameters and replacing components such as the ring die and pressure roller, it can produce pellets of different specifications and shapes.

How does the MZLH768 organic fertilizer granulator machine work?

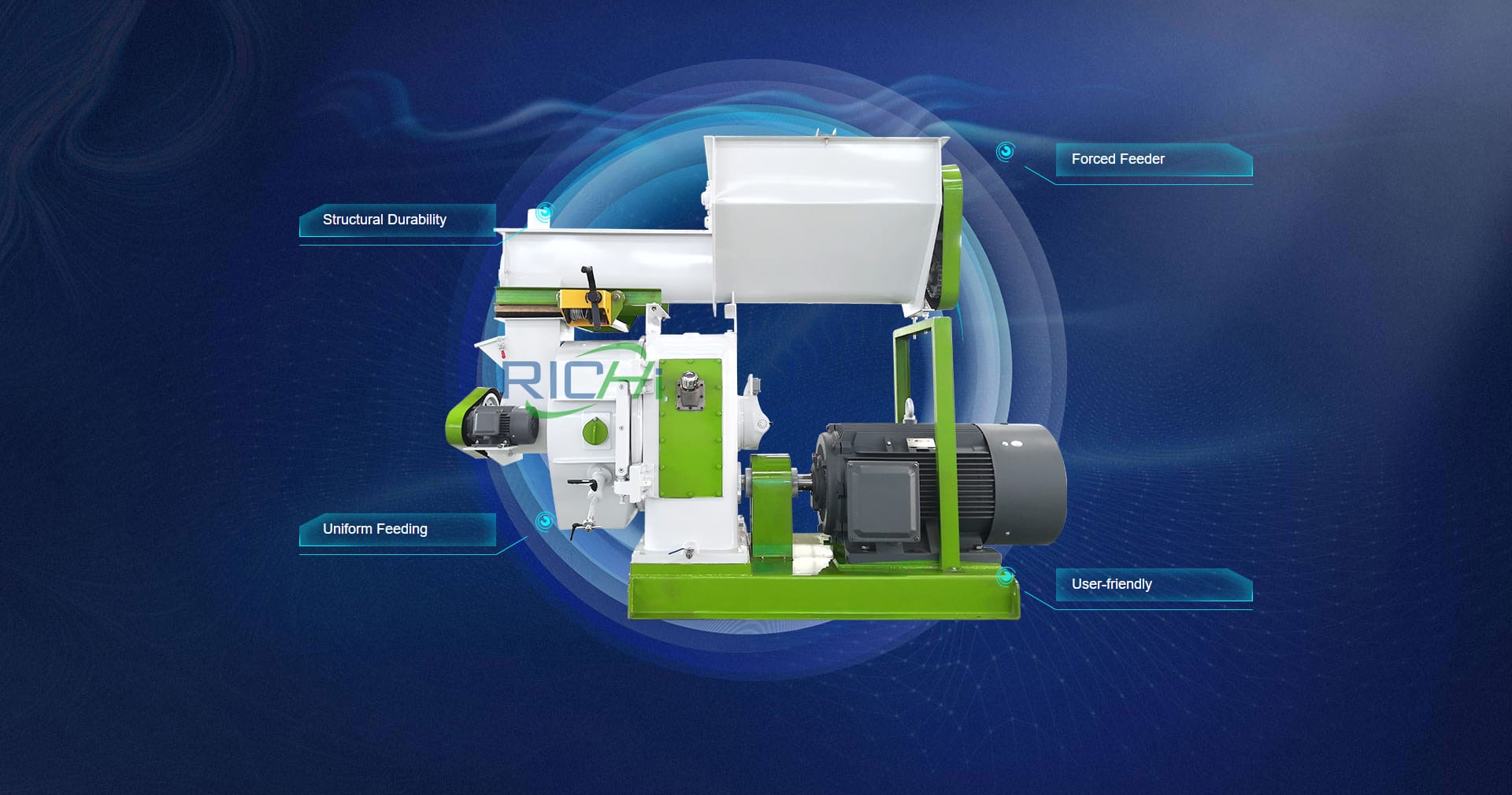

The horizontal ring-die fertilizer granulator machine is a relatively common model. Its structural feature is a horizontal layout, with the main machine and motor installed on the same horizontal plane.

The working principle of the horizontal granulator is to use the relative movement of the material from top to bottom and the mold from bottom to top.

The loose powder or granules are pressed into granular form through the mold, and then cooled and screened to finally obtain the desired products.

Specifications of MZLH768 organic fertilizer granulator machine

| Model | MZLH768 |

| Output (t/h) | 9-10 |

| Main motor power (kw) | 250 |

| Main motor series | 8P |

| Ring die diameter (mm) | 762 |

| Finished pellet diameter (mm) | 2-12 |

| Device Configuration | Ring die material: 42CrMo Stainless steel feeder: with anti-caking function Door of pelleting room: 6mm /SUS304 Forced feeding: Worm gear reducer Gear box: HT250 Gear: 42CrMo Gear shaft: 42CrMo Spindle: 42CrMo Empty shaft: 42CrMo Bearings: The gear shaft and main shaft bearings are SKF, and the pressure roller bearings are domestic high-quality bearings Oil seal: Germany/Taiwan Overload mechanical protection: safety pin Serpentine spring coupling drive Lubrication system: Configurable automatic oil injection system |

MZLH768 organic fertilizer granulator machine price

The price of MZLH768 fertilizer granulator machine is generally: 45,000-60,000 USD

RICHI new type organic fertilizer granulators are widely used, and the price is naturally of great concern. However, the price of any commodity is not fixed and will change as some factors change. Organic fertilizer granulator is no exception. So, what factors will affect the price of organic fertilizer granulator?

There are many factors that affect the fertilizer granulator machine price. In addition to national policies, there are also the price of steel, the price of raw materials, the price of organic fertilizer, etc.

- Impact on upstream industries. Since the main material of the organic fertilizer granulator machine price is steel, steel has the greatest impact on the price of the compost granulating machine. The price of steel fluctuates from time to time, which will inevitably affect the price change of organic fertilizer granulator machine.

- Impact on downstream industries. The materials that organic fertilizer granulator machines are often used to granulate include animal manure, various agricultural and forestry wastes, and various urban wastes. The prices of these raw materials will inevitably affect the price of organic fertilizer granulators.

- Of course, the organic fertilizer granules making machine will also be affected by the brand itself. When you buy big brands, you are bound to pay higher prices. But at the same time, we also gained more advanced technology and more guaranteed quality and service.

Featured organic fertilizer granulator machine project

organic fertilizer granulator machine In Vietnam

- Country: Vietnam

- Production: 2500 t/a

- Ingredients: industrial waste

- project price: 80,000 USD

organic fertilizer granulator machine In Mexico

- Country: Mexico

- Production: 10,000 T/A

- Ingredients: livestock manure

- project price: US$110,000

organic fertilizer granulator machine In United States

- Country: United States

- Production: 50,000 T/A

- Ingredients: poultry litter

- project price: US$430,000

organic fertilizer granulator machine In Lithuania

- Country: Lithuania

- Production: 35,000 T/A

- Ingredients: food waste

- project price: 410,000USD

organic fertilizer granulator machine In Thailand

- Country: Thailand

- Production: 55,000 T/A

- Ingredients: chicken manure

- project cost: 570,000 USD

organic fertilizer granulator machine In indonesia

- Country: indonesia

- Production: 10,000 T/A

- Ingredients: animal manure, straw

- project cost: 190,000 USD

organic fertilizer granulator machine In canada

- Country: canada

- Production: 6,000 T/A

- Ingredients: livestock manure

- project cost: $160,000

organic fertilizer granulator machine In Pakistan

- Country: Pakistan

- Production: 30,000 T/A

- Ingredients: cow manure, Bagasse

- project cost: $385,000 USD

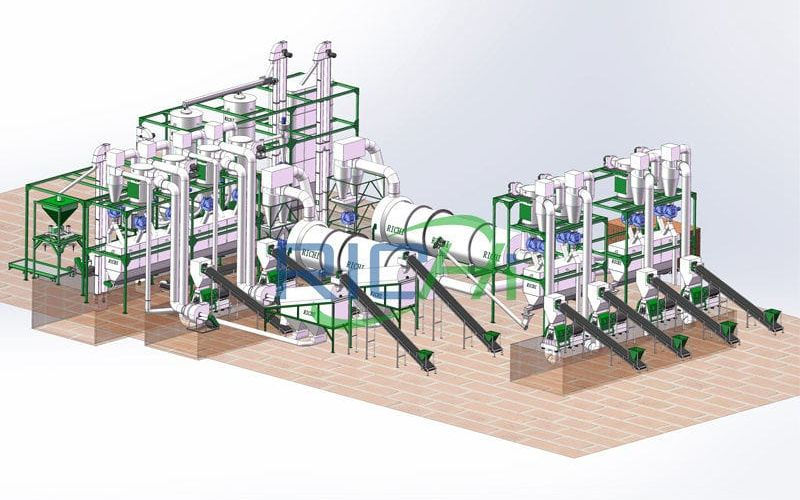

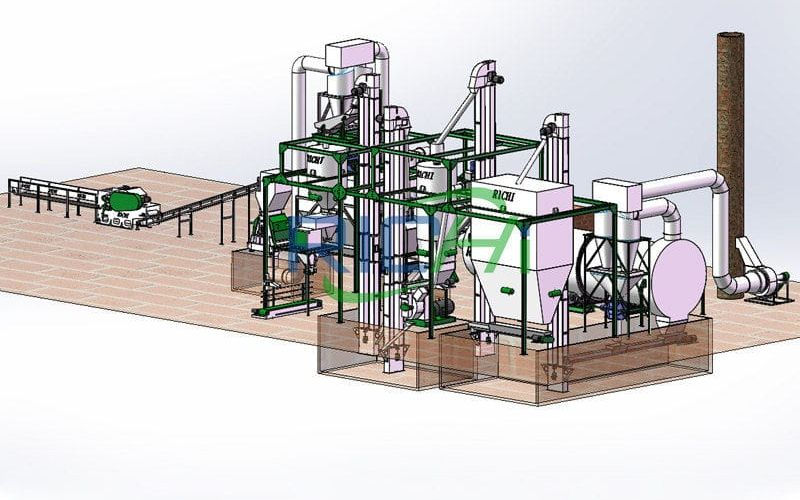

How to process organic fertilizer granules? Complete organic fertilizer process flow

The extrusion granulation method uses extrusion force to extrude the mixed wet raw materials through a die. This method is suitable for raw materials with certain plasticity, such as organic fertilizers, compound fertilizers, etc. The steps of a complete organic fertilizer production line include: raw material mixing → feeding → granulation → cutting → drying → screening → packaging.

1.Prepare raw materials

- Collect organic raw materials, including farmland straw, livestock and poultry manure, food processing waste, etc.

- Carry out raw material processing, such as crushing, mixing, etc.

2.Fermentation and composting

- Stack the processed raw materials in the fermentation pile.

- Turn the pile regularly to promote the fermentation process.

- Control the compost temperature and humidity to ensure fermentation effect.

3.Anaerobic fermentation

- Move the organic raw materials that have undergone preliminary fermentation to the anaerobic fermentation tank.

- Control the oxygen supply in the fermentation tank to promote the decomposition of organic matter.

- Stir the fermentation material regularly to ensure uniform and sufficient fermentation.

4.Accumulation

- Stack the fermented organic matter in an open dump.

- Control the oxygen supply and humidity of the accumulation and maintain appropriate accumulation conditions.

5.Crushing and screening

- Use crushing equipment to finely crush organic matter.

- After screening, the appropriate particle size is separated.

6. Formulation and Mixing

- Mix finely divided organic matter with other additives according to the product formula ratio.

- Control mixing uniformity to ensure product quality.

7. Granulation

- Granulate the mixed organic matter through organic fertilizer granulator machine.

- Control the temperature and humidity of the granulation equipment to ensure particle shape and density.

8. Drying

- Use drying equipment to dehydrate and dry organic fertilizer particles with excessive humidity.

- Control the temperature and wind speed of the drying equipment to ensure the quality of organic fertilizer pellets.

9. Packaging and storage

- Pack the dried organic fertilizer particles and use appropriate packaging materials.

- Store organic fertilizer granules to ensure quality and shelf life.

10. Finished product inspection

- Conduct quality inspection on packaged organic fertilizer granules.

- Check the nutrient content, microbial content and other indicators of organic fertilizer.

11. Product sales

- Put qualified organic fertilizer products on the market.

- Carry out market promotion and distribution channel construction.

The above is the basic process flow of organic fertilizer production line, which can be reasonably adjusted and optimized according to actual production needs.

equipment for building whole organic fertilizer granulator machine system

Compost Turner

Turning height:

0.5-2.0 m

Motor:

32-300 KW

Compost Grinder

Capacity:

3-25T/H

Main Power:

30-160KW

organic Fertilizer Mixer

Capacity:

250-2000 kg/P

Main Power:

4-30 KW

organic fertilizer Dryer machine

Capacity:

Customized

Rotate Speed:

3-8 R/Min

organic fertilizer granulator machine

Capacity:

1-12T/H

Main Power:

37-280KW

How to choose organic fertilizer granulator machine?

The selection of fertilizer granule making machine will directly affect the production cost and product quality of organic fertilizer, as well as the size of the production site and the surrounding environment.

With the rapid development of organic agriculture, the demand for organic fertilizers is increasing. As an important equipment for the production of organic fertilizer, the choice of organic fertilizer granulator directly affects the production efficiency and quality of organic fertilizer. So, how to choose a suitable organic fertilizer granulator? Here we will introduce it in detail from the following aspects.

1. Understand the types of organic fertilizer granulators

Organic fertilizer granulators are mainly divided into two types: flat die granulators and ring die granulators. The flat die pellet machine has a simple structure, low pressure in the pelletizing chamber, and loose requirements for raw materials. However, the production efficiency is low, the discharge material is loose, and the molding rate is unstable.

The ring die fertilizer pellet machine has high pressure, high production efficiency and high molding rate, but has a complex structure and high manufacturing cost. Therefore, when choosing an organic fertilizer granulator, you must choose the appropriate model based on actual needs and production conditions.

2. Consider the production capacity of the organic fertilizer granulator machine

When choosing organic fertilizer granules manufacturing machine, you must choose the appropriate production capacity according to your own production needs.

If the production demand is large, you can choose an organic fertilizer pellet machine with a higher output; if the production demand is small, you can choose an organic fertilizer pellet machine with a lower output. At the same time, factors such as energy consumption and operating costs of the organic fertilizer granulator must also be considered.

3. Pay attention to the quality of organic fertilizer granulator

The quality of the organic granular fertilizer making machine directly affects its service life and performance. When choosing an organic manure pellet mill, you should pay attention to its manufacturing materials, technology, structure and other aspects.

A high-quality organic fertilizer granulator should have the characteristics of reasonable structure, excellent manufacturing, and smooth operation, which can ensure long-term stable operation and improve production efficiency.

4. Consider the operation and maintenance of organic fertilizer granulator machine

When choosing an organic fertilizer pellet making machine, you should also consider its ease of operation and maintenance. The easy-to-operate and maintain organic fertilizer granulator can reduce labor costs and maintenance costs and improve production efficiency.

Therefore, when choosing an organic fertilizer granulator, you should pay attention to the design of its operating interface, maintenance and other aspects.

5. Compare the prices of different fertilizer granule making machines

The prices of organic fertilizer granules making machines of different brands and models vary greatly. When choosing an organic fertilizer granulator, you should compare and choose based on your own budget.

At the same time, you should also pay attention to the cost-effectiveness of the organic fertilizer pellet mill and choose an organic fertilizer granulator that meets your needs and is reasonably priced.

In short, when choosing an organic fertilizer granulator machine, you must comprehensively consider the above aspects according to your actual needs and production conditions.

Only by choosing a suitable organic fertilizer granulator can you ensure the production efficiency and quality of organic fertilizer and improve agricultural production efficiency. Feel free to contact RICHI Machinery for quotation!

How to choose an organic fertilizer granulator machine manufacturer?

When choosing an organic fertilizer granulator machine manufacturer, you need to consider multiple factors to ensure you choose the right manufacturer. Here are some suggestions for consideration:

- It is necessary to investigate and understand the organic fertilizer granulating machine manufacturers on the market. Relevant information can be obtained through the Internet, industry exhibitions, professional forums and other channels. When understanding the basic information of a manufacturer, you need to pay attention to the manufacturer’s size, strength, qualifications, product quality and services.

- It is necessary to determine the technical strength of the manufacturer. The fertilizer granulator has a high technical content, so the manufacturer needs to have corresponding technical strength and R&D capabilities. The technical strength of the manufacturer can be evaluated by understanding the manufacturer’s technical team, technical level, intellectual property rights, etc.

- You need to consider the cost-effectiveness of the manufacturer’s products. When choosing a fertilizer granulation equipment manufacturer, you should not only focus on the price but ignore the quality and performance of the product. It is necessary to conduct a comprehensive evaluation of the manufacturer’s products, including product performance, reliability, service life, after-sales service, etc.

- You need to understand the manufacturer’s cases and user feedback. The manufacturer’s cases can reflect the manufacturer’s actual experience and strength, and user feedback can help understand the manufacturer’s product and service quality. When choosing a manufacturer, you need to understand this information to better evaluate the manufacturer’s strength and service quality.

- Communicate and exchange with manufacturers. When choosing an organic fertilizer granulator machine manufacturer, you need to fully communicate with the manufacturer to understand the manufacturer’s service attitude, professional level, delivery time and other information. Through communication and communication, the strength and service quality of manufacturers can be better evaluated, and stronger support can be provided for selecting the right manufacturer.

To sum up, choosing a suitable compost granulating machine manufacturer needs to consider many factors, including the manufacturer’s scale and strength, technical strength, product cost performance, cases and user feedback, as well as communication and exchanges with manufacturers.

By comprehensively considering these factors, the manufacturer’s strength and service quality can be better evaluated, providing stronger support for selecting the right manufacturer.

Future development of organic fertilizer granulator machine

The following are three advantages for the future development of organic manure making machine:

01 The market demand is large and seasonal requirements are low.

In recent years, due to improper operation and other reasons, the soil compaction problem has become increasingly serious. The organic matter content in the soil has decreased, and the organic matter content has gradually decreased in many countries. Organic fertilizer has the function of conditioning the soil, which means that the demand for organic fertilizer has a broad prospect.

At present, there are still few large-scale organic fertilizer manufacturers in various countries, and governments in various countries have more policy preferences for organic fertilizers. Therefore, the market prospect of compost pellet making machine is also huge.

02 Lower production costs and higher profits.

Simply based on the nutrient content, it is stipulated that the total nutrient content should be around 5% to meet the standards. The ratio of each nutrient content is not mentioned, so that companies can consider the proportion of input formula according to the specific market conditions.

In addition, organic fertilizer has lower requirements for organic fertilizer granulator machine, and the infrastructure can be a drum process. It is understood that the raw material cost of standard organic fertilizers from some manufacturers is very low, while the ex-factory price can be several times higher, resulting in huge profit margins.

03 Environmental issues.

Since the raw materials of organic fertilizers are mostly recycled resources, the hard pollution to the environment will be much lower than that of other fertilizers. This is also very important in today’s society that advocates environmental protection.

Development status and prospects of organic fertilizers

Organic fertilizer is made from organic matter such as livestock manure, tail vegetables, mushroom residues, etc., through microbial decomposition and composting. At present, the application of organic fertilizers in the agricultural field has gradually received attention, and has shown the following current status and development prospects:

- Current situation: As people’s awareness of food safety and environmental protection increases, the demand for organic agricultural products is gradually growing. Organic fertilizer made by organic fertilizer granulator machine is widely used as a sustainable and environmentally friendly fertilizer. Many countries and regions have established organic agriculture certification systems and introduced policies to support the development of organic agriculture.

- Agricultural sustainability: The use of organic fertilizers can improve soil structure, increase soil organic matter content, and improve soil fertility and water retention capacity. Compared with chemical synthetic fertilizers, organic fertilizers have less impact on soil health and the ecological environment, helping to achieve sustainable development of agriculture.

- Food safety and quality: The use of organic fertilizers can reduce chemical residues in agricultural products and improve food safety and quality. More and more consumers are choosing to purchase organic agricultural products, driving the demand for organic fertilizers.

- Rural economic development: The manufacture and application of organic fertilizers can promote the development of rural economy. Farmers can realize resource recycling and increase the added value of agricultural products by converting agricultural waste into organic fertilizers.

- Environmental protection: The raw materials of organic fertilizer are mainly livestock manure, straw, mushroom residue, traditional Chinese medicine residue, branch straw and other wastes. Making them into organic fertilizer not only solves the problem of waste pollution, but also realizes resource utilization. of reuse.

- Technological innovation and industrialization: With the continuous advancement of science and technology, the production technology and formula of organic fertilizer are also constantly improved and innovated. At the same time, the development of the organic fertilizer industry chain has also led to the rise of related equipment, technology and services, forming a complete industrial system.

To sum up, the current situation and development prospects of organic fertilizers are very broad.

As people pay more attention to sustainable agriculture and consumer demand for organic agricultural products grows, organic fertilizers made by organic fertilizer granulator machine will play a more important role in the agricultural field and contribute to sustainable agricultural development and food security. (Find RICHI on YouTube)